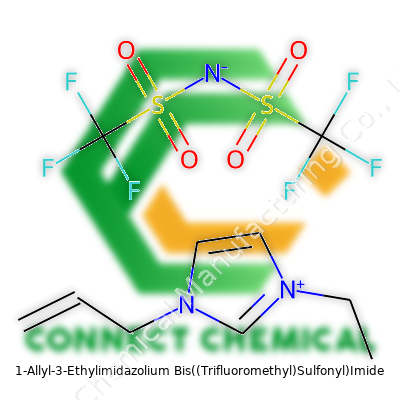

An In-Depth Look at 1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide

Historical Development

The journey of ionic liquids like 1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide has changed the way labs and industries think about solvents. Researchers started exploring imidazolium-based ionic liquids in the late 20th century, chasing the promise of non-volatile, thermally stable alternatives to the volatile organics stinking up their labs. The combination of imidazolium cations with anions like bis(trifluoromethylsulfonyl)imide gave chemists the rare blend of high chemical stability and tunable properties. Early curiosity about these materials grew into practical applications, driving more robust manufacturing methods and new ways to use these room-temperature liquids.

Product Overview

1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide is an ionic liquid that has grown popular for its safety and environmental benefits compared to volatile organic solvents. It works as both solvent and electrolyte across a range of fields, thanks to its wide electrochemical window and low melting point. Once a curiosity in a few niche labs, this material now shows up everywhere from ultracapacitors to battery technology and organic synthesis.

Physical & Chemical Properties

With a melting point that usually stays below room temperature and a negligible vapor pressure, this ionic liquid has little risk of evaporation under lab bench conditions. It shows broad electrochemical and thermal stability, making it tough enough for oxidative and reductive conditions. The fluorinated anion guarantees chemical inertia to water and many strong nucleophiles, resisting breakdown in strongly basic or acidic environments. Its density often sits between 1.3 to 1.5 g/cm³, and the viscosity can rival light mineral oils, which affects how it flows and mixes with other substances. These features open the way for applications demanding solvent recovery or minimal loss through evaporation. The ionic conductivity stands above many organic solvents, making it crucial in electrochemistry.

Technical Specifications & Labeling

You’ll find carefully detailed labels on commercial packaging. Manufacturers publish the CAS number, structural formula, suggested storage conditions, and purity level—often 98% or higher for lab work. Labels spell out the moisture content, since water changes both physical properties and reactivity. Lot numbers connect each bottle to its production run for quality tracking. Depending on use, labeling can differ to highlight intended applications, like high-purity lines for electronics, or general-grade stock for solvents. All containers need clear hazard designations due to the trifluoromethylsulfonyl group’s low, but non-negligible, environmental risk.

Preparation Method

Ionic liquids rarely come straight from nature. Most producers rely on stepwise synthesis starting from 1-ethylimidazole, reacting it with allyl chloride under basic conditions to attach the allyl group. The resulting 1-allyl-3-ethylimidazolium chloride then reacts with lithium bis(trifluoromethylsulfonyl)imide in a metathesis reaction, which swaps out the chloride for the desired bis(trifluoromethylsulfonyl)imide anion. After phase separation and multiple washes to remove inorganic salts and residual water, the product gets dried under vacuum. Each step requires careful monitoring because traces of water or halides can damage further use, especially in sensitive battery and sensor work.

Chemical Reactions & Modifications

Chemists treat this ionic liquid as a platform for even more versatile solvents and catalysts. The imidazolium ring stays stable with most acids and bases, so synthetic modifications often target the allyl and ethyl groups. Cross-metathesis with other alkenes, alkylation, and even direct electrochemical reduction of the imidazolium core have brought forth derivatives tuned for specific solubility and reactivity profiles. Thanks to the anion’s strong electron-withdrawing effect, side reactions including nucleophilic attack or hydrolysis stay at bay, which boosts reliability across many chemical processes.

