1,3-Diethylimidazolium Bromide: A Down-to-Earth Commentary

Historical Development

People who work in the chemistry world have watched the story of ionic liquids like 1,3-Diethylimidazolium Bromide unfold over the last few decades. Its roots go back to scientists searching for better, less volatile solvents in the late 20th century. Traditional organic solvents used to fill labs with fumes, leading chemists to hunt down alternatives that could handle the same workloads without shaking up health and safety standards. This search led down the path toward imidazolium-based ionic liquids. Early research focused on swapping chloride and hexafluorophosphate ions in simple imidazolium salts. By the 1990s, bromides showed up, opening the door to salts like 1,3-Diethylimidazolium Bromide, thanks to its manageable synthesis and promising characteristics. Universities and research groups worldwide contributed articles and patents that steadily built up our understanding. With time, the chemical marched out from lab benches and into pilot-scale chemical manufacturing sectors, slowly but surely grabbing a foothold in extraction, catalysis, and electrochemistry.

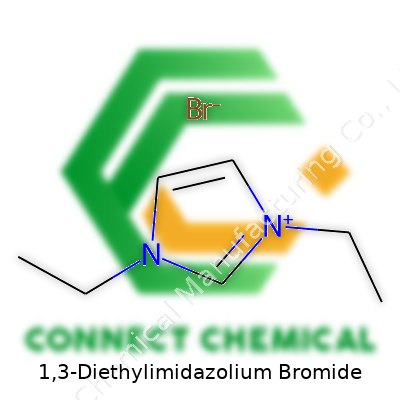

Product Overview

Anyone who handles 1,3-Diethylimidazolium Bromide knows it presents as a pale, hygroscopic crystalline solid at room temperature. The compound belongs to ionic liquids, a family of salts that melt at temperatures far below normal table salt, often at or even below 100°C. This property gives it a set of uses most organic solvents can’t touch. Unlike some ionic liquids that stick or clump, 1,3-Diethylimidazolium Bromide keeps a fairly consistent texture, so dosages stay predictable in both research and industrial contexts. Its chemical structure comes down to a five-membered imidazolium cation, where both nitrogen atoms wear ethyl groups, paired with a bromide anion. The molecular setup brings some marked benefits: strong stability, good solubility in solvents like ethanol and water, and low vapor pressure, which keeps workplace air clearer than traditional solvents ever have.

Physical & Chemical Properties

Over the years, researchers have mapped the physical and chemical details of 1,3-Diethylimidazolium Bromide with solid consistency. Melting points fall between 70°C and 90°C. Its hygroscopic nature pulls moisture from the air, which means chemists often store it in dry conditions to avoid clumping. The salt dissolves readily in water, ethanol, and acetone, delivering ease of use in many aqueous and organic settings. Chemically, its ionic nature makes it a stable solvent or catalyst that doesn’t easily break down or ignite. On the electrochemical front, its broad window allows for conducting electricity in devices like batteries or supercapacitors. Its bromide counterion also enables unique reactivities compared to its chloride cousins. This opens doors for synthesis routes and applications that call for bromide’s nucleophilicity or the ability to act as a soft leaving group in organic reactions.

Technical Specifications & Labeling

Product labeling for 1,3-Diethylimidazolium Bromide reflects the attention to detail necessary for handling specialty chemicals. Purity usually runs at ≥98%, which helps avoid side reactions in sensitive workflows. Labels list CAS numbers, UN shipping classifications, hazard symbols, and shelf life. Modern labeling demands meet strict REACH and GHS standards. Storage recommendations flag humidity sensitivity and call for tightly sealed containers, away from incompatible substances (like strong oxidizers). Users should pay attention to batch-specific certificates of analysis to verify that the synthesis and purification procedures met the latest regulatory demands.

