1-Allyl-3-Butylimidazolium Tetrafluoroborate: Digging Into an Uncommon Yet Transformative Ionic Liquid

Historical Development

People never get far by standing still, and chemistry feels this drive more than most disciplines. The story of 1-allyl-3-butylimidazolium tetrafluoroborate ($[ABIM][BF_4]$) started as a wider hunt for stable ionic liquids—salts that melt below 100°C—with the hope of greener, tunable options for chemical processes. Researchers in the late 1990s and early 2000s zoomed into the imidazolium family, fascinated by their ability to carry a variety of functional groups without losing their liquid character. The addition of the allyl side chain, followed by a butyl group and the tight, non-coordinating tetrafluoroborate anion, proved a winning combination for solubility and thermal endurance. Since those early trials, this ionic liquid has quietly made itself useful not just in labs, but increasingly in commercial processes that call for something tougher and cleaner than classic organic solvents.

Product Overview

1-allyl-3-butylimidazolium tetrafluoroborate stands out due to its unique pairing: an aromatic imidazole core with both an allyl and a butyl side group, counterbalanced by the bulky fluorinated tetrafluoroborate anion. The resulting product pours as a viscous, nearly colorless liquid. This recipe means unmatched flexibility for researchers seeking both solvating power and reactivity. Instead of one-size-fits-all solutions, chemists now reach for $[ABIM][BF_4]$ when they want to avoid volatile organic compounds, curtail environmental load, or simply coax stubborn reactions toward higher yields.

Physical & Chemical Properties

The physical side reveals why it’s worth a second look. The liquid holds a melting point near room temperature, usually around 14–22°C, so it rarely crystallizes during storage. High chemical stability under both acidic and basic conditions means it brushes off decomposition at temperatures up to and sometimes past 200°C. The viscosity remains moderate, preventing handling headaches that plague heavier ionic liquids. It dissolves a wide range of organics, inorganics, and even polymers, showing real promise for process integration. Conductivity, another key trait, often lands between 1–5 mS/cm, dropping only slightly with higher viscosity at low temperatures. Its negligible vapor pressure means you can work with it in open environments without facing headaches from evaporation or inhalation. Resistance to hydrolysis and compatibility with metal salts and catalysts further lift its standing among colleagues.

Technical Specifications & Labeling

Suppliers often ship 1-allyl-3-butylimidazolium tetrafluoroborate as a clear to pale yellow liquid, typically at a minimum purity of 99%, confirmed using NMR and chromatographic analysis. Bottles require labeling with hazard data, storage guidance, and batch traceability. CAS number 255112-89-7 shows up on material safety data sheets, alongside H and P statements that cover risks around skin and eye irritation, plus recommendations to use gloves, goggles, and exhaust ventilation. Specifications cover limits for moisture, halide content, and thermal decomposition points, modeled on international standards like REACH and GHS.

Preparation Method

Production of this ionic liquid tends to use alkylation reactions. It starts with 1-allylimidazole, offering the allyl side group, mixed with butyl bromide under controlled temperature, often in acetonitrile, using a base to mop up excess acid. The resultant halide salt then swaps its anion with sodium tetrafluoroborate in an aqueous phase exchange. This method yields high-purity liquid after drying over vacuum or inert gas and filtration to remove residual salts. Experienced chemists note that meticulous dryness makes all the difference for product stability and performance down the road. Scaling from grams to kilograms presents minimal scaling headaches, lending itself to both research labs and larger producers.

Chemical Reactions & Modifications

1-allyl-3-butylimidazolium tetrafluoroborate carves out a niche as both a solvent and a participant in synthetic chemistry. That allyl side chain opens doors for click chemistry, Diels–Alder reactions, and nucleophilic additions right at the liquid’s surface. It’s been harnessed to stabilize reactive intermediates, scavenge transition metals, and support phase-transfer catalysis. Blending with other ionic liquids or switching up the anion or cation leads to custom solvent systems tailored for protein extraction, dye solubilization, or metal electrodeposition—tasks where classic organics miss the mark for selectivity or environmental safety. In catalysis, the imidazolium core sometimes shines as a ligand itself, helping metal centers perform their tasks more selectively or efficiently.

