1-Allyl-3-Ethylimidazolium Hexafluorophosphate: Deep Dive Into a Versatile Ionic Liquid

Historical Development

Synthetic chemistry shifted gears in the late 20th century with the discovery of room-temperature ionic liquids. 1-Allyl-3-ethylimidazolium hexafluorophosphate emerged as one of those pivotal breakthroughs. Early investigations embraced it as an answer to the limitations of volatile organic solvents. Labs around the world started experimenting with these salts, not just for the sake of novelty but driven by practical goals like safer handling and superior performance in catalysis and extractions. By the time researchers in Europe and Asia took up the challenge, the understanding deepened, linking crystal structure, functionalization, and actual performance — not just on paper but in actual synthesis routines.

Product Overview

Chemists recognize 1-allyl-3-ethylimidazolium hexafluorophosphate by its clear or pale yellow oily appearance, easily flowing at room temperature. The imidazolium core, functionalized at distinct N-positions, delivers stability and tunability. Its reputation lies in compatibility with countless organic compounds. Compared to related salts, it holds its own — not showing excessive viscosity or hygroscopic behavior, making it favorable for bench-level manipulations. Across research catalogs, this compound lands in specialty solvent ranges, often next to other tailored ionic liquids.

Physical & Chemical Properties

This liquid displays a density clinging close to 1.2 g/cm³, and it resists decomposition until well above 250°C. Water worry? Only a trace. Solubility tends to depend on the counterion, but this hexafluorophosphate version rarely absorbs much unless pressed under humid air for days. Its conductivity fits squarely in the moderate range — a plus for electrochemistry applications. The allyl group brings a gentle reactivity, ready for chemical modification under the right catalytic conditions; in my own glovebox work, I've found moisture control speeds up purification steps.

Technical Specifications & Labeling

Bottles carry purity labels pushing past 98% for most commercial sources. Detailed certificates point out trace metals, halide levels, and residual solvent. Researchers chasing high-precision work read these metrics the way a painter assesses colors before working — each impurity introduces its own interference. Storage recommendations read straightforward: sealed containers, dry atmosphere, shaded from light if possible. You catch flammable and irritant pictograms, though the real-life hazard profile rarely matches the pictures unless you attempt open-flame experiments.

Preparation Method

Practical routes start from 1-ethylimidazole, undergoing alkylation with allyl halides. After stirring this two-phase mixture and neutralizing with base, the imidazolium salt precipitates. Addition of hexafluorophosphoric acid swaps out halide for PF6-, leaving behind the familiar oily ionic liquid after thorough washing and vacuum drying. I've watched glassware turn sticky from trace product, underlining the importance of slow, patient washing protocols to avoid yield loss. Certain synthetic tweaks, such as alternative solvents or carefully controlled temperatures, improve yield for those willing to experiment.

Chemical Reactions & Modifications

This compound invites personalization. Chemists run alkene metathesis straight onto the allyl group, attach polymer backbones, or insert functional handles. The imidazolium ring tolerates mild electrophilic attack, and robust anion exchange opens up novel combinations by using alternative fluorinated anions. Its chemical backbone shrugs off most oxidants under ambient conditions. In more advanced projects, I’ve mixed it with palladium catalysts and watched reaction rates jump, a testament to its effect on metal-centered transformations.

Synonyms & Product Names

Catalogs might show names like 1-allyl-3-ethylimidazolium PF6 or [AEIm][PF6], although systematic IUPAC nomenclature gets longwinded in practical use. Each vendor carries its own label translation, but they converge on the shorthand AEImPF6. Cross-referencing ensures a chemist doesn’t order a mismatched anion and accidentally scramble reaction results.

Safety & Operational Standards

Researchers handling this ionic liquid follow routine glove and eye protection rules. It does not present acute toxicity by skin, but accidental splashes sting, so rinsing quickly alleviates discomfort. Inhalation risk runs low due to minimal volatility. Some environmental chatter circles the long-term persistence of PF6- anions; wastewater disposal demands neutralization or specialized collection, echoing lab best practices for minimizing environmental footprint. Our own group uses splash-resistant gloves and conducts all manipulations in fume hoods, aligning workflow with recommended operational standards.