Preparation Method

Anyone can track down a handful of reliable synthesis routes for this bromide salt. One of the most direct ways starts with 1,3-diethylimidazole or its base imidazole, which reacts with an alkyl bromide such as ethyl bromide under controlled heat. The process sometimes calls for a solvent like acetonitrile and a touch of base to mop up unwanted byproducts. Heat stirs the imidazole and ethyl bromide into a salt, and the cooling stage crystallizes the product, sometimes after repeated washing or recrystallization to remove leftover unreacted materials. Commercial batches may swap solvents or tweak conditions to control particle size and moisture.

Chemical Reactions & Modifications

Chemists turn to 1,3-Diethylimidazolium Bromide as more than just a passive solvent. Its active participation in organic synthesis ranges from phase-transfer catalysis to nucleophilic substitution reactions. That bromide ion can drive core alkylation or displacement chemistry, lending itself to greener halide-based organic syntheses. Its imidazolium ring serves as a platform for further functionalization—either by direct modification or through exchange with other anions in metathesis reactions. Cation swapping experiments lead to new salts with diverse solubility or thermal properties. Researchers continually explore how its chemical backbone adapts to tunable reaction sites or electronic needs, whether in forming temporary complexes or stabilizing radical intermediates.

Synonyms & Product Names

Over the years, 1,3-Diethylimidazolium Bromide has gone by many names in supplier catalogs and research papers. Some call it DEImBr, DEIMBr, or 1,3-Diethylimidazolium bromide. You might spot entries as Imidazolium, 1,3-diethyl-, bromide or simply “ethylated imidazolium bromide” in shortcut form. Catalogues from chemical distributors highlight these names, sometimes grouping it with its chloride or tetrafluoroborate analogues in the imidazolium series.

Safety & Operational Standards

Handling 1,3-Diethylimidazolium Bromide calls for standard laboratory hygiene. Its low vapor pressure limits inhalation risks known from volatile organic solvents, but skin and eye protection remains necessary. My own experience has taught me never to underestimate an ionic liquid’s ability to cause dermatitis after prolonged exposure or splashes— nitrile gloves and splash goggles stop these risks from becoming headaches. Its material safety data sheet warns users to avoid breathing dust and to wash hands thoroughly after handling. Any waste needs double-checking before disposal to prevent bromide leaching into the water supply. Thermal stability keeps fire risks down, but spills on benchtops should be wiped up using dry techniques, as its hygroscopic character makes simple water cleanup less effective.

Application Area

Industries and academic groups use 1,3-Diethylimidazolium Bromide in cutting-edge ways that range from green chemistry to advanced electronics. In my lab days, we tried it as a solvent for cellulose processing, sidestepping the need for hazardous acids in making biofuels or specialty polymers. It has found its way into catalysis for both organic synthesis and industrial scale reactions. Electrochemists value it in the development of batteries, dye-sensitized solar cells, and supercapacitors, capitalizing on its wide electrochemical window. Extraction specialists select it for dissolving and separating rare earth metals or organic feedstocks. In analytical chemistry, its low volatility improves sample prep by reducing background interference. Each sector tweaks the handling and dosage to suit its application, but all benefit from the chemical's balance of stability and solubility.

Research & Development

Progress in 1,3-Diethylimidazolium Bromide research shows no signs of slowing down. Many universities direct grants toward optimizing reactions in its ionic liquid media to push boundaries on reaction selectivity and yield. Private industry invests in scaling up “greener” syntheses that swap toxic reagents for this bromide salt. Collaboration between policy, academia, and manufacturing has created international standards for purity, handling, and certification. Patent offices have received steady streams of filings involving customized versions for next-gen batteries or improved extraction. R&D heads know that further tailoring, whether with new cations, co-solvents, or temperature control, could reveal ways forward for pharmaceuticals, nanomaterials, and recyclable plastics. It’s the drive toward better, safer chemistry that keeps this area lively and competitive.

Toxicity Research

Toxicity studies spotlight questions that every chemist and workplace health professional needs to face. 1,3-Diethylimidazolium Bromide hasn’t escaped scrutiny. Lab animal studies and aquatic assays have found that, like many ionic liquids, it can show moderate toxicity to aquatic life. It doesn’t break down readily in the environment, so spills or large-scale discharges should raise concerns about waterway contamination. In human exposure studies, its low volatility protects against inhalation, but chronic skin contact can cause irritation. Environmental chemists keep tabs on its fate and transport, especially where manufacturing or disposal scales up. Regulatory agencies set concentration limits in waste streams and sometimes require trace monitoring. Knowing the long-term environmental impact still needs more independent peer-reviewed data.