Synonyms & Product Names

Chemists sometimes refer to this liquid as ABIM BF4, 1-butyl-3-allylimidazolium tetrafluoroborate, or simply [C4allylIM][BF4] in journals. Brand names and catalog listings will include abbreviations like [ABim][BF4] or variations based on counterion and alkyl chain specifics. These synonyms matter because mix-ups can mean wasted batches or failed reactions, especially with suppliers carrying dozens of similar-sounding ionic liquids. Careful cross-checking of molecular structure, CAS, and certificate of analysis counts for more than relying on branding alone.

Safety & Operational Standards

Handling ionic liquids means giving safety more than lip service. Though low volatility makes inhalation less likely, skin contact can lead to irritation and, given repeated or prolonged exposure, more serious health effects. Standard practice in labs and commercial plants calls for gloves, splash-proof goggles, and fume extraction. Emergency protocols lay out steps for spills, including neutralization or sorption and careful waste segregation. Storage away from strong acids or oxidizers in sealed, labeled bottles helps prevent unexpected reactions or contamination. Waste disposal regulations classify ionic liquids like 1-allyl-3-butylimidazolium tetrafluoroborate as special chemical waste. Teams need to work with approved disposal operators and comply with regional and national guidelines.

Application Area

Most users turn to this ionic liquid for work in organic synthesis, electrochemistry, catalysis, and advanced materials science. Its solvating strength and reactivity bring real value in making specialty polymers, extracting rare earth metals, dissolving cellulose, and mediating green synthesis routes that avoid chlorinated solvents or strong acids and bases. Battery researchers lean on it for electrolytes that work across wide temperature ranges with zero risk of ignition, and those working in biotechnology now probe its ability to stabilize proteins or extract sensitive natural products without denaturing complex molecules. Dyes and sensor developers run tests in this medium for enhanced stability and conductivity, opening up new frontiers in smart materials.

Research & Development

Over the last decade, the field has seen hundreds of papers probing this ionic liquid’s role in both fundamental and applied sciences. Projects home in on fine-tuning its structure for greater extraction efficiency, lower toxicity, and broader biocompatibility. Electrochemical studies reveal potential as an electrolyte when mixed with lithium or other conductive additives, providing strong cycling stability and low flammability—traits in dire need for safer energy storage. In catalysis, research gears toward immobilizing transition metals or enzymes with 1-allyl-3-butylimidazolium as a support, testing reusability and resistance to fouling. Environmental studies weigh its ability to recover chlorinated pesticides, dyes, and heavy metals from water, pointing to greener remediation methods than those based on activated carbon or incineration.

Toxicity Research

Toxicological data for this ionic liquid continue to evolve. Early cell line and aquatic toxicity studies suggest modest persistence in the environment. Chronic exposure tests show potential impacts on aquatic invertebrates, hinting at the need for strict containment and disposal. Regulatory agencies keep an eye on long-chain or aromatic imidazolium liquids for bioaccumulation, though allyl and butyl versions so far show lower retention compared to aromatic analogs. Risk assessments make clear that in any scale-up or routine use, comprehensive workplace training and regular environmental monitoring keep risks at bay, both for those on the lab bench and those downstream in wastewater treatment.

Future Prospects

Every new use, from higher performance batteries to reclaiming metals from e-waste, raises questions about sustainability and safety. Current research looks to combine the solvent power of 1-allyl-3-butylimidazolium tetrafluoroborate with biodegradable or recyclable frameworks. Advances in synthetic routes point to replacing the tetrafluoroborate anion with organic acids or greener, less persistent ions, reducing both production cost and environmental hazard. Collaborations between academia, producers, and regulators promise to move beyond the laboratory, scaling up applications in electronics recycling, carbon capture, and smart materials. My view, shaped by working in both academic and commercial labs, is that its adaptability gives it staying power, but safe diversification and transparent risk management will decide just how far it travels from niche chemistry to the core of sustainable manufacturing.

