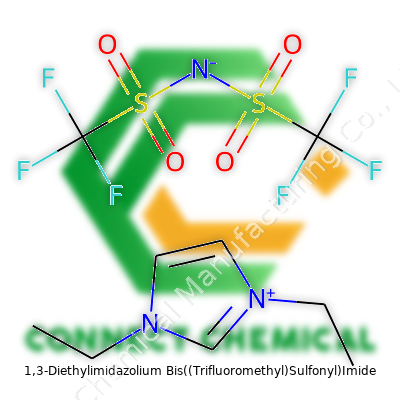

1,3-Diethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: Analysis and Outlook

Historical Development

Stepping back a few decades, chemists started paying more attention to ionic liquids like 1,3-diethylimidazolium bis((trifluoromethyl)sulfonyl)imide, often called [Et2Im][NTf2]. The late twentieth century brought a burst of interest driven by calls for greener solvents. Early discoveries in ionic liquid synthesis cracked open new possibilities, with researchers seeking alternatives to volatile organic solvents. The chemistry community found value in salts like [Et2Im][NTf2] because they stay liquid at room temperature, expanding both lab work and scalable production. My own lab relied on ionic liquids to test the boundaries of classic separation methods. Even back in undergrad, it was clear that [Et2Im][NTf2] played a role in bridging environmental targets and performance.

Product Overview

[Et2Im][NTf2] stands out among ionic liquids for its stability, low melting point, and resilience against hydrolysis. The compound belongs to a lineup of imidazolium-based salts paired with the familiar bis(trifluoromethylsulfonyl)imide anion, also called NTf2. It packs unique traits: negligible vapor pressure, non-flammability, and high thermal stability. In the warehouse, bottles of this liquid often ship with moisture-tight seals. Clear, colorless, and slightly viscous, [Et2Im][NTf2] resembles ordinary organic solvents at a glance but shelters quite different properties in the details.

Physical & Chemical Properties

The liquid form stays clear and nearly colorless. With a melting point that dips below -30°C, flow never becomes an issue in most labs. Its density ranges around 1.45 g/cm3, a bit heavier than water. Viscosity sits modestly higher than organic solvents, but with the right heater or stir plate, pour and mix remain manageable. Its high ionic conductivity appeals to anyone running electrochemistry tests. Under a glass hood or in a glove box, it barely forms a vapor. This low volatility comes directly from the strength of the ionic interactions inside. Chemically, the liquid refuses to ignite, even when exposed to open flame, sidestepping concerns I’ve had with flammable organics. Immune to hydrolysis under most conditions, it shrugs off water but can slowly take on moisture from open air, which means dry box storage makes sense for sensitive uses.

Technical Specifications & Labeling

Reputable suppliers deliver [Et2Im][NTf2] at purity levels above 99%. Material safety data sheets call out its CAS number, appearance, density, melting point, and sometimes impurities. Bottles carry batch numbers and date codes, with labeling required to warn about skin and eye contact. Some suppliers also print recommendations for storage temperature, usually between 15°C and 30°C, plus reminders to keep containers tightly closed. Any unreacted starting material or water content gets listed on a certificate of analysis. My own purchases often included direct advice about avoiding contact with strong oxidizers and keeping the compound tightly sealed. Lab practice dictates labeling all transfer bottles in plain language to avoid confusion—just to keep things simple and safe.

Preparation Method

Making [Et2Im][NTf2] begins with N-alkylation. The imidazole ring reacts with ethyl halides under controlled temperature—less chemistry wizardry, more steady patience at the bench. This step yields the diethylimidazolium halide. Then, metathesis swaps the halide for NTf2 anion using lithium or sodium bis(trifluoromethanesulfonyl)imide. The byproduct halide salt precipitates out and the remaining liquid phase holds the ionic liquid. Careful washing and drying finish the job. Back at my university’s synthetic chemistry lab, we leaned on this protocol, but always filtered over activated alumina to strip out lingering halides. One overlooked wash led to ruined conductivity readings, a reminder not to skip corners on purification.

