1-Allyl-3-Ethylimidazolium Chloride: Shaping the Future of Ionic Liquids

Historical Development

Ionic liquids came out of left field in the late twentieth century, and nobody in the chemical world could ignore their impact. Bench chemists trying to ditch traditional volatile organic solvents ended up gravitating toward salt pairs that stayed liquid at room temperature—and 1-Allyl-3-Ethylimidazolium Chloride, often known by trade names like AEImCl or [AEtIm]Cl, became a staple for good reason. Development took off as researchers looked for new electrolyte materials, alternative solvents, and catalytic media. The imidazolium cation itself had punk energy for experimentalists—a modular core, easily tweaked, and pretty sturdy. Adding an allyl group helped open doors in functionalization, while the ethyl enhanced physical stability. By the turn of the millennium, journals tracked a spike in citations: this molecule could handle heat, pressure, and a lineup of industrial processes that left weaker solvents in the dust.

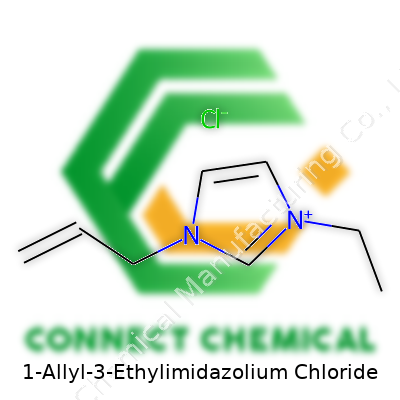

Product Overview

1-Allyl-3-Ethylimidazolium Chloride delivers a blend of stability, tunability, and user-friendliness. Commercial formulations pop up as white powders or viscous liquids, depending on storage conditions and the purity achieved. Users look for clarity, fast solubilization, and freedom from contaminants such as halide impurities or water content above 0.1%. Markets get it packaged in sealed amber bottles. Most vendors print chemical formula (C8H13ClN2), molar mass (172.66 g/mol), and batch-specific purity north of 98% right on the container.

Physical & Chemical Properties

Folks compare its thermal stability to that of established salts. Melting point hovers between 50 to 60°C, depending on microenvironment—an unusually low temperature range for what is essentially a salt. Water and polar solvents absorb it like a sponge; it doesn’t mix with ethers or hexanes. Electrochemical behavior shows a nice, wide potential window. Conductivity changes sharply with temperature, so meticulous users keep an eye on lab conditions. Viscosity sits higher than classic solvents, slowing down stirring but boosting ionic transport when used in batteries or capacitors.

Technical Specifications & Labeling

A detailed label for 1-Allyl-3-Ethylimidazolium Chloride spells out CAS number 141920-33-0, UN listings if shipped internationally, shelf life, recommended storage (desiccator, cool room, away from strong oxidants), as well as barcodes for traceability. Manufacturing specs list potassium ferrocyanide test for halide, Karl Fischer titration for water content, and a certificate of analysis. Users in regulated industries appreciate the absence of residual heavy metals and organic contaminants, which can show up in low-grade alternatives.

Preparation Method

Most synthetic routes start by alkylating imidazole with ethylchloride, then turning the resulting 1-ethylimidazole into 1-allyl-3-ethylimidazolium through electrophilic substitution with allyl chloride. Aqueous or organic solvents—frequently acetonitrile or acetone—make it easy to separate product from starting material. Washing and repeated recrystallization strip off unreacted intermediates. In a pinch, ion-exchange resins help eliminate trace inorganic impurities, giving a sharper melting profile and cleaner NMR spectrum. Scale-ups use stirred tank reactors with water cooling to handle the exothermic stages—nobody wants runaway reactions at this price point.

Chemical Reactions & Modifications

By tweaking the imidazolium core or the substituent groups, chemists swap in functional tails to boost selectivity or alter solubility. In the lab, the allyl group stands out as a handle for click chemistry, radical additions, or even metathesis, letting users graft on specialty side chains. Chloroalkylation reactions start with this base, yielding whole libraries of ionic liquids for specific catalysis or material science experiments. Combining with metal salts or Lewis acids sparks more reactivity than the sum of parts. Cations hold up under mild acidic or basic conditions, crucial for iterative modifications in combinatorial chemistry or pilot plant expansion.

Synonyms & Product Names

Ordering gets confusing if you don’t watch for synonyms: 1-Allyl-3-ethylimidazolium chloride, AEImCl, [AEtIm]Cl, and sometimes, N-ethyl-N-allylimidazolium chloride. Some catalogues use alternate spellings for the imidazole ring or drop the numerical position designators. Users in pharma, coatings, advanced energy storage, and academic labs know the different trade names but trust IUPAC nomenclature for cross-checking.