Application Area

1-Allyl-3-ethylimidazolium hexafluorophosphate lends itself to a surprising variety of tasks. As a solvent, it stabilizes reactive intermediates and allows for cleaner separation of products — a detail I’ve seen firsthand in organometallic complexes and nanoparticle stabilization. The high ionic conductivity opens doors in battery electrolytes and electrochemical cells, while its robust compatibility with CO2 established it in green chemistry circles for capturing gases or driving recycling cycles. Catalysis, separation science, and thin-film technology all feature reports leveraging this liquid’s distinct combination of solubility and chemical stability.

Research & Development

The scientific literature on this compound keeps growing. Academic labs test new applications, pushing performance in energy storage and designing new catalytic regimes. Many efforts focus on tuning the molecular structure for specialized tasks: swapping the allyl for other chains, or exploring greener synthesis that avoids halogen waste. My own stint in a catalysis project saw us experiment with this ionic liquid as both modifier and medium, revealing measurable effects on reaction selectivity. Its pivotal role in accelerating research on alternative solvents and sustainable processes continues to attract government and industry funding.

Toxicity Research

Early animal testing signaled moderate toxicity at high doses, mainly due to the PF6- anion rather than the imidazolium core itself. Recent cell studies look for chronic effects, especially with prolonged environmental exposure, as ionic liquids sometimes resist breakdown in wastewater. I keep a cautious eye on regulatory guidance because risk profiles change as more evidence surfaces. Environmental scientists urge careful studies on aquatic persistence, suspecting that fluorinated anions could accumulate if unchecked, prompting calls for greener alternatives or recovery procedures in manufacturing.

Future Prospects

As research teams keep searching for adaptable and sustainable materials, compounds like 1-allyl-3-ethylimidazolium hexafluorophosphate remain under the spotlight. Promise shows in electrochemistry, continuous-flow synthesis, and even bio-inspired catalysis. Real advances will come from bridging laboratory innovation with scalable, low-impact production pathways. Any widespread use in green tech or advanced manufacturing needs sound safety data and proven protocols for reclaiming or recycling spent ionic liquids. As the conversation about chemical sustainability grows louder, this compound stands out for practical versatility, provided researchers keep tightening safety and waste management controls as new data rolls in.

The Building Blocks: Structure and Formula

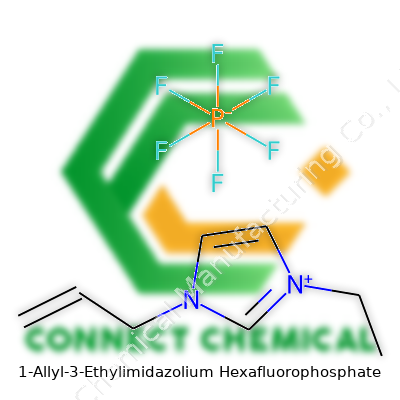

Taking a look at 1-Allyl-3-Ethylimidazolium Hexafluorophosphate feels a bit like peering through a microscope at modern chemistry’s creative side. On paper, this compound carries the formula C8H13N2·PF6. What’s distinctive here is the combination of an organic cation and an inorganic anion.

The core structure centers around the imidazolium ring: a five-membered aromatic ring with two nitrogen atoms at positions 1 and 3. At the first nitrogen, an allyl group (–CH2CH=CH2) reaches out. On the third nitrogen, you find an ethyl group (–C2H5). This pairing creates a positively charged cation known for its stability under a range of conditions. The hexafluorophosphate anion (PF6−), on the other hand, sits nearby with a cluster of six fluorine atoms crowding around a phosphorus atom like fans around an athlete.

Why the Details Matter

Every chemist I meet has a story about solvents and electrolytes that stumble because they either evaporate off in seconds or chew through the flask they’re poured into. That’s where molecules like 1-allyl-3-ethylimidazolium hexafluorophosphate stand out. Their “ionic liquid” nature makes them both thermally stable and non-volatile. You spill the regular stuff in a lab, and it vanishes before you even grab a mop. This one puddles on the bench until you clean it up. In real-world research, using a liquid with these traits means fewer fire drills and less wasted money.

People often overlook how the arrangement of just a few atoms can flip an entire field. Green chemistry gets a shot in the arm from ionic liquids like this because the classic problems—flammability, nasty fumes, tedious separation—start to fade. The imidazolium ring acts like a reliable anchor, while that hexafluorophosphate brings resistance against harsh acids and oxidizers. That makes it possible to tackle tough chemical reactions that solvents like acetone or toluene just can’t handle.