Future Prospects

Looking ahead, 1,3-Diethylimidazolium Bromide sits at the crossroads of old and new chemical thinking. As industries shift focus toward sustainability, chemicals like this bromide salt must rise to the challenge of replacing old solvents while staying cost-effective and safe. Breakthroughs might come by tweaking its structure to improve biodegradability or recycling. Researchers are testing its potential in circular economy projects, where used salts get cleaned and cycled back into production lines, shrinking waste streams overall. In advanced batteries, its stability promises longer cycle lives and fewer hazardous byproducts than conventional electrolytes. As bio-based manufacturing grows, demands for biocompatible or less hazardous process aids may drive further development. The door remains open for companies and labs ready to invest in training, handling, and transparently sharing risk data—the foundation for trust and safety as this compound finds its way into new corners of the chemical industry.

Getting to Know the Chemical

1,3-Diethylimidazolium bromide sounds like something reserved for the back shelf in a chemistry stockroom, but this compound gets steady use in research and industry. It belongs to a family of chemicals called ionic liquids, which share a knack for staying liquid at room temperature. That single trait means experiments don’t need super-high heat or harsh solvents.

Many folks first encounter this compound in college-level chemistry courses or as part of their graduate research. Even in my own undergrad days, we heard stories about these ionic liquids turning tough experiments into straightforward tasks. Once you actually use them, you get hooked on the idea of a salt that pours like water.

Solvent Powerhouse in the Lab

The main thing 1,3-diethylimidazolium bromide brings to the table revolves around solvency. Standard organic solvents—think acetone or ethanol—do the job, but these ionic liquids take things to another level. People working with tough-to-dissolve chemicals or looking for a way to separate two sticky substances out of a messy mix often choose this compound. Whether it’s breaking down plant matter for biofuel research or working with pharmaceuticals, it keeps the wheels turning where traditional choices fall short.

Academic journals track the rise of ionic liquids, noting that over the past ten years, studies using compounds like 1,3-diethylimidazolium bromide have tripled. A lot of this growth comes from green chemistry efforts. The goal there is to swap out toxic solvents for options less likely to poison you or the planet. Labs using this compound often cut back on their hazardous waste output—something most researchers take seriously.

Catalysis and Synthesis

Organic synthesis can be frustrating. Reactions stall, side products sneak in, and everything gets sticky—sometimes literally. Here, 1,3-diethylimidazolium bromide sometimes steps in as both solvent and catalyst. That dual role means shorter reaction times and better yields. In college, I remember running a reaction overnight with traditional solvents. After switching to an ionic liquid like this one, the same reaction often finished before lunch.

Researchers use it for synthesizing fine chemicals, pharmaceuticals, and new materials. In recent years, this compound helped speed up cross-coupling reactions, a key process in drug discovery and material science. With the growing demand for custom drugs and better batteries, tools like this become hard to overlook.

Sustainability and Challenges

There’s a push these days to make chemistry cleaner. Many students and professionals like the idea of a solvent that suits green chemistry goals. 1,3-diethylimidazolium bromide doesn’t evaporate easily, so labs cut down on harmful fumes—an improvement for researchers and the environment.

Not everything is perfect. The compound is expensive. Disposal rules for ionic liquids change by location, and no one wants to trade one set of environmental problems for another. In the classroom, students wonder if scaling up these chemicals for big factories makes sense. Companies and universities continue to test safer, more biodegradable alternatives. The field moves fast, and what seems like a magic bullet today might get replaced tomorrow.

The Road Ahead

Learning about 1,3-diethylimidazolium bromide means tracking a trend toward better, safer chemistry. Today, it helps build new materials, boosts green research, and gives scientists another way to solve old problems. Folks guided by safety, speed, and sustainability should keep an eye on these modern solvents and demand clear data on health, cost, and environmental fallout.

