1,3-Dimethylimidazolium Dihydrogen Phosphate: A Deep Dive

Historical Development

Long before the term “ionic liquid” found its way into everyday chemical conversations, scientists were searching for safer, more flexible alternatives to traditional solvents. The story of 1,3-Dimethylimidazolium Dihydrogen Phosphate stems from this broader pursuit. The late 20th century brought a rush of discoveries around imidazolium-based ionic liquids, each shaped by the developmental arc of green chemistry. The phosphates, especially ones like this, broke into the scene with a promise—less volatility, tailored properties, fewer headaches in the lab. Early journals started referencing these compounds as tools for catalysis and separation. Bench chemists at the time craved liquids that didn’t catch fire at the hint of warmth or vanish once the hood’s air kicked in. Once researchers cracked the synthetic routes, industry interest grew, and so did real-world applications.

Product Overview

1,3-Dimethylimidazolium Dihydrogen Phosphate, sometimes abbreviated as [DMIM][H2PO4], functions as a room-temperature ionic liquid created from the coupling of the methylated imidazolium ring with a simple yet versatile phosphate counterion. Instead of sticking to the confines of a single field, its reputation spread equally across organic synthesis labs, battery workshops, and the world of polymer processing. Its appeal comes from a marriage of tuneable acidity and tough-earned stability, letting manufacturers and researchers work with a less hazardous alternative to many older hydrophilic solvents.

Physical & Chemical Properties

You can spot this compound by its clear or faintly colored appearance, usually existing as a viscous, almost syrup-thick liquid at standard room temperature. One of its signature features shows up in its melting point—typically well below 100°C, marking it out as a go-to for those who want to ditch high-temperature processes. Its density tends to land modestly above water, hinting at the presence of heavier ions moving around in its structure. Those chemists who care about cleanliness also appreciate its low volatility—fewer evaporative losses, less exposure risk. As for solubility, this phosphate salt happily blends with water and a range of polar organic solvents, making sample loading and extraction procedures less of a hassle. Its ionic character ensures stable conductivity and a non-flammable nature, setting minds at ease in a busy workplace.

Technical Specifications & Labeling

Suppliers deliver 1,3-Dimethylimidazolium Dihydrogen Phosphate in tightly sealed containers, labeled for both purity levels and hazard classification. The labeling includes everything you need from batch numbers for traceability to warnings about skin and eye contact. Typical analytical guarantees hover at 98% or higher, with testing for moisture and impurities like halides or transition metals. Reliable suppliers provide SDS paperwork in line with international transport and workplace safety standards.

Preparation Method

Producing this ionic liquid calls for a straightforward synthesis. The route starts with 1,3-dimethylimidazolium chloride or bromide. These salts react with a stoichiometric amount of phosphoric acid—no extravagant equipment, just standard glassware. After the acid-base neutralization step, you get a solution containing your target compound. Careful evaporation removes unwanted solvents, yielding the pure ionic liquid. A filtration or crystallization step can further polish the product by removing unreacted materials or side-products. Each stage benefits from keeping an eye on water content and reaction temperature, since hydrolysis risks and exothermic spikes pose genuine safety concerns.

Chemical Reactions & Modifications

1,3-Dimethylimidazolium Dihydrogen Phosphate doesn’t just stay inert. The molecule’s acidic hydrogen can drive esterification, dehydration, and transesterification reactions. In the lab, this property gets exploited for both catalyzing organic synthesis and breaking down biopolymers. Researchers looking for a platform to mount new functional groups onto the imidazolium or to swap out phosphate with other counterions count on the base structure’s reliability. Its ionic environment stabilizes reactive intermediates—enabling milder conditions for transformations traditionally run at nosebleed temperatures. The liquid can pick up or shed a proton, participate in hydrogen bonding, and act as a supporting electrolyte, especially in green electrochemistry projects.

Synonyms & Product Names

You’ll find this compound under a slew of trade and catalog names. Some call it 1,3-dimethylimidazolium phosphate, DMIM H2PO4, or simply imidazolium phosphate. Catalogs in Europe might refer to it as DMI dihydrogen phosphate, or sometimes by an explicit abbreviation of its chemical formula. The core structure stays the same, but the names shift to fit supplier traditions and database conventions. Common synonyms help users spot the material regardless of regional naming quirks or packaging styles.

Safety & Operational Standards

Direct exposure to 1,3-Dimethylimidazolium Dihydrogen Phosphate brings irritant risks, demanding gloves and eye protection. Even though it boasts low volatility, accidental spills deserve prompt cleanup to prevent long-term contact with surfaces. Inhaling dust or mist is rare but possible, especially during large-scale drying operations. Disposal should avoid direct dumping; instead, containers and residues go through established hazardous waste channels. Local regulations guide disposal, often referencing both phosphate and imidazolium components. Best practice demands chemical fume hoods for measuring and mixing, grounded storage containers to prevent static buildup, and regular employee training on first aid for chemical exposure. Reputable labs keep SDS sheets within reach and maintain fire extinguishers even if the compound rarely poses a flammability threat.

Application Area

Manufacturers in specialty chemicals lean on this ionic liquid for catalyzing esterification and transesterification, especially during the conversion of plant biomass into valuable fuels and platform chemicals. Electroplating shops and battery developers find uses for it in their electrolytes; it delivers stability in both aqueous and some nonaqueous systems, giving equipment longer usable lifespans. Research groups push it into cellulose dissolution and extraction, breaking down tough plant cell walls for sugar recovery—an area with big hopes for bioethanol and “green” plastics production. Analytical chemists value its low toxicity and non-flammable nature; running chromatography sometimes calls for a mobile phase with ionic liquid support. In the polymer world, it tweaks properties of resins and adhesives, affecting plastic flow and cure profiles without bringing in harsh solvents. More recently, groups working on recyclable electronics and eco-friendly coatings have started looking at ionic liquids like this as binders or processing aids.

Research & Development

Backed by a steady stream of journal articles, R&D around 1,3-Dimethylimidazolium Dihydrogen Phosphate moves into new territory every year. In recent research meetings, I overheard groups from both biotech and electrochemistry backgrounds debating how this compound could bridge the gap between traditional solvents and performance-improving additives. Studies in enzymatic catalysis, for example, reveal that this ionic liquid can stabilize fragile proteins or accelerate substrate breakdown. Electrochemical research digs into how the conductivity and solvation properties compare to other phosphate-based ionic liquids. Material science projects focus on polymer blending and the search for improved flame-retardant additives. My experience with grad students and postdocs shows they enjoy the willingness of this compound to perform in tricky set-ups—whether it’s in a microreactor, a beaker, or on a kilo-scale run. Developers keep chasing modifications to make the structure even more degradable, hoping to tune it for sensitive applications like pharmaceuticals and food processing.

Toxicity Research

Decades of toxicology assessments weigh in on the relative safety of this ionic liquid. Most studies report low acute toxicity; in real-world settings, long-term exposure shows few adverse effects, provided workers handle it according to guidelines. Oral and dermal LD50 values climb much higher than those of traditional organic solvents such as benzene or toluene, showing less concern over accidental short-term exposure. Concerns linger about environmental persistence and the fate of the released phosphate under wastewater treatment conditions, driving researchers to set up biodegradation studies. Compared with older imidazolium salts, its profile appears milder, but persistent contact still causes redness or short-lived inflammation. Eye contact draws even more caution; even a splash can trigger serious irritation. Chronic inhalation studies remain limited, so regulatory bodies advise using it in enclosed systems or well-ventilated spaces. The compound doesn’t fall under strict carcinogen or mutagen classifications, which suggests moderate peace of mind for those dealing with it at an industrial scale.

Future Prospects

Growth in sustainable production methods and the drive for greener chemistry puts compounds like 1,3-Dimethylimidazolium Dihydrogen Phosphate at the center of innovation. As big manufacturers look for ways to cut hazardous waste and lower the carbon impact of their operations, interest in ionic liquids rises. There’s a push already underway for more biodegradable imidazolium salts, with researchers exploring tweaks to side chains or counterions. Battery and supercapacitor companies push the frontier to test this compound in next-generation electrolytes, while polymer scientists screen its use in blends and composites. The future likely includes stricter scrutiny from environmental agencies, pushing chemists to prove each new ionic liquid’s safety and recyclability. The best hope rests in keeping the conversation between manufacturers, researchers, regulators, and end-users open, turning every hard-won property of these liquids into practical, safer tools for tomorrow’s industries.

What Makes This Chemical Special

1,3-Dimethylimidazolium dihydrogen phosphate looks like just another chemical name to most people. My first encounter with it came during a research stint on green chemistry. It showed up in a project notebook at a university lab—not as a star, but as a workhorse. Many chemists reach for it because it’s an ionic liquid. Unlike water or acetone, it barely evaporates. No harsh fumes, no flammable clouds, just a stable liquid, right on the bench.

Cleaner Options for Chemical Processes

Traditional solvents like acetone and chloroform have stuck around for years, problems and all. They pollute air, add fire hazards, and make waste disposal a regulatory headache. Ionic liquids such as 1,3-dimethylimidazolium dihydrogen phosphate haven't replaced them everywhere. Still, I saw professors gravitate toward these substances because their stability and low volatility translate into fewer health risks and, usually, less environmental trouble. The green chemistry movement has been pushing companies and universities alike to swap out polluting solvents. This ionic liquid fits well into that puzzle.

Applications Where It Stands Out

Chemical research runs at the pace of problem-solving. I remember an organic synthesis professor using 1,3-dimethylimidazolium dihydrogen phosphate to improve yields in a tricky reaction—one where water would mess with the sensitive reagents, and classic organic solvents risked explosions. The ionic liquid neither caught fire nor poisoned the air. Reactions using it often move faster and push chemical bonds in new directions. Its main claim to fame comes in catalysis. Researchers have mixed it with metal catalysts to convert cellulose—plain plant matter—into sugars, which can end up as biofuel. That’s not just lab curiosity: converting waste to clean energy depends on technology like this.

A Shift in Teaching and Industry Norms

Teaching labs have started experimenting with these solvents for student safety. Instructors noticed fewer headaches, fewer chemical burns, and less anxiety about that “what if” moment every time someone opens a bottle. Industry chemists have fought inertia for years, but the push from organizations like the EPA and REACH means a gradual shift. Documentation points to real improvements: less hazardous waste output, tighter control of emissions, and safer storage. By mid-2020s, markets tracked steady growth in ionic liquid demand. The trend lines suggest this is not a passing fad.

Real-World Limits and Future Potential

No single chemical solves every problem. Disposal still matters. Some ionic liquids, including 1,3-dimethylimidazolium dihydrogen phosphate, can harm aquatic life if dumped down the drain. The right solution needs chemists to plan collection and treatment, not just substitution. Universities and companies now train staff to keep ionic liquid waste out of water supplies. On the upside, the versatility of this solvent continues to pull investment into research. More industries—pharmaceuticals, materials science, green fuels—test and adjust recipes with this chemical in mind. My work with research teams made it clear: safe, stable solvents turn risky ideas into routine projects if we handle them responsibly. Science only moves forward by asking if there’s a better option, and more often today, this chemical has an answer worth trying.

Treating Chemicals Like This With Respect

It’s easy to overlook some of the lesser-known chemicals if you’re not often working in a lab, but anybody who handles 1,3-Dimethylimidazolium Dihydrogen Phosphate should know this compound means business. Over the years, working with all kinds of corrosive and reactive substances, I’ve learned the hard way that shortcuts in safety eventually catch up. That applies here. This isn’t a chemical to treat like kitchen vinegar or table salt; it deserves careful handling from start to finish.

What Exposure Feels Like in Real Life

The mixture of an imidazolium cation and a dihydrogen phosphate anion brings along moderate to strong acidity. If you get even a small splash on bare skin, irritation follows pretty quickly. Think sharp tingling, intense redness—sometimes like a squat acid burn. Eyes involved? Forget about just rinsing for a few seconds; this stings fiercely, and damage can stick around unless you wash out the eye for plenty of time and get help ASAP. During one of my graduate lab stints, a colleague missed a single droplet on her glove, and by lunch there was a sore patch that didn’t heal for days. Gloves, lab coats, and goggles were on after that for every person at every bench.

Smell, Inhalation, and Ventilation Concerns

Many ionic liquids claim low volatility, but nobody wants to risk inhaling even “mild” acidic vapors. Extended exposure to aerosolized particles ends up putting strain on the lungs and throat. Consistent use of a chemical fume hood cuts this risk way down. If pipetting or transferring small amounts, I always make sure the airflow’s on full and all containers stay capped except for the moments I’m working with them. It’s not about paranoia—just a small habit that keeps accidental exposures rare.

Spills, Storage, and Cleanup Realities

Chemical handling always starts with good labeling and smart storage. 1,3-Dimethylimidazolium Dihydrogen Phosphate likes dry, capped environments, away from sunlight and heat. Storing with incompatible acids or reactive metals could set up corrosion or even dangerous reactions over time. Before touching any bottle, check it for leaks or crust, because even a little contact with air means higher risk for spills and degradation.

Spills make a fast mess. I keep spill kits with gloves, absorbent pads, and neutralizing agents within arm’s reach. Paper towels or bare hands belong nowhere near cleanup. If this stuff hits a surface, I sweep up the bulk, then clean the residue with a mild base like sodium bicarbonate—always watching for fizzing or surprising heat. Disposal means treating all residues and cleaning media as hazardous waste, not ordinary trash. Local regulations often require sealing this in specific containers so that no one down the line gets hurt.

Training, Communication, and Honesty

Overlooked details lead to surprises in the lab or warehouse, and surprises with chemicals rarely turn out well. Every year, we run through review sessions on proper procedure for every chemical, including this one. It’s not enough to toss a safety data sheet into a folder; practical, hands-on training gives people the confidence to respond automatically in emergencies. For many workers, language can be a barrier, so we use clear signage and check-ins after every training. Nobody should be embarrassed to ask a question. A few minutes clarifying now prevents visits to the ER later.

Why Real Safety Culture Matters

Working safely with chemicals like 1,3-Dimethylimidazolium Dihydrogen Phosphate means respecting the substance, your team, and yourself. Decades in science have shown me that a culture where people look out for each other and speak up about unsafe shortcuts lets everybody go home at the end of the day in one piece. In the end, recipes for safety boil down to vigilance, personal accountability, and a willingness to double check before reaching for the next reagent. That’s the real precaution every lab, plant, and class should adopt.

Why Storage Choices Matter for Chemical Stability

Every researcher who works with ionic liquids like 1,3-Dimethylimidazolium Dihydrogen Phosphate learns quickly that mishandling even small volumes can turn a project sideways. It sits on the bench, caught between routine and risk — what you do with the bottle once it arrives shapes its future behavior and anyone’s exposure to it.

What Direct Experience Teaches About Moisture and Contamination

Once, back in my university days, our team ignored the warning about humidity and kept a half-open vial out in the main lab near the sink. Within days, the substance clumped and produced a sharp, acidic smell. That change didn’t just ruin our next experiment — it brought questions about safety to the surface. Many imidazolium salts love to absorb water and pick up contaminants from the air. If the seal gets sloppy, purity flies out the window.

Putting 1,3-Dimethylimidazolium Dihydrogen Phosphate in a tightly closed, air-tight glass bottle — not plastic — preserves its dry state. Toss in a fresh desiccant pouch, and stash it in a dry cabinet away from water or acid fumes. Even a small mistake, like leaving the bottle ajar between uses, invites trouble.

Controlling Temperature Cuts Down on Risk

Some might ask about just leaving it at room temperature, and, for a compound like this, minor fluctuations don’t pose an immediate drama. Still, direct sunlight or placement on a shelf above a steam radiator shifts those odds. Heat nudges chemical reactions and pushes decomposition along. The safest routine places chemicals like this in cool, dark storage — room temperature works but stay on the lower side and out of any direct light.

Labeling as Part of Safe Storage

Good labeling stands between a safe lab and costly errors. More than once, I’ve seen bottles with fading ink or unreadable handwriting get mistaken and mixed up. A clear label, listing the full name, date received, and who opened it last, holds folks accountable and makes tracing an issue much faster.

Add hazard symbols. Even when colleagues think they know the routine, sharp reminders on a label clue in newcomers and save time during inspections.

Preventing Human Harm and Environmental Leaks

There’s an old habit in some labs to place extra or less-used chemicals in under-sink cabinets or high shelving. That only raises the chance for leaking containers or accidental spills, which then turn into emergency clean-ups. Always put the bottle on a stable middle shelf, away from sinks and drains, in lockable storage if possible. A drip tray catches mistakes before they become problems.

Preparedness Beats Luck in Any Setting

No one wants to think about fires or accidents, but every chemical stash shares space with others that bring their own risks. Keep incompatible substances apart. Store 1,3-Dimethylimidazolium Dihydrogen Phosphate far from oxidizers, strong bases, or organic solvents. If the lab features shared storage, post clear instructions where anyone can see them.

Proactive Habits Support Trust and Quality

Every secure chemical bottle reflects a group that cares about long-term outcomes and each other. Reducing exposure, avoiding spoilage, and keeping records mean fewer experiments lost to sloppy prep. That investment in storage doesn’t take much time, but it protects science, health, and reputation.

Understanding Chemical Behavior in the Real World

Most folks outside of chemistry labs don’t think much about ionic liquids. 1,3-Dimethylimidazolium dihydrogen phosphate isn’t a household name, but it keeps turning up in research focused on cleaner and smarter chemistry. I’ve spent time in university labs watching grad students swirl similar compounds into beakers. The goal? To find less toxic, more sustainable alternatives to traditional solvents, and certain ionic liquids hold promise. But the real acid test always happens at the interface between the compound and reliable old water.

Mixing with Water: More Than Just Dropping Crystals In

Real-world chemistry deals with actual stuff—how compounds interact, dissolve, and behave under pressure. 1,3-Dimethylimidazolium dihydrogen phosphate has a mouthful of a name, but its story with water is simple. Chemists report that these imidazolium-based salts dissolve readily in water, even at room temperature. The cation (1,3-dimethylimidazolium) binds well with the anion (dihydrogen phosphate), and when the salt hits water, those bonds get pulled apart freely. Water’s polarity tugs at both parts, allowing the compound to dissolve without much coaxing. People working in chemical synthesis or biomass processing usually assume clear mixtures here, no residue left at the bottom.

Plenty of scientific papers back this up. For example, recent work out of green chemistry labs shows this salt acts as a good solvent for cellulose and even some proteins, precisely because it mixes right in with water. Data published in peer-reviewed journals shows high solubility—numbers in the tens of grams per 100 mL at standard lab temperatures. That’s more than enough for most tasks involving cleaning, dissolving, or catalyzing.

Why Water Solubility Matters for the Way We Work

It’s one thing to read technical specs, but practical experience makes the issue clear. If a salt like this didn’t dissolve, researchers would have a hard time using it in the pulping of plant fibers or the deconstruction of stubborn polymers. I remember a project tearing apart switchgrass for biofuel research, and nothing wastes more time than a solid that just won’t dissolve. That’s why having a salt that goes directly into solution without endless stirring or heat makes labs more efficient and keeps costs down.

On top of that, safer lab work depends on water compatibility. Traditional organic solvents often carry fire risks or lingering toxicity. Chemists looking for ways to avoid these hazards see high water solubility as a big step in the right direction. It allows for easier cleaning and less hazardous waste, since leftover solutions mix with standard water treatment flows better.

What Can Go Wrong, and How We Move Forward

Nothing’s ever perfect in chemistry. Even with excellent water solubility, users need to keep an eye on the solutions’ stability and possible unwanted reactions. Over time, exposure to air or impurities can change the mix. A contaminated water supply might throw off results. Labs can reduce this risk by checking purity and storing solutions properly.

Scale-up brings its own problems. While lab beakers handle 100 mL with ease, factories deal in gallons or more, where impurities and water quality matter most. Engineers and chemists must partner to test larger batches and watch for unexpected results—especially since ionic liquids sometimes interact unpredictably with metal, glass, or plastics in industrial equipment.

Solutions from Field and Lab

Chemists solving these problems focus on good lab hygiene, steady batch testing, and keeping detailed records. They swap notes with peers, looking for better, cleaner salts and checking on large-scale experiments. Building trust in these compounds depends on transparency about how they behave in real-world water, not just ideal lab conditions.

Researchers keep exploring, chasing more sustainable and user-friendly chemical tools. The reliable solubility of 1,3-dimethylimidazolium dihydrogen phosphate stands out as a strength, helping both seasoned scientists and up-and-coming researchers make progress toward greener, safer lab and industrial protocols.

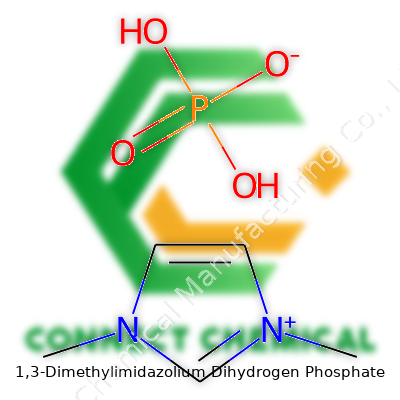

Understanding the Chemical Structure and Formula

1,3-Dimethylimidazolium dihydrogen phosphate looks a bit daunting at first, but its core gives it unique value in the world of green chemistry. The chemical formula stands as C5H11N2O4P. That breaks down to a 1,3-dimethylimidazolium cation paired with a dihydrogen phosphate anion. To visualize this, the imidazolium ring sports two methyl groups on the nitrogen atoms at positions one and three, forming a positively charged unit (C5H9N2+). On the other side, the dihydrogen phosphate (H2PO4-) brings in a negative charge to balance the salt.

Organic chemists often sketch the imidazolium core as a five-membered ring, two nitrogens in the ring, the methyls attached to each, crowning the structure with stability. The phosphate bit comes from familiar phosphoric acid, but with only the hydrogen pairs giving it its signature.

Why Its Structure Matters

Most people won’t come face to face with a vial of this stuff, but researchers, especially those hunting sustainable solutions, see 1,3-dimethylimidazolium dihydrogen phosphate as a game changer. Its value starts with its ionic liquid nature. Unlike classic solvents, it doesn’t evaporate at room temperature. That trait knocks down air pollution from volatile organics—one small tweak in procedure, big change for laboratory safety and cleanliness.

Another major benefit comes from its tunable solvating power. The shape and size of the imidazolium ring, paired with the acidity and hydrogen bonding tricks of the dihydrogen phosphate, let chemists dissolve cellulose and other stubborn biopolymers. Many researchers, including groups working with wood waste or agricultural byproducts, rely on this compound to break down these tough materials—a critical piece of turning trash into valuable chemicals and fuels.

From the Lab Bench to Greener Processes

Early on, the field got stuck using noxious and expensive solvents to pull apart plant material and synthesize specialty chemicals. 1,3-Dimethylimidazolium dihydrogen phosphate opened new paths: lower toxicity, less risk, and higher efficiency. I recall frustration with old protocols requiring fume hoods and disposal headaches. Swapping in this ionic liquid meant more straightforward cleanup and less constant checking for leaks or vapor.

Safety matters in the lab, but the broader environmental impact drives a lot of the appeal. Ionic liquids like this one often get described as “green” because they can be tailored to minimize waste and energy use. They last for multiple cycles, cutting both cost and emissions. It’s not a fix-all—each synthesis and application brings unique problems, from salt buildup to separation challenges. Still, engineers continue to find ways to recycle and purify these solvents, pushing the field closer to a closed-loop model.

Pathways to Improvement

The push for even better solvents continues. Some labs experiment with changing the side chains on the imidazolium ring or substituting related phosphates to see if stability or solubility can be boosted even further. There’s work to do around full biodegradability and toxicity checks, too. Collaboration across industries, open access to findings, and responsible sourcing will help keep progress on the right track.

The bottom line: the story of 1,3-dimethylimidazolium dihydrogen phosphate reflects a wider shift. Chemists find power in precise molecular design and a willingness to trade tradition for cleaner alternatives—one bond and one decision at a time.