Safety & Operational Standards

Researchers know ionic liquids like this one can be less flammable than organics—but they don’t treat it like table salt. Eye and skin irritation pops up in MSDS data, and ventilation stops headaches in confined spaces. For plant-scale use, splash goggles, lab coats, and gloves come standard. Inhalation risk runs low at ambient temperature, but fine dust deserves respect. Spills respond well to simple absorbents; disposal routes favor incineration or vested hazardous waste collection. Regulatory compliance lines up under REACH, TSCA, and safety standards that keep accidental release below local occupational exposure limits.

Application Area

Batteries, polymer electrolytes, catalysts, cellulose processing—every sector seems to find new tricks for 1-Allyl-3-Ethylimidazolium Chloride. In lithium-ion and sodium-ion energy storage, it gives greater thermal and cycling stability without solvent emissions. Metallurgists use it to dissolve tough ores or leach rare elements—including lanthanides—at moderate temperatures. Synthetic chemists exploit it for phase-transfer catalysis and green solvent applications, swapping out chlorinated solvents for environmental wins. Researchers in bioprocessing use it to dissolve cellulose or chitin, prepping feedstocks for bioplastics and advanced textiles. In the world of separation science and analytical chemistry, it modifies stationary phases for new chromatographic selectivity or acts as an extraction medium for polar analytes.

Research & Development

More funding keeps pouring into investigations of ionic liquids, with this compound among the favorites. Teams experiment with the molecular backbone, engineering versions for improved biocompatibility, lower cost, and higher conductivity. Spectroscopic studies dig into solvation structures and intermolecular interactions, with plenty of supercomputer modeling to nail down transfer mechanisms. Engineers fine-tune process controls to move from bench to pilot plant, designing continuous-flow reactors that minimize waste and maximize yield. Patents target specialized catalysts based on this backbone—pharmaceutical companies see opportunity in asymmetric synthesis and greener active pharmaceutical ingredient production.

Toxicity Research

Early optimism about ionic liquids suffered a gut check once toxicity studies ramped up. 1-Allyl-3-Ethylimidazolium Chloride doesn’t evaporate into the air, but aquatic toxicity flags started to wave as researchers found persistence in water and trouble for some aquatic organisms. Chronic toxicity studies pointed to membrane disruption for certain bacteria and algae, though vertebrate models found only moderate toxicity at high doses. Biodegradability lags behind simpler organic solvents, giving environmental scientists a cautionary tale. Risk assessment teams focus on better waste stream management, alternative disposal techniques, and new derivatives that break down more quickly in nature.

Future Prospects

With energy storage and green chemistry still racing ahead, this molecule isn’t fading from view. Raw material price swings and evolving eco-standards will shape how much manufacturers rely on it. Researchers aim to unlock biocompatible and fully degradable versions, with the goal of using ionic liquids as recyclable, cradle-to-cradle solvents and electrolytes. Advances in process intensification could lower cost barriers that keep this compound from industrial volume. Lessons from toxicity research keep pressure on the field to produce safer, smarter ionic liquids, pushing the frontier forward with every conference and patent.

The Chemical in the Lab and Beyond

Anyone who has spent even a little time in a chemistry lab knows that some substances pack a surprising punch in certain processes. 1-Allyl-3-Ethylimidazolium Chloride, with a name only a chemist could love, falls into this rare category. Its claim to fame rests on its status as an ionic liquid—one that stays liquid even at room temperature. While water-based solutions dominate everyday thinking, this ionic liquid holds properties few common solvents offer.

Back in graduate school, I spent countless hours wrestling with substances that just wouldn’t dissolve or unwanted side reactions from water or organic solvents. Ionic liquids like 1-Allyl-3-Ethylimidazolium Chloride became a welcome alternative. Their stability and near-zero vapor pressure mean that chemists breathe a bit easier in the lab, figuratively and literally. This chloride variant has carved out niches in a handful of complex tasks, especially in processes where traditional solvents hit a wall.

A Problem Solver in Green Chemistry

One of the main draws for this compound is its roll in green chemistry. Traditional volatile organic compounds can harm health and release plenty of pollutants into the atmosphere. 1-Allyl-3-Ethylimidazolium Chloride offers a safer route for many reactions that demand strong solvents but cause fewer environmental headaches. Several studies—especially the work coming out of universities in Germany and Japan—show that these ionic liquids can help break down stubborn cellulose or separate reusable catalysts, making industrial chemistry a bit less toxic.

