1,3-Diethylimidazolium Hexafluorophosphate: Commentary on Modern Use and Development

Historical Development

My career in chemistry has seen a turning point during the last two decades, and 1,3-Diethylimidazolium hexafluorophosphate has played a big role in it. Back in the 1980s, only a handful of researchers cared about ionic liquids. Many saw them as an academic curiosity. Gradually, scientists in Europe broke new ground by highlighting their unusual ability to remain liquid at room temperature. The combination of an organic imidazolium cation with an inorganic anion like hexafluorophosphate led to salts that didn't crystallize as most salts do. Early work focused more on 1,3-dialkylimidazolium salts, and once chemists nailed down consistent synthesis and purification of these compounds, applications began to multiply. As the green chemistry movement gained steam in the late '90s, ionic liquids like 1,3-diethylimidazolium hexafluorophosphate shifted from chemical oddities to serious contenders for solvent replacement in synthetic reactions. Patents started popping up for their use in extractions, catalysis, and electrochemistry, driven by mounting concern over volatile organic solvents in industrial environments.

Product Overview

1,3-Diethylimidazolium hexafluorophosphate looks like a colorless to pale yellow liquid, and it packs a punch way beyond its appearance. It rarely smells, unlike the overpowering aroma that comes from traditional solvents. What draws researchers and industrial chemists to it stems from its low volatility, non-flammable nature, and thermal stability. If looking at its catalog numbers and trades names, you'll spot it under entries like [emim][PF6] or simply EMIM PF6, among others. Bottles tend to come with tightly sealed caps and warning labels about hygroscopicity, for good reason. Water can foul up its use, changing the physical profile and making some applications unpredictable.

Physical & Chemical Properties

A memory that jumps to mind is the first time I weighed out this compound—no static charge carried powder onto the scale or dusted my gloves, a common headache with crystal salts. Its melting point falls significantly below room temperature, down near minus 8 Celsius. Boiling details are trickier, since thermal decomposition happens before classic boiling, showing the need to respect handling guidelines. Its density sits around 1.28 g/cm3 at 25°C, noticeably thicker than water. I once used it as a solvent for palladium-catalyzed coupling reactions, and the solubility for organic reactants was immediately apparent. Not all ionic liquids mix well with water, and EMIM PF6 highlights that with notable hydrophobicity. This hydrophobicity, paired with decent electrochemical stability, explains why many labs keep it for battery prototyping and electrodeposition studies.

Technical Specifications & Labeling

Bottles from major suppliers usually state minimum assay values above 98% purity. Moisture content typically stays below 0.1%, sometimes even less, to avoid switching up the physical character mid-reaction. Labels carry more practical warnings than generic hazard icons: "Handle under dry Argon or Nitrogen" stands out, as routine air exposure could spike impurity levels. Whenever I've worked with industrial buyers, I've seen how trace analysis for elemental fluorine and phosphorus determines batch rejection or acceptance, connecting purity directly to outcome reliability. Particle filtration or distillation instructions sometimes accompany technical bulletins, not just for lab cleanup but to prevent catastrophic failures during upscaling.

Preparation Method

Lab synthesis of 1,3-diethylimidazolium hexafluorophosphate shakes up any chemist’s understanding of salt formation. Usually, you start with 1-methylimidazole, dialkylate it using ethyl halides, then treat the intermediate imidazolium halide with potassium hexafluorophosphate. Filtration gets rid of KCl or similar inorganics, and a water wash removes polar remnants. Drying becomes a contest against time; any slip-up adds water or degrades product quality. Commercial plants run similar reactions, just at absurdly larger scales, swapping batch flasks for continuous reactors that track temperature, dosing rates, and moisture at every point. If you’ve worked with glassware, watching the solution move from pale to an oily, nearly colorless phase gives a sense of professional accomplishment. Keeping product water-free until bottling is the hardest part, since atmospheric humidity threatens purity every step along the way.

