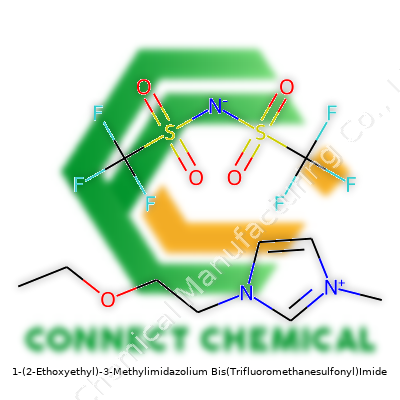

1-(2-Ethoxyethyl)-3-Methylimidazolium Bis(Trifluoromethanesulfonyl)Imide: An In-Depth Commentary

Historical Development

The story of 1-(2-Ethoxyethyl)-3-Methylimidazolium Bis(Trifluoromethanesulfonyl)Imide, often shortened to [C2OEtMIM][NTf2], links tightly with the rise of ionic liquids as chemists began looking for new solvents that cut down on volatility, flammability, and environmental hazard. After the 1990s, the race to tame room-temperature molten salts exploded. Early adopters saw these strange salts as a way to move beyond fossil-derived solvents, especially as more environmental regulations choked off the traditional routes. The [NTf2] family emerged in the early 2000s, offering reasonable stability, broad electrochemical windows, and a knack for tolerating tough conditions. Lab after lab dove into [C2OEtMIM][NTf2]'s unique properties, carving a path for its use from niche academic studies straight into high-tech industry.

Product Overview

You don’t find many industrial solvents that refuse to evaporate or burn. This ionic liquid comes as a colorless to pale yellow viscous liquid, slightly denser than water, and pretty much immune to air humidity. Its main draw comes from that blend of the imidazolium core, an ethoxyethyl chain, and the sturdy NTf2 counterion. This set-up brings non-flammability, almost no measurable vapor pressure, and a chemical stability that makes it stand out. With such characteristics, [C2OEtMIM][NTf2] wins fans in battery research, separation science, organic synthesis, and as a platform for advanced catalysis.

Physical & Chemical Properties

What truly sets [C2OEtMIM][NTf2] apart is a set of physical and chemical properties that tick a lot of boxes for modern labs. The density measures close to 1.42 g/cm³ at room temperature, which beats most water-based solvents for solvating power. Transparency and high thermal stability mean researchers push it as a medium for photochemical reactions and high-temperature syntheses. The negligible volatility almost kills any risk of inhalation during handling. Its unique ion structure shields it from hydrolysis; splashes of water barely touch it, and strong acids or bases present more of a challenge. For electrochemists, the electrochemical window stretches well beyond 4V, making it great for next-generation batteries and supercapacitors. Viscosity remains relatively high, sometimes a challenge for fast mass transfer, but the solubility spectrum includes a wide range of polar organics and gases.

Technical Specifications & Labeling

Producers stick to strict standards to ensure users get a reproducible product. Usually, technical sheets list purity above 99%. Trace moisture content runs below 200 ppm to avoid unwanted side reactions in anhydrous syntheses. Standard labeling shows its full IUPAC name, CAS number (1040997-38-8), molecular formula (C12H19F6N3O5S2), and hazard pictograms for eye and skin irritation. Barcoding and batch numbers support traceability. Some suppliers check for residual halides, alkali metals, or organic impurities by NMR and mass spec, so advanced users can expect a full analytic report.

Preparation Method

The traditional preparation method starts with N-methylimidazole and 2-ethoxyethyl chloride reacting to build the imidazolium cation. After purification — sometimes using charcoal to remove trace organics — the salt meets lithium bis(trifluoromethanesulfonyl)imide in water. A double ion-exchange process forms a strongly layered organic phase, quickly separated out and dried under high vacuum. This approach minimizes halide contamination and lowers cost, though many labs run extra distillation or chromatographic purification to suit highly regulated industries or research work.

