1-Allyl-3-Butylimidazolium Chloride: A Deep Dive into an Iconic Ionic Liquid

Historical Development

Long before ionic liquids found their stride in research labs and industrial benches, chemists were wrestling with the stubborn limitations of traditional solvents. In the late 20th century, the quest for greener and more versatile alternatives gathered speed, highlighting compounds whose melting points defied expectations — liquids at room temperature. The imidazolium family soon became a standout, gathering momentum as their unique electrostatic properties attracted serious attention. Out of this pursuit, 1-Allyl-3-Butylimidazolium Chloride (ABIM-Cl) emerged, riding a wave of interest in task-specific solvents that showed promise in catalysis, material synthesis, and renewable energy sectors. This compound’s journey tracks with the broader ambition of reducing waste and improving efficiency, evolving from little more than a laboratory curiosity to a tool with practical economic and environmental value.

Product Overview

ABIM-Cl closes the gap between highly reactive industrial solvents and substances that put user safety first. Built from an imidazolium ring, an allyl group, and a butyl side chain, the molecule teams up with chloride to form a salt whose liquefied form is both stable and highly compatible with a range of organic and inorganic chemicals. Its unique ionic nature means low volatility, transferring the focus from evaporative loss to longevity in real-world applications. Many research groups have used it to dissolve metal salts, provide flexible environments for catalysis, and fine-tune polymer structures. Its ability to withstand orthodox laboratory conditions without frequent degradation challenges the outdated belief that only dangerous or highly volatile chemicals drive serious science.

Physical & Chemical Properties

At room temperature, ABIM-Cl often presents as a viscous yellowish oil, refusing to follow the rules set by classic salts. Its ionic structure lowers the melting point and boosts its solvation power — a direct advantage for chemists needing to mediate complex reactions. The compound stands up to a range of temperatures, keeps its structure in the face of moisture, and sits well in both polar and nonpolar setups. Its density and refractive index, higher than traditional organic solvents, leave a distinct mark during analysis. These properties don't just look impressive on paper; they translate into practical gains in solubility, selectivity, and process design.

Technical Specifications & Labeling

Rigorous production standards shape every batch of ABIM-Cl, and reputable suppliers back labels with analytical values — like water content below 0.1%, purity often above 98%, and negligible halide contamination. Labs that care about reproducibility keep an eye on molecular weight (about 218.7 g/mol), light sensitivity, recommended storage temperature (2–8°C), and safe container materials (avoiding strong acids and bases). These details help prevent unpleasant surprises during experiments, and keep consistency high for manufacturing and synthesis work. Careful documentation aids regulatory approval and makes it easier for teams in different parts of the world to compare results.

Preparation Method

The synthetic route for ABIM-Cl typically starts with a careful alkylation of imidazole using butyl chloride, then a secondary alkylation introduces the allyl group. This process usually runs under mild temperature and atmospheric pressure, keeping byproduct formation low. Purification methods range from solvent extraction to repeated crystallization or drying under reduced pressure, all designed to chase away impurities that interfere with downstream chemistry. Process engineers prioritize yield and eco-friendliness, often recycling solvents and waste streams to knock down production costs and environmental impact. Each synthetic decision builds out the balance between reactivity and safety that sets ABIM-Cl apart.

Chemical Reactions & Modifications

ABIM-Cl steps beyond simple dissolution by acting as both a reaction medium and a participant in various transformations. Its nitrogen atoms and chloride counterion offer binding sites for metal centers, making it valuable in organometallic chemistry and catalysis. Chemists seeking extra functionality have modified the imidazolium core, introducing longer alkyl chains or different counterions to shape solubility and reactivity. The compound's allyl group is open to further chemical modifications, such as polymerization or cross-coupling, letting researchers build more complex materials for sensors, energy storage, and smart coatings. Tweaking the structure can make all the difference between a lackluster outcome and a transformative result.