Challenges and Paths Ahead

Safety isn’t always a guarantee just because something sounds scientific. There’s no ignoring the issue that comes with fluorinated compounds; they don’t break down easily in the environment. While hexafluorophosphate salts shine in performance, researchers need to keep digging for more biodegradable or less persistent alternatives. My own experience with electronic waste showed me how fast these byproducts end up in rivers and soils after the ambitious projects wrap up.

Cost can also be a talking point. Not every school or startup gets easy access to these so-called “designer solvents” because purification remains pricey and complicated. Scaling up production without cutting corners on purity still poses a headache for manufacturers. Open-source research and collaborations between universities and industries could help bring the cost curve down, and possibly push safer-by-design ionic liquids into mainstream use.

What the Future Could Look Like

Electrochemistry and battery research are just waking up to what compounds like 1-allyl-3-ethylimidazolium hexafluorophosphate can offer. By customizing the alkyl groups on the imidazolium ring, teams can tune properties like viscosity, melting point, and even color. Real breakthroughs will happen when safer anions replace hexafluorophosphate but keep all the sought-after traits. Chemists live for moments like those—turning today’s complex formulae into tomorrow’s reliable tools, all while caring about the world outside their fume hoods.

Diving Into Its Real-World Uses

Among ionic liquids, 1-Allyl-3-ethylimidazolium hexafluorophosphate (AEImPF6) pops up in labs and industries that keep our world running. This isn’t your everyday salt – it’s a liquid at room temperature, which means it offers up all kinds of interesting abilities. In my own work around green chemistry and materials science, I see AEImPF6 stand out because it shakes up old ways of doing things, especially where traditional organic solvents fall short.

Electrochemistry and Batteries

Electrochemical applications aren’t just a side note – they define where AEImPF6 grabs headlines. Lithium-ion batteries store power in almost every gadget, and their future depends on better electrolytes. This ionic liquid brings chemical stability, high ionic conductivity, and a wide voltage window. That means batteries can last longer, run safer, and push energy density further. Just as importantly, AEImPF6 doesn’t go up in flames like some classic organic options, so it adds a layer of safety. Studies from the Journal of Power Sources and Electrochimica Acta published research showing AEImPF6-based electrolytes raise battery performance and lifetime, especially under high voltage.

Catalysts and Green Chemistry

Chemical synthesis leaves a heavy mark on our environment. The search for solvents that don’t pollute or evaporate easily ain’t new, but AEImPF6 adds a fresh chapter. It comes with almost no measurable vapor pressure. That means fewer emissions in both pilot projects and industrial scales. In the lab, chemists use AEImPF6 to speed up reactions that struggle in water or traditional solvents. This property opens doors for greener chemical manufacturing. The Environmental Protection Agency and top green chemistry journals highlight ionic liquids as key to helping heavy industry cut back on volatile compounds. My experiences mirror that: cleaner air in the lab and less hazardous waste.

Materials Science Applications

In the field of polymers and advanced materials, AEImPF6 acts as both solvent and reaction medium. For instance, synthesizing conductive polymers like polyaniline or polythiophene used in electronics needs solvents that don’t react or break down under voltage. AEImPF6 handles these tasks easily, letting researchers fine-tune material properties for the latest sensors and flexible devices. Universities in Asia and Europe report boosts in electrical conductivity and processing safety when developing “smart” fibers and films, much of it credited to the stability this ionic liquid brings.

Cleaning Up Tough Jobs: Extraction and Separation

Industrial processes produce plenty of hard-to-remove pollutants. AEImPF6 joins the fight in extraction and separation, grabbing metals, dyes, and other tough pollutants from wastewater. Its chemical makeup attracts a range of ions and organic molecules, boosting selectivity in separating out toxins. Real-world projects in mining and chemical plants have shown recovery rates shoot up while downstream waste drops – not just hype, but measured in cleaner discharge and lowered cost.

Making the Most of AEImPF6

As someone working with both startups and established labs, I see AEImPF6 push teams to test new ideas, but hurdles remain. Cost and possible toxicity mean we need clear safety protocols and recycling systems. Researchers across Europe and North America now look into sustainable production and end-of-life solutions, keeping this ionic liquid on the right side of both innovation and environmental responsibility. The future likely includes bio-based or recyclable versions, letting science keep pace with society’s green demands.