Chemical Reactions & Modifications

As a solvent, EMIM PF6 takes on roles where traditional solvents fall short. I’ve run C–C and C–N coupling reactions using it, marveling at how selectivity and yield spike without the headaches of peroxides or explosive vapors. The ionic nature brings up new reaction possibilities; transition metal complexes coordinate in ways they rarely do in alcohols or ethers. Oxidative transformations benefit from its stabilizing effect on high-valent metal species. Working in electrochemistry, I’ve watched EMIM PF6 withstand voltages that would break down most organic mixtures. Unfortunately, chemical modification outside the cation or swapping the anion changes everything—replacing PF6− with BF4− or NTf2− dramatically changes solubility and sometimes thermal and electrochemical windows. The variety of reactivity pathways means only careful experiment can guide functional group tolerance when making new products on its backbone.

Synonyms & Product Names

There’s a confusing array of trade names for this substance, which causes headaches for supply chain specialists. EMIM-PF6, 1,3-Diethylimidazolium hexafluorophosphate, 1-Ethyl-3-ethylimidazolium PF6, and [emim][PF6] all refer to the same structure. Having worked with procurement, I know clerical errors in ordering can delay projects or send the wrong material to a sensitive process. Tracking certificates of analysis under varying CAS numbers (commonly 171058-17-6) keeps quality managers up at night if the paperwork doesn’t match the drum labels. This creates extra administrative work for chemists who prefer to focus on bench results.

Safety & Operational Standards

Safety culture drives every conversation about handling ionic liquids. EMIM PF6 offers some relief by not catching fire or releasing clouds of toxic fumes at room temperature, but long experience has shown health hazards still matter. Accidental spills need fast cleanup with absorbent pads and follow-up decontamination—back during a drybox purge, I witnessed a water spill leading to PF5 formation, a nasty compound if inhaled. Technical data sheets highlight potential for skin and eye irritation. I always recommend nitrile gloves, full goggles, and backup lab coat when working with volumes above a few grams. Waste disposal policies demand careful neutralization, collection, and off-site incineration due to the fluorinated anion. Maintenance training for exhaust fume hoods cuts exposure risk for long-term lab workers.

Application Area

Over the years, application areas keep expanding. I’ve used EMIM PF6 as a replacement for acetonitrile in chromatography, spotting better peak resolution along with less background noise. Colleagues in electroplating rely on its broad electrochemical window to protect expensive electrodes in prototype batteries. Others exploit its ability to dissolve cellulosic fibers for green chemistry projects in textiles. The solvent power opens doors in catalysis, extraction, and polymer processing, especially where environmental regulations squeeze out traditional, more volatile materials. I have yet to see a one-size-fits-all approach; every industrial sector extracts a different value from its unique property set, and trial runs usually reveal new wrinkles in process steps.

Research & Development

R&D investment in ionic liquids like EMIM PF6 benefits from cross-disciplinary exchange. Collaborative projects between university synthetic chemists, battery manufacturers, and environmental labs drive discoveries that keep the field moving. I’ve seen breakthroughs in CO2 capture and enzyme-catalyzed transformations, both areas where classic aqueous or organic solvents failed. Funding from green chemistry initiatives over the last decade has seeded dozens of pilot plants using ionic liquids to recycle plastics and upcycle biomass. Because each new use needs fundamental test data, R&D labs keep returning to old questions: How does the ionic environment affect catalyst turnover? Can novel ionic liquids cut production costs or raise safety margins? Open data sharing—unusual in proprietary industries—has kickstarted rapid learning curves, and though skepticism lingered early on, published successes in peer-reviewed journals helped steady broader confidence.

Toxicity Research

We can’t ignore toxicity just because ionic liquids seem safer than toluene or chloroform. Early reports sold the idea that EMIM PF6 would be harmless, but careful testing with zebrafish and other models revealed chronic toxicity at unexpected levels. Fluorinated anions, in particular, trouble environmental toxicologists, who worry about groundwater leaching and bioaccumulation. A decade ago, a long-term test on cell cultures flagged DNA strand breaks from metabolic byproducts. That memory stuck with me and convinced my lab to invest in extensive personal protective equipment. Wastewater treatment protocols from the chemical industry still don’t catch every trace, so ongoing research tracks degradation under real-world conditions. Safety guidelines now mandate secondary containment, fume hoods, and strict transport documentation, reflecting new awareness from toxicity studies.