Chemical Reactions & Modifications

[Et2Im][NTf2] stands up to a range of harsh chemical conditions. What caught my attention was its resistance to oxidation and hydrolysis. It allows for strong acid and base catalysis, often acting as a reaction medium rather than a simple solvent. Chemists sometimes tweak the cation or the anion to adjust properties—switching out the Et groups with longer chains or bringing in different anions like PF6 for new functionality. On the application side, researchers dissolve metal complexes, organic molecules, or even nanoparticles within [Et2Im][NTf2] to push boundaries in catalysis and green synthesis. This adaptability opens the compound up to customization depending on project needs, from increased hydrophobicity to precise solubility tuning.

Synonyms & Product Names

This ionic liquid shows up under several names in literature and catalogs. The most common tag is 1,3-diethylimidazolium bis(trifluoromethylsulfonyl)imide or [Et2Im][NTf2]. Some suppliers use 1,3-diethylimidazolium bistriflamide, as the NTf2 anion sometimes gets called bistriflamide. Other tags might reference the cation’s abbreviation, like Et2Im, or the anion alone, NTf2. Specialty sellers may list the material under commercial code numbers or product lines—one quarter, I ordered it as part of a custom electrolytes kit, with its own part number. No matter the label, the chemical formula keeps things grounded: C11H16F6N4O4S2.

Safety & Operational Standards

Personal experience in handling [Et2Im][NTf2] taught me the right habits. Contact with skin or eyes leaves a sting, and gloves become non-negotiable. Fume hoods offer solid airflow, though the low vapor pressure makes inhalation less likely compared to volatile solvents. Safety sheets note that decomposition at high temperatures produces hazardous fumes, so heating goes slowly with plenty of ventilation. Many facilities log containers with special chemical codes, and training includes strict spill control and disposal steps. If the liquid hits bench surfaces, absorbents soak it up and clear labeling keeps everyone on the same page. In my work, storing containers above corrosives and away from oxidizers reduced the odds of trouble.

Application Area

[Et2Im][NTf2] stretches across fields. Synthetic chemists lean on it as a reaction solvent, exploiting the ionic environment to drive clean conversions. Electrochemical labs put it to work in batteries, supercapacitors, and electroplating. Its stable electrochemical window proves invaluable for long-lasting devices. Because of its resistance to ignition and evaporation, the liquid sometimes appears as a lubricant in high-vacuum pumps, where vapor pressure is critical. Pharmaceutical companies explore its potential in green synthesis and separation, streamlining drug production steps. In analytics, the liquid helps dissolve otherwise stubborn analytes, smoothing out advanced chromatographic techniques.

Research & Development

Universities and corporations continue to invest in new uses for [Et2Im][NTf2]. Teams analyze how slight tweaks to the cation or anion can dial in melting point, solubility, or toxicity. Pilot programs target recycling and reusability, aiming to recover and purify the ionic liquid after use to cut costs and waste. Instrumentation labs look for improved conductivity and compatibility with modern electrodes. On the regulatory side, research explores green chemistry certifications, providing proof for sustainability claims. Colleagues in materials science test [Et2Im][NTf2] with advanced polymers and hybrid materials, measuring changes in mechanical strength and stability.

Toxicity Research

The industry sees ongoing debate around the safety of imidazolium-based ionic liquids. Toxicity studies flag mild to moderate effects on aquatic life if [Et2Im][NTf2] enters waterways, forcing labs to design tighter waste streams. Animal studies register low acute toxicity but raise concerns about chronic effects and bioaccumulation. My own care about chemical footprint means advocating for responsible disposal and recycling above sewer release. Regulatory bodies in Europe and North America tend to err on the side of caution, requiring full documentation and risk mitigation. Steps like secondary containment and trace-level monitoring help facilities track the compound and prove accountability.