The Weight of a Formula: C7H13BrN2

C7H13BrN2 doesn’t mean much to most people at first glance, yet this simple formula tells a story rooted in chemistry labs and real-world applications. I remember sitting in a cramped research room, pipetting ionic liquids like this one, experimenting on ways to make industrial processes cleaner and more efficient. This particular salt, 1,3-Diethylimidazolium bromide, played an important role. Once you know its structure—an imidazolium ring with two ethyl groups and a bromide counterion—it's hard to stop thinking about its possibilities.

Why Knowing the Formula Matters

Formulas aren’t just academic curiosity. C7H13BrN2 represents a class of ionic liquids with a range of talents. 1,3-Diethylimidazolium bromide brings its own set of properties: low melting point, non-volatility, and the ability to dissolve an impressive number of compounds. Scientists prize this compound for green chemistry projects. In my experience, swapping hazardous solvents for ionic liquids like this one reduced modest lab smells and improved safety. Major manufacturers have taken notice too, gradually replacing old solvents in extraction and catalysis.

Real-World Impact

Understanding 1,3-Diethylimidazolium bromide starts with its chemical relationships. That imidazolium ring, flanked by ethyl groups, sets its reactivity and thermal stability. Bromide, on the other hand, influences solubility. I saw firsthand how temperature-resistant this salt could be—surviving in environments where typical organics would decompose or lose potency. Energy companies and recyclers benefit from these qualities, especially when handling metals or organic waste streams. Data published in the Journal of Hazardous Materials points to ionic liquids like this one cutting down emissions during synthesis steps.

Risks and Challenges on the Lab Bench

No chemical comes without trade-offs. 1,3-Diethylimidazolium bromide can be persistent, staying in waterways if discharged without proper treatment. Bromide ions add to potential toxicity for aquatic life. Many chemists, including those in my group, started double-checking disposal protocols, switching to absorbent materials instead of just rinsing everything down the sink. Industry guidance from organizations like the American Chemical Society flags the importance of containment and recycling, which keeps ionic liquids out of natural systems.

What Happens Next?

Wider adoption depends on scaling up production and making sure environmental controls keep pace. Researchers continue to tweak the basic structure (sometimes swapping the bromide for less persistent anions), chasing better biodegradability and lower costs. Open-source databases show the number of new ionic liquids rising sharply each year. This wave of research reflects both hope and caution—appreciating the value while watching for new risks. Companies investing in greener chemistry are finding the right mix of research, regulation, and responsible practice sharpens competitiveness. From experience, transparency and willingness to share data on environmental fate make a difference.

People often overlook the story behind a formula. With 1,3-Diethylimidazolium bromide, each lab test and application adds another layer. The surface-level letters and numbers only hint at the impact this compound can have on industries eager to change for the better.

Looking Into the Safety Questions

People working in chemistry circles sometimes talk about 1,3-diethylimidazolium bromide as a clever solution. It pops up in labs and production floors where folks need ionic liquids for chemical reactions or separation work. On the surface, it sounds like just another chemical tool, but the core question hangs in the air: how safe is it, really?

What Science Says About Risk

Many ionic liquids carry a reputation as “green” solvents. Some claim low vapor pressure keeps them from wafting around and bothering lungs. For 1,3-diethylimidazolium bromide, the story isn't that smooth. Take a look at published data from the OECD and a few peer-reviewed studies, and you see some important flags. Recent work published in Chemosphere and related journals has shown several imidazolium-based compounds cause irritation to skin and eyes if handled without the right protection. Rodent studies suggest, at high enough doses, there’s potential for problems involving the liver and kidneys.

Even though it doesn’t explode or ignite like some older solvents, its impact on aquatic life can turn serious fast. It gets into water, it doesn’t just vanish. Research groups in Germany and Japan have both noted toxicity to algae and small aquatic animals, impacting growth and even leading to population drops in controlled tanks. That alone demands a hard look at local wastewater treatment whenever a facility handles this compound.

