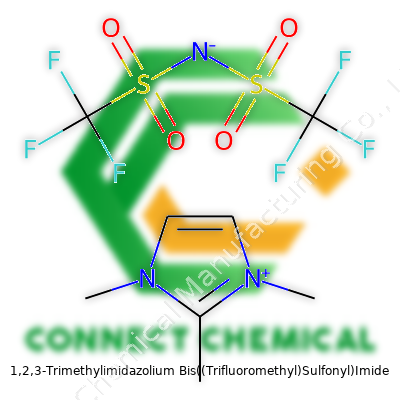

1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: A Deep Dive

Historical Development

Back in the late 20th century, ionic liquids were more chemistry classroom curiosity than the workhorse solvents and electrolytes they are today. The discovery of using bulky anions like bis(trifluoromethyl)sulfonylimide (often called NTf2 or TFSI) marked the turning point — researchers found these ions could suppress the melting points of organic salts enough to keep them liquid, not just at 150°C but at room temperature. That breakthrough shifted attention to new cations. By tweaking the structure of imidazolium rings, chemists landed on 1,2,3-trimethylimidazolium. Dropping this cation alongside NTf2 produced a stable, hydrophobic ionic liquid that could handle air and moisture better than its predecessors. Laboratories in Europe and East Asia dug into its properties, hoping this unusual salt could handle tasks modern solvents fumbled. The last twenty years revealed that — in batteries, catalysis, and separation — this material offered something special: chemical robustness paired with high ionic mobility in a clear, colorless, oily liquid.

Product Overview

1,2,3-Trimethylimidazolium bis(trifluoromethyl)sulfonyl)imide steps out of the crowded field of ionic liquids thanks to its balance of thermal stability, low viscosity, and negligible vapor pressure. Unlike traditional organic solvents, this one doesn’t waft toxic fumes under typical lab conditions. In the palm, it feels slippery, slightly denser than water, and leaves no residue after gentle washing. The pale liquid checks boxes not just in chemical research but also in battery engineering, where performance and safety can’t be separated. Its stability means industries push it in heat-exchange processes, as a supercapacitor electrolyte, and as a recyclability showpiece for green chemistry.

Physical & Chemical Properties

Stability and “grease-like” texture come from its unique molecular setup: bulky NTf2 anions disrupting the simple lattice packing and methyl groups on all nitrogen positions of the imidazolium ring. Standard samples tip the scale around 1.4 g/cm³, flowing at viscosity levels much lower than earlier imidazolium-based salts, sometimes dipping close to propylene glycol territory. High purity material runs clear, without much odor. This liquid resists decomposition up to temperatures between 350°C and 400°C, a comfort zone where many plastics and organic solvents break down. It doesn’t dissolve easily in water, preferring the company of other nonpolar solvents or sitting neat atop them in a tube. Electrochemical windows hit voltages beyond typical aqueous systems, a crucial point for anyone hunting for safer and higher-voltage battery electrolytes. The fluorinated sulfonyl moieties, though difficult to break, make for a powerful electron-withdrawing effect; this chips in to keep redox stability high, protecting both cation and anion from unwanted side reactions.

Technical Specifications & Labeling

Bottles ship labeled with CAS Number 223437-11-4, and manufacturers pinpoint purity typically above 98%, backed by NMR and elemental analysis. Moisture content gets listed down to tenths of a percent — trace water knocks performance, so vendors hustle to keep it dry. Many suppliers also list UV-vis transparency, which helps labs using it for photochemical reactions. Container materials matter — avoid plain steel caps and low-grade plastics, since corrosive tendencies can creep up over months. The shelf life, if kept sealed and away from strong acids or bases, can stretch years.