Future Prospects

Innovation in [Et2Im][NTf2] faces both hurdles and fresh opportunities. Industry needs better methods to reclaim and recycle spent liquid, cutting down on chemical waste without breaking budgets. Breakthroughs in low-toxicity variants could unlock bigger roles in energy storage and pharmaceuticals. Advances in computational chemistry help predict new pairings of cations and anions, saving resources and shortening development times. Large-scale manufacturing continues to search for greener and safer processes, especially as regulatory demands climb. In my own view, the future hinges on closing the loop—maximizing performance while shrinking risk and environmental load. Researchers and companies who crack the code on responsible scaling stand likely to shape what comes next for ionic liquids like [Et2Im][NTf2].

Inside the Lab: A Chemist’s Perspective

Watching how researchers use 1,3-diethylimidazolium bis((trifluoromethyl)sulfonyl)imide—usually labeled as [DEIM][TFSI]—reminds me how much the science world leans on specialized chemicals these days. I remember working on battery projects, noticing how this compound grabbed attention with its ability to dissolve a range of salts while standing up to high temperatures. You won’t find this material in home cabinets. Instead, it gets attention in research labs and advanced tech shops where pushing performance means everything.

Electrochemistry: Pushing Battery Tech Further

Battery innovations depend on finding liquids that handle ions quickly and reliably, no matter how stressful the environment gets. Researchers like me wind up spending late nights tracking slight performance jumps, hunting every bit of safety and stability. [DEIM][TFSI] delivers by offering a wide “electrochemical window.” This means batteries using it can run at higher voltages before breaking down, solid news for electric vehicles and grid storage.

One thing people working on lithium batteries love—this ionic liquid is non-flammable. Drop a tool, get a spill? It won’t ignite and take the whole bench with it, unlike the usual solvents (like ethylene carbonate). Reports show researchers building safer, longer-lasting batteries with this chemical. Solid-state batteries, in particular, benefit from the stability and low vapor pressure. Recyclers, too, see potential for [DEIM][TFSI] to separate out valuable metals without creating a hazardous mess.

Solvent With a Superpower: Green Chemistry Uses

Seeing green chemistry come alive, [DEIM][TFSI] often stands beside ionic liquids that chemists praise for being “room-temperature, task-specific.” This one in particular barely evaporates at normal temperatures and won’t react easily—qualities that cut chemical loss and exposure in factories. During pharmaceutical and chemical manufacturing, it can dissolve tricky organic and inorganic substances. This unlocks reaction pathways that water and common organics cannot, sharpening results or cutting steps.

One of my colleagues worked on cellulose processing. Traditional solvents barely budge tough plant fibers. With [DEIM][TFSI], he watched cellulose dissolve without harsh acids, making way for new bioplastics and strong fibers. Industrial catalysis teams also chase it for its ability to create uniform micro-environments, which can drive up yields on specialty chemicals or enable greener pathways.

Electronics and Advanced Coatings

The world craves smaller devices, thinner displays, and faster chips. Fabrication plants now dabble in ionic liquids to control nanostructures or lay down ultra-flat coatings. [DEIM][TFSI] resists water, dissolves conductive salts, and stays stable under high voltages. This turns it into a tool for electroplating, etching, and preparing advanced polymer films.

With electronics, controlling impurities and moisture matters. I’ve seen teams swap out classical solvents for [DEIM][TFSI] to cut defects in thin films or avoid corrosion under humid conditions. Display manufacturers lean on this chemical to smooth out industrial processes—helping OLEDs and flexible electronics reach markets faster.

Room for Growth and Responsible Use

[DEIM][TFSI] opens many doors for scientists and industry. Yet, challenges linger. High cost and specialized handling rules slow adoption. Research into its long-term health and environmental impact must continue. Sustainable chemistry works best when paired with thorough safety, waste treatment, and recycling practices. If companies keep sharing data and learn from pilot projects, broader applications might emerge—especially as the drive for safer batteries and greener manufacturing builds momentum.