Why Ionic Liquids Need Special Care

Ionic liquids often show up in labs as slick, futuristic replacements for traditional solvents. People get excited about them because they don’t evaporate easily, don’t burn like gasoline, and work in a variety of chemical reactions. This all sounds great. But, in practice, storing ionic liquids brings up some problems few notice at first. The wrong steps can hurt your results and, sometimes, your team.

The Real Risk in Day-to-Day Work

I’ve seen folks treat ionic liquids like they treat most solvents—throw them in any old bottle and call it a day. That sort of habit costs labs money and credibility. Some ionic liquids suck up water from the air. Others corrode certain plastics. A sealed glass bottle and a clean, dry hood make a world of difference. A cool cabinet away from sunlight prevents slow breakdown over time. Metal, unless the label says it’s safe, often sparks unwanted reactions—so I keep those far apart.

Humidity Ruins More Than You Think

Humidity isn’t just a theoretical hazard. Over the years, I’ve seen entire batches of expensive ionic liquids go from crystal clear to hazy soup because someone forgot the desiccator. One group lost days of work to a single seal left open for ten minutes. Even small moisture levels can shift the properties of these liquids, especially in sensitive syntheses. Your recipes rely on water-free conditions for a reason. Anhydrous storage, silica gel packs, and regular checks cut down on those scary “why didn’t this work” moments.

Labels Are Not Just for Bureaucrats

Clear labels meet safety requirements, but they also save nerves when multiple batches line the shelves. Mixing up a hydrophobic ionic liquid with a hygroscopic one? That error takes you back to square one. For every bottle, I apply bold, clear names, the date received, any additives, and the storage precautions needed. More than once, this habit sidestepped a disaster at 3 a.m. during late experiments. Good records help everyone stay on track, especially when teams rotate or appointments change. GHS-compliant labels mean everyone stays on the same page during emergencies.

PPE: Beyond the Basics

Some labs get casual after one too many routine weeks. Ionic liquids often feel safer than their flammable cousins, but they still pose unknown risks. New chemistries come with gaps in toxicology. I never let anyone handle these without gloves and goggles. If a bottle breaks or leaks, splash goggles and a lab coat keep irritating burns off the skin. I’ve read studies showing some ionic liquids slip through latex, so I use nitrile. Good ventilation—the overlooked hero—catches stray fumes, which might sneak under the radar with mild odors but nasty effects after hours of exposure.

Building Better Habits

The science keeps evolving. Researchers still unearth strange side reactions from light, trace metals, or oxygen. Staying ahead means learning from small slip-ups before bigger mistakes can unfold. I see successful labs lock in routines—double-checking seals, reviewing chemical compatibility, rotating stocks, and keeping fresh spill kits ready. Companies like Sigma-Aldrich recommend reviewing updated MSDS sheets before each project, as new data shows up quickly. Small steps like these protect budgets, results, and, most importantly, the people who work with these advanced materials every day.

Looking Beyond the Scientific Name

People hear the name 1-allyl-3-ethylimidazolium hexafluorophosphate and probably picture a chemistry lab and sealed vials with strict warning labels. These ionic liquids show up in places like batteries, catalysis, and chemical separations—jobs that create performance demands, but also safety concerns. The chemical's real risk profile often gets lost behind its long name and promise of being a “green solvent.” I've read enough lab reports and MSDSs to know a long name doesn’t make a substance any safer or more dangerous by default. Real risks depend on how it’s used, what it contacts, and who handles it.

The Hazards Become Clear Under Scrutiny

Many ionic liquids do reduce fire risk and don't always evaporate into the air, which helps a lot in keeping air exposure down. Hexafluorophosphate is a different animal. It sounds clean-cut, but I learned early on that fluorinated chemicals can run into issues of persistence. Once spilled or released, they stick around. In a lab environment, I’ve seen the sharp focus on PPE, air handling systems, and waste treatment. Eye, skin, and respiratory protection are not suggestions for good reason. Some ionic liquids get absorbed right through gloves if those gloves weren't chosen wisely.

A deeper look at toxicology data matters. Imidazolium cations can irritate skin and eyes. Swallowing or inhaling some versions of these chemicals hasn’t had a ton of study, but related compounds have led to organ concerns in animal tests. The anion, hexafluorophosphate, isn’t harmless either. It reacts with water and acids to form hydrofluoric acid, a substance with a wicked bite. Even the idea of “non-flammable” solvents sounds less comforting knowing that, in a fire, they might break down to release toxic gases like hydrogen fluoride or phosphorus oxides. That's not something you'd want to breathe.