Synonyms & Product Names

You’ll spot this compound under several aliases, often shortened to [AEtIm][NTf2] or the full IUPAC name. Some catalogs refer to it as 1-Allyl-3-Ethylimidazolium NTf2, and you can find it under specialized codes in supplier databases. Rarely, the abbreviation IL-2094 or simply "imidazolium-based ionic liquid" shows up in older catalogs, but vendors now prioritize clarity in their naming to avoid costly ordering errors.

Safety & Operational Standards

While ionic liquids avoid the choking fumes of traditional solvents, safety still ranks high. Gloves protect from skin absorption, especially during large-scale transfer and blending. Spills require prompt cleaning since the persistent fluorinated anions tend to resist natural breakdown. Goggles, lab coats, and well-ventilated workspaces reduce accidental exposure, especially where elevated temperatures or electricity may release harmful decomposition products. Proper disposal, governed by local hazardous waste regulations, keeps these non-volatile but persistent chemicals out of waterways. Labs and facilities follow established chemical hygiene protocols, including regular workspace wipe downs and proper reagent storage in moisture-proof bottles.

Application Area

Utility beyond organic synthesis now draws advanced battery researchers, electroplaters, and even green chemistry advocates. The high ionic conductivity and low volatility create safer electrolytes for supercapacitors and lithium-ion batteries that need stable interfaces and long shelf-lives. Organic chemists swap it in for traditional solvents in cross-coupling and alkylation, tuning selectivities unavailable with conventional liquids. Even analytical labs experiment with this ionic liquid in chromatography, leveraging selectivity and unique solvating powers. Oil refineries and polymer scientists chase its promise as a cleaner alternative for extraction and polymerization, while still keeping an eye on costs and recycling efficiency.

Research & Development

Active projects look at this ionic liquid from different angles. In materials science, research explores its compatibility with advanced electrodes and membranes. Chemists dig into using it in new reaction pathways, exploiting its wide electrochemical window. Studies also examine its recyclability and ease of purification, since nobody wants to toss expensive, highly purified liquids after just one run. Environmental chemists race to find ways of breaking down or capturing residual anions. As demand grows in electronics and pharmaceuticals, the hunt for greener, more scalable manufacturing processes keeps scientists at the bench.

Toxicity Research

No chemical enjoys a blank check on safety, so researchers test this ionic liquid for acute and chronic effects. Animal models have shown low acute toxicity, but the fluorinated anion and the imidazolium ring both resist fast breakdown in the environment. Some studies report mild irritation in prolonged skin contact or inhalation at elevated temperatures, so handling guidelines recommend avoiding unnecessary contact. Longer-term concerns focus on bioaccumulation, since many ionic liquids linger in ecosystems if released. In my own lab experience, direct exposure has caused fleeting skin dryness, reminding me that even the cleanest-seeming solvents demand respect. Regulatory bodies continue to issue guidance as new data on persistence and breakdown arrives.

Future Prospects

Optimism runs high for expanded roles in green chemistry, especially as traditional solvents face tighter rules. Industry wants more recyclable, non-volatile solutions, with less waste and safer working conditions. Researchers keep tailoring the cation and anion partners, dialing properties for custom separation, catalysis, and energy storage uses. Progress in cost-effective production and improved handling procedures will shape how quickly this material becomes standard outside the lab. New regulations around fluorinated and persistent chemicals will push for even better, safer alternatives, spurring innovation across chemical manufacturing and sustainable technology. As new applications spark interest and environmental policies evolve, the future of this ionic liquid looks full of promise and challenge alike.

Chemistry’s Quiet Workhorse

Some chemicals never turn up in grocery aisles or on TikTok, yet carry out heavy lifting behind the scenes. 1-Allyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide — let’s call it AEIm-TFSI for sanity — belongs to a group of ionic liquids that get most of their attention in research circles. Ionic liquids like AEIm-TFSI don’t evaporate like water, and they don’t catch fire easily, which gives them a huge advantage in labs hunting for better solvents or safer battery components.