Personal Experiences and Workplace Concerns

Working on a project for a manufacturing line a year ago, I watched chemists glove up, make sure no skin was exposed, and work under vent hoods just to measure this material. If a spill happened, we weren’t just worried about slippery floors—we called in special disposal folks. The focus was always on avoiding direct contact and making sure nothing headed out a drain. These steps take time and money, but nobody in that lab wanted unexplained headaches or rashes at the end of a shift.

Long-Term Effects and Environmental Footprint

Long-term, the real question rests in what these compounds do as they build up in the environment. A 2021 study from Switzerland followed streams for a year and traced imidazolium ions even after multiple cleaning cycles. Their persistence means buildup happens unless strong safeguards stay in place. There’s also the unknown of bioaccumulation—what low levels do over years to people, plants, and animals exposed every day.

Smarter Handling and Better Answers

Nobody needs to panic, but getting complacent would be just as dangerous. Smart policies put the priority on education and containment. Engineers can design setups where exposure never gets a foot in the door. Lab training matters, not just on paper but in the way people practice and prepare for unexpected spills. For companies, sharing full safety data with teammates builds trust. Vendors should show transparency, and buyers need to read all the way to the fine print—not just the highlights.

Looking beyond instant fixes, research keeps turning up new ionic liquids meant to be less toxic, drawing on biodegradable, renewable ingredients. Until those prove out, anyone using 1,3-diethylimidazolium bromide owes coworkers and the wider community care for every step of its journey—from receipt and storage to waste handling and final disposal.

Understanding the Material’s Nature

1,3-Diethylimidazolium bromide falls into a class of ionic liquids often used in research and advanced chemical applications. The odd thing about chemicals like this is how easy it is to overlook their quirks in storage. Folks may treat them as if they are any old lab salt, but real life tends to teach lessons quickly.

Learning from Everyday Lab Work

On a typical morning in the lab, humidity climbs, and even sealed bottles sweat with condensation. My colleagues and I have dealt with clumpy reagents more than once because someone left a cap loose or forgot about the effect of moisture in the air. 1,3-Diethylimidazolium bromide might start out as a free-flowing solid, but it will pick up water from the air almost as fast as an open bag of sugar.

This hygroscopic (water-loving) tendency means the chemical changes before your eyes, then gives you headaches by affecting your experiment's results. The problem isn’t just messiness. The extra water can make reactions unpredictable, degrade purity, or encourage breakdown over time. You might come in expecting the same reliable substance, only to find a sticky mess or mismatched weights in your bottle.

Common-Sense Storage Techniques

Good storage comes down to discipline and practical choices, not just fancy science. First step: keep 1,3-Diethylimidazolium bromide in a tight, screw-capped bottle or jar. Those clumsy snap lids you find on some old jars just don’t do the job. Glass containers with a good seal give better protection against air and stray moisture.

Many labs have started moving to amber bottles for sensitive chemistries. Direct sunlight causes trouble for a surprising range of substances, sometimes breaking bonds and other times just speeding up unwanted changes. While 1,3-Diethylimidazolium bromide handles regular light well, avoiding direct sun helps guarantee it stays as designed. Storage in a cool, shaded spot or a chemical storage cabinet avoids unnecessary risks.

Most storerooms run around 20 to 25 degrees Celsius. Consistency in temperature keeps chemical properties on track. Heating can drive off water at first, but repeated heating and cooling cycles force air in and out of the bottle, bringing more chance for contamination. In my early years, I saw how a cheap plastic cap led to a ruined batch when daily temperature swings made the seal flex and let ambient air inside.

Labeling and Tracking Keep Mistakes Away

People sometimes scribble quick notes in marker or slap a half-torn piece of tape on a bottle. Later on, nobody remembers if that bottle came from a new batch or an old one. Take five extra seconds to write the purchase or opening date and batch number. A printed label holds up better over time. When something looks off, or a reaction fails, you have a clear paper trail and don’t end up guessing about your supply’s quality.

For shared spaces, clear labeling stops mix-ups. A mislabel in the fridge once landed my group with unexpected – and dangerous – fumes. It’s easier to set a simple rule: every container gets legible, resistant labels, no excuses.