Future Prospects

Looking ahead, EMIM PF6 offers tantalizing prospects for further innovation. Pressure from regulators and consumer demand for greener manufacturing will likely move more companies into the ionic liquid space. As battery and supercapacitor research matures, the value of safe, stable, non-volatile electrolytes will only grow. Researchers are developing new synthesis techniques to minimize toxic byproducts and enable end-of-life recycling for ionic liquids. Years in the trenches convinced me continuous process improvements and green engineering make or break commercial rollout. Scaling up from bench to pilot plant poses persistent challenges, especially controlling impurity loads and maintaining worker safety. Down the road, EMIM PF6 could serve as a template for building totally new families of functional ionic fluids, each tuned for a niche need—whether solvent, catalyst support, or electrolyte—anchored on lessons learned through decades of hard-won laboratory work.

Opening Up Chemical Possibilities

Back in my student lab days, traditional solvents created a lot of mess and environmental headaches. Many chemicals left behind are tough to handle and far from eco-friendly. People in research started to look for better options, and that's where compounds such as 1,3-Diethylimidazolium hexafluorophosphate grabbed attention. This chemical serves a purpose in chemistry labs and industry out in the real world. Unlike old-school solvents, it falls into the ionic liquids category—salts that stay liquid at room temperatures.

A Shift Beyond Water and Regular Solvents

Water and organic solvents help reactions along, but both show clear limits. Water struggles with dissolving oils or other uncharged compounds. Organic solvents bring toxicity, flammability, and disposal problems. Ionic liquids like 1,3-Diethylimidazolium hexafluorophosphate break this pattern. Their strong ion pairs allow them to dissolve a wide range of molecules, even those that scared off water or other solvents. This versatility led to their rise in chemical transformations, especially those with strict purity or environmental standards.

Electrochemistry and Next-Gen Batteries

Lab talk aside, this chemical found a home in cutting-edge battery research. Rechargeable lithium and sodium batteries use ionic liquids for stable, non-volatile electrolytes. Researchers trust 1,3-Diethylimidazolium hexafluorophosphate because it doesn’t catch fire like traditional battery liquids. That firesafe quality became vital after high-profile phone and car battery accidents. Plus, it keeps working in wide temperature ranges, giving more flexibility to engineers pushing battery performance. A study in Journal of Power Sources saw improved ionic conductivity and lifespan for lithium batteries that replaced legacy solvents with ionic liquids. Batteries can last longer, charge faster, and sit in tough environments without degrading.

The Role in Green Chemistry

Green chemistry no longer stays away from tough industrial reactions. This compound got tested for recycling metals, designing pharmaceuticals, and making advanced polymers. Since it doesn’t evaporate much, workers face fewer inhalation hazards, which makes for safer labs and factories. In my short stint interning at a process chemistry group, swapping out classic volatile solvents for ionic liquids like 1,3-Diethylimidazolium hexafluorophosphate cut down on air-quality complaints from the staff. By sidestepping volatile organic compounds, factories avoid costly emissions penalties and public backlash.

Room for Progress and Safer Chemistry

Some pushback crops up over how to recycle or dispose of ionic liquids, but the tide is turning. Teams focus on recovery and reuse techniques, so less chemical winds up in the landfill. University consortia and private firms continue to invest in research, recognizing that a shift away from hazardous solvents pays returns in worker safety and public image. Europe’s REACH regulations and the EPA’s awards show regulatory backing for safer alternatives, nudging more labs to give them a shot.

Looking Ahead

Chemicals like 1,3-Diethylimidazolium hexafluorophosphate open new doors for safer, more effective chemistry. The road leads through energy storage, greener synthesis, and streamlined manufacturing. With society putting the squeeze on waste and risk, these ionic liquids move from niche curiosity to mainstream solution. Focusing on continued safety testing and showing responsible end-of-life management will cement their place in tomorrow’s labs and production lines.

Getting a Grip on the Risks

Handling chemicals like 1,3-Diethylimidazolium hexafluorophosphate (DEIMPF6) brings up the same practical concerns I’ve seen crop up in many labs. I’ve worked alongside chemists who always double-check the label, but with ionic liquids like DEIMPF6, most people barely hear about them outside niche research. Still, this stuff shouldn’t be treated lightly. It’s a salt with a peculiar mix of organic groups and fluorinated phosphorus, which means health and environmental concerns can sneak up on the casual user.