Batteries: Pushing Past the Old Limits

Over the last decade, smart minds in academia and industry have explored AEIm-TFSI as a promising electrolyte. Regular batteries rely on clunky mixtures where flammable liquids shuffle ions from one end of the device to the other. That comes with safety headaches. AEIm-TFSI brings rock-solid thermal stability and non-flammability. It keeps doing its job even if you crank up the temperature — handy for electric vehicles or solar storage units sitting under a blazing sun. The high chemical stability stops it from breaking down after a few charge cycles, helping batteries last longer and cut running costs.

A peer-reviewed study in Advanced Energy Materials spotlighted AEIm-TFSI blends in lithium batteries where regular solvents start to fizzle. They showed improved cycling and good ionic conductivity, which really matters as next-generation batteries shift away from fossil fuels. It feels like these advances move technology from fragile prototypes to something parents can trust parked in their garage.

Green Chemistry: Moving Beyond Toxic Solvents

AEIm-TFSI steps up as a safer replacement for harsh solvents in chemical reactions and extractions. Classic methods rely on petrochemicals, which stink up labs, pollute water, and put staff at risk for accidents. Because AEIm-TFSI barely evaporates, it cuts down on air emissions and waste. In my own work with laboratory scaleups, finding a solvent that isn’t a ticking time bomb or a leaky eco-hazard saves time and opens up opportunities to run experiments outside of high-end fume hoods.

Green chemistry isn’t just a buzzword; it’s a matter of daily choices. Projects run smoother when people know they won’t end up with a headache by lunch or spill something impossible to clean up. AEIm-TFSI ticks boxes for safety, ease of disposal, and even recovery for reuse, which matters for budgets and the planet. Publications in Green Chemistry back up its use in organic synthesis, extraction, and catalysis, trimming down the need for industrial solvents that once seemed irreplaceable.

Industry: From Lab Curiosity to Broad Application

Looking beyond the lab, AEIm-TFSI often appears in advanced manufacturing. Companies mixing specialty polymers or designing membranes value its ability to dissolve tough substances or boost conductivity. In my collaborations with engineers, folks appreciate not having to deal with the tendrils of toxic fumes or constant risk training updates. Change happens slow, but step by step, ionic liquids like AEIm-TFSI are making the jump from academic projects to scalable solutions.

Despite a higher upfront cost, the trade-off for durability and safety wins converts in large-scale applications. That shapes a future where less hazardous waste leaves the plant, less money goes to emergency PPE, and innovative processes don’t just stay locked in journals.

Challenges and Possible Steps Forward

No chemical comes without baggage. AEIm-TFSI’s production can require specialty raw materials, and sometimes disposal raises questions about long-term environmental impact. But researchers keep tweaking the structure or inventing recycling cycles to close the loop. Honest conversations with suppliers, rigorous safety audits, and open publishing of new data give companies and labs confidence to lean in — not just for show, but for results everyone can rely on.

Understanding What You’re Working With

Mixing and using chemicals with long-winded names is part of the job in many labs. 1-Allyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide falls into a group called ionic liquids. These solutions pop up in research because they don’t evaporate easily and they dissolve just about anything. Labs use them for tasks ranging from electrochemistry to making new materials. With that kind of utility, people are spending hours around these bottles and beakers. Knowing how to work with it safely isn’t just a rule to follow, it’s crucial for your health and everyone nearby.

Personal Experience in the Lab

At the bench, I don’t treat ionic liquids as friendly or predictable. This particular one contains both fluorine-heavy groups and an imidazolium base, and that alone rings alarm bells. Even though some papers tout their low volatility as a “green” advantage, skin feels the sting quickly if you spill any. This isn’t a solution to slap on a glove and forget about. An accidental splash can bring burning or itching, often worse than simple household solvents. If direct skin or eye contact happens, rinsing with water is essential, and you’ll want to fill out an incident report.