Chemical Reactions & Modifications

Unlike simple organic solvents, [C2OEtMIM][NTf2] doesn’t just sit idle. The ethoxyethyl tail and imidazolium core unlock selective solubilizing power, facilitating alkylation, acylation, and even cross-coupling reactions — changing how sensitive substrates behave. Some groups modify the side chain to fine-tune viscosity, solubility, or polarity, and swap the anion for superhydrophobicity or tuneable acidity. On the catalytic side, the imidazolium can stabilize reactive intermediates, often leading to higher yields, cleaner product, and fewer hazardous by-products compared to fossil-derived solvents. At the same time, [NTf2] anion resists nucleophilic attack, so it won’t crash during tough syntheses or electrochemical cycling. Researchers focus on functionalizing the cation, sometimes attaching catalysts or biological ligands to make chiral or enzyme-mimicking ILs for green processes.

Synonyms & Product Names

You sometimes find this chemical under different names depending on country or supplier labeling policies. Common variations include 1-(2-Ethoxyethyl)-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, [C2OEtMIM][NTf2], and simply EMIM-EtOEt NTf2. Registry numbers, especially CAS 1040997-38-8, help labs avoid mix-ups in multistep synthesis or procurement. Marketing names often try to simplify, so catalogues might use EZ-NTf2 or ETIm-NTf2 for quick reference, especially in industry.

Safety & Operational Standards

You pick up certain habits when working around ionic liquids. They rarely spit out toxic vapors, but skin contact can irritate over time, so gloves matter. Eye protection stays on, since even the most stable ILs can sting if splashed. Proper ventilation is less critical than with VOC-heavy solvents, yet safety data sheets always highlight the importance of spill containment and compatible containers, because some metals corrode with long exposure. Most facilities treat waste through basic organic solvent protocols, as some states still lack dedicated IL disposal guidelines. Transport regulations in the EU and US set IMDG and IATA codes, but [C2OEtMIM][NTf2] escapes most strict flammable or toxic labeling thanks to its low hazard profile.

Application Area

This ionic liquid covers a spectrum of real-world challenges. In lithium-ion and sodium-ion batteries, it handles both high and low temperatures, cutting the risk of thermal runaway, even under abuse conditions. Some developers substitute [C2OEtMIM][NTf2] for classic carbonate electrolytes in solid polymer batteries, chasing longer life cycles and improved safety. In organic synthesis, tough transformations like nucleophilic substitutions or metal-catalyzed couplings take place smoothly, saving on energy and cutting hazardous emissions. Hybrid systems, such as supported ionic liquid membranes, use it to boost gas or solvent separation. In analytics, chemists turn to this liquid for advanced NMR studies or as a matrix in MALDI mass spectrometry, where thermal and chemical stability pays off.

Research & Development

Most labs see ionic liquids as not just alternatives, but essential platforms for pushing chemistry into new spaces. Collaborations span battery research, catalysis, nanomaterials, and even pharmaceutical crystallization, given the tweaks possible at both the cation and anion. European and East Asian research groups pour resources into scalable, green production of [C2OEtMIM][NTf2], aiming to drop price and environmental load. Electrochemical societies back studies measuring window expansion and stability under cycling; synthetic chemists keep chasing greater selectivity and better yields. Environmental work focuses on life-cycle analysis, biodegradability, and developing less fluorinated anions for safer closed-loop use. Journals fill with new derivatives, structure–property relationships, and fresh applications, speaking to how deeply ILs have taken hold.

Toxicity Research

As much as ionic liquids reduce hazards, questions still surface about chronic toxicity, environmental persistence, and bioaccumulation. Animal studies show that [C2OEtMIM][NTf2] carries moderate acute toxicity by ingestion, with LD50 values in the hundreds of milligrams per kilogram, but it rarely volatilizes enough to pose an immediate inhalation threat. Skin uptake remains low, though repeated contact and waste spills deserve ongoing attention. Soil and aquatic studies reveal slow degradation and potential impact on microorganisms, which has prompted a search for versions with cleavable bonds or faster hydrolysis. Most significant spills get scooped up with absorbents and incinerated as organic waste. Ongoing assessment, both in regulatory labs and academic settings, aims to close gaps in long-term toxicity knowledge and pave the way for safer formulas down the line.