Personal Protection Matters

I once watched a colleague splash a similar liquid on bare skin—he thought “ionic liquid” sounded harmless. He spent the day with irritated skin and learned his lesson. DEIMPF6 can irritate skin and eyes, so gloves (nitrile, not latex, for chemical resistance) and eye protection come first. Lab coats with long sleeves shield arms, and good lab shoes help keep feet safe if anything spills. For bigger jobs, splash goggles and a face shield give extra peace of mind. It’s not just a good idea; regulations demand it. The safety data sheet (SDS) from any supplier spells that out clearly.

Proper Air and Clean-up

I’ll never forget one stuffy storage room full of mixed chemicals—a recipe for headaches. DEIMPF6 shouldn’t fill your workspace with fumes, but tiny amounts can vaporize depending on conditions. I always stand by proper ventilation: chemical fume hoods or at least a well-ventilated bench. Clear the air, shut the sash. Spills require absorbent pads, not paper towels, and the waste belongs in a sealed hazardous waste container. Blot up, then wipe down. Toss everything used in the clean-up right into the hazardous bin—never the general trash. Even minor chemical residues can turn up in unexpected places, so I always double-check the spill site before calling a clean-up finished.

Safe Storage Avoids Big Problems

During my university years, I saw incompatible chemicals store side by side—trouble brewing quietly. DEIMPF6 reacts with water and acids, sometimes releasing irritating or toxic fumes. Dry, sealed containers make a difference; keep it in a cool place away from sunlight, acids, or bases. Label everything clearly. By keeping incompatible chemicals apart, you cut down the risk of accidental release, which beats scrambling during an emergency any day.

Good Habits for Handling

I remember an early job where a senior tech drilled into us: never eat, drink, or touch your face when handling chemicals. Wash hands after every use, before leaving the lab. Keep workspaces tidy; clutter hides trouble. Containers with small openings help avoid splash hazards, and slow, deliberate movements keep stuff in the bottle. Mistakes usually come from shortcuts.

Training and Emergency Prep

I’ve been through more safety drills than I can count, and those moments count when something actually goes wrong. Everyone should know the nearest eyewash and safety shower. Have spill kits on hand—one for acids, one for organics. Safety never feels convenient, but it beats dealing with injury or exposure. The best teams treat training as part of the job, not just a box to tick.

Thinking Forward

DEIMPF6 shows up in electrochemical and green chemistry research, areas where more folks join the field every year. Safety comes down to culture. Experience, clear labels, personal protective equipment, and frequent refreshers help new faces avoid the same mistakes many of us made early on. It’s worth getting right every time.

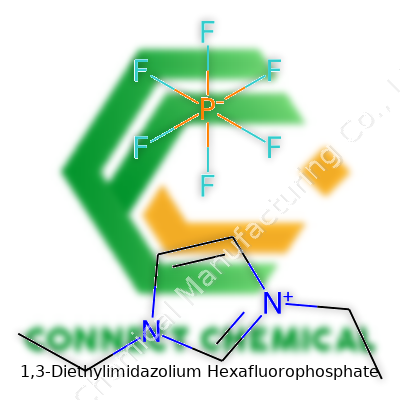

Getting to Know the Compound

1,3-Diethylimidazolium hexafluorophosphate isn’t something you find in a kitchen cabinet. Its formula, C7H15F6N2P, paints a picture of an ionic liquid with two prominent players. The diethylimidazolium cation and the hexafluorophosphate anion come together to make a salt that stays liquid at room temperature. People in labs usually just call it [Et2Im][PF6]. The structure features an imidazole ring, but instead of the usual simple ring, it’s padded with two ethyl groups at the 1 and 3 positions, giving the ring more bulk and changing the way it interacts with other chemicals.

This imidazolium salt joins a larger family of ionic liquids. In my own years working with different advanced solvents, this one stands out for its blend of stability and practical features. Sitting in a bottle, you’ll see a clear, viscous liquid, setting it apart from the solid white salts many chemists grew up using. The hexafluorophosphate part isn’t something to gloss over, either. Six fluorine atoms wrap around a phosphorus, creating an anion that resists breaking apart in water or organic solvents. That makes the overall salt less likely to take on water from the air and spoil an experiment, which anyone who’s lost a batch of a sensitive product can appreciate.