Understanding What’s in the Bottle

1,3-Diethylimidazolium bis((trifluoromethyl)sulfonyl)imide often pops up in research as an ionic liquid, a niche but useful solvent for green chemistry and battery science. Most folks working in a chemistry lab will run into this stuff in small bottles, usually with a label full of long words and hazard symbols. Just because it sounds fancy doesn’t mean it’s harmless. My years in a university lab taught me that anything with a Teflon-sounding fluorinated group grabs attention for good reason—some can do real harm due to toxicity or persistence once spilled.

What Do We Actually Know About the Risks?

Information on niche ionic liquids can get sparse, but safety data on 1,3-diethylimidazolium bis((trifluoromethyl)sulfonyl)imide shows potential harm if inhaled or if it hits your skin or eyes. Some studies highlight possible irritation and delayed effects. Others suggest ionic liquids could build up in the environment because microbes don’t break them down fast. You won’t find it on most toxic substance lists, but treating it lightly just because it’s “green” or “modern” risks accidents.

Practical Precautions: What I Learned Matters Most

Working with unfamiliar chemicals, my rule stays the same: gloves, goggles, and good ventilation. The best latex or nitrile gloves keep spills off your skin—don’t rely on old, thin ones punched with holes from too much use. Goggles mean your eyes won’t sting after a splash. I’ve seen enough red and itchy hands from folks who figured “one drop can’t hurt.” A real ventilation system—ideally a fume hood—pulls away vapors, keeping the air clear even during small transfers or mixing. Ionic liquids like this one may seem stable at room temperature, but a flask heating on the bench or an accident with incompatible chemicals turns calm into chaos fast.

Storage and Disposal Mistakes to Avoid

Chemists I’ve worked with sometimes set bottles of new compounds too close to heat or light for convenience. This liquid handles best sealed tight, far from direct sunlight and away from copper, steel, or reactive metals. Forgetting to double-check a chemical-compatible waste container or labeling waste with full names instead of gibberish codes can cause bigger headaches down the line. Ionic liquids don’t evaporate like water, so wiping spills with a paper towel doesn’t cut it—use proper absorbent pads, and treat cleanup gear as contaminated waste. Don’t pour leftovers down the drain or toss in the trash: follow a real disposal process, even if it takes more paperwork.

Changing Habits in the Lab

Many labs now build safety routines into daily schedules, including peer checks before any tricky procedure. People starting new projects chat regularly about the hazards and keep safety sheets handy. I’ve picked up useful habits, like scanning for digital SDS sheets on a phone before handling a new bottle or taping emergency contacts to cabinet doors near chemical stocks. If unsure, folks call on the experienced technician or safety officer rather than hoping for the best—a five-minute consult beats an ER visit any day. These steps build a safer culture and help new chemists stay careful with every chemical, even those with names no one can pronounce.

Why Knowing Chemical Structure and Molecular Weight Matters

Chemistry turns abstract theory into tangible progress. Anyone spending time in a research lab learns quickly that a compound’s structure has everything to do with how it acts—whether it touches lives with healing, provides fuel for energy, or triggers a new environmental puzzle. Think about a pharmacy shelf. That painkiller on top shares a basic element or two with an herbicide, but give each a distinct arrangement of atoms and you get wildly different results in the body. Small differences in atomic connections determine if a substance helps or harms.

Drug developers work with this daily. For example, the difference between thalidomide’s two mirror-image forms means relief for some and tragic birth defects for others. Biological activity flows from precise chemical architecture, no guesswork allowed. Fluorine tossed onto an aromatic ring can keep a medicine in the bloodstream longer, or a methyl group tucked into a certain spot can block a molecule’s toxicity. Accuracy in structure isn’t just academic; it’s a matter of real-world consequences.