Looking Closer at the Structure

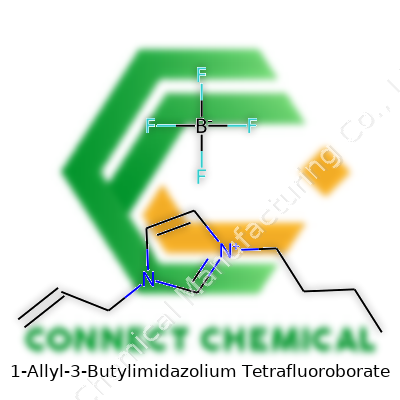

Curiosity in the lab often pushes me to look up molecules like 1-Allyl-3-Butylimidazolium Tetrafluoroborate. The formula doesn’t trip off the tongue, but the substance means something to a lot of chemists. The chemical structure features two main parts: the cation and the anion. On one side, there’s the imidazolium ring—a five-membered ring with two nitrogens at the 1 and 3 positions. Add to one nitrogen an allyl group, which is three carbons long with a double bond. Add to the other nitrogen a straight butyl group, a simple four-carbon chain.

The positive charge sits on the imidazolium ring (the cation), thanks to the resonance stabilization those nitrogens provide. The full name spells this out: 1-Allyl-3-Butylimidazolium. The other half of the molecule, tetrafluoroborate (BF4-), balances out the charge. Tetrafluoroborate has a boron atom surrounded in a tetrahedral shape by four fluorine atoms, making it stable and remarkably inert.

What Makes This Structure Special

I remember the first time I poured liquid into a vial labeled as an "ionic liquid,” a class where this imidazolium salt fits. Room-temperature ionic liquids used to sound exotic, but in the case of 1-Allyl-3-Butylimidazolium Tetrafluoroborate, it’s just a collection of ions, connected mainly by weak forces. This leads to low melting points and that famous viscosity.

The molecular structure ditches strong directional bonds for a chunky, irregular shape, favoring the liquid state. The imidazolium ring, with its butyl and allyl arms, keeps the cations from packing neatly, so the solid state doesn’t stand a chance at room temperature. The BF4- anion’s broad charge and shape keep the molecules moving, not stacking.

Why Understanding the Structure Matters

Getting a clear picture of the bonds and charges shapes how chemists use this substance. The imidazolium’s polar nature lets it dissolve both salts and some organics. I’ve seen labs use it to pull metals out of water or catalyze organic reactions that often stall in traditional solvents. With such a broad window of chemical behaviors, the cation and anion pairing gives researchers flexibility that standard organic solvents can’t touch.

Fluorine atoms surrounding boron provide stability, but there’s a responsibility that comes with handling them. Fluorinated compounds sometimes linger in the environment, so waste management and containment matter as much as performance. Constant monitoring of worker exposure, glove choice, and ventilation keeps safety front and center. It’s tough to see the impact from a small bottle on a shelf, but little spills build up in a busy lab.

Building Toward Responsible Innovation

There’s huge promise in ionic liquids like this one, especially where traditional solvents fall short in safety or performance. The answer isn’t just to switch and hope for the best. Before dumping other solvents for these, reviewing toxicity reports, life-cycle analyses, and cost impact makes a big difference. Universities push for greener synthesis, and industry wants more efficient extraction. Both could push researchers to engineer even safer and smarter pairings of cations and anions.

Newer versions of ionic liquids tweak the side chains or swap out the anions to deliver better safety and less environmental risk. Investment in thorough research will mean future breakthroughs aren’t limited by today’s blind spots. It’s the understanding of the basic structure—the building blocks—that guides safer and smarter chemistry.