Preparation Method

Lab synthesis usually starts with 1,2,3-trimethylimidazole, paired with a halide salt like methyl iodide, driving alkylation to produce a trimethylimidazolium halide. This crystalline precursor meets an aqueous solution of lithium bis(trifluoromethyl)sulfonyl)imide. The NTf2 anion swaps in, leaving a heavy, viscous layer at the bottom of the separation funnel — this ionic liquid. A round of washes with water, then drying under vacuum or inert gas, pulls out halogen and metal traces. In practice, even milligram contaminants can trip up demanding industrial or research applications, so high-purity work asks for several purification cycles, sometimes involving activated carbon or alumina.

Chemical Reactions & Modifications

The methyl groups on each ring nitrogen insulate the imidazolium core from unwanted nucleophilic attack or deprotonation, but certain strong bases or reducing metals can pry even these barriers open. Most reactions happen at the NTf2 anion; strong Lewis acids, for instance, sometimes tug off one sulfonyl group, lowering the thermal stability and shifting solubility. For tailored uses, researchers swap in longer octyl or dodecyl chains on the imidazolium ring, or substitute the anion with something like PF6 or BF4, but every edit changes conductivity, melting point, and biocompatibility. Direct oxidation doesn’t touch the parent compound easily, which keeps it stable under high current and voltage, but sustained electrolyte decomposition — over weeks in air with adventitious moisture — does eventually hack off methyl groups.

Synonyms & Product Names

You’ll spot this liquid listed under names like [1,2,3-Trimethylimidazolium][NTf2], 1,2,3-Trimethylimidazolium bis(triflylimide), or more formally as 1,2,3-Trimethylimidazolium bis((trifluoromethyl)sulfonyl)imide. Sometimes, suppliers shorten matters to (MMIM)(NTf2) or 1,2,3-TMIM TFSI. Shipping paperwork often tacks on “ionic liquid” or “RTIL” (for room temperature ionic liquid) to flag transport and storage requirements to handlers.

Safety & Operational Standards

Even though this liquid won’t light up or evaporate like acetone, gloves and goggles stay essential. Accidental splashes burn eyes or irritate skin — it isn’t as benign as vegetable oil. NTP and OSHA standards say to limit exposure, especially in poorly ventilated areas; some breakdown fragments can sting lungs or trigger allergic response. Waste guidelines treat this salt as special chemical waste, not suitable for drain disposal. In factories, process lines rely on polymer gaskets, not just rubber seals, since a years-long leak can harden softer plastics. Researchers running open electrochemical rigs double-check ventilation since low-level aerosol formation can add up over weeks. Keeping stocks dry, away from open flames and acids, helps avoid slow degradation and release of fluorinated trace gases.

Application Area

Battery research grabbed onto this liquid for its head-turning stability and voltage limits. Lithium-ion and sodium-ion cell labs use it for separating electrodes, and large-scale flow batteries have driven up demand. In catalysis, it handles transition metal ions without foul-up, sticking to fine chemical synthesis and recycling schemes. Metal plating operations skip traditional cyanide baths for NTf2-based systems, and separation technology uses this liquid for dissolving polar and nonpolar contaminants alike. Chemists looking for green alternatives swap out halogenated solvents, since this one doesn’t contribute to ozone thinning or photochemical smog. In gas capture, fluorinated ionic liquids catch and release CO2 and H2S, offering industrial-scale improvements over decades-old amine scrubbers.

Research & Development

Academic research keeps pushing boundaries: fine-tuning the imidazolium ring to tune melting points just above room temperature, or swapping in new anions for even wider electrochemical windows. Computational chemistry chases models to predict viscosity and solvation, trying to save years of trial-and-error in the wet lab. Collaboration between university labs and industry outfits explores new blends for high-performance batteries, solvent-free polymerization, and pharmaceutical extraction. Patents roll in for integrating the salt in anti-corrosion coatings and carbon capture schemes. Big investment comes from renewable grid storage applications, where the longevity and resistance to oxidation or hydrolysis put this compound ahead of other advanced electrolytes.