Take lignocellulosic biomass. Most people wouldn’t think twice about that pile of sawdust or crop waste left behind after harvesting. Yet, unlocking its value presents a challenge. Here’s where this ionic liquid plays a crucial part: it breaks down the tough bonds of cellulose and hemicellulose, enabling industries to produce bioethanol or other renewable products more efficiently. Without solvents like this one, the dream of sustainable fuels stumbles on slow, inefficient processing.

Pushing Forward in Material Science

Electrochemistry is another field catching on to this quirky liquid. High ionic conductivity and thermal stability mean batteries and capacitors enjoy a stable, low-risk electrolyte. Early work using 1-Allyl-3-Ethylimidazolium Chloride as a glucose sensor medium pointed to reliable performance, even after several cycles. In my own postdoc work, experiments using this ionic liquid as an extraction medium for rare metals ran smoother, with higher yields than with any traditional approach. This aligns with reports from industry, backing up what I experienced firsthand.

Potential Issues and Steps Forward

Like many new tools, this compound doesn’t solve every problem on its own. Cost still acts as a barrier compared to standard solvents, especially for companies locked into small profit margins. Toxicity profiles look better than for many traditional solvents, but these are not entirely benign. Research from ECHA points to low volatility and manageable risks with proper handling, but a careless spill can still cause harm. Labs and factories pushing ahead with ionic liquids must keep building safer protocols into routine work.

Growth in the use of 1-Allyl-3-Ethylimidazolium Chloride hinges on scaling up production efficiently and refining its reuse in closed-loop systems. Scientists and engineers have a job ahead, cracking the code for mass manufacture and recycling. With every hurdle passed, that pile of seemingly useless biomass, those tricky separations, and those hard-to-power batteries come a bit closer to a better future—thanks in part to obscure compounds like this one.

A Closer Look at Molecular Makeup

Chemistry woven into the daily grind shapes many corners of industry, science, and even things at home most folks take for granted. One molecule making ripples lately bears the name 1-Allyl-3-Ethylimidazolium Chloride. Rolling off the tongue, that’s a mouthful, but breaking it down helps take away some of the mystery.

Starting with the core, this compound has an imidazolium ring. That’s five atoms joined together: three are carbon, two are nitrogen, pieced together to form a stable backbone. It’s got a plus charge on the ring, so the whole structure feels a bit lopsided if you imagine charges as weights on a scale. Attachments hanging off this ring give the compound its unique identity. At one spot (the 3-position on the ring), an ethyl group sits—just a two-carbon chain, nothing fancy there. Swing over to the 1-position, an allyl group branches out. This arm stretches to three carbons, with a double bond tucked between two of them, a simple yet lively feature that brings reactivity.

Now, the chloride comes in—as a counterion, carrying a negative charge to balance things out. It doesn’t stick to the structure like super glue, but it holds the whole entity together energetically, completing the story in water or many organic solvents.

Why This Structure Matters

Each bit of this molecule serves a clear purpose. That ring—tough and reliable—works as the anchor, a pattern seen across thousands of “ionic liquid” compounds. The ethyl and allyl groups on the ring tune the material’s behavior. That double-bonded allyl group can jump into reactions, link to other materials, or help dissolve a motley crew of chemicals.

Chloride, as a counterion, gets attention in labs because it’s easy to handle. It keeps the compound from gumming up or reacting in strange ways during storage or industrial processing. Changing the groups around the imidazolium core lets chemists fine-tune melting points, solubility, and how well it works at dissolving substances—from cranky metal salts to stubborn organic dyes.

Practical Implications and Future Choices

Not all ionic liquids wear the same shoes, but 1-Allyl-3-Ethylimidazolium Chloride stands out in processes like catalysis and electrochemical devices. In my experience, seeing a salty liquid at room temperature that won’t evaporate quickly or catch fire easily makes a difference, especially where safety matters. This chemical doesn’t just serve as a solvent. It nudges reactions forward or sometimes protects sensitive compounds working their way from the lab bench to the bottle.

Safety and environmental questions often surface. Many traditional solvents foul up groundwater or air. Ionic liquids, including this one, promise less volatility and fewer nasty fumes, cutting back on the downstream health and ecological mess. Still, not every “green” label lives up to the hype. Just because something doesn’t evaporate doesn’t mean it disappears safely in nature. Long-term studies tracking breakdown products, bioaccumulation, and exposure risks offer a smart path forward before scaling up use. As a chemist, mixing practicality with caution seems to produce the best results.