Long-Term Environmental Questions

After laboratory use, disposal can grow into a headache. Standard wastewater treatment doesn’t do much against persistent chemicals. Hexafluorophosphate ions can move through soil and water for a long time. No one wants that drifting into drinking supply or building up in river ecosystems. Regulatory lists still review these types of chemicals, but the EPA and European agencies keep tightening rules for anything persistent and fluorinated. Producers rarely volunteer everything about long-term risks, so it falls on researchers and workers to dig up data and act cautiously.

Managing Risks and Responsibility

There's pressure to use safer chemicals. Some labs asked whether swapping imidazolium hexafluorophosphate with less persistent options made sense. It gets tricky—replace one problem, find another—but the growing body of research does help inform decisions. Thorough ventilation, containment, and spill readiness should be the rule. Pouring anything like this down the drain should stay off the table.

A better solution starts with transparency. Companies that make and sell these chemicals need to provide clearer, more complete data. Training users—whether in big industries or small labs—makes a world of difference. All involved need genuine buy-in for responsible handling and waste management. The trend toward greener chemistry looks promising, but it shouldn’t sweep aside real safety conversations. Sometimes high-tech “solutions” need more scrutiny before calling anything non-hazardous.

Getting Clarity on Purity

Anyone who spends much time dealing with chemicals—whether for research, medicine, or even baking—ends up talking about purity. For most people, though, purity sounds like one of those fuzzy buzzwords you see on product labels: pure sugar, pure vitamins, pure gold. It actually means something very specific, especially once you leave the grocery store and enter the lab.

Understanding Typical Purity Levels

Lab-grade chemicals often come in percentages, like 99% or 99.9%. Pharmaceutical companies, electronics manufacturers, and food producers all deal with these numbers daily. Take sodium chloride, the classic kitchen salt. The stuff in your shaker can hit about 99% pure, but medical or scientific applications go out of their way to ensure fewer strange minerals end up with the final product—usually at 99.5% or higher. Electronics manufacturers need even higher grades. Semiconductors, for example, use silicon so pure that trace metals get measured in parts per billion rather than percent.

Gold gets sold as 24-karat when it’s basically pure (about 99.9%), but jewelry makers will mix in copper or silver for strength, and then mark the ratio. Pure water (used in IV drips or microchip cleaning) gets a similar treatment, with tests that pick up even the faintest contamination.

People sometimes ask: Why all the fuss? Even a tiny impurity can send chemical reactions off course, mess with medicine formulas, or fry a whole batch of chips. In research, one poorly measured impurity will throw off years of work. Customers trust that suppliers know what they’re doing, but a mistake here can mean real danger—think toxic elements in children’s toys or additives in supplements that shouldn’t be there.

Verifying Purity: No Room for Guesswork

There’s a saying in quality control: Trust, but verify. I remember my old college chemistry teacher warning us that even store-bought vinegar wouldn’t measure exactly 5% acetic acid. Most of the time, verification means running a specific test in a professional lab. Spectroscopy, chromatography, and titration rank among the most reliable techniques. Gas chromatography separates out all the chemical components, so even a tiny unwanted visitor shows up. Spectroscopy uses lasers or electromagnetic waves to spot impurities by the way materials react.

Companies serious about transparency issue certificates of analysis for each batch they sell. These certificates list out purity by percentage, test methods, and even the dates tested. Anyone can check batch or lot numbers on packaging; a quick scan or email to the supplier brings up traceability info—sometimes even downloadable lab reports.

Real-life failures have carved these practices into stone. In 2008, contaminated heparin (a blood thinner) shipped worldwide because a supplier skipped standardized, traceable analysis steps. Casual errors like these cost lives. That’s why anyone buying high-purity chemicals— drug manufacturers, breweries, solar panel builders—relies on approved methods to double-check claims.

Improving Verification: The Next Steps

No one wants recalls or negative headlines. Some organizations push for stronger regulations, wider transparency, and better cross-industry agreement on what counts as “pure enough.” Using blockchain to track chemicals from origin points to finished barrels promises less fraud. Home testing kits lately help with basics, like water purity, but don’t touch the accuracy found in a proper lab.

As technology gets better and customer standards keep climbing, the bar for purity rises higher. That’s a good thing. Whether for safety or innovation, one lesson sticks with me: never take numbers at face value. Ask to see proof, and make sure experts stay in the loop.