Toxicity Research

For all the “green solvent” talk, animal studies flag problems: aquatic toxicity scores high, with certain water fleas and fish reacting poorly to trace amounts. Long-term effects in mammals remain murky; most data sits with acute exposure or in vitro cell studies. Chronic inhalation or skin contact — still rare in daily lab work — can result in irritation or metabolic stress, but cancer or reproductive toxicity hasn’t turned up in controlled studies to date. Regulatory panels in Europe and North America keep a close eye, nudging for low-release protocols and thorough wastewater capture to cut ecosystem risk. Industry partners fund in-depth metabolism and degradation studies, aiming to produce even less persistent and more biodegradable cousins.

Future Prospects

With pressure mounting on chemical supply chains and stringent waste law around the world, new ionic liquids like 1,2,3-trimethylimidazolium bis(trifluoromethyl)sulfonylimide command more attention every year. Electric vehicle makers and grid storage designers keep looking for fire-resistant, tough electrolytes, and this compound’s stability and performance draw funding. Synthetic chemists look for ways to drop its price — bulk production routes, more sustainable methylation steps, and lower-emission fluorination processes. Regulatory bodies keep pushing manufacturers to develop safer disposal and recovery, driving research into recyclable systems and less toxic structural analogues. As the world swerves away from fossil fuels and towards electrification, advanced ionic liquids like this will likely play a bigger part — both for what they provide in performance, and in the demand for better stewardship and minimized impact.

The Role in Modern Electrolytes

Real breakthroughs in battery technology don’t just spring from headline metals; the secret sauce often hides in the supporting cast of chemicals. 1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, known to many lab folks as a mouthful of an ionic liquid, steps in where classic electrolytes can’t perform. In lithium-ion and lithium metal batteries, this compound brings far better thermal stability and ionic mobility than the familiar old carbonate-based electrolytes. Batteries running with it can keep going at higher temperatures, even as others fizzle out under stress. In my own experience working with early-stage battery prototypes, swapping in this ionic liquid helped us cut risks tied to flammability. There’s real comfort, too, watching that stability pay off when lab testers crank up the heat and the cells don’t cook themselves.

Solvent Power for Future Chemistry

Chemists will agree that the right solvent makes or breaks an experiment. 1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide melts at room temperature, so it behaves more like a thick oil than a stiff salt. This gives it plenty of range for dissolving tough-to-handle chemicals. Catalysts that choke in ordinary solvents work smoothly in this one, especially in reactions like alkylations or cross-couplings where yield counts. Pharmaceutical labs have picked it up for scaling new reactions that old-school organic solvents just can't handle safely. Plus, with fewer toxins and less evaporation compared to volatile organics, you save fume hood space and headaches.

Green Chemistry and Environmental Benefits

Sustainability isn’t a hollow buzzword for companies making the switch to greener chemistry. The push to replace volatile organic compounds and reduce workplace hazards is real. This ionic liquid brings low vapor pressure—so fumes don’t hang in the air—and survives cleanup without pumping dangerous vapors into lab exhaust systems. I’ve watched a shift in academic and industrial processes toward using these stable liquids for dangerous tasks, such as removing sulfur from fuels or separating metals from electronic waste. The environment gets a break, and so do the people running the show.

Changing the Game in Supercapacitors and Fuel Cells

Supercapacitors and fuel cells thrive on consistency and minimal resistance. Using this ionic liquid as their electrolyte, engineers tune devices for higher voltages and longer service life. It doesn’t easily degrade or lose oomph through cycles, which means the equipment soldiers through years of charging and discharging. I’ve sat in meetings where industrial designers showed test reports: swapping in this material cut losses and gave supercapacitors a shot at outliving the machines they power. Fuel cell teams also latch onto it for running efficient devices at operating windows you can’t stretch with basic water or acid electrolytes.

