1,3-Dimethylimidazolium Acetate: A Deep Dive Into the Science and Its Role In Today’s Industry

Historical Development

Interest in ionic liquids has grown rapidly over the past two decades. 1,3-Dimethylimidazolium acetate didn’t start in the spotlight, but rose as chemists searched for greener solvents. Its roots tie back to the push for alternatives to volatile organic compounds. In the late twentieth century, researchers needed something that could dissolve cellulose efficiently and stay non-volatile. Academic labs and chemical industries alike began to take note of this acetate derivative. People who spent years working with traditional harsh solvents saw 1,3-dimethylimidazolium acetate as an eye-opener. Published work through the early 2000s put its properties on the map, and soon, it left the niche and entered production lines across several fields, marking a turning point for ionic liquids.

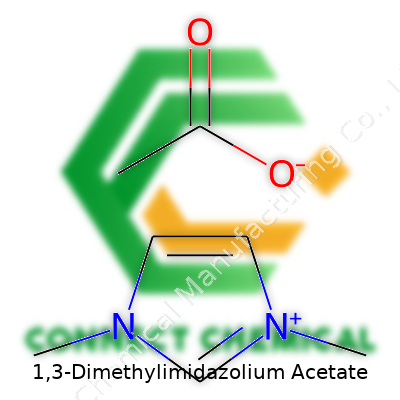

Product Overview

1,3-Dimethylimidazolium acetate comes off as a clear to pale yellow liquid at room temperature. Its formula, C7H12N2O2, can be written as [C1C1im][OAc]. You’ll see it listed in catalogs as both a research reagent and an industrial solvent. It often replaces harsher or more volatile organic systems in cellulose dissolution, pharmaceuticals, and biomass processing. The balance between its cation and acetate anion makes it less aggressive than older nitrile- or chloride-based ionic liquids. Some use it to extract certain bioactive compounds or refine polymers, appreciating its catching blend of stability and reactivity.

Physical and Chemical Properties

The liquid sits with a melting point below room temperature, around minus 10 °C, and it boils far above, without decomposing under normal operating conditions. 1,3-Dimethylimidazolium acetate has a density between 1.1 and 1.2 g/cm3, and dissolves in water with ease. It carries a moderate viscosity, which means working with it in labs feels somewhere between syrup and a light oil. Conductivity stays within the range seen for other imidazolium salts. Its ionic nature and strong hydrogen-bonding capacity help it dissolve tough substances, such as cellulose. Heat it, and decomposition only sets in above roughly 200°C, making it robust enough for demanding chemical processes. Some slight odor hints at its acetate part, but not enough to cause discomfort in a fume hood.

Technical Specifications & Labeling

Warehouses and labs stock this compound labeled by IUPAC name, CAS number 64736-09-0, and often by grade—ranging from technical to high purity for research. Standard bottles display handling precautions like “moisture sensitive” and recommendations for air-tight storage. Most suppliers post pH information, typically sitting on the basic side. Trace metal content, water content below 0.2%, and purity above 97% gets checked batch by batch. Large-volume customers look for detailed safety data, shelf-life, and packaging tailored for stability—because nobody needs a surprise polymerization or contamination. Labels also carry hazard statements, since acetate ionic liquids can present a risk if mishandled or overheated.

Preparation Method

Synthesizing 1,3-dimethylimidazolium acetate starts with the alkylation of imidazole. React it with methylating agents, usually methyl iodide, to form 1,3-dimethylimidazolium iodide. This intermediate reacts with sodium acetate in an anion-exchange process to form the acetate variant. Throughout, water handling and exclusion from air keeps the process clean. Producers often recover solvents and recycle byproducts, which helps scale the procedure up from flask to drum without pollution ramping up. Purification follows with vacuum drying or column filtration, so the final product avoids colored tints or unwanted metals. Someone with hands-on synthesis experience knows that trace water or leftover ions can skew later performance—a reason why tight control during every step matters.

Chemical Reactions & Modifications

1,3-Dimethylimidazolium acetate doesn’t get used just as a static solvent. Its ionic nature means it exchanges anions easily, letting chemists tweak properties for different tasks. The acetate version can go toward esterification or transesterification reactions, supporting synthesis in pharmaceuticals and plastics. In research, it enables homogeneous catalysis and green oxidation reactions. People modify the side chains to influence solubility or thermal stability, pushing the performance envelope for new applications. The structure also opens a pathway for creating imidazolium-based polymers, where the acetate plays a critical role as a counter-ion or a reactivity director. These chemical opportunities drive innovation in both academia and industrial labs busy refining bio-based processes.