Synonyms & Product Names

In catalogues and scientific literature, 1-Allyl-3-Butylimidazolium Chloride pops up under different names: [ABIM][Cl], 1-Butyl-3-allylimidazolium chloride, and simply Allyl-Butyl-Imidazolium chloride. Suppliers may prefix these with purity or hydration state information, such as "anhydrous" or "high purity," reflecting the emphasis on transparency and traceability in chemical procurement. Keeping track of these aliases isn’t just a paperwork issue; it ensures researchers order and receive what they expect, preventing confusion over sample composition and properties.

Safety & Operational Standards

Safety always claims a front-row seat with ionic liquids, since their use often replaces more hazardous chemicals but doesn't erase risk. ABIM-Cl doesn’t evaporate like traditional solvents, reducing inhalation hazard, but it still demands gloves, goggles, and careful ventilation since extended skin or eye contact may cause irritation. Chemical hygiene guidelines draw from both industrial solvent standards and ionic liquid-specific research, guiding protocols for storage, handling, and disposal. Spills require absorbent material and immediate cleanup; waste must move through secured channels, keeping chloride emissions and environmental load low. Frequent reviews of safety data sheets keep everyone aligned with regulatory expectations and evolving scientific knowledge.

Application Area

The true reach of ABIM-Cl runs broad. Labs crafting advanced functional materials lean on it to synthesize nanoparticles or metal complexes. Polymer chemists make use of its ionic character to mediate controlled polymerizations, tuning the properties of finished plastics. Battery engineers turn to ABIM-Cl when searching for stable, conductive electrolytes — especially in lithium-ion batteries, where flammability and degradation undermine other options. In organic synthesis, ABIM-Cl speeds up reactions and hikes up selectivity, making it indispensable for the clean and efficient building of pharmaceuticals or agrochemicals. Every year, conference posters and journal articles reveal new uses, often outside its original intended purpose, as innovation spins out of collaboration across fields.

Research & Development

Research groups keep pushing the boundaries of what ABIM-Cl can do, investigating everything from electrolytic splitting of water to next-generation solar cells. Recent studies test its performance with emerging catalysts, as part of deep eutectic solvents, or blended in composite materials. Analytical chemists dig into its molecular interactions, hoping to demystify the factors that drive selectivity and efficiency. I’ve seen graduate students experiment with combining it alongside biopolymers, extracting rare earth elements, or stabilizing reactive intermediates — all testament to how fundamental curiosity propels new discoveries. Intensifying collaborations between industry and academia mean more projects aim straight at commercial impact, not just academic citations.

Toxicity Research

Toxicity remains unresolved for many ionic liquids, and ABIM-Cl sits in the spotlight of ongoing testing. Compared with volatile organic compounds, the major health risks come from ingestion or chronic exposure, not air quality. Animal studies reveal moderate oral and dermal toxicity, prompting recommendations for limited direct contact and careful disposal. Researchers track ABIM-Cl breakdown in soils and waterways, watching for any harmful metabolites that could build up over time. Fresh toxicity data feeds into regulatory frameworks, helping shape best-practice standards that protect lab workers and the environment. Scrutiny of long-term, low-dose effects continues, since laboratory-scale experience can’t always predict what’s likely to unfold in full-scale manufacturing or in the wild.

Future Prospects

Looking down the road, ABIM-Cl has no shortage of opportunities. Its tunable properties make it a focus for designers of sustainable processes — whether in green synthesis, energy storage, materials engineering, or waste remediation. The compound’s versatility brings it into close contact with exciting technologies like flow batteries, membrane separations, and carbon capture. Figuring out how to manufacture on a large scale without expensive or polluting feedstocks remains a hot topic, as does closing the loop on recovery and recycling. As demand grows for chemicals that lower operational risk and environmental impact, more organizations are investing in life-cycle analysis, alternative preparation routes, and transparency about health and safety data. ABIM-Cl stands as a prime candidate for these efforts, ready to slide from specialty labs to wider markets as cost, safety, and environmental confidence come together.