Why 1,3-Diethylimidazolium Hexafluorophosphate Matters

This compound changes the way chemical processes run. Think battery research, catalysis, even green chemistry. Its low volatility means you won’t inhale anything hazardous by accident during normal use. That gives industry and labs more options for working safely. In a world focused on cutting industrial emissions and limiting exposure to toxic chemicals, alternatives like ionic liquids become a valuable asset. Right now, researchers use [Et2Im][PF6] as a solvent for reactions that demand high stability in both air and water, and as an electrolyte in systems searching for better energy storage. Flammable, toxic organic solvents have burned out chemists and engineers for decades. This class of compounds is rewriting that story.

Some chemists I’ve worked with say the flexibility in solubility and thermal stability saves time and reduces waste. The structure — a robust imidazolium cation and a non-coordinating, stable anion — helps keep reactions on course, especially in fine chemical synthesis, where an unexpected reaction with a solvent can ruin days of work. The unique combination of imidazolium’s electron-rich ring and the bulky, non-coordinating PF6- balances reactivity and inertness, a rare feat in lab chemistry.

Looking At the Challenges

No story in chemistry runs smooth. Hexafluorophosphate anion has come under fire for environmental persistence and the toxicity of its breakdown products. Accidental release can send fluorine-containing compounds into the ecosystem. Handling any compound requires respect for safety guidelines—years in the lab have shown me shortcuts never pay off when hazardous decomposition can lurk beneath the surface. Regular disposal procedures—often overlooked with more “exotic” compounds—protect the people and the planet around a lab or plant. Companies and researchers need to keep an eye on new alternatives, some of which swap out fluorinated components for greener ones.

Shortcomings in sustainability won’t erase the practical successes this compound offers, but they do keep the field moving. Transparency in production and waste handling, strong personal protective equipment practices, and honest conversations about alternatives shape the real impact of innovative chemicals like 1,3-diethylimidazolium hexafluorophosphate. Progress keeps rising on the back of tough questions and responsible lab work.

Why Storage Choices Matter for Chemical Longevity and Safety

Anyone working in a chemistry lab eventually meets chemicals as finicky as 1,3-Diethylimidazolium Hexafluorophosphate. This ionic liquid takes part in high-tech applications — catalysis, electrochemistry, solvent work. Even seasoned researchers who know their way around a glovebox learn to approach these materials with a healthy respect. No one wants to manage an accident or lose a costly bottle to careless planning.

Long-term reliability depends on thinking about where and how you store this stuff. Hexafluorophosphate salts, especially with an organic cation like diethylimidazolium, don’t fall apart at room temp, but they definitely demand some boundaries. If you skip the basics, you invite decomposition and contamination. I’ve seen first-years discover a cloudy mess in what should have been a clear bottle — all because a lid wasn’t tight or a bottle met humidity it couldn’t handle.

Problems Start with Moisture and Air

The big enemy here: water. 1,3-Diethylimidazolium Hexafluorophosphate reacts with moisture, unleashing toxic hydrogen fluoride. I once watched a careless chemist shrug off drying and then scramble to clean up the aftermath of a leaky bottle. Fluoride corrosion eats into metal lab equipment and leaves behind a stinging reminder: pay attention to the seal. A screw-top bottle with a PTFE lining holds up best, forming a barrier that slows down any sneaky water vapor, with less worry about chemical etching.

Good air-tight containers take you most of the way, but the location on the shelf matters just as much. I’ve had to hunt down a stash moved next to a window. Sunlight cooks chemicals, and heat speeds up all sorts of mischief. By storing in a cool, shaded cupboard away from direct light, you keep those slow reactions dormant. Even in a shared lab, a single mishap near a heating source or under a frosty AC vent can cut shelf life in half.

Organized Storage Beats Problems Down the Road

Labels fade over time, especially on bottles jostled in a high-traffic space. Whenever I’ve worked with new researchers, the first advice is: date every bottle and write out the name, not just the abbreviation. Disorganization breeds wasted time, accidental use of degraded product, or even worse — confusion during spills.

Segregating incompatible chemicals matters, too. 1,3-Diethylimidazolium Hexafluorophosphate gets along with a lot, but acids and strong oxidizers cross a line. I’ve heard horror stories about fumes in shared chemical fridges, traced back to poor segregation. Store this ionic liquid with other inert organic salts or on a shelf reserved for moisture-sensitive reagents.