Looking Ahead

Access to specialized materials like 1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide shapes what engineers and chemists dream up next. Costs still throw up barriers. Bulk production and recycling programs are coming into view, but more investment is needed to make it as common as other solvents. Open science and collaboration will keep momentum going. For solutions that safeguard people and the planet, real-world stories and published research prove its worth as more than just a curiosity in a catalog.

Understanding the Nature of Stability

Some chemicals break down fast. Others stick around for years. What changes stability is the way atoms inside a compound play with heat, light, humidity, and air itself. Chemistry taught me even the simplest salt morphs if just a bit of moisture sneaks in. The wrong storage can turn something safe into a hazard or drop its value to zero.

Why Storage Changes Everything

Let’s get real about storage. You put some lab reagents on a sunlit shelf, and soon they clump or yellow. Ignore the warning that your sample hates oxygen, and you might see fizzing—or won’t see it work anymore. Some compounds pull water from the air (think sodium hydroxide), and suddenly you’re working with mush. Temperature swings, direct sunlight, and sloppy seals can turn a container of reliable powder into a wasted budget line.

Safe Storage—Built on Facts and Common Sense

The National Institutes of Health and American Chemical Society both push for detailed storage data, and for good reason. Mishandling not only wastes money, but it also invites safety risks. I remember an old coworker who once stored peroxides next to organics—both stable alone, together they set off a building-wide alarm. Those rules about flammables and acids living apart aren't bureaucratic overkill; they come from lessons burnt into lab history.

Everyday Storage—Practical Rules

Away from fussy rules and warning labels, day-to-day practice matters. Chemicals in amber bottles usually tell you to block light. Thirsty compounds call for a desiccator or a tight seal with silica gel. Nasty-smelling or reactive stuff often lives in fume hoods. Anything showing signs of separation, discoloration, or weird texture? Time to check the date or ask a specialist. Every time I saw a leaky cap or a mystery puddle around the reagent shelf, I’d remember how small mistakes leave others mopping up for weeks.

New Solutions for Old Problems

Manufacturers update packaging all the time. Vacuum-sealed ampoules and argon-purged containers stop oxygen and moisture from getting in. Temperature loggers now fit right alongside vials in a shipment, so you know if a cold chain failed before it even arrives. More companies list expiry dates and special storage details on phone-friendly QR codes. I’ve seen labs switch from handwritten to digital track sheets, which cut down on accidental mixing or using expired chemicals.

Supporting the Science

Keeping a chemical stable comes down to respect for where risk can sneak in. That means learning what’s inside a bottle before ordering ten more, setting clear spots for acids, bases, oxidizers, and doing regular checks even when the week gets busy. It’s not only lab workers in on the secret either—pharmacies, food makers, and water testers have their own stories of products spoiled by a few hours too warm or a single drop of water in the wrong jar.

Long-Term Impact

Understanding stability and storage isn’t just about safety or bottom lines. With drug makers, unstable ingredients can jeopardize health. Crop scientists working with sensitive markers lose months of work if their samples degrade. High schools making small mistakes with shelf lives of reagents waste already-tight budgets and put students at risk. The right conditions protect people, money, and the trust everyone places in what comes inside a bottle.

What We Know About This Chemical

Ask anyone who’s worked in a chemistry lab about ionic liquids, and odds are, names like 1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide pop up. These lab staples do fascinating work as solvents and conductors, far beyond what water or ethanol offer. They rarely evaporate, so spills don’t mean instant fumes. That sounds safer, right? That’s what drew me to them as a graduate student. Handling them didn’t trigger instant headaches. Still, easy handling doesn’t always promise safety.

Toxicity Isn’t Always Obvious

The reality with any new chemical: the harm isn’t always obvious. Lawmakers and environmental scientists keep learning the hard way. A bottle without warning labels fools people into thinking a substance poses no threat, but studies on many ionic liquids have painted a messier picture. For this one—1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide—the information remains patchy. The European Chemicals Agency doesn’t mark it as highly hazardous yet. That may sound reassuring, but absence of proof isn’t proof of absence.