Disposal and Emergency Considerations

Storing chemicals also means planning for problems. Spills from poorly closed bottles or accidental knock-overs happen more than most like to admit. A spill kit nearby can save time and prevent small mistakes from becoming bigger cleanup jobs. In my own lab, keeping absorbent pads and gloves in reach has prevented many awkward phone calls to safety officers.

Building a Safer Lab Culture

People who store chemicals right rarely get dramatic applause, but their work keeps experiments safe and reliable. 1,3-Diethylimidazolium bromide doesn’t present huge day-to-day dangers if used with respect, but shortcuts stack up over time. Storing it in dry, airtight bottles, away from direct light, with accurate labels, and within arm’s reach of spill equipment turns good habits into better results. Science, at its root, grows from careful routines, not just bold ideas.

Understanding What 1,3-Diethylimidazolium Bromide Really Is

You don’t see 1,3-Diethylimidazolium Bromide on headlines or TikTok feeds, but in the labs, it pops up more than most folks realize. At room temperature, this compound stands as a solid, thanks to the bromide ion locking the structure together. Its white to pale powdery look tells you it’s not flashy, but chemists reach for it all the time. Why? It melts when needed, typically just above 120°C, and once you hold it molten, it proves itself as one of those ionic liquids that make difficult reactions easier.

The Structure Shapes Its Special Traits

With two ethyl groups stapled to an imidazole ring and teamed up with a bromide anion, this salt doesn’t dissolve in nonpolar solvents like hexane; water and polar organics work out much better. In a beaker, it’ll absorb water right out of the air — that classic hygroscopic behavior. That means storing it in a dry spot matters, or you end up with clumps or unwanted side reactions.

The stability shows up in acid and base resistance. It’ll stick around in a reaction without breaking down, so the focus can stay on your main goal, not on byproducts. That’s more than just a curiosity — stability keeps experiments reproducible, cuts down on wasted time, and supports solid results worth trusting.

Chemical Performance Where It Counts

This salt gets attention for its ionic nature. Ions zip through it much like they would in other molten salts, and that means it supports current, both literally and metaphorically, in electrochemistry. You see it in battery science and in green chemistry labs, especially for dissolving cellulose and as a reaction medium where traditional solvents fall short. There's respect for how these salts can carry charge with a much smaller carbon footprint than many petroleum-derived options.

I’ve seen researchers use it as a solvent for metal-catalyzed cross-couplings that water or alcohols shut down. It stabilizes certain reactive species, so you get higher yields for less effort. Its thermal stability means it can stand up to high-temperature syntheses without falling apart, a big plus for those tweaking reaction conditions to maximize efficiency.

Handling and Environmental Impact

Tossing around any bromide salt calls for respect. 1,3-Diethylimidazolium Bromide doesn’t smell or fume, but its ionic nature helps it move through the environment if spilled. Safe handling is the rule, and careful labeling prevents slip-ups, which goes for any specialty chemical. Compared with traditional organic solvents, many ionic liquids, this salt included, score better on volatility and flammability — less risk of fire or toxic fumes. But they're not perfect; disposal runs into regulatory questions, especially if contaminated with metals or reactants.

I’ve heard from colleagues that cycling these ionic liquids for re-use, purifying them between runs, helps cut costs and waste. For industrial users, that’s important, both from a green chemistry perspective and for the bottom line. Research keeps pushing toward safer, more easily recycled ionic liquids, and 1,3-Diethylimidazolium Bromide often serves as a model for new developments.

Where Challenges Meet Solutions

Developing new solvents to replace toxic and hazardous chemicals takes real-world testing and patience. Ionic liquids bring fresh options, and 1,3-Diethylimidazolium Bromide delivers a reliable mix of stability, low volatility, and useful solubility. Price, scale-up, and safe disposal all present hurdles, and every lab benefits from a mindset focused on sustainability and safety from the start. Reusing and recycling salts, minimizing exposure, and sticking to best practices turn risks into manageable factors.