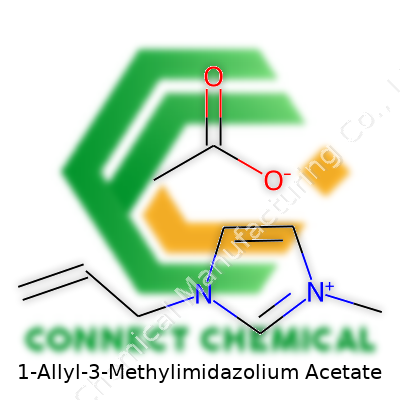

1-Allyl-3-Methylimidazolium Acetate: Insight and Impact

Historical Development

Ionic liquids have gone through waves of discovery and rediscovery over the last few decades. The rise of 1-allyl-3-methylimidazolium acetate speaks to a quiet revolution in solvent technology. In the late twentieth century, researchers looked for greener, more versatile fluids that break away from volatile organics. Imidazolium-based options, especially those carrying the acetate anion, answered this call. Early work around 2002 put a spotlight on acetate derivatives, which open doors to cellulose dissolution and make way for a new world in processing biomass. Universities and institutes, chasing efficiency and sustainability, zeroed in on this ionic liquid’s uncommon mix of stability and reactivity. The ripple effect spread from basic research benches into pilot-scale trials, creating a demand for reliable, scalable production and standardization along the way.

Product Overview

1-Allyl-3-methylimidazolium acetate belongs to a group known for handling demanding chemical environments. The compound consists of an imidazolium ring with an allyl and a methyl group, paired with an acetate anion. This combination shows considerable promise in tackling tough separation tasks and advanced material preparations. Unlike conventional solvents, it resists evaporation, even under heat, which reduces operational hazards and waste. That means labs and businesses searching for higher performance in cellulose processing, catalysis, or polymer synthesis won’t have to settle for tradition-bound limits. The trade name sometimes appears as AMIM Ac, AMIMAc, or simply as its full chemical name in catalogs around the world.

Physical & Chemical Properties

In a beaker or flask, this ionic liquid stands out with a pale-yellow, viscous liquid appearance. Its melting point dips well below room temperature, making storage and use straightforward, even without temperature control. Density sits between 1.08 to 1.12 g/cm³, depending on purity, while its low vapor pressure almost eliminates inhalation risks during handling. Dissolving power gives it a strong edge, especially with biopolymers like cellulose and chitin. The acetate anion, by design, brings both basicity and nucleophilicity, which means this liquid can participate in or even catalyze some reactions. It’s hydrophilic, mixing easily with water and some polar solvents, but it resists breaking down in air. Compared to halide-based analogs, acetate versions avoid corrosion issues and create fewer downstream compatibility headaches.

Technical Specifications & Labeling

Reliable supply chains matter, especially for researchers and industrial users. Reputable producers supply 1-allyl-3-methylimidazolium acetate at purities of 98% and above, backed by standard COA documentation. Labels must spell out the batch, production date, and shelf life. Residual water content stays below 0.5% for most premium batches, because extra water cuts into cellulose solubility and can hinder some catalytic uses. Viscosity and color often serve as rough quality checks—samples that darken or thicken beyond spec signal contamination or degradation. Common packaging includes dark glass bottles or HDPE containers, fitted with tamper-evident seals. Clear hazard symbols for irritancy, chemical exposure, and environmental concerns line up with legal requirements and lab best practices.

Preparation Method

Getting a reliable batch starts with careful synthesis. Most producers follow a two-step approach: quaternization and ion exchange. Methylimidazole reacts with allyl chloride, typically in acetonitrile under nitrogen, forming 1-allyl-3-methylimidazolium chloride. Washing, drying, and then metathesis with sodium acetate or silver acetate brings on ion exchange, leaving behind the chloride ion and pairing the imidazolium cation with acetate. Extraction and vacuum drying drive off residual solvents, and tight purification steps guarantee product stability. Each step needs close monitoring—side products from incomplete reactions or over-alkylation throw off performