Deep Dive into 1,3-Dimethylimidazolium Tetrafluoroborate: Foundation, Applications, and Future Direction

Historical Development

1,3-Dimethylimidazolium tetrafluoroborate emerged from the broader search for stable, room-temperature ionic liquids in the late 20th century. Researchers needed alternatives to traditional volatile organic solvents to reduce environmental and health risks in chemical industries. Chemists discovered that imidazolium-based salts provided a roadmap toward new solvents with useful electrochemical profiles, good thermal stability, and negligible vapor pressure. Over time, this compound gained popularity in both academic and industrial contexts for its versatility. Decades of published papers and patents track each step, as process engineers and bench chemists tested new reaction conditions and separation techniques, looking for greener and safer processes.

Product Overview

Better performing than many classic organic solvents, 1,3-dimethylimidazolium tetrafluoroborate stands out due to its ability to dissolve a wide range of organic and inorganic compounds. The product appears as a colorless to pale-yellow liquid at room temperature, though it can be crystalline under cooler or dry conditions. Chemists value its reproducibility in experimental setups. Due to its tightly held ion pair—between the 1,3-dimethylimidazolium cation and the tetrafluoroborate anion—it maintains consistent electrochemical and thermal properties, allowing careful measurement and reuse. Its utility shines in analytical labs, synthetic chemistry, electrochemistry, and separation methods.

Physical & Chemical Properties

This compound’s melting point usually falls below 20°C, making it easy to handle as a liquid. Its boiling point often exceeds 200°C before decomposition begins, so thermal stability is strong for most lab or industrial processes. The viscosity exceeds that of water, providing advantages in controlling reaction diffusion but also challenges with stirring and mixing on a large scale. Conductivity remains high among ionic liquids, which attracts attention for use in batteries and supercapacitors. The tetrafluoroborate anion boosts hydrophobicity, so water solubility is limited, especially when compared to some other imidazolium-based salts. The density typically sits around 1.2 g/cm3 at room temperature.

Technical Specifications & Labeling

High-purity variants (above 98%) are standard in research labs, with labeling required under GHS guidelines due to its chemical nature. Certificates of analysis generally report on impurities like halides, water content, residual starting materials, and trace metals. The CAS number, molecular formula (C5H10BF4N2), and batch information ensure traceability. Shipping and storage recommendations highlight moisture exclusion by keeping contents in tightly sealed, inert-atmosphere containers. In line with E-E-A-T, reputable suppliers regularly provide in-depth documentation and transparent safety information.

Preparation Method

An established route begins with methylation of imidazole, usually with methyl iodide or methyl sulfate in aprotic solvent under controlled temperatures. This results in 1,3-dimethylimidazolium iodide or sulfate. Next, metathesis with sodium tetrafluoroborate, often in aqueous or acetone media, causes precipitation of sodium iodide or sulfate, leaving the desired ionic liquid in solution. Filtering and passing through activated carbon removes residues. Solvent evaporation and drying under vacuum yields the finished product. Skilled chemists keep water and other contaminants to a minimum throughout this process, as even minor impurities can alter the properties crucial to sensitive applications.

Chemical Reactions & Modifications

1,3-Dimethylimidazolium tetrafluoroborate resists most nucleophilic attack, providing chemical resilience in many transformations. At elevated temperatures or in the presence of strong bases, slow decomposition releases boron trifluoride and hydrogen fluoride, which requires strict control in process environments. Modifications often target the imidazolium backbone, introducing longer alkyl chains for solubility or functional handles, while maintaining the tetrafluoroborate as a counterion. In electrochemical systems, it survives repeated redox cycling with minimal degradation. Its structure enables it to serve as both solvent and, in some cases, a co-catalyst in organic and organometallic reactions.

Synonyms & Product Names

Other names include 1,3-Dimethylimidazolium fluoroborate, DMIM-BF4, or simply [MMIM][BF4]. Certain catalogs reference it as Dimethylimidazolium tetrafluoroborate to emphasize the two methyl groups in the cation, and suppliers often use product codes that indicate grade or application, like "Electrochemical Grade" or "HPLC Grade."

Safety & Operational Standards

Moisture triggers slow hydrolysis of the tetrafluoroborate anion, with release of traces of boron-containing acids and fluoride ions, both hazardous substances for labs lacking robust ventilation and waste disposal. Eye protection, gloves, and lab coats should always be worn. Long-term handling guidelines draw from decades of case reports, warning of irritation if inhaled or in contact with the skin. Emergency response guidance centers on dilution with water and thorough washing after accidental spills. For broader sustainability goals, waste containing tetrafluoroborate needs collection as hazardous chemical waste rather than being poured down drains. Countries vary in regulatory strictness; the European Union and United States both classify it as requiring special handling, especially for mass-scale operations.

Application Areas

Across science and technology, 1,3-dimethylimidazolium tetrafluoroborate helps solve complex problems. Its non-volatile, conductive, and thermally robust nature makes it ideal for high-performance electrolytes in lithium-ion and flow batteries. Synthesis labs choose it for its solvating power and tunable polarity, supporting everything from organometallic catalysis to green chemistry initiatives. It plays a big role in materials science, helping to dissolve polymers for membrane fabrication or serving as a medium in nanocomposite production. Electrochemical sensors and devices rely on its stability under cycling, and in analytic instrumentation, it functions as both an extractant and a separation medium. Engineers in pharmaceutical and fine chemical production have begun to assess it as a safer alternative in specialty synthesis processes, aiming to minimize hazardous waste while maintaining high product yields and purity.

Research & Development

Research picked up pace after early 2000s publications revealed the promise of room-temperature ionic liquids in green chemistry. Regular symposiums now feature presentations showing new applications, from improved battery performance to novel catalysts in organic transformations. Academic labs examine structure-property relationships, tweaking the cation and anion for greater thermal or electrochemical performance, while industrial partners push to scale up production and integrate closed-loop recycling. The latest studies investigate compatibility with biomass processing and CO2 absorption, where longevity and negligible vapor pressure offer clear sustainability advantages. As new regulatory pressures target traditional solvents, universities and companies find increasing incentive to move to safer ionic liquids for day-to-day procedures.

Toxicity Research

Experiments with aquatic organisms and mammalian cells show low acute toxicity for the parent compound, though chronic exposure remains under investigation. Most of the concern revolves around slow hydrolysis of the tetrafluoroborate, which releases fluoride ions, an environmental and occupational risk if mishandled or disposed incorrectly. Research groups systematically report LD50 values and cytotoxicity data, guiding safe concentration limits in diverse applications. Modern in vitro studies track metabolite profiles, seeking to catch any bioaccumulation or long-term organ-specific effects, particularly if ionic liquids spread beyond controlled lab environments. Regulatory agencies urge adoption of closed-circuit handling, robust air and liquid waste filtration, and thorough personnel training. Some research points at possible endocrine disruption at high concentrations, so regular updates in material safety data help users stay informed and protected.

Future Prospects

The next decade holds opportunity for 1,3-dimethylimidazolium tetrafluoroborate to play a leading role in sustainable chemistry and energy storage. As the push for non-toxic, high-performance materials grows stronger, collaborative research between academia and industry will keep moving the benchmark for solvent safety and usability. Growing adoption in lithium-ion and next-gen battery tech could yield longer-lasting, more stable systems. Ongoing innovation in synthetic routes may reduce cost and limit hazardous byproducts, making larger-scale production more feasible. Advances in computational modeling drive the design of new derivatives, probing the limits of ionic liquid performance. Young scientists can expect to see research funding flow toward understanding environmental fate, recycling methods, and ways to minimize societal or ecological risks, as demand rises for scalable and greener alternatives throughout chemical supply chains.

A Closer Look at the Chemical

Stories about chemicals rarely make headlines unless something’s gone wrong, but 1,3-Dimethylimidazolium Tetrafluoroborate is earning more interest every year. To most people, the name tumbles out like a code, but for those in laboratories or on factory floors, this compound means better options. It’s known as an ionic liquid and skips the showy volatility of so many industrial solvents. Pour it out and you’ll see a barely noticeable sheen, but what this substance lacks in flash, it makes up for in tough industrial problems it can solve.

The Push for Cleaner Chemistry

I used to spend time around old-style industrial chemistry, soaked in familiar but harsh solvents that left a stench lingering on my clothes for days. There, popularity went to anything that could get the job done fast, never mind the headaches or environmental cost. 1,3-Dimethylimidazolium Tetrafluoroborate challenged this thinking. Its job often looks simple: dissolve things, carry electrons, or trigger a reaction. The real story goes deeper. Unlike familiar organic solvents, this compound leaves behind less waste and gives off barely any vapor—a blessing for those breathing the air day in and day out.

Applications in the Real World

Take battery manufacturing. People working on cutting-edge batteries often pull in ionic liquids to push energy storage further. This particular imidazolium salt offers stability at higher voltages, which old-school solvents can’t manage without breaking down. I’ve seen colleagues put months into optimizing battery chemistry. Swapping in a better solvent can mean devices that last longer and charge faster. It’s tough to overstate how much a new battery formula can change daily technology.

Meanwhile, in metal processing and electroplating, companies bank on this ionic liquid because it helps metal ions move around without the usual side reactions. Plating gold or nickel on a surface grows simpler and more precise. If you’re wearing a sleek watch or carrying electronics with sparkling connectors, ionic liquids probably helped out along the way. This careful approach means less dangerous byproducts and cleaner working environments.

Addressing the Challenges

People want innovation, but nobody wants to trade one problem for another. Toxicity, cost, or breakdown under real-world conditions can stall even the most promising chemical. 1,3-Dimethylimidazolium Tetrafluoroborate brings its own set of questions. Some imidazolium-based compounds show up in aquatic toxicity tests—researchers keep an eye on possible environmental concerns. Disposal, regulation, and ongoing studies make up a key part of the conversation, especially for those managing large-scale operations.

Looking Ahead: Solutions and Smart Use

Industries adjusting to new environmental rules look for solvents that lower risk, not just for workers, but for the world outside their factory. Recycling strategies keep gathering steam, turning old used liquid into something usable again. Investment in recovery systems stops material from leaking out into the environment and saves money too. Honest labeling, transparency, and open access to test data let customers trust what they’re buying. That shift to responsibility feels overdue to those of us who’ve spent time breathing chemical fumes in the name of progress.

Keeping an open conversation about chemicals like 1,3-Dimethylimidazolium Tetrafluoroborate gives scientists, industries, and communities a better shot at smarter and safer technology. With pressure rising for greener solutions, this ionic liquid could keep earning its place on lab shelves and industrial lines, if we keep valuing health, transparency, and smart design just as much as raw performance.

Understanding What We’re Working With

Most labs run into chemicals like 1,3-dimethylimidazolium tetrafluoroborate at some point. Chemists use it as an ionic liquid for things like electrochemistry, organic synthesis, and some battery R&D. Like many specialty salts, the formula isn’t something you splash around carelessly.

Safety means knowing hazards, and this stuff deserves a bit of respect. On paper, it doesn’t jump out as a severe toxin or an obvious danger. The trouble comes from the combination of its components. The cation lends stability and low flammability, but that anion — tetrafluoroborate — rings some alarm bells. Heat this compound too much or mix it with the wrong substances, and nasty things like hydrogen fluoride gas can pop up. Anyone who’s been around a fume hood knows hydrogen fluoride is a nightmare: corrosion, tissue injury, tough to detect by smell.

Personal Experience in the Lab

At a teaching lab, I once watched someone pipette without gloves, splashing a few drops of an ionic liquid onto their hand. Unassuming liquids lure you into bad habits. For a moment, nobody noticed. Later, redness developed on the skin and a mild burn followed. Turns out, even if a chemical doesn’t feel harsh like acid, it may still cross the skin barrier or trigger irritation.

Another day, a colleague heated a test vial too hard. The compound smoked and set off the chemical sensor. Fumes drifted further than expected, thanks to the low vapor pressure but high toxicity of some byproducts.

It only takes a small slip: a forgotten glove, a fume hood not fully closed, rushing through cleanup. Training matters but so does reminding each other that familiarity breeds carelessness.

Toxicity and Exposure Concerns

Digging through literature and material safety data sheets, most ionic liquids like this one appear less flammable than classic solvents. The real worry is chronic, repeated contact — or breakdown in strong acids or bases, which brings out the worst from the boron-fluorine chemistry. Skin absorption can happen without much warning. Research shows some ionic liquids punch holes in cell membranes, and tetrafluoroborate’s track record includes slow release of fluoride ions.

Inhalation risk bumps up in confined spaces. Even liquid in a beaker can let off invisible vapors, especially if something reacts unexpectedly. Reports track breathing difficulties and chest tightness after poor handling.

Practical Handling Tips

From experience, a few habits make this material easier to handle. Good nitrile gloves, splash goggles, and a fresh lab coat keep skin safe. Always work under a properly running fume hood. Never heat unless you’re sure about decomposition temperatures and nothing else might react with the solution. Label everything clearly. Keep cleanup solutions ready, not locked away, and rinse all glassware straight after use.

Room for Improvement

Training helps, but refreshers and real examples drive the message home. Labs should share incident reports and near-miss stories. Equipping every workspace with visible hazard charts — not buried in digital folders — helps keep dangers fresh in mind. Pushing for less hazardous alternatives works too, and some research groups already experiment with other ionic liquids.

Respect beats recklessness. Chemicals like 1,3-dimethylimidazolium tetrafluoroborate don’t need to frighten, but they should never get underestimated.

Understanding the Chemical

Dealing with chemicals at the bench or in the stockroom takes more than just knowing a label. 1,3-Dimethylimidazolium tetrafluoroborate doesn't draw much attention on the shelf, but ignoring its quirks sets up trouble. This salt, often an ionic liquid, plays a part in labs focused on green chemistry, catalysis, and electrochemical applications. Since its structure lets it stay liquid at room temperature, it's tempting to treat it like water or salt. That’s a mistake a lot of younger lab workers tend to make. My own work in university labs hammered home one lesson: chemicals don’t forgive shortcuts.

Keeping Moisture Out

This compound pulls water from the air like a thirsty sponge. Storing it in a humid spot turns a dry, stable product into a messy, potentially reactive goo. Standard advice says to keep hygroscopic materials in a tightly-sealed container. That’s not just textbook wisdom — in practice, skipping that step ruins both the integrity and value of the chemical. In my experience, a desiccator, even a simple one with silica gel, works wonders. Colleagues once left a sample exposed for the weekend and came back to find it diluted and clumpy. An anhydrous environment, at least as dry as a silica-packed box, saves you hassle and safeguards your budget.

Saying No to Sunlight and Heat

Direct sunlight and extra heat risk triggering chemical changes. My mentor used to point out the sun always finds a gap in the blinds, so never store chemical bottles on window-facing shelves. 1,3-Dimethylimidazolium tetrafluoroborate behaves better in the dark, at room temperature or cooler. Refrigerators set between 2°C and 8°C tame most risks without pushing the cost up. Freezers rarely offer extra benefit, and you'll fight condensation issues every time you reach in. A solid storage routine skips stress over failed experiments.

Labeling and Segregation: Lessons Learned

Accident reports fill up with stories where labeling fell short. Someone’s handwriting blends into a blurred, ink-stained label, or the bottle sits right next to a reactive acid or base. I always recommend bold, clear labeling with full chemical names and hazard symbols. It’s not about bureaucracy, it’s about protecting your teammates and your research. Segregating storage also matters. The tetrafluoroborate anion stays stable under typical lab conditions, but storing next to strong acids or oxidizers adds unnecessary risk. Acids give off fumes that corrode seals. Neighboring oxidizers act as wild cards if spills happen. Most experienced chemists set up dedicated shelves for ionic liquids and salts, separated from reagents that don’t play nice together.

Responsible Storage Prevents Costly Mistakes

No research group likes to spend money twice because of ruined stock. Real costs aren’t just in the price of the chemical. Downtime, repeated syntheses, and safety incidents add up. Storing 1,3-dimethylimidazolium tetrafluoroborate with care—cool, dark, dry, sealed, and clearly labeled—forms a foundation for safe, efficient lab work. Routinely checking inventory for signs of contamination or degradation should become a habit. Labs that commit to these habits avoid wasted resources and ensure everyone walks out as healthy as they walked in.

Diving Into the Science

1,3-Dimethylimidazolium tetrafluoroborate stands out as a curious example from the family of ionic liquids. The backbone is a surprisingly simple imidazolium ring with two methyl groups attached at sites 1 and 3. What happens with those methyl attachments? They influence how the molecule interacts with other components, and in labs, this can mean the difference between a liquid that works for your reaction and one that won’t.

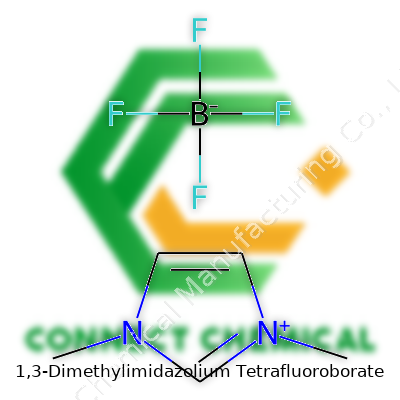

A Closer Look at the Structure

The cationic portion, 1,3-dimethylimidazolium, consists of a five-membered ring—three carbons and two nitrogens. Methyl groups, each made of a carbon and three hydrogens, attach to the nitrogens. These substitutions make the ring more resistant to water or other things that try to break it apart. The molecular formula for the cation looks straightforward—C5H9N2—but that ring structure gives it characteristics that chemists lean on, especially in research.

What about the counterion? Tetrafluoroborate, known as BF4−, has a boron atom at its core surrounded by four fluorine atoms. This brings stability and boosts the salt’s resistance to both heat and many solvents. Together, these two ions form a salt with a low melting point, turning it into a liquid at or near room temperature. Handling this sort of material in the lab has opened up options for reactions where conventional organic solvents fall short.

Importance in the Real World

Ionic liquids like this aren’t just scientific curiosities. Researchers wanted better ways to carry out chemical processes without the hazards common with volatile organic solvents. With their negligible vapor pressure and thermal stability, ionic liquids answer that call. I’ve seen colleagues switch to 1,3-dimethylimidazolium tetrafluoroborate to avoid fire risk—especially in scale-up experiments where safety matters just as much as results. In my view, the move to safer chemistry aligns with efforts to protect both environment and human health.

In real applications, workers use this compound for tasks ranging from catalyzing reactions to separating chemicals. Early chemists working with solvents like chloroform or benzene probably wouldn’t have guessed we’d someday rely on salts like this to keep both chemists and the environment safer. The tetrafluoroborate’s stability also means you’re less likely to see unexpected side reactions—a gift in any carefully planned synthesis.

Challenges and Moving Forward

The growth of ionic liquids in industry and academia brings its own questions. Disposal remains a sticking point, since the fluorinated anion can persist in the environment. Policies on managing waste from these substances still lag behind their growing popularity in labs. More researchers keep eyes on ways to recover and recycle used ionic liquids; some experiments I’ve watched repurposed spent liquid for new reactions, saving money and reducing waste.

Another push involves finding less persistent, more biodegradable counterparts for the tetrafluoroborate anion. Until then, attention to safety guidelines stays crucial. Wearing proper protective gear and using good ventilation goes a long way, something I learned from mentorship in my first lab job. For industries looking to cut carbon footprints, ionic liquids like 1,3-dimethylimidazolium tetrafluoroborate might point toward greener chemistry, if they can manage waste and keep byproducts in check. As the science moves forward, that balance between utility and responsibility will keep the chemistry community busy for years to come.

The Chemical Behind the Name

1,3-Dimethylimidazolium tetrafluoroborate might sound like a mouthful, but it’s an ionic liquid you’ll find in certain research labs and industry workspaces. Folks use it thanks to its solvent abilities, especially in tricky chemical processes. Despite its convenience, this compound doesn’t belong in the regular trash or down the drain.

The Hazards Hiding in the Bottle

This isn’t a substance people should treat like sugar or salt. Spilling or releasing it can mess with water sources and put extra stress on treatment facilities. The tetrafluoroborate part can break down and release fluoride ions, which are toxic to aquatic life. Mishandling poses risks not just to workers but to whole ecosystems tied to local waste streams.

Real-World Steps for Responsible Disposal

The best approach for ditching this stuff isn’t always obvious to someone just reading a label. After years working alongside chemists and safety pros, one classic principle pops up every time: partner up with your Environmental Health and Safety (EHS) crew or talk to folks managing hazardous waste in your town. The law usually calls this stuff “hazardous,” which triggers stricter rules for disposal.

Labs with a waste-handling contract often funnel their spent chemicals into labeled containers. These containers go into locked cabinets and out the door in regular pickups handled by pros who know the ropes. Waste gets shipped off to high-temperature incinerators or chemical treatment facilities certified to neutralize both the organic and inorganic bits. That way, neither the waste handlers nor the planet get an unwanted dose of toxins.

Documenting the Disposal Journey

Leaving things undocumented can land you (and your workplace) in deep water with regulators. The paperwork trail or digital logs matter just as much as the stuff inside the container. Each step, from filling up the waste bottle to sending it to the disposal crew, should go on record. I’ve seen a simple oversight lead to big headaches during audits or surprise inspections. Dotting i’s and crossing t’s makes sure your team stays off regulators’ radar and keeps their good standing with environmental agencies.

The Ethics of Responsible Chemical Handling

Risk often hides in the details, and one shortcut can ripple through an entire community. Ethically, anyone who spends time working with chemicals owes a duty to people and places downstream. This is where experience meets principle. Shortcuts, such as dumping into the regular trash or trying to rinse residues, never stay hidden for long.

Training each set of new hands on the job doesn’t just keep labs out of trouble; it protects the water we drink and the air we breathe. Swapping out waste containers regularly and signing off on every transfer delivers safety and shows newer team members what real stewardship looks like.

Better Alternatives and Staying Ahead

The green chemistry movement offers hope here, pushing for safer solvents and friendlier alternatives to ionic liquids. Still, 1,3-dimethylimidazolium tetrafluoroborate continues to show up in processes where safer options haven’t measured up yet. Until a replacement makes the rounds, teams should insist on proper collection, labeling, and off-site disposal by the right professionals. No one gets a free pass just because disposal fees cost extra or paperwork feels tedious. Keeping these chemicals out of the drain and landfill pays off in cleaner rivers and healthier neighborhoods.