Future Prospects

There’s a clear sense that [C2OEtMIM][NTf2] and its siblings have a solid role in cleaner, safer chemistry. With electric vehicle batteries pushing into wider climates, heat resistance and non-flammability draw growing interest from automakers and renewable energy companies. Alongside energy storage sits the push for smart, “designer” solvents that could adapt to catalytic processes or precision separations in biotech and pharma. Green chemistry guidelines shape future development, with industry working to shrink fluorinated waste and close the loop with recyclable ILs. Students bring fresh perspectives, testing them in emerging areas like CO2 capture or next-gen manufacturing. The future of these ionic liquids will likely tie scientific rigor, market needs, and sensible stewardship into new ways of making, storing, and powering everything from medicines to machines.

Electrolytes in Energy Storage

The first time I came across 1-(2-Ethoxyethyl)-3-Methylimidazolium Bis(Trifluoromethanesulfonyl)Imide, I was working on a project that focused on next-generation batteries. Lithium-ion batteries keep growing in popularity, but the real pain point remains their safety and stability. This imidazolium-based ionic liquid stood out because of its fantastic electrochemical window and thermal stability. Battery engineers look for solvents that do not catch fire, break down, or degrade after hundreds of charge cycles.

Publications back this up: ionic liquids like this one help boost the safety profile of batteries. Fluorinated imides reduce flammability and offer high ionic conductivity, which means batteries run cooler and last longer. The market for electric vehicles and grid storage depends on breakthroughs here, with every small improvement adding up to real benefits—not just for consumers but for companies looking to meet stricter regulations.

Solvent for Chemical Processes

Lab-scale work with organic synthesis shed light on another crucial use. Chemists aim to maximize reaction rates without generating piles of toxic waste. Conventional solvents often end up as hazardous materials. This ionic liquid, though, shows an ability to dissolve a wide range of both organic and inorganic compounds—for instance, it allows for efficient catalyst recycling and lowers the use of volatile organic solvents. The green chemistry angle cannot be overlooked anymore; researchers and companies face growing pressure to reduce environmental impact from their processes.

As someone who’s participated in “greener chemistry” seminars, I’ve watched academic groups demonstrate how ionic liquids open up new reactions, simplify separation steps, and lower costs over time. Real benefits emerge in pharmaceuticals, where purity and process safety come first, or in specialty chemical manufacturing that demands tight control.

Role in Electrochemistry

Anyone tinkering with metal plating or electrochemical etching will appreciate the control that comes with using 1-(2-Ethoxyethyl)-3-Methylimidazolium Bis(Trifluoromethanesulfonyl)Imide. The ionic liquid supports consistent electrodeposition because of its stability across a wide voltage window. Real-world examples include high-purity metal coatings and advanced microfabrication.

As manufacturing scales up, trace impurities and unstable solvents can cause defects and downtime. This ionic liquid offers repeatable results, even under tough operating conditions. As a bonus, some operations recover and reuse ionic liquids, which speaks to both sustainability goals and cost control.

Challenges and Solutions

The price tag still poses a barrier for mass adoption, especially in consumer-facing products. Large-scale syntheses can drive costs down, and collaborative efforts between researchers and private firms often unlock new efficiencies. Disposal must be handled carefully to avoid fluorinated byproduct contamination. Regulators and industry watchdogs keep an eye on these substances, pushing for responsible use through improved recycling and monitoring efforts.

Industry can help bridge knowledge gaps by supporting open-source testing data and sharing real-world results. Universities and companies can partner so students and workers learn best practices early. When more people understand the impacts and safe handling, broader adoption gets easier—and that’s a win for new technology, the environment, and public safety.