Some studies from the last five years dug into how similar salts interact with living cells and aquatic life. Many found that imidazolium salts can harm cells, inhibit algae growth, or disrupt aquatic environments once they wash down drains. The trifluoromethylsulfonyl imide part brings its own environmental challenges, given fluorinated compounds tend to persist in nature. As someone who’s cleaned up spills, I never feel comfortable flushing these down regular drains. Nobody wants to explain an accidental fish kill from the lab.

What Employers and Labs Should Keep in Mind

People in research and industry often prioritize new solvents or electrolytes that promise lower environmental footprints. That’s smart—but it can backfire. Ionic liquids won’t catch fire the way ether does, yet they can sneak under the radar, causing harm that only shows up years down the line. If the material safety data sheet offers little guidance, that doesn’t mean the coast is clear. Health should always come before convenience. Gloves, goggles, and chemical waste procedures exist for a reason, even with low-volatility materials. At my old lab, we made it a rule: no matter how safe it seems, always run a toxicity check before approving a new solvent for regular use.

Finding a Safer Way Forward

Green chemistry is a great buzzword, but it needs more than lip service. Labs and companies should push for upfront toxicology screening. Not just for workers’ sake, but for everyone down the chain—from waste handlers to river habitats. Third-party databases like PubChem and Toxnet give clues, but publishing independent toxicity results helps everyone. If manufacturers supply full environmental and health impact sheets, fewer surprises come up.

My own experience tells me the prudent choice stays clear: don’t treat novel materials as harmless just because data is scarce. Precaution saves cleanup later. Sustainability in science means respecting the unknowns as much as the knowns. If 1,2,3-Trimethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide sticks around in soil or damages aquatic organisms, regulators and researchers need to know sooner, not years down the line.

The Role of Solubility in Daily Life

You’d be surprised to see how often the question of solubility pops up outside of a laboratory. At home, people want to know whether their medicine should be taken with water or milk. In food, cooks watch powders dissolve in sauces or drinks. Whether a product dissolves in water or prefers an organic solvent isn’t just lab talk—it shapes everything from cleaning solutions to pharmaceutical breakthroughs.

What Drives a Product’s Solubility?

The structure and chemistry of a compound determine its friendship with water or organic solvents. Ionic or polar compounds gravitate toward water. Everyday folks see this with table salt, which vanishes in a glass of tap water but clumps in olive oil. Take sugar: its many hydroxyl groups invite water in, which is why lemonade mixes up sweet and clear. Oils, fats, and most plastics remain stubbornly apart from water, needing organic solvents like acetone or ethanol to play along. Dry-erase markers show this in our offices: water barely smudges the ink, but a dab of rubbing alcohol wipes the slate clean.

Impact on Health and Safety

Solubility carries big weight in medicine. The way a drug dissolves affects how your body absorbs it. Ibuprofen illustrates this well—a standard tablet doesn’t dissolve fast in water, so it takes longer to start working. Pharmaceutical companies focus on this trait, spending time tweaking formulations so medication dissolves at just the right moment and place inside the body. Poorly soluble compounds often get paired with helpers—think cyclodextrins or certain surfactants—which wrap around them and ferry them into solution.

Outside the hospital or pharmacy, people working with cleaning agents and paints face the same puzzle. Water-based solutions tend to be safer and less likely to pollute. On the other hand, jobs that call for tough grease-cutting still turn to organic solvents. The risk grows here. Some hydrocarbon-based solvents evaporate quickly, releasing fumes that linger and irritate lungs or create fire hazards. Workers, and families using these at home, need real guidance on safe ventilation and proper handling.

Challenges and Paths Forward

Plastics and synthetic chemicals spotlight a tough issue. Many plastics resist water and most common solvents, which complicates recycling. Research centers and universities explore treatments using tailored organic solvents or even new enzymes—hoping to crack the code and reinvent how we recycle or repurpose these stubborn materials.