Synonyms & Product Names

Working across labs or checking chemical databases means finding 1,3-dimethylimidazolium acetate under several names: [C1C1im][OAc], 1,3-dimethyl-1H-imidazol-3-ium acetate, DMI-acetate, or sometimes plain “BMIM acetate” by mistake (though that label points to a different methylation pattern). The different branding may seem confusing, but most catalogs list the CAS number directly alongside the name as a fail-safe. Buyers from industry contexts often sort compounds by these numbers and their synonym lists, keeping things clear when sourcing material from different global regions.

Safety & Operational Standards

Safe handling has never been an afterthought with ionic liquids. 1,3-Dimethylimidazolium acetate, while less flammable or volatile than classic solvents, still demands gloves, eye protection, and ventilation. Several industries publish guidelines for its safe use, focusing on exposure limits and first response procedures. Spills clean up with absorbents, but thorough washing follows, as the material can irritate skin and mucous membranes. Storage in amber bottles, away from acidic or oxidative materials, keeps degradation at bay. People who work daily with this compound keep safety data sheets on hand, knowing that disposal routes must line up with local environmental rules. Training staff on emergency procedures creates a line of defense, so operational safety evolves beyond standard checklists.

Application Area

The reach of 1,3-dimethylimidazolium acetate stretches from cellulose dissolution in green chemistry to catalyst support in pharmaceutical manufacture. Textile labs take advantage of its power to dissolve natural fibers, opening a route to novel materials and bio-composites without toxic byproducts. Research groups value it for extracting lignin from biomass, which lets them turn waste streams into fuels or specialty chemicals. Drug manufacturers use its tailored solvation properties to run sensitive transformations that traditional solvents fail to deliver. Lab techs handling bioactive compound isolation rely on its tuneable polarity. Newer uses pop up in electrochemistry, where stable ionic liquids improve battery electrolytes or solar cell efficiency.

Research & Development

Research into this acetate variant never stands still. Labs across the globe push past the original applications, exploring tweaks to the imidazolium ring, swapping out the acetate for better thermal stability, or testing new purification processes. A lot of innovation springs from seeing how slight property changes affect extraction yields or end-product purity. Teaming up with industrial partners, academic groups work to expand the scope, from producing medical-grade films to recyclable solvents. Some R&D funding comes from pushes for greener chemistry, and the results show in patents for process improvements, safer formulations, and lower-cost synthesis methods. By joining forces, science teams and companies keep this chemical from stagnating, pushing boundaries in both old and emerging industries.

Toxicity Research

Toxicity studies for 1,3-dimethylimidazolium acetate show a mixed picture. Compared to heritage organic solvents, toxicity drops, particularly for inhalation and chronic exposure. Acute testing in animals points to moderate skin and eye irritation, but genotoxic studies suggest a low risk at operational concentrations. Environmental persistence still raises some questions, especially regarding aquatic toxicity and breakdown products. Labs testing for cytotoxicity focus on both the imidazolium ring and the acetate counter-anion, as each can produce different biological effects. At the moment, regulatory bodies continue watching for long-term impacts, and a safety-first approach guides disposal, recycling, and effluent management. Staying ahead of new findings allows responsible use, lowering accident rates and environmental harm.

Future Prospects

Expect 1,3-dimethylimidazolium acetate to see expanded roles as a top-tier solvent in green process engineering and advanced materials research. As pressure builds on industry to drop fossil-derived and volatile chemicals, this ionic liquid lines up as a better choice. Advances in production will cut costs and bump availability, making it a more approachable option outside specialized labs. Startups work on recycling protocols, while emerging tech firms eye its use in high-performance batteries, wearable electronics, and pharmaceutical synthesis. Ongoing research holds promise for finding even safer and more biodegradable alternatives, but for now, this acetate remains a mainstay for dissolving cellulose and powering sustainable chemistry. Engineers combining practical know-how with up-to-date science will keep finding creative ways to push the boundaries of what this ionic liquid can deliver.

Unlocking Cellulose: The Real Value of This Chemical

1,3-Dimethylimidazolium acetate walks into the spotlight any time someone talks about dissolving cellulose from plants. Labs have struggled with breaking down tough plant fibers for years. Cellulose sticks together in wood and cotton because of hydrogen bonds. Traditional solvents barely make a dent in it. That’s where this ionic liquid steps in, offering researchers a more direct approach. Over the years, scientists have leaned on it to dissolve wood pulp, old newspaper, and cornstalks. So, if you're in the field of biofuels and want renewable energy or better paper recycling, you’re probably familiar with its name.