Why Stability Shapes Safety and Value

Chemical stability sets the ground rules for how a product behaves over time. Get this wrong and you’re left with unreliable results, wasted materials, or—worst of all—health and safety risks. Years ago, I saw a batch of reagents lose their punch just because they sat near a sunny window for a week. No lab or warehouse wants that kind of mistake.

Every product comes with its own quirks. Some chemicals handle room temperature fine, others shift or break down if they catch too much heat or light. As an example, hydrogen peroxide in its usual bottle will steadily degrade if exposed to warmth; what starts at 3% turns weak enough to become almost useless for its main jobs. In healthcare, that kind of slip-up can risk infection control or test accuracy. Facts like this aren’t rooted in abstract guidelines—they come from accidents and lessons repeated across labs, hospitals, and workshops.

Key Storage Practices that Make a Difference

You can’t talk about keeping things stable without getting practical about storage. Real-world solutions work best. Clear, informative labels help avoid confusion. Color-coded or standardized containers reduce the chance of mix-ups—no one wants nitric acid ending up in a soda bottle. Location matters too. Strong chemicals belong in ventilated, locked cabinets, not balanced on an open shelf.

Temperature control goes a long way. Refrigerators serve more than just the milk in the break room. Sensitive chemicals often call for cool, dry conditions, out of reach from direct sunlight or rapid temperature changes. Some materials—think certain pharmaceuticals, vaccines, or volatile solvents—suffer from even a short spell at the wrong temperature. I’ve seen jobs lost because a shipment of temperature-sensitive goods spent two hours in a delivery van parked in the sun.

Moisture and air cause their own headaches. Silica gel packs and regular checks for condensation help guard against water creeping in. Oxygen breaks down some substances over a few days. Sealing containers immediately after use and keeping lids tight may seem minor, but these habits extend product life and protect everyone in the building.

Why Training Matters as Much as Technology

No policy or container replaces people who know what they’re handling. Regular training and refreshers prevent slips in judgment. It only takes once for someone to ignore a label or forget to check for a leak. For me, seeing colleagues form good habits—instead of just reciting rules—makes all the difference. In one case, a team caught a leaking drum of a corrosive agent before it could seep into a drain, all thanks to routine inspection.

Chemical suppliers now share updated data sheets with practical tips. Modern software tracks expiry dates and lot numbers, sending alerts long before trouble hits. These measures tie back to lived experience; they aren’t just about compliance but about what genuinely works day in and day out.

Looking for Better Practices

Trouble often starts with small oversights, so real improvement begins with small habits. Grouping chemicals by type and hazard class, sharing up-to-date storage diagrams, and reviewing emergency plans help everyone. Opening a discussion about transparent records sheds light on weak spots. Short-term investments in good shelving, clear labeling, and routine training set the stage for fewer losses and safer workplaces.

After mistakes, I’ve learned that solid chemical stability and dependable storage build trust, safety, and value for everyone—whether in a sprawling warehouse or a corner pharmacy. Stay practical, respect the science, and those lessons will stick.

Why Knowing the Risk Matters

Grabbing a chemical container can feel routine in the lab or workshop. Yet years spent around chemicals taught me: shortcuts turn minor risks into real trouble. Back in my early university days, a careless spill left harsh burns on a coworker’s arm. No one thought much of it at the time, but looking closer, the material safety data sheet warned about serious skin injury. That lesson stuck with me—listening to those warnings prevents pain every time.

Call Out the Risk

Some substances will irritate the eyes, nose, or skin. Others quietly attack organs after repeated exposure or linger as fumes that build up in closed rooms. The difference between a bad headache and a hospital trip can come down to how you treat even a modest sample. Famous cases from industry—like the Bhopal disaster—show what happens once people ignore hazard labels or underestimate chemicals. The Environmental Protection Agency keeps tallies of these incidents, and serious harm rarely comes from unique, exotic reactions. It comes from treating hazardous compounds like ordinary soap or sand.