Health Risks and Evidence

The chemistry proves worrisome. Trifluoromethyl groups are not benign, and the imide anion tends to show up in discussions about toxicity. The National Institutes of Health points out that ionic liquids can damage cell membranes, which could explain eye and skin irritation. Published studies on this compound indicate moderate to severe toxicity for aquatic life. If it spills down the drain, it doesn’t just disappear. While researchers debate how persistent and mobile these substances are in the environment, we shouldn’t be their test dummies.

Handling and Storage Advice

Good practice means relying on more than a pair of thin nitrile gloves. I grab a lab coat, splash goggles, and, if possible, work in a fume hood. The fumes don’t fill the room but particles and microdrops still escape during transfers. Sealing the bottle tightly, storing it in a cool, labeled area, and never mixing with water unless you know the reaction are basics that keep accidents rare. My own slip-ups, rushing to finish a protocol, always came when skipping one of these rules. Don’t count on remembering everything after the fact — label spills, wash up, and alert others immediately.

Safety Data Matters

Before pouring or pipetting any new ionic liquid, reading the safety data sheet fully is routine. This document shares real numbers on toxicity, environmental impact, how to manage spills, and what first aid steps beat panic in a crisis. Colleagues who’ve suffered from not heeding this step have faced hospital visits and ruined experiments. It’s not just box-ticking. Knowing flash points, compatibility, and cleanup instructions means you avoid guessing on the job.

Building Safer Habits

Manufacturers of these chemicals push them for their technical benefits, but they don’t stand by you in the lab to clean up spills or head to the doctor. Safe handling isn’t about paranoia; it’s respect for what these tools represent. Pressure to work quickly or push boundaries never outweighs the risks to your health. Sharing tips, keeping up with recent toxicological reports, and using protective gear helps the whole team. Everyone deserves to clock out with health and safety intact.

Physical Properties Speak Volumes

1-Allyl-3-ethylimidazolium bis((trifluoromethyl)sulfonyl)imide has a name that can twist a tongue, but its liquid form can slide off any surface before you figure out the pronunciation. This compound stays liquid over a strikingly wide temperature range, down to below zero and up past boiling water. High thermal stability makes sure it keeps its shape—liquid—right up till conditions most lab plastics can't handle. No random whiff will reach your nose, either; it's practically odorless, which can fool you into thinking it’s plain water. Touch it, though, and its viscosity says otherwise: it's slick, heavier than water, and doesn’t splash around as freely. Transparency lets you see right through, making it look clean even without being pure. The density often edges above 1 g/cm³, giving that heavy feeling in small glass vials.

Chemical Personality Explained

This ionic liquid doesn’t play nice with water, sidestepping most efforts to dissolve fully. The bis((trifluoromethyl)sulfonyl)imide part brings in strong resistance to hydrolysis, meaning it won’t break apart when wet. That makes it fit for harsh conditions where regular solvents crumble. Fluorine atoms build a shield around the molecule, boosting its chemical stability and pushing it into the league of “designer solvents” that barely react unless you tell them exactly how. The imidazolium ring at its heart, loaded with an allyl and an ethyl side group, keeps the charge spread out, making this liquid nimble with ions but not reactive with air or water.

If you’re curious about handling electricity, this compound gives a high ionic conductivity—a key reason battery and capacitor researchers pay attention. Organic synthesis labs have grabbed it as a green alternative, sidestepping the volatility of old-school solvents. Still, it won’t catch fire like alcohols do, and leaves you less worried about fumes meeting a stray spark. That brings an extra layer of safety—no small concern given lab accident statistics from the American Chemical Society, which points to solvents as a leading cause of fires and injuries.