What Sets This Compound Apart

In labs and factories, 1-Allyl-3-Butylimidazolium Tetrafluoroborate attracts attention for how it shakes up routine chemical work. It’s part of the ionic liquid family, known for being liquid at room temperature, refusing to burn, mixing well with organic compounds, and dissolving salts that won’t budge in water. Its low volatility makes workplace air safer—a fact that anyone who’s ever picked up chemical-filled glassware can appreciate.

Pushing Batteries to Do More

Across energy storage projects, researchers pick up this ionic liquid to help design batteries that last longer and handle more charge-discharge cycles. In lithium-ion cells, regular electrolytes hit a wall with high voltages, swelling up and breaking down. Tetrafluoroborate salts bring more stability. They don’t allow moisture to barge in as quickly and can handle the heating that comes with charging. Experiments point to longer cycle life and better safety, addressing energy storage headaches faced by electric vehicle makers and the people who rely on a phone that needs to last all day.

Building Better Chemistry in Industry

Organic chemists relate to the problems solvents cause—flammable, temperamental, and often dangerous. Green chemistry research points toward ionic liquids as alternatives that hold up under pressure. 1-Allyl-3-Butylimidazolium Tetrafluoroborate often surfaces where reactions need a stable, recyclable solvent. In places that build pharmaceuticals or specialty polymers, the less time spent managing toxic waste, the better. This compound supports processes where precious metals help build up complex molecules. Recovery gets easier, and costs drop when fewer solvents evaporate into thin air.

Extracting Value from Waste and Ore

Materials extraction doesn’t always need brute force. Industries use this ionic liquid to strip metals from ores and recover valuable components from electronic waste. It dissolves metal salts with less fuss than traditional acids. Recovery rates for gold, copper, and rare earths show a boost in setups that swap mineral acids for ionic liquids. Labs highlight lower emissions and less hazard for technicians—a huge step for anyone who knows how sharper extraction tools help both budgets and health.

Keeping Catalysts in Play

Catalyst losses drive up costs in chemical plants. Ionic liquids offer a way to keep those expensive particles working longer. 1-Allyl-3-Butylimidazolium Tetrafluoroborate acts as a host for metal-based catalysts, helping teams rediscover efficiency in chemical loops. Less leaching, better control over reaction conditions, and easier catalyst recovery—these improvements turn up in published papers and industrial case studies. This adds up for folks tasked with stretching every dollar in product output.

Improving Sensor and Membrane Technology

Anyone following the evolution of membranes or sensors comes across ionic liquids regularly. Their broad electrochemical windows, high conductivity, and remarkable stability make them ideal for building sensors that work under harsh conditions. Solid-state batteries, fuel cells, gas separation, and water purification each benefit from membranes doped with this compound. This adaptability stands out, especially for engineers racing to make more efficient environmental sensors and clean energy devices.

Toward a Greener Future

Demand for safer, sustainable, and high-performing chemicals grows as society tackles climate and pollution issues. 1-Allyl-3-Butylimidazolium Tetrafluoroborate pulls its weight in labs, on production lines, and across waste recycling facilities. Better handling guidelines, process optimization, and supply chain transparency will help push its use further without losing sight of worker safety and environmental effects. It’s not perfect, but every step that moves industry away from risk and waste deserves attention.

Understanding What’s at Stake

Ionic liquids have roots in labs chasing something better than traditional solvents—higher stability, lower volatility. After working with these materials in university research, I’ve watched both newcomers and seasoned pros handling them. It’s surprising how much trust people put in their glass bottles, forgetting that these substances can be just as unpredictable as any lab chemical if ignored.

Simple Approach, Real Risks

Before uncapping any bottle, let’s accept that, while ionic liquids don’t evaporate easily, they respond to air and moisture. In one project, our team left an open vial out “just for a minute,” only to come back to a thickened mass that wouldn’t dissolve as expected. Water in the air had crept in, and the sample changed overnight. Beyond messing up your results, moisture can trigger slow degradation or alter reactivity, spinning your project off course.