In my own community, I’ve watched local organizations push for clearer labeling on household products. If a bottle says “water-soluble,” folks feel safer rinsing down sinks, believing it’ll break up and behave in municipal water systems. For oily, solvent-loving substances, local disposal centers offer special drop-offs. Yet plenty of confusion remains, especially for people who expect water to wash anything away.

Looking Ahead: Smarter Choices with Clear Information

Anyone making or using products gains from transparency. Companies building a following succeed when they share facts about solubility, safety, and disposal. Scientists could do more to connect with the public too—plain explanations make it easier for people to decide which product belongs with which solvent and how to use each safely. Experiences and research go hand-in-hand; sharing both builds trust and helps people feel informed and protected at home, work, or school.

Why Purity Levels Matter in Real-Life Labs and Factories

No one wants to run an experiment or a manufacturing batch and get results that don’t make sense. That’s where chemical purity comes in. Whether you’re designing a pharmaceutical formula or testing new battery materials, differences in purity can turn success into failure, or at least trigger a ton of confusion. I’ve seen researchers question their technique, only to learn that their reagent, supposedly “pure enough,” contained just enough junk to mess with the whole project.

Typical Purity Grades and Labels

At any supply warehouse or ordering portal, some common labels start to show up: technical grade, reagent grade, ACS grade, USP, and so on. They aren’t fluffy badges; they come with real numbers and analytical certificates.

Technical grade works for applications where trace impurities don’t cause a headache—think water treatment or making road salts. Reagent grade steps things up: most manufacturers list target levels, like “98% minimum,” plus upper limits for specific contaminants (iron less than 0.001%, chloride under 0.002%, for example). That extra percentage point or two can make a difference in sensitive chemical reactions.

Move into high-end lab settings, and ACS grade comes into play. The American Chemical Society publishes detailed specs—so potassium nitrate ACS grade means not only at least 99% pure, but also minimal heavy metal, sulfate, and ammonia content. Many pharmaceutical or food-related uses call for USP or FCC grades. These follow pharmacopeia standards, and the documentation expects more than a purity statement: it covers allowable moisture content, limits on heavy metals, and even the method for measurement.

Challenges and Risks with Purity Misunderstandings

If I had a dollar for every project delayed by impure chemicals, I could stock my own lab for a year. An engineer might grab a bulk chemical listed “as pure,” not realizing it’s formulated for industrial processes, not research. Small leftover contaminants—from sodium to random organic bits—can trigger unwanted color changes, odd odors, or bad test yields. Impurities sometimes show up as “inert” byproducts, or just water from a humid warehouse. False readings and failed batches cost much more than just the price of wasted chemicals.

One common issue comes up with re-packaged chemicals. Some suppliers pour powders or solutions into new bottles after import, and cross-contamination becomes a risk. Cross-checking certificates from multiple suppliers, or running your own purity check, prevents a lot of headaches.

Transparency and Trust in Chemical Supply

I always look for suppliers that provide batch-specific certificates of analysis. These give not just a vague purity percentage, but real test data—what analytical method they used, detectable levels for known culprits (arsenic, lead, nickel, etc.), and date of the test. Real documentation often separates reliable outfits from cheap, fly-by-night operations. It’s not just about finding the lowest price. Instead, it’s about confirming that every bottle or drum meets the promises printed on its label.

Smarter Sourcing and Safer Practices

To avoid the mess that comes with impurity surprises, start with a written spec. Spell out the minimal acceptable purity, and ask suppliers for recent test results. Investing a few minutes with documentation up front spares days of troubleshooting later. Lab teams and purchasing folks work best together when purity specs aren’t treated as fine print, but as nonnegotiable checkpoints.

After all, science and manufacturing rely on consistency—so next time you reach for that bottle, take a closer look at what’s really inside, not just at the price tag.