Smart Choices for Industry and Academia

As demand for efficient, less hazardous processes grows, the right chemical structures hold real sway. 1-Allyl-3-Ethylimidazolium Chloride carries both familiar strengths and open questions. For those working with complex processes, knowing exactly how its atoms arrange and move shines a light on better technique, safer work, and fewer regrets when the day ends.

Looking at 1-Allyl-3-Ethylimidazolium Chloride in the Lab

Spending hours among chemicals in research labs brings an appreciation for how little attention people sometimes give to lesser-known substances. 1-Allyl-3-ethylimidazolium chloride lands in that bracket. Its name rarely sparks fear. Yet, anyone used to wearing gloves and holding MSDS sheets would treat this stuff with respect.

Understanding What We’re Dealing With

This compound comes from the family of ionic liquids, a group that packs interesting properties. They don’t catch fire like many solvents, nor do they evaporate easily. People value them in labs working on catalysis, separations, and advanced batteries. Ionic liquids often get billed as "green" options—this reputation grows out of their low volatility and low flammability. Still, being hailed as "green" doesn’t erase basic risks that come from ignorance or carelessness.

Toxicity and Health Concerns

Research points out that some imidazolium-based ionic liquids show toxicity to both humans and aquatic life. For instance, certain members of this chemical family damage cell membranes. One scientific review in Chemosphere from 2017 reports even modest doses harming zebrafish and algae over time. While data on 1-allyl-3-ethylimidazolium chloride itself remains patchy, chemical structure matters. Experience says it’s best not to assume a “green” solvent is any safer for skin contact or breathing than traditional solvents like acetone.

Chemical suppliers flag the risk of irritation if it touches eyes, skin, or the respiratory tract. I’ve watched colleagues rush to the eyewash after an accidental splash with similar ionic liquids. Several ionic liquids can trigger headaches or lung irritation from short exposure. Chronic effects aren’t yet well mapped. With government safety rules often trailing behind fast-moving lab trends, waiting for ironclad evidence isn’t practical if you hope to stay healthy.

The Role of Safe Lab Practice

Experience taught me early: don’t let the reputation of a new “eco-friendly” chemical blur your judgment. A few years back, a friend tried working with a new ionic liquid in an open flask—he trusted the hype. That day ended with a mild chemical burn on his wrist. The lesson stuck. Treat every unfamiliar bottle like it hides a hazard. Safety goggles, a lab coat, gloves, and good ventilation make a difference. Never skip the fume hood if dust or mist might form. Most importantly, don’t work alone.

Disposal also deserves attention. Ionic liquids have a nasty habit of persisting in water systems. Research from the Journal of Hazardous Materials highlights challenges in breaking them down with standard wastewater treatments. I learned to collect all cleanup waste for special disposal, despite disposal costs or how “benign” a chemical initially looked on paper. Consider future environmental impact instead of convenience.

Better Safety Moves

No chemical comes with zero risk. Anyone handling 1-allyl-3-ethylimidazolium chloride benefits from a healthy dose of skepticism. Seeking detailed information before use, checking the latest studies, and using basic personal protection gives everyone a better chance to avoid unnecessary accidents. If lab managers invest in regular safety briefings and push for up-to-date training, fewer surprises crop up. Respect for the unknown doesn’t slow research—it lets it keep moving.

Why Storage Matters for This Chemical

1-Allyl-3-Ethylimidazolium Chloride doesn’t belong in the same category as common table salt or vinegar. This ionic liquid lands in the toolkit of researchers, lab technicians, and chemists because it brings unique solutions for challenging problems. Still, handling it without care leads to headaches nobody wants. Just like perishable foods need the fridge, certain chemicals require special treatment to last and stay safe.

Practical Storage Conditions

Routine habits in the lab often come with good reasons. For this compound, it’s wise to avoid exposure to air for long stretches. Lids snap shut with purpose to prevent moisture creeping in. Water in the atmosphere brings unwanted reactions over time, which can change how this chemical works. Not all containers fight off humidity equally, so glass or high-grade plastic with a reliable seal works best.

Stable temperatures make a real difference. Heat speeds up movement at the molecular level, coaxing unwanted changes or breaking down what you need. Storing this chemical at room temperature—somewhere between 20°C to 25°C—keeps things predictable. Avoiding places near hot equipment or windows matters, and nothing beats the reliability of a cool, shaded shelf. Cold storage isn’t always needed unless long-term holding enters the picture, but rapid temperature swings make contaminants harder to avoid.

Keeping Chemicals Safe From Light and Contamination

Some chemicals throw tantrums when exposed to sunlight. For compounds like 1-Allyl-3-Ethylimidazolium Chloride, limiting exposure sounds boring but really pays off. Dark, opaque containers peel off another layer of risk, like sunblock for sensitive skin. Most labs use brown glass, and for good reason: direct light means energy, and energy sometimes launches reactions you didn’t ask for.