Moving Beyond Lab Curiosity

It’s not just a flashy trick for research journals. Factories exploring new ways to produce bioethanol or advance textiles have started paying close attention. I remember reading about a project in Sweden using 1,3-dimethylimidazolium acetate to break down used cotton and spin it into new threads. In the lab, pure chemistry turns into something you can wear or put in your gas tank. The innovation isn’t just about speed — it’s about making the process less wasteful and easier on the planet compared to heavy acids or stinky, hazardous solvents.

Addressing Safety and Sustainability

Every time a new chemical gets popular, safety questions follow. 1,3-Dimethylimidazolium acetate doesn't release toxic fumes under normal conditions, but it has to be handled with respect. Spills require fast cleanup; skin contact calls for a wash. There’s not a massive trail of data about its long-term health effects, so labs enforce gloves, goggles, and fume hoods. Sustainable chemistry fans have pointed out that ionic liquids like this one don’t evaporate like regular solvents, so they cut back on air pollution. Recovery and reuse of the solvent matters, so process engineers have designed closed systems to capture and clean it. It’s a work in progress.

Real-World Challenges

Scaling up leaves no room for shortcuts. This ionic liquid can cost hundreds of dollars per kilogram. Big teams have chased after cheaper ways to make it or swap it for close relatives with similar magic. If the process requires thousands of liters, researchers do their best to recover and clean the solvent after every cycle. Otherwise, costs jump, and environmental promises fade. It’s a balancing act between pushing technology forward and not blowing the budget.

Possible Next Steps

Everybody loves an easy fix, but there are no shortcuts here. Green chemistry experts continue sharing ways to recycle and reuse this ionic liquid without losing performance. Once its production becomes less expensive and easier to scale, watch for more companies to jump on board. Sharing data on human and environmental safety can also ease worries on the shop floor, and that’s how this solvent could become a staple beyond the research lab. The real power comes from turning waste into something useful, and this is one chemical offering a genuine shot at it.

A Look at What Makes It Tick

Spend enough time in a research lab and you start to develop an appreciation for the quirks of different chemicals. 1,3-Dimethylimidazolium acetate—usually just called [DMIM][OAc]—is one of those ionic liquids that shows up often in green chemistry circles. It flows at room temperature, a clear sign it’s a liquid, not a salt that crunches under your spatula. The first thing you notice: it has a slight odor, almost reminiscent of vinegar, thanks to its acetate group.

Handling and Appearance

DMIM acetate looks like water, but its texture tells a different story. Try swirling it in a beaker and you’ll see it clings to the sides. Its viscosity stands out, with the liquid moving slower than water or acetone. Getting it to evaporate takes patience; leave a dish out and you’ll probably see most of it still sitting there after hours. It won’t ignite or catch fire in your hand because it’s practically nonflammable. That earns it points in safer lab operations, and it makes a difference for anyone worried about lab fires.

Dissolving Power and Stability

Part of the excitement comes from how DMIM acetate interacts with other chemicals. Traditional solvents like hexane keep to their own types of friends—nonpolars mixing with nonpolars. This ionic liquid breaks those rules. Drop in cellulose, the stubborn stuff in wood pulp, and watch how quickly it dissolves compared to what you’d see in good old ethanol. That’s not just a chemical curiosity; it has real-world consequences for things like environmentally friendly textile production or biomass recycling, where breaking down plants matters.

From a stability perspective, DMIM acetate won’t break down fast at room temperature. Acidic and basic conditions can shift that. I’ve seen samples turn yellowish after some time exposed to open air, especially in humid spaces. That color change suggests some hydrolysis happens, an issue if you plan on storing it for a year or more.

Safety and Environmental Feelings

A common question comes up in every safety meeting: “Is it dangerous to use?” This chemical doesn’t carry the acrid burn on your skin that classic acids or bases do. Still, wearing gloves is smart. Inhalation, eye exposure—those are never a good idea, so ventilation and goggles stay part of the equation.

On the environmental side, DMIM acetate holds promise. Its lack of volatility means less breathing in fumes, and its use in greener processing methods is well-documented. Swedish researchers have published studies showing it can break down lignin from wood without resorting to harsh chemicals. Finding ways to recycle it after use cuts down on waste.

Where the Big Questions Remain

Nothing’s perfect. Disposal presents a challenge. You can’t pour it down the drain. Some labs reclaim and reuse it, but this asks for special equipment to remove impurities.

If research can deliver easier and cheaper recovery or improved ways to keep DMIM acetate pure between uses, that could push it even further as a green chemistry tool. The more we dig into how these ionic liquids behave—how stable they are, which molecules they can dissolve, their quirks under different temperatures—the more we open up new ways to make chemistry more sustainable and less hazardous for those of us working at the bench.