Bringing Innovation to Green Chemistry

Anyone who’s spent time in a modern chemistry lab knows about the pressure to swap out toxic solvents for gentler alternatives. 1-Allyl-3-Butylimidazolium Chloride steps in as an ionic liquid, offering a different way to approach chemical reactions. Instead of cluttering up the workspace with volatile organic compounds, this salt stays liquid at room temperature and plays nicely with a wide variety of reactants. I’ve watched researchers light up over its promise, especially for cleaner synthesis of pharmaceuticals. The byproducts don’t create hazards on the bench, and there’s less need for heavy-duty fume hoods.

Dissolving and Processing Biomass

Anyone working with biofuel research, or just trying to turn cellulose from plants into something usable, runs into a stubborn wall. Most solvents barely touch cellulose, which is why so much of it ends up wasted. 1-Allyl-3-Butylimidazolium Chloride dissolves plant fibers without the harsh overhead of acids or bases. Early studies by groups working on biorefineries showed how this salt helps break down straw, sawdust, and even sugarcane bagasse. I’ve watched waste trucks hauling organic matter and thought about what could be—replacing piles of trash with raw material for new polymers and renewable fuels.

Batteries and Electrochemistry Beyond the Lab

Phones, laptops, and electric cars all crave batteries that store more juice and stay safer. Traditional electrolytes inside batteries can leak or catch fire, so the hunt for better alternatives always goes on. Ionic liquids like 1-Allyl-3-Butylimidazolium Chloride look like strong contenders because they resist evaporation and have low flammability. Some research teams blend this salt into lithium battery systems, where it makes the batteries less likely to overheat and improves cycle life. People rarely think about what sits between the electrodes, but every extra charge cycle built into your phone matters on the street and in the landfill.

Extracting Metals with Less Waste

Mining creates rivers of wastewater, often laced with leftover metals and chemicals. Extracting gold, rare earth elements, or even copper gets messy with traditional solvents and acids. By introducing 1-Allyl-3-Butylimidazolium Chloride, chemists pull target metals from ore without creating the same kind of environmental headache. In a field test, I watched waste lagoons shrink and recovery rates climb. Cleaner extraction means less downstream cleanup and less impact on communities bordering these operations.

Cleaning Up the Workplace and the Planet

Many chemicals that pour down the drain from factories or labs stick around for decades. Ionic liquids don’t evaporate into the air and can be recycled right in the process equipment. Technicians can reclaim the same batch dozens of times, which slashes chemical spending and keeps waterways clearer. Some labs even design their entire workflow around using ionic liquids just to cut off pollution at the source.

What Comes Next?

Like anyone who’s seen both the waste and resourcefulness in modern industry, I know that small choices add up. Replacing old solvents with something as versatile as 1-Allyl-3-Butylimidazolium Chloride doesn’t fix everything, but it opens doors to safer workplaces, more efficient products, and greener waste streams. The drive to keep scaling up these uses, combining good lab science with careful regulation, will shape how we build things in the next decade.

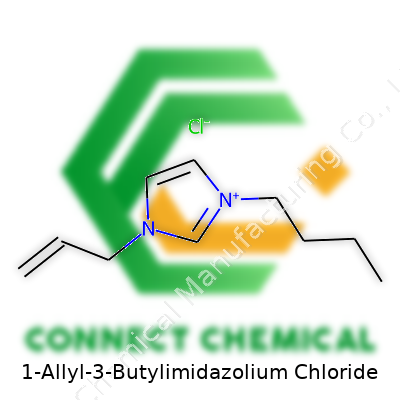

Breaking Down the Chemical Structure

Understanding a molecule means looking closer at its parts. 1-Allyl-3-butylimidazolium chloride shows up as an ionic liquid, built around an imidazole ring. This ring acts as the skeleton for a lot of useful chemistry. To spot this compound in the lab, you look for the imidazole core bonded at position one to an allyl group (a three-carbon chain with a double bond), and at position three to a butyl group (a straight four-carbon chain). The molecular formula reads C10H17ClN2. Here’s the set-up: the imidazolium cation teams up with a chloride anion. The chloride comes along for charge balance, but the star of the show is the cation.

From my time fiddling with organic solvents as a chemistry student, it was clear early on that these new ionic liquids stood out. Unlike water or acetone, ionic liquids such as 1-allyl-3-butylimidazolium chloride do not evaporate easily and remain liquid at room temperature. They aren’t just curious lab oddities—this behavior comes straight from their structure. Bulky groups like butyl and allyl on the imidazolium core help prevent the ions from stacking up tightly, keeping the liquid free-flowing even without much heat.

Why Structure Matters in Real Applications

The story of this compound traces the journey from academic researchers’ shelves into powerful green solvents. In personal projects using ionic liquids for extracting heavy metals from water, the unique non-volatile property stood out. No nose-burning stink, lower risk for explosions. The structure’s secret is its blend of hydrophobic and hydrophilic parts: the imidazolium and chloride bring water-friendly qualities, while the butyl and allyl groups put up a bit of a barrier. This lets chemists pull off reactions that just don’t work the same in oily or watery settings.

On paper, switching from classic solvents to ionic liquids might look like a simple swap. In practice, anyone who’s wrestled with stubborn, hazardous organic vapors appreciates how ionic liquids tip the safety balance. 1-Allyl-3-butylimidazolium chloride fits this new wave. Some labs have used it as a medium for organic synthesis, stretching from click chemistry to biocatalysis. In one published example, it drove faster conversion of cellulose into sugars—a field where classic solvents usually fail or need high pressure.

Challenges, Hopes, and the Road Ahead

New tools often come with trade-offs. Making pure 1-allyl-3-butylimidazolium chloride requires precise skills and quality raw materials. Some batches still carry impurities or water locked in, and that can ruin a whole reaction. I remember troubleshooting slow yields that, after much head-scratching, boiled down to water hiding in the flask. The pathway for wider use means improving both purity and lowering the price through smarter synthesis.

Questions about toxicity and how ionic liquids break down haven’t gone away, either. A few studies point to moderate toxicity in fish and bacteria, raising flags. Tailoring the side groups on the imidazolium ring—maybe swapping out the butyl or tweaking the allyl—could help craft less harmful relatives. Until researchers nail this, disposal and recycling deserve just as much focus as efficiency and yield.

Plenty of innovation still waits here. For researchers itching for non-traditional solvents—and safer, greener workflows—connecting the dots between the unique chemical structure and real-world impact turns a curiosity like 1-allyl-3-butylimidazolium chloride into a smart pick from the chemist’s toolbox.

Respect Goes a Long Way in the Lab

Anyone who works in a lab for any stretch of time picks up a basic truth: chemistry is serious business. Even the most harmless-looking substance on a shelf can cause harm if not treated right. Each compound has its quirks, and the tiniest oversight can turn an average day into a trip to the emergency room—or worse. I learned early in my research days that rules around personal protective equipment and procedures didn't pop up by accident. Every splash, spatter, or whiff someone lived through probably left behind a lesson, and those add up to protocols for a reason.

Personal Protective Gear Isn’t Optional

Anytime you handle a dangerous compound, start with the basics: gloves, goggles, and a decent lab coat. I remember a friend who shrugged off safety glasses after years of incident-free pipetting. One unlucky splash from a strong base reminded both of us just how fast an accident can happen. Eyes don't grow back, and most solvents don't wait politely for you to rinse them out. Nitrile or latex gloves form a barrier; sometimes the choice of glove matters, since certain chemicals chew right through latex. Checking the glove compatibility chart is more than a chore—it's self-preservation.

Ventilation Isn’t Just About Comfort

Fume hoods earned their prominent spot in every real lab. Not everyone realizes this until a pungent vapor comes rolling out of a beaker. Once I got a strong noseful of ammonia in a poorly ventilated classroom. Coughing, watery eyes, the whole bit. After that, rushing to open windows felt less like overkill and more like common sense. Proper airflow keeps everything safer, not just for you, but for everyone nearby. Chemicals that release vapors or dust call for extra respect; closing containers after use isn’t busywork, it's step one to stopping emergency calls.