Practical Storage Starts with Awareness

Keep these materials in tightly sealed containers—ideally borosilicate bottles with secure caps. Glass gives peace of mind, but make sure the cap’s integrity isn’t compromised. I always label every bottle with the opening date and contents. It seems obvious, but more than once, unmarked bottles turned into mystery projects for folks down the line.

Don’t rely on ordinary plastic containers. Some types of ionic liquids react with plastics, leading to contamination or even damage to the container itself. One colleague lost an expensive batch this way.

Dry, Dark, Cool: The Golden Trio

Finding the right place isn’t only about convenience. Keep ionic liquids out of sunlight and away from heat. Light and heat can nudge these chemicals into producing unwanted byproducts or change their color and properties. I remember shifting all our bottles into an opaque cabinet after a lesson learned the hard way—a formerly clear ionic liquid turned yellow within days of window exposure.

Temperature swings invite trouble. Use a dedicated section of the refrigerator or temperature-controlled cabinet. Extremes, whether from a freezer or a spot near the heater, can push ionic liquids out of their comfort zone, making them unstable or thick.

Ongoing Safety: More than Gloves and Goggles

Using gloves and goggles is standard, but consider ventilation as another layer of security. The misconception that low vapor pressure means no risk led to a near incident at our facility, when vapors escaped during a spill and made the space uncomfortable. Fume hoods do more than trap dangerous fumes—they offer a clean area, isolating your material from airborne moisture and contamination.

Spills demand immediate cleanup with absorbent lab wipes and disposal protocols. Never wash material directly down the sink or toss wipes in regular trash. Some ionic liquids pose environmental risks; local authorities usually offer guidance on disposal best practices.

Building Good Habits Early

Converting protocols from guidelines into habits saves time, money, and headache. Track usage and purity; testing samples every few months keeps surprises to a minimum. Colleagues who treat ionic liquids like other solvents risk lost batches, slow progress, or safety issues—problems that grow over time if ignored.

As research trends shift toward green chemistry and sustainable materials, ionic liquids gain value. Quality management, solid labeling, and airtight storage give you every edge—between a sample that works and one that leaves you scratching your head.

Getting to Know This Chemical

1-Allyl-3-butylimidazolium tetrafluoroborate belongs to a group known as ionic liquids. Labs across the world rely on these liquids for their handy properties—good solvents, stable under high heat, and generally easy to handle compared to some of the nasty stuff used in decades past. In all my time around lab benches, though, I’ve learned that “safe to use” never really means “harmless.” Each chemical deserves a closer look, especially if you’re weighing up long-term exposure or large-scale handling.

Where Science Draws the Line on Risk

The research on 1-allyl-3-butylimidazolium tetrafluoroborate feels pretty thin. No big regulatory body stamps it “safe,” nor does it show up on lists of known carcinogens or persistent toxins. Still, that’s not much comfort in chemistry. Reports suggest that like many other ionic liquids, it can disrupt cell function—some studies put it in the moderately toxic category for aquatic organisms, which should make anyone take a pause before pouring waste down a regular drain.

A paper I remember reading from a reputable environmental journal showed that this class of substances can accumulate in water and affect fish. While it won’t melt your skin off on contact, simple nitrile gloves and lab coats aren’t some magic armor. Lab accidents remind us that direct contact or spills add up one careless day at a time. In poorly ventilated rooms, some of these chemicals release fumes with the potential to irritate airways. Not every researcher or technician knows how quickly symptoms like headaches or rashes can sneak up after even short exposure.

Why Care About Long-Term Effects?

The promise of ionic liquids often hides their drawbacks. People once said these new solvents would solve pollution worries linked to older organic solvents because they evaporate less. That doesn’t mean they never break down into harmful byproducts. Over the past few years, toxicologists pointed out that tetrafluoroborate ions might split, producing corrosive substances like hydrofluoric acid under certain conditions. If you handle these liquids at high temperatures or mix them with the wrong reagents, you run the risk of unexpected reactions. I’ve seen stories about minor spills turning into lingering headaches for an entire lab group.