A Common Chemical Comes into Focus

1,3-Dimethylimidazolium acetate pops up often in scientific research. It’s part of a family called ionic liquids. These chemicals don’t look or act like most household products: they stay liquid even at room temperature and help break down tough substances such as cellulose from plants. Scientists lean on them for cleaner and more efficient chemical processes. They’ve been held up as greener alternatives to strong acids or solvents—at least on paper.

Toxicity: Beyond the Hype

I’ve spent years looking at chemicals’ fine print, not just what gets advertised in abstracts. So it’s natural to wonder: does 1,3-dimethylimidazolium acetate live up to its reputation for safety, or does a hidden risk lurk somewhere? The answer gets complicated fast. The chemical industry often latches onto words like “green” and “benign,” but proper toxicology asks for real numbers, not hype. If a solvent can break down wood, it probably needs respect.

Several peer-reviewed studies examined toxicity in aquatic organisms. For instance, research found that imidazolium-based ionic liquids, including variants similar to 1,3-dimethylimidazolium acetate, can cause harm to water fleas (Daphnia magna) and zebrafish embryos at concentrations that might occur during industrial spills. They interfere with cell membranes and enzyme systems, sometimes leading to cell death. While data on this specific compound isn’t as complete as for some industrial solvents, the pattern with its close relatives sets off some alarms.

Skin, Eyes, and Inhalation

Working with chemicals like this in the lab means reading safety data sheets closely. In practice, gloves and goggles aren’t optional. Direct skin contact may cause irritation; eye exposure brings a risk of redness or worse. Vapor pressure is low, so you won’t usually breathe in much by accident, but splashes or spills just aren’t worth the gamble. A single mishap can mean hours in the safety office—nobody loves giving an incident report.

Kids, Pets, and Long-Term Exposure

No solid evidence points to this ionic liquid building up in human tissues over time, but that doesn’t mean we’re off the hook. Chronic exposure studies still show gaps, especially outside rats or aquatic critters. Nature rarely hands out free passes. Just because a chemical breaks down in water or on exposure to air doesn’t mean residues can’t do damage before vanishing. Pets, children, and workers could face health risks if safety habits slip.

Responsible Action: What Needs to Happen

Companies and researchers should stay humble about the “green” label and support it with ongoing tests. Regulators need to keep an eye on what gets released into water or air. There’s no shortcut here—risk has to be measured, not assumed away. Training lab workers, enforcing containment, and investing in wastewater treatment go further than PR campaigns promising safety. Consumers and scientists alike have a role: demand transparency, read up before buying the hype, and support tougher reviews of both new and old solvents.

Real green chemistry honors both innovation and caution. Living with chemicals such as 1,3-dimethylimidazolium acetate calls for vigilance, not just optimism.

Why It Matters to Pay Attention

I’ve found that chemistry doesn’t always leave room for do-overs. From my time spent in research labs and talking with process engineers, one lesson stands out: the way we store and handle chemicals shapes both safety and reliability in the workplace. 1,3-Dimethylimidazolium acetate won’t announce its dangers with a strong odor or fire hazard, but trust me, mishandling it can throw off your whole operation. Think ruined experiments, equipment that won’t run quite right, even regulatory headaches if you’re not careful.

Understanding the Risks and Properties

1,3-Dimethylimidazolium acetate belongs to the ionic liquid family. This class looks harmless—clear, often barely a wisp of vapor, almost oily. Many turn to it for greener chemistry, especially in cellulose processing or as solvents in research. Less volatility compared to other chemicals doesn’t mean no risks. Moisture sneaks in, spoiling the product over time. Prolonged skin contact can trigger irritation. Fumes, though mild, could bother the lungs if you work in tight spots. That reality hit home during one project in an old lab with stale air—stuffiness and headaches, even when the air looked clear.

Essential Storage Steps

Pure product makes a difference, so leave nothing to chance. Store this ionic liquid in tightly sealed glass bottles or chemical-resistant high-density polyethylene containers. Big jugs from the hardware store don’t cut it—quality control dips fast if the wrong plastic interacts with the contents. Moisture is the chief enemy. Humidity seeps in, sometimes unseen. Any water can mess with both reactivity and measurement accuracy. Keep storage containers dry and shut, using desiccators for small quantities if the air stays damp.

I’ve had good experiences keeping stock at room temperature—nothing extreme needed. Skip bright window ledges and don’t tuck bottles near heat sources like radiators or hot plates. Sunlight and heat impact long-term stability, and even slight tweaks in sample quality can mean the difference between a successful reaction or wasted materials.