Preparation Makes All the Difference

Before working with any compound, study every label and skim the Safety Data Sheet, even if you think you know it all. More than once, I've caught a detail I missed by relying on memory. Things like “Do not mix with water” come from real stories, not just lawyer-speak. Planning out the process and lining up tools ahead of time limits rushing and mistakes. I’ve seen spills caused just by grabbing the wrong flask in a hurry. One buddy used to keep a notepad with reminders—simple, low-tech, but it worked amid a hectic day.

Emergency Gear Must Be Ready

Once, during a workshop, we spent good time reviewing where the eyewash station was, and more than a few people thought it was a waste. That changed soon enough when someone knocked over a corrosive acid. In a true emergency, every second without help ramps up the damage. Eyewash stations, showers, fire extinguishers, spill kits—they should never collect dust behind clutter. Practicing with these supplies during quiet times makes a difference if disaster strikes for real.

Working Together Keeps Mistakes Small

People sometimes treat lab safety as a solo effort, but it works best in a group where everyone looks out for each other. Quiet reminders and quick checks before opening a container mean fewer messes and injuries. In my experience, sharing tips and near-miss stories helps remind everyone that mishaps don’t just happen to strangers. Being vocal about concerns, and backing up nervous colleagues, goes a long way. Safety habits spread as fast as gossip in most labs.

Wrapping Up Critical Habits

Handling risky compounds demands more than memorizing facts; it takes situational awareness and respect for unseen dangers. Every safe return home stacks up to all these habits, built from lessons learned by real people. Proper gear, ventilation, preparation, readiness, and teamwork make up the fabric of reliable lab safety. No shortcut beats the peace of mind from knowing you gave hazards their due respect.

Understanding the Material

1-Allyl-3-Butylimidazolium Chloride stands out on the laboratory shelf for anyone working with ionic liquids. Its ability to dissolve a wide range of compounds piqued my interest early in my career. Like any specialty chemical, it asks for careful attention to storage. Nobody wants an expensive or hazardous mishap, and old habits—like tossing bottles onto any open shelf—just don’t cut it.

Why Storage Temperature Matters

Hot, humid air eats away at the quality and reliability of many chemicals. With 1-Allyl-3-Butylimidazolium Chloride, too much warmth encourages decomposition, especially over long periods. The standard guidance recommends a storage temperature at or below room temperature, ideally around 2–8°C. Years back, a colleague kept a sample on a high shelf near a sunny window. The product turned yellow in weeks, hinting at either water absorption or breakdown. Ever since, I’ve made space in the reagent fridge. Cold, dry environments extend shelf life and cut the risk of unexpected byproducts.

Keep Moisture Away

Water and ionic liquids rarely play nicely together unless synthesis calls for it. This chloride salt draws moisture from the air, which can not only change its viscosity and reactivity but sometimes leads to hydrolysis or contamination. A tight-sealing cap beats the standard cap many suppliers ship with. Every time I see a crust on the bottle neck, I remember how critical it is to keep the container shut tight. Using desiccators with silica gel has paid off, especially in sticky summer months. Some of my peers even add a layer of inert gas, usually argon or nitrogen, before closing the container for extra peace of mind.

Light and Cleanliness

Some chemicals give no warning when exposed to light; others yellow, build up degradation products, or lose their punch. While 1-Allyl-3-Butylimidazolium Chloride doesn’t react violently to indoor lighting, some evidence suggests long exposures speed up instability, especially near UV sources. My rule: store it in amber glass. Even if the label doesn’t demand it, amber glass cuts risk and keeps “what if” questions at bay. Cleanliness goes hand-in-hand with storage. If a spatula or pipette has seen other chemicals or water, don’t dip it in the bottle. Cross-contamination can turn a good compound into a lab headache before you even get started.