Utility, Risks, and Future Steps

The list of applications keeps growing: from electrolytes in new battery tech to reaction media where a chemist needs stability and selectivity. Pharmaceutical researchers see potential for dissolving or separating challenging compounds. This flexibility comes with real-world downsides. Few long-term toxicity studies exist, and the environmental profile gets murky, particularly with the fluorinated parts. Wastewater treatment systems can struggle to break these down. My experience in working with ionic liquids tells me that people underestimate disposal. Disposables pile up, and what looks like a safer replacement for traditional solvents can cause headaches downstream.

Designing greener versions matters. Researchers are now tweaking imidazolium-based liquids to reduce the environmental impact. Some swap out the trifluoromethyl sulfonyl group for bio-based alternatives. Regulators at the European Chemicals Agency track these substances, keeping a close eye on emerging research so risks get managed. Proper handling—using gloves, goggles, and fume hoods—cannot be skipped, even for something that seems less toxic than regular lab fare. Students sometimes get lulled into carelessness when liquid spills show no immediate harm, but repeated exposure or unchecked disposal does leave a mark.

Solutions and Sound Choices

Smart choices kick off with better lab protocols. Training on safe disposal and personal protective gear stops accidents before they start. Researchers keep innovating, searching for ionic liquids that deliver performance with minimal harm. Funding should back long-term studies, not just applications. Stronger collaboration between industry and regulators ensures risks get identified early. Every lab using these compounds plays a role in shaping how society handles new chemical technology—responsibility doesn’t end at bench level.

Looking Past the Fancy Name

Anytime I hear about ionic liquids like 1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, memories of time in the university research lab come to mind. You see a lot of intimidating chemical names thrown around, but storing a substance like this isn’t about fear—it’s about respect for its properties. Many people working in labs day in and day out develop a gut sense for where danger lurks, especially when dealing with materials packed with fluorine and sulfur like this one.

Know the Risks Before You Open the Bottle

The big risk with imidazolium-based ionic liquids comes from their reactivity and the by-products that could form if you leave them exposed or stored poorly. Mismanagement could mean degradation, which threatens the safety of everyone in the facility, not just the person working with the substance. While this class of materials has a reputation for being “green” because of their low vapor pressures, that’s no excuse for sloppiness. Leaks or chemical breakdowns cost more than just dollars—they chew up your time and undermine experimental results.

Temperature and Light: Enemies of Laziness

From years in the lab, one thing stuck: never trust a substance left out on the bench to behave the same way as one kept cool and dark. 1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide can start shifting properties if hit by light, oxygen, or fluctuating temperatures. Sure, suppliers always remind people to store these liquids in tightly sealed containers and recommend a consistent temperature, preferably below 25°C. But in reality, I’ve watched careless storage—sun peeking through a window, fridge doors left ajar—ruin perfectly good samples. There’s enough literature confirming thermal degradation creeps in above room temperature for many ionic liquids.

Water: Stealthy Saboteur

One overlooked point: moisture sneaks in fast. Even though many imidazolium salts stay liquid well below 0°C, water contamination changes viscosity and can set off hydrolysis. Silica gel packs inside the storage container help a lot. Personal experience says: don’t just toss these chemicals in the back of a fridge—dedicate airtight desiccators for them, especially if you’re working in humid climates. Regular checks on humidity indicators inside those desiccators pay off much more than rushing through your end-of-day routine. The research from chemical suppliers and academic journals all call for low humidity as a non-negotiable condition.

Label, Log, and Never Get Lazy

No one ever regrets keeping a meticulous notebook. Log the opening date, original manufacturer, and even the storage location for every bottle. As inventory ages, knowing how long a sample has sat on the shelf can prevent reliance on degraded chemicals that could lead to unsafe reactions or unreliable data. I once witnessed a colleague pour months into an experiment, only to discover a slow contamination problem started from using a compromised sample. Waste like that hurts, and it’s avoidable with regular checks and discipline.