Molecular Weight: A Practical Number

In lab meetings, you’ll always hear talk about molecular weight—also called molar mass. Chemists calculate it fast, because a wrong value throws off every experiment downstream. Molecular weight lets you measure out the right amount of a compound, whether for an antibiotic dose or mixing up a batch for plastics production. Eat too much salt—sodium chloride—and a technician can tell you just how many grams tip the balance from seasoning to surplus.

This number teases out key properties. Large molecules like proteins struggle to cross cellular barriers, while tiny molecules slip through with ease. The molecular weight of a compound shapes how it dissolves, how it travels inside organisms, and sometimes how hazardous it can be. That’s how environmental chemists estimate pollutant spread or how forensic teams trace toxic substances at a crime scene.

The Search for Answers: Reliable Sources

I often pull up trusted resources such as PubChem, ChemSpider, or Reaxys to check a compound’s blueprint. These databases keep snapshots of molecules—showing atoms arranged just so, with bonds in every direction a chemist could demand. Each record lists atomic details, formulas, and that crucial molecular weight. Scientists upload peer-reviewed information, so the facts come from synthesis records or experimental data rather than guesswork.

Experience has taught me to avoid obscure or unsourced diagrams circulating in online forums. Sometimes professional judgment just means going back to the original paper or analytical report. X-ray crystallography, nuclear magnetic resonance, and other techniques expose structure down to the atom. With advances in machine learning, identifying molecular structures from spectral data gets faster and more reliable, but nothing beats skilled analysis of real-world measurements.

Better Access to Chemical Information

One hurdle still holds back progress—open access to quality data. Some chemical knowledge sits behind paywalls or gets buried in legacy journals. University collaborations, open science initiatives, and transparent public databases break down these walls. More students, researchers, and developers can learn and innovate when basic chemical facts are just a web search away.

Understanding the molecules around us doesn’t only drive scientific breakthroughs—it keeps people safe, inspires new business ideas, and untangles problems from pollution to disease. Next time a headline brings up a new compound, it’s worth looking past the formula and picturing the world of possibilities hiding in its structure and molecular weight.

Understanding What You're Handling

Working in a lab introduces all sorts of liquids, salts, and powders, each with its own quirks. 1,3-Diethylimidazolium bis((trifluoromethyl)sulfonyl)imide shows up as an ionic liquid, and I’ve watched many teams use it for electrochemistry, synthesis, and even as a battery electrolyte. Its stability over weeks or months can make or break a set of experiments, especially if you're chasing precise measurements.

Environmental Sensitivities: Air, Water, and Light

Any chemist will tell you most ionic liquids might shrug off a few drops of water or a passing draft of air. This one, though, likes to stay dry. Even a little humidity can change how it behaves, not always in ways you notice right away. Storing it in tightly sealed glass containers, away from open air, keeps it working as intended. Desiccators aren’t only for powdery solids—using one here pays off. Even with a cap, moisture has a way of creeping in, especially after repeated opening and closing of bottles.

Temperature tells another part of the story. Too much warmth speeds up any unwanted reaction with whatever stray compound sneaks in. The sweet spot I’ve seen most often is below room temperature—10 to 20°C works, though standard refrigerator shelves (4°C) also serve well for longer-term storage. Not every freezer works for chemicals, since some ionic liquids thicken or separate, but a steady, cool spot on a laboratory fridge usually keeps the material intact.

Shielding from Light and Heat

Even if you store the bottle capped and away from steam or sun, light can weaken the bond integrity over time. I’ve seen clear bottles turn yellow when left near a window. Amber glass bottles cut the risk, but drawing curtains or stashing the bottle deep in a cabinet takes little effort and prevents slow changes that later ruin careful work. In chemical storage, a few extra steps early always feel easier than explaining spoiled samples later.

Minimizing Contamination and Cross-Talk

Every time someone pours from one bottle to another, the risk of cross-contamination jumps. Even a fleck of dust or drop of solvent from previous experiments can play havoc. I’ve seen labs reserve special utensils—spatulas, pipettes—just for handling their ionic liquids. Labeling the container with the date and any transfers helps track if something goes off down the line. Avoiding metal tools cuts down on stray catalytic effects. Even tiny traces of metal can start reactions you’ll never see coming until your results don’t match expectations.