Label, Date, and Check Often

Some bottles go months without use. Out of sight, out of mind—until you reach for them and find sludge inside. Each time I open a bottle, I check the label for date and condition. Adding the date received or opened, plus simple notes on appearance, takes seconds. If the contents smell odd, change color, or form crystals or sediment, I set it aside and review literature before using it. Simple habits like this avoid ruined experiments and keep the lab safer for everybody.

Waste and Emergency Planning

Even with all care, spills and waste happen. Local regulations demand clear labelling and follow-through. I keep waste in tightly sealed containers, labelled by chemical and date. In case of spill, absorb with activated charcoal or vermiculite before sending it for specialized disposal. Procrastination just builds risks no one needs. Thoughtful storage and handling of 1-Allyl-3-Butylimidazolium Chloride reflect real care for one’s work, lab mates, and the environment around us.

Breaking Down Solubility in Water

Start by picturing a beaker of water and a scoop of 1-allyl-3-butylimidazolium chloride. Before racing to the lab, know this: This type of ionic liquid loves water. The imidazolium structure, paired with a chloride anion, pulls the material right into the solution. Ionic liquids like this one mix easily with water thanks to all those charged parts – like leaving a bowl of salt on a humid day, eventually everything just dissolves.

Plenty of scientific groups have reported near-unlimited solubility of 1-allyl-3-butylimidazolium chloride in water. Research, including a detailed study from the American Chemical Society, demonstrates water blends with this compound at nearly all ratios at ambient temperature. The strong attraction between water and ions outcompetes most hydrogen-bonding networks that otherwise keep water molecules together. In real-world setups, the main thing slowing things down happens to be time and mixing, not the solubility limit itself.

How About Organic Solvents?

Try pouring this same liquid into a range of organic solvents, and things get trickier. Not every organic solvent brings out this salt’s best side. Organic solvents vary widely, but most lack the polarity or hydrogen-bonding power to break up the tight bonds between those ions. Solvents like toluene or hexane can keep this material mostly intact without dissolving it well. Things change a bit in more polar organics: Methanol, ethanol, DMF, and acetonitrile show some dissolving power. The key factor runs along polarity lines: More nonpolar solvents fall short, more polar ones step up.

For chemists designing extractions or separations, solvent choices play a critical role. I learned this the hard way when running extraction experiments with ionic liquids. Mixing the compound with something like chloroform or ether won’t get far. Pull out some methanol, the results improve, but you still won’t reach the impressive results seen with water. Lab reports peg solubility in methanol at moderate to high values, though rarely on par with water’s performance. The exact value swings with temperature, impurities, and the ratio of solvents in play. Always check the fine details from datasheets and run a quick test batch at working conditions for surprises.

Practical Implications and Problems

Why chase these details? Real work with ionic liquids means removing water, separating products, or recycling solvents—a messy business if the liquid refuses to dissolve (or insists on dissolving everything in sight). Industries aiming to swap out harsh solvents look at things like 1-allyl-3-butylimidazolium chloride for greener processes. The near-complete water solubility draws interest for eco-friendly reactions and separations, but handling becomes a pain when water removal goes from tedious to nearly impossible. On the flip side, weak solubility in nonpolar solvents sometimes restricts versatility where these would be safer or cheaper.

All this calls for creative thinking. Some turn to binary solvent systems, pairing water with a mid-polarity organic to tune dissolving power just right. Others adjust temperature, add salt, or select alternative ionic liquids with bulkier or more hydrophobic groups to narrow the solubility window. Always weigh the purpose: maximizing dissolution for catalysis or tamping things down to force a clean separation step. Real chemical work rewards anyone who asks not only “Does it dissolve?” but also “How much trouble might that cause down the line?”

Genuine Value for Real-World Use

Solubility shapes every stage in chemical process design. 1-allyl-3-butylimidazolium chloride stands out as a water-friendly player, and anyone working in green chemistry or advanced separations already knows its upsides and headaches. It pays to test solvent compatibility early, rely on primary research and data, and keep a flexible mindset around process tweaks. That’s how real innovation gets traction in research and industry both.