Acting on Proper Information

The right place to start: read the label, reach for the safety data sheet (SDS), and never rely solely on memory. Those sheets lay out everything needed—such as if the compound burns to produce toxic smoke, reacts with water, or causes nerve damage. The American Chemical Society found that nearly half of laboratory incidents happened when workers couldn't access the SDS, or didn’t believe the risks.

Gear That Shields

For many corrosive or toxic powders and liquids, gloves must shield every inch of skin. Goggles protect eyes from splashes. Long sleeves, coats, and closed shoes keep unpleasant surprises off your body. NIOSH research recommends using respirators or fume hoods any time airborne fumes occur. I remember one case: a coworker mixed a volatile acid outside the vent, and those fumes quickly filled the entire space, sending everyone outside. That single shortcut forced hours of evacuation and extra checks.

Smart Storage and Handling

It pays to store anything dangerous away from heat, sunlight, and incompatible mates. Keep acids apart from metals, bases, or organics. Never rely on weak plastic containers—corrosives eat right through those. Strong glass or approved plastics stand up far better. Spills need containment trays, and materials like sand or spill pads should be kept nearby for quick action.

Emergency Steps Save Lives

If a spill reaches skin or eyes, wash for no less than fifteen minutes before even thinking about anything else. Know where the eyewash station and emergency shower sit—waiting for help costs precious seconds in a crisis. Make accident reporting a habit, even for small splashes or wafts. Health symptoms sometimes appear later, and sharing information helps the entire team protect themselves in the future.

A Culture of Respect for Chemicals

Everyone benefits when safety becomes a team habit, not just a list stuck on the wall. Talking with coworkers about near misses and lessons learned helps everyone go home healthy. Training, regular checks on gear, and an honest attitude toward caution build an environment where chemical mishaps stay rare. In my own experience, listening to the warnings and respecting every compound—every time—pays off in health, knowledge, and confidence.

PURITY SPECIFICATIONS: WHY THEY MATTER

Purity specifications may sound technical, but their impact reaches down to anyone using chemicals in labs, factories, or even classrooms. As someone who’s handled various chemicals for both research and commercial projects, I’ve learned not all grade labels mean the same thing. For many folks, seeing “99% pure” on a product may sound like a gold standard, but those last few points matter more than most people realize once you’re dealing with sensitive processes or scientific research.

Let’s take laboratory reagents as an example. Analytical testing often calls for “ACS-grade” materials, which must conform to the standards set by the American Chemical Society. These materials generally hover at or above 99% purity, with strict limits on trace metals or other elements. Beyond analytical work, industries such as electronics demand even higher levels, where impurities in the parts-per-billion range can mess up entire production runs. Laboratories working on pharmaceuticals rely on “USP” (United States Pharmacopeia) or “Ph. Eur.” (European Pharmacopoeia) grades, with tight controls to prevent contaminants that could throw off results or, worse, harm end-users.

On the other side, technical grade serves industrial applications like cleaning or general manufacturing, where cost has to balance with standard quality. For these uses, 90–98% purity often does the job. In my experience, some manufacturers go so far as to offer custom specifications, working directly with customers to meet precise limits for metals, moisture, or organic residues.

PACKAGING SIZES: MATCHING THE NEEDS OF DIFFERENT USERS

Packaging looks simple until you start needing to move three tons of sodium chloride across the globe or ship a few grams of gold chloride to a nanotech startup. Most suppliers provide a range: laboratory chemicals come in small jars or bottles, usually around 100 g, 250 g, or 500 g. That’s the right size for folks running tests or pilot-scale experiments. Academic settings favor these packages, as they cut down on waste and keep storage manageable.

Bulk users in mining, agriculture, or large-scale manufacturing need much more—sometimes sacks, barrels, or intermediate bulk containers (IBCs) that hold hundreds of kilos or even thousands of liters. Pallets stacked with 25-kg bags have become a standard sight in warehouses. Shipping in drums and totes makes sense for liquids, while super sacks (big bags in the one-ton range) work for powders or granular materials.

A practical issue that comes up involves storage and stability. Smaller bottles sealed to resist humidity work best for materials prone to clumping or degradation, especially reactive chemicals. Factories go for larger containers with built-in safety features like tamper-evident seals or one-way valves. Logistics can throw in curveballs—customs regulations may limit shipment sizes, or certain chemicals get classified as hazardous, meaning packaging has to meet extra requirements.

CHALLENGES AND BETTER PRACTICES

Mislabeled purity or packaging can turn into an expensive mistake. I’ve seen projects delayed or scrapped due to impurities traced back to packaging that allowed contamination during transit. Verifying batch certificates and inspecting packages become more than just paperwork—they’re safeguards.

Choosing the right purity and packaging comes down to talking with suppliers, sharing details about intended use, and keeping an eye on safety and sustainability. Some suppliers now offer recyclable or returnable packaging to cut down on waste, a trend I hope continues. At the end of the day, those small details—purity numbers, container sizes—shape the reliability and efficiency of everything from routine lab work to major industrial operations.

Understanding the Impact of Disposal Methods

You don’t need a science degree to see leftover products pollute water, soil, and air. Tossing chemicals, electronics, batteries, or plastics into the regular trash feels easy, but that lazy moment can come back to bite us. Take batteries, for example. Heavy metals, like cadmium and mercury, leak out and poison groundwater. I’ve lived in a neighborhood where it took decades for the land to grow vegetables safely again after a dump site leached toxins. It affects families, food, pets—everything.

Electronics contain lead and flame retardants. They always look like a pile of innocuous junk until the rain hits a landfill, and more than just trash washes into the earth. Simple actions add up. If more of us paid even a little attention to how we threw out old cell phones, there’d be less of those headaches in the long run.

Sorting, Separation, and Drop-Off Points

Every community has guidelines about separating waste. No one loves sorting plastics or plastics from metals, but those symbols and numbers on packaging are there for a reason. In my city, we have to separate food waste, paper, soft plastics, and hazardous items like paint or solvents. Some people ignore the rules until someone’s caught dumping used motor oil in an alley. Then come the fines, the grim faces from neighbors, the realization that these rules do, in fact, keep the local park from smelling like a car garage.

Collection points for paint, batteries, electronics, and chemicals aren’t hard to find. Even grocery stores have bins for recycling light bulbs or rechargeable batteries. Dropping off an old phone or a can of solvent takes less effort than planting a tree or picking up trash along the river. I’ve done both and would much rather drop something off in the right bin than spend three hours on a Saturday scrubbing oil stains off concrete.

The Value of Producer Responsibility

Manufacturers shape the world’s waste streams. Extended Producer Responsibility laws push makers to take back worn-out goods. Companies like Apple and Dell offer programs to return gadgets for safe dismantling. When the brands you trust take responsibility, everyone feels more invested. I’ve mailed back cracked phones and used printer cartridges, feeling that small sense of doing right by the planet, even if it cost me a walk to the post office.

Regulations exist for a reason—to protect our health, wildlife, and climate. Not every rule seems fair or logical, but the bigger picture means thinking beyond the trash can. The European Union has strict rules for electronics (RoHS, WEEE), and the U.S. Environmental Protection Agency publishes simple guides. No matter where you live, you can ask your local waste office what’s required. They might surprise you with a solution that saves time and spares the landfill.

Personal Steps Make a Difference

Before tossing out a product, check labels for recycling codes or warnings. Use up chemicals fully before disposal, rinse containers, and keep hazardous stuff out of drains and dumpsters. Reusing and fixing items, donating electronics, or choosing goods with less packaging all play a role. Ignoring disposal rules can poison the environment and hurt public health, but a little effort keeps our air, water, and communities cleaner. I’ve seen firsthand how good habits catch on; one person does it right, and neighbors start paying attention, too.

We owe it to each other to keep the chain of care going. It starts at our kitchen tables, in hardware store recycling bins, and with the questions we ask before we toss something away.