Common-Sense Measures Backed by Research

Peer-reviewed articles paint a clear picture that well-stored ionic liquids retain their properties for much longer. Dry atmosphere, cool storage, and minimal light exposure add up to steady performance. If available, an inert atmosphere like argon or nitrogen does even better, but most routine labs do fine limiting exposure by working fast and closing bottles immediately.

Institutional safety guidelines match this lived experience. Wearing gloves, protecting skin from accidental contact, and keeping spill cleanup materials nearby shows respect for the hazards. The price of sloppiness shows up in lost material, wasted experiments, or emergency department visits. Rushing and ignoring protocols always costs more in the long run.

Building these habits into lab routines saves not just money and data, but health, too. Proper storage of 1,3-Diethylimidazolium Hexafluorophosphate is less about fancy technology and more about sticking to fundamentals: keep it dry, sealed, cool, and organized. Both science and experience point in the same direction—pay attention and the rest falls into place.

A Look at Physical Properties

1,3-Diethylimidazolium hexafluorophosphate doesn’t come from the shelves with a familiar face. Its most common form—a lot like many ionic liquids—shows up as a colorless or pale yellow liquid at room temperature. No one would call this a gentle aroma; a whiff brings a bite, though the vapor stays quite low. Handling this stuff, you notice right away its dense, viscous character. Unlike everyday solvents, it does not evaporate into thin air. Instead, it clings, and its heaviness can surprise.

Take it to a cold lab, and freezing won’t happen easily. The melting point sits well below water’s, so it flows even when you’d expect ice crystals in other bottles. Resistance to electrical flow? It’s minimal. That low resistivity draws plenty of attention for electrochemical work. Water struggles to dissolve it; hydrophobicity comes out as a core trait. Pop it into water and it barely blends, an oil-and-water kind of behavior. This avoids complications for moisture-sensitive applications and lets scientists push boundaries where classic salts trip up.

The Chemical Foundation

This isn’t a compound that just sits quietly; it tells a story in its structure. Imidazolium rings form the backbone, decorated with ethyl branches. The hexafluorophosphate piece isn’t just a counter-ion; it brings toughness against heat and chemical insult. In a test tube, you’ll see strong ionic bonding and remarkable thermal stability. Temperatures climbing near 200°C won’t ruin it. Traditional organic solvents might break down faster, so this endurance gives real value in demanding settings.

Volatility rarely enters the conversation. Little vapor escapes, even under aggressive conditions. This trait not only limits exposure hazards but lessens accidental releases that can pose fire or health risks in a messy workshop. The molecule holds up against air and light under normal lab use, though you shouldn’t throw caution away—hexafluorophosphate parts mean hydrolysis can generate acidic byproducts if water does sneak in. Awareness matters, especially when lab routines get rushed.

Impact on Laboratory and Industry Work

Every property, good or tricky, drives why people care about 1,3-diethylimidazolium hexafluorophosphate. Electrochemical engineers benefit from its stable conductivity, finding it helps batteries and supercapacitors run cooler and longer. Chemists rely on its solvent action for reactions that tear apart lesser salts. Less volatility also means fewer headaches with environmental controls. Cleanup takes less air filtration, and cross-contamination events drop off compared to solvents that readily vaporize.

Risks deserve a close look. The hexafluorophosphate ion’s ability to release PF6– in hydrolysis situations—especially with moisture—brings the possibility of forming hydrofluoric acid. Practitioners learn quickly to store and dispose of containers with respect, locking out water’s access to the system and using personal protective equipment. The chemical’s interaction with organic and inorganic substances can create new, persistent fluorinated byproducts, now a source of global concern for environmental safety.

Finding Better Solutions and Responsible Use

Ionic liquids like this one answer tough technical questions, but only through honest risk assessment and practical measures. Better engineering controls, robust personal gear, and rigorous environmental monitoring all build trust in safe usage. Researchers continue to design alternatives that keep performance high without sacrificing safety or longevity. In the meantime, understanding the tricky balance of physical and chemical attributes in compounds like 1,3-diethylimidazolium hexafluorophosphate helps labs, factories, and communities stay a step ahead.