Better Safety Through Information and Action

Relying on personal experience, the best protection comes from taking every chemical seriously, not just the ones splashed in hazard symbols. Companies and academic labs ought to update safety data sheets regularly. Easy-to-read sheets go a long way for new researchers and students. Fume hoods, proper gloves, and eye shields work best paired with an understanding of just what’s in those bottles. I encourage colleagues to run regular disposal reviews. Treatment plants don’t always break down industrial waste into safe leftovers; keeping ionic liquids out of wastewater in the first place saves headaches down the line.

We need more solid data—more animal studies, more measuring of breakdown products, more real-world studies tracking what happens after a spill. The chemical itself opens the door to safer research with fewer flammable vapors, but responsible stewardship matters most. Only when we respect both the potential and the pitfalls can we call progress real.

Everyday Examples Make Things Click

When I think about melting point, my mind goes straight to the kitchen. Watching a pat of butter hit a hot pan says a lot more than a chemistry lesson. Butter starts to lose shape before your eyes, turning from solid to liquid fast. That’s its melting point in action. The same goes for chocolate—try baking on a summer day and see how it sticks to your fingers. Chocolate melts just below our body temperature, so a warm hand is all it takes to see science in action.

Melting Point—Not Just for Chefs and Chocolatiers

Melting point pops up in places you might not expect. It makes a difference to people working in construction, manufacturing, ice cream trucks, and drug laboratories. Asphalt on roads softens in high heat because its melting point can’t keep up with scorching summer afternoons. Engineers study melting points to pick materials that keep their shape, even in tough environments. In the world of medicine, drugs with high melting points last longer in storage. If a drug starts to melt or break down in a warehouse, it loses its punch before reaching your medicine cabinet.

Solubility Shows Up in the Small Stuff

Solubility touches regular life more often than you’d guess. Take a cold glass of tea and a spoonful of sugar. Stir and the sugar sits at the bottom, refusing to disappear. Try again with hot tea, and the sugar vanishes. That’s solubility at work. Temperature changes how much of a substance will dissolve. Pharmacies use this property to decide how much medicine to pack into a single pill. If a medicine doesn’t dissolve in water or oil, the body can’t use it properly. That’s a big deal for people counting on that pill to work.

Real-World Stakes

Sometimes, ignoring these properties gets expensive or downright dangerous. Salt sprinkled on icy roads lowers the melting point of ice, making it safer to drive. Water pipes in the north face bursting each winter because frozen water expands and the melting point of ice gets tested. Batteries in your pocket or car work better in part because companies chase after the right melting point in their components. Electronics and food science both depend on knowing when something changes state or dissolves.

Getting the Basics Right in Science and Manufacturing

Accurate measurement tools and solid record-keeping shape the world more than most folks notice. Scientists lean on clear numbers for melting point and solubility to create safer products and longer-lasting materials. At home, this knowledge sneaks in when storing chocolate or making homemade popsicles. In factories, entire careers grow from keeping a sharp eye on these two properties.

Stronger Science Means Safer Choices

Letting kids tinker with baking and mixing colors in water is a simple way to introduce these principles. Schools and community workshops score big when they mix hands-on learning with real examples. For the bigger questions—safer roads, more reliable medicine, less waste—it makes sense for industries to keep investing in research and stay clear on the basics. Knowing how and why things melt or dissolve turns out to be more than schoolbook trivia—it shapes safer living, smarter shopping, and even what lands on our dinner plates.

Looking Ahead—Better Tools, Better Results

Building better thermometers and digital measuring devices helps keep mistakes down. Food labels with clearer storage instructions would save families money and cut spoilage. If medicine bottles came with easy-to-find melting and solubility info, patients could avoid ruined pills. From companies to classrooms, a sharper focus on these everyday properties has ripple effects worth noticing.