Good Handling Practices on the Ground

One slip with a solvent or acid might show up as an instant burn. With 1,3-Dimethylimidazolium acetate, the hazard feels subtle, but the results pile up: dermatitis, poor quality mixes, wasted time re-making solutions. I’ve always insisted on gloves—nitrile does the trick. Lab coats, long sleeves, and safety goggles belong in the basics; even cautious workers sometimes wipe their faces by mistake. Wash up thoroughly after use, even for short jobs.

Pouring and transferring should always take place in a fume hood or at a bench with strong airflow. Ventilation means fewer unpleasant surprises, especially if there’s a spill. For larger amounts, I recommend splash goggles and chemical-resistant aprons, no excuses. Clean up spills with absorbent material, placing waste in clearly labeled, chemical-resistant bags or bins.

Building Team Awareness and Accountability

I’ve seen jobs go wrong when people treat routine chemicals as harmless. A five-minute training review at the start of each semester or project run saves pain later on. Label every container the moment you get it, including the concentration and date received. Rotate stock regularly. Expired or discolored ionic liquid belongs in the hazardous waste line, never back on the shelf.

By respecting the quirks of 1,3-Dimethylimidazolium acetate, chemistry moves forward safely, research stays reproducible, and you avoid unnecessary risk. This isn’t about being paranoid—just treating lab life with the respect it demands.

Working With an Unconventional Solvent

Walking into a modern lab or production plant, I still get surprised at just how much work revolves around finding the right solvent. Chemists and engineers keep searching for liquids that handle tough jobs, especially as the pressure to cut down on harsh chemicals keeps building. 1,3-Dimethylimidazolium acetate, a type of ionic liquid, keeps showing up in these conversations. The funny thing about this material—unlike old-school solvents like acetone or methanol, it barely gives off vapor and usually won’t catch fire. That already makes life easier on anyone worried about air quality or hazardous waste.

Unpacking Big Impact: The Pulp and Paper Scene

Take the pulp and paper field, for instance. The “delignification” step—stripping wood of its stubborn glue and turning it into something pulpy—usually chews through strong acids or bases. Ionic liquids like 1,3-dimethylimidazolium acetate offer a gentler way. They dissolve lignocellulosic biomass without ripping apart valuable cellulose. Researchers jumped in after seeing that this solvent can break down hardwood sawdust or straw, giving pulp with less leftover junk. Fewer byproducts means tidier waste streams and less post-processing. For anyone who’s ever cleaned up after a chemical digester, this stuff earns a thumbs up.

Making Biofuels That Compete

Switching from fossil fuels to greener sources sounds great in meetings, but turning plant matter into useful sugars drags without something to help. This ionic liquid pulls apart plant walls, making cellulose ready for enzymes. After a bit of tweaking, bioethanol plants found that they could get higher sugar yields, sometimes cutting pretreatment hazards and odor too. Labs play with different feedstocks—corn stalks, wood chips, even agave waste—to see just how far this solvent can push the numbers. For startups hoping to prove that biofuels can hit big scale, this tool often shaves months off development.

Recycling: Metal Recovery Without the Mess

Scrap electronics and industrial catalysts hide valuable metals. Pulling gold, copper, or palladium from tangled leftovers usually brings on strong acids or smelters belching smoke. 1,3-dimethylimidazolium acetate pairs up with selective extraction agents to grab metal ions in solution. Labs use this to strip valuable metals out while sidestepping sulfuric acid and avoiding clouds of toxic dust. It’s a quieter, less dangerous recovery, the kind you could imagine growing past pilot plants once supply chains wake up to stubborn shortages.

Boosting Advanced Materials

Ionic liquids found a spot among folks making new polymers and composites. Here, 1,3-dimethylimidazolium acetate plays host in synthesizing specialty plastics or helping spread nanoparticles through fibers. Because it won’t evaporate in a snap, the process can run hotter or longer. That makes a difference in shaping films, gels, or coatings where finicky additives or fragile bio-based ingredients often make a mess with old solvents.

Looking Down the Road

Every new solvent brings its own headaches. Some ionic liquids hang onto water or clutch impurities a bit tight. Industry leaders tackle these by recycling the solvents after use, or designing new blends that keep costs under control. Rules around worker safety and waste disposal force companies to re-examine every step. But having worked across both the basic science and application end, I keep seeing more teams turn to tools like this as they chase processes that work with the planet instead of against it. The real story sits in the results—higher yields, less waste, and fewer headaches for the next person down the line.