Other issues can sneak in during day-to-day use. Every time someone opens a bottle, airborne particles have the chance to settle in. Keeping storage separate for different chemicals stops cross-contamination in its tracks. If you have handled acids or bases earlier, washing hands and using fresh gloves prevents sticking residue from mixing.

Why Materials and Labels Matter

Not all plastics stand up to ionic liquids. Metal containers corrode or react over time, so sticking to proven glass or chemical-resistant plastics beats repair costs later. Labels sometimes get overlooked, especially over years of accumulation. Marking clear names, hazard signs, and the date of opening goes further than most people realize. It only takes a moment to update, and that attention to detail can stop confusion down the line.

Handling and Emergency Prevention

Anyone who’s spent long hours in a lab knows accidents happen fast. Spills mean more than a simple cleanup if the chemical touches skin or gets in the eyes. Heat-resistant gloves, safety goggles, and a proper waste bin keep incidents rare. After use, returning the bottle to its shelf—never leaving it out on benches—cuts down both clutter and risk.

Proper ventilation matters, especially if using larger amounts or working for long periods. Unpleasant odors or fumes signal trouble in the making. If something leaks, having a spill kit on hand instead of tucked away in storage can make the difference between a scare and a reportable incident.

Building Safer Labs and Smarter Habits

Storing 1-Allyl-3-Ethylimidazolium Chloride properly doesn’t take fancy equipment—it just requires routine, clear labeling, and a little patience. Safe storage prevents spoiled experiments, and more importantly, it protects the hands and eyes of everyone in the lab.

The Roadblocks in Chemical Sourcing

Finding specialty chemicals like 1-Allyl-3-Ethylimidazolium Chloride often feels like an inside game in academic labs and industrial R&D. You search for an online supplier, dig through forums, and compare catalogues listing purity percentages, chemical forms, and minimum order quantities. There’s a sense of pressure—when research deadlines or grant milestones loom, any delay feels magnified. This isn’t just about making a purchase. At the university, we sometimes had to wait weeks after requesting quotes, sometimes just receiving news that the compound was out of stock.

Safety and Legitimacy

This chemical is an ionic liquid, showing up in electrochemistry, catalysis, and materials science. Before placing an order, double-check the supplier’s reputation. Trusted vendors like Sigma-Aldrich, TCI America, or Alfa Aesar provide thorough documentation. Yes, prices climb higher at these companies, yet you get peace of mind: certificates of analysis, full SDS details, and robust batch tracking. Smaller chemical suppliers occasionally offer lower prices, but cutting corners on sourcing high-purity compounds sets up real risks. A bag labeled “1-Allyl-3-Ethylimidazolium Chloride” from a shady vendor feels like playing roulette in a dark room.

Quality and Purity Matter

My earliest experience with ionic liquids in a teaching lab came with a painful lesson. A cheap batch failed to dissolve a simple dye. Turns out, the impurity led the experiment awry, wasting an entire afternoon and costing the lab far more than the tiny savings looked like on paper. Chemical impurities don’t post warnings. Only through solid vendor documentation do you actually know what’s in a vial. Suppliers often specify “research grade” or “analytical grade.” For most lab experiments, aim for 97% purity or higher.

Regulation and Shipping Issues

Shipping restrictions trip up even experienced buyers. This chloride salt isn’t classified as especially hazardous in most countries, but chemical control laws tighten all the time. Some suppliers ship only to universities or companies, never private addresses. Expect to show institutional credentials. A procurement office in a regulated environment will insist on a purchase order, checking the chemical’s status under local and federal rules. Some countries, like China, require filing for an import license. Missing papers can stall a delivery indefinitely.

Verifying Supplier Credibility

Not every company offering chemicals online does real business. Look for clear business addresses, open communication about the material’s origin, and reliable customer reviews. Real scientists in peer-reviewed journals often cite their sources: if a chemical vendor appears in published research, you gain a bit more confidence.

Solutions for the Struggling Buyer

If you struggle to buy 1-Allyl-3-Ethylimidazolium Chloride because of location, pricing, or regulation, look into chemical exchanges or try collaborating with a larger institution. Sometimes, buying collectively through a consortium or reaching out to other research groups helps meet high minimums and splits shipping costs. Speak to your institution’s procurement team. They often know which vendors follow compliance, and some already hold dormant contracts. Never overlook the benefit of science community networks; a colleague might have surplus or a batch ready to share.