Community Over Individual Habits

If your team stays on the same page—with regular reminders, shared best practices, and clearly marked storage zones—the risks drop dramatically. Training goes further than warning signs or laminated safety posters. Bring the whole team into the conversation about chemical management. Share stories of things that worked, and own up to mistakes. I found that keeping an open line made everyone more observant and accountable.

Final Word: Care Earns Trust

Proper storage isn’t just about ticking a regulatory checkbox. It’s about building an environment where you trust that what you reach for will behave as expected. That trust, between worker and chemical, grows from habits you don’t rush through—clear labels, airtight containers, cool and dry spaces, and honest team conversations. That’s the backbone of a safe, productive laboratory experience.

A Fresh Face in Solvent Science

Scientists have always searched for ways to separate, modify, or preserve compounds without damaging them. This is where ionic liquids step up, with 1-Allyl-3-Ethylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide—often called AEIm-TFSI—taking a special place. Some may see this mouthful and picture another lab curiosity, but the unique blend of high thermal stability, low volatility, and impressive solvation power attracts attention for a reason. With a track record in research, AEIm-TFSI is not just another ingredient—it stands out for mixing and dissolving difficult substances, all while being engineered to tolerate some pretty tough conditions.

Moving Chemistry Beyond Water

Traditional solvents come with flammability or toxicity, and many can’t even touch certain materials. People want options that cut out fire hazards and health risks, especially in chemical synthesis, catalysis, and extraction. AEIm-TFSI opens new doors. Take catalysis: chemists chase higher yields and lower waste streams, but regular solvents turn the reactor into a headache. AEIm-TFSI allows metal complexes to stay dissolved, even at higher temperatures, which keeps reactions humming for longer and with fewer impurities. In my time spent in a university research lab, the shift from old-school solvents to ionic liquids like AEIm-TFSI did more than just reduce our headaches over spill containment or fume exposure—it sparked new ideas and let us push boundaries on reactions we’d shelved years before.

Cleaner Processing in Industry

Industry looks for consistency and cost savings. AEIm-TFSI delivers in areas like cellulose processing and extraction of rare-earth metals. Ordinary solvents often can't untangle plant fibers or wrestle metals out of hard ore. That’s no small thing, considering how much of the electronics world runs on rare metals. AEIm-TFSI enables people to grab these resources at lower temperatures and without the clouds of toxic byproducts seen with some old chemical processes. Studies from the American Chemical Society reveal ionic liquids make biomass breakdown more efficient, turning waste into useful materials, including biofuels and biodegradable plastics.

Greener Batteries and Smarter Electronics

Battery design challenges engineers wherever lithium-ion reigns. Safety, stability, and performance top the wishlist. AEIm-TFSI’s resistance to heat, outstanding ionic conductivity, and non-flammable nature put it in line as a strong candidate for modern electrolytes. Researchers at Argonne National Laboratory found batteries using these salts could keep running at higher voltages without the leaks or fires linked to standard electrolytes. Imagine cars able to travel longer between charges or phones less likely to overheat. That’s practical progress for anyone depending on reliable electronics—or for the engineers who build them.

Finding Balance: Safety and Sustainability

With all these upsides, the conversation must include safety and environmental impact. Ionic liquids often trade one problem for another, so ongoing research checks toxicity, recyclability, and life-cycle costs. There’s push for greener, more biodegradable options, but AEIm-TFSI’s story shows what’s possible when researchers and industry collaborate. Focused investment into greener chemistry and public-private partnerships can smooth the path from academic discovery to industrial mainstay.

The Real Stakes

AEIm-TFSI brings new tools to labs, workshops, and factories. Its value shows in chemical efficiency, safer workplace policies, and reduced environmental footprints. The hard work comes down to widespread testing, regulation, and honest assessment of what works and what needs fixing. Experience with these materials proves innovation isn’t just about what’s new—it’s about what works better in the world people actually live in.