Watching for the Unexpected

It helps to build the habit of inspecting the liquid after storage. Any darkening, new cloudiness, or changes in consistency deserve attention. A quick sniff sometimes spots trouble—a whiff of something sulfurous or unusual flags an issue. Testing a small aliquot before using in a critical process saves time and trust.

Why Good Storage Matters

Research projects live or die on the quality of their chemicals. I’ve seen careers stall over degraded samples and wasted months. Reliable storage frees up time to focus on results. Accidents happen, but most issues trace back to avoidable handling mistakes: heat, light, moisture, careless labeling. A little discipline and investment up front multiply reliability and trust in the data you generate.

Appearance Tells a Story

Looking at any chemical, I always pay attention to the way it looks. Appearance says more than people realize. Some powders seem pure white and sit in their bottle like fresh snow, while others show off a crystal-clear shimmer. Color can hint at purity—which matters for labs and manufacturing. Subtle hints like a faint off-white tint or a yellowish hue often trace back to tiny amounts of leftover reagents or breakdown products. Small, seemingly cosmetic details can warn about contamination or improper storage.

I remember years ago getting a batch labeled “fine white crystals.” The powder looked a touch grayish; that shade cost us hours of headaches during quality checks. Physical state matters, too—granules, flakes, needles: each brings a different story about how the compound was made and what it might contain. These details grab attention, especially in pharmaceuticals or food ingredients, where appearances affect safety, perception, and sales.

Melting Point: A Window Into Purity

Most of the serious headaches in chemistry come from a compound’s melting point. Melting point gives a solid number—if you know the true value. Bad batches look normal on the outside, but testing with a reliable thermometer uncovers the truth. Pure compounds melt at a steady, tight range. Impurities? They throw everything off, lowering the temperature or widening the melting window. Organic acids, pharmaceutical actives, industrial salts—they all get scrutinized in the same way.

On the factory floor, melting point matters, too. If a compound has a low melting point and you run a plant at high temperatures, you end up with sticky machinery and wasted resources. At the same time, products designed for cold-chain distribution need to survive on long truck rides. It’s not just a detail for textbooks—these numbers shape the entire supply chain. I’ve seen companies lose entire shipments because they underestimated how sensitive their product was to summer heat.

Solubility: The Make-Or-Break Feature

Few properties cause as many arguments as solubility. One chemist’s “insoluble” is another’s “slightly soluble”—it all depends on the solvent, the temperature, and whether you add a little stirring. Tablets have to dissolve at the right rate in the human body. Dyes need to blend with fibers in ways that last through hundreds of wash cycles. Adhesives, coatings, cleaning agents—they all demand a careful look at what actually mixes and what settles out.

Testing isn’t glamorous. It involves adding pinch after pinch to water or oil, sometimes waiting overnight to see if anything cloudy shows up. The hard facts matter: grams per 100 milliliters, measured across a range of temperatures. In my own experience, missing a hidden insoluble trace in a batch of pigment made a whole vat of paint unusable. That’s a costly mistake, especially when the numbers weren’t double-checked.

Solubility challenges don’t only frustrate chemists—engineers, marketers, and safety officers care, too. The right solvent can turn a stubborn powder into a market-ready solution. Sometimes a problem with clogging pipes or ruined equipment tracks back to a hidden change in solubility between batches.

The Bigger Picture

Trust in a chemical product starts with honesty about appearance, melting point, and solubility. Not just for compliance, but because problems hidden in these small details have real effects on safety, cost, and reputation. Regular, careful measurements—combined with knowledge picked up from the shop floor—help spot trouble early. No lab instrument beats experience, but sharp eyes and patience still prove themselves, time and again, in catching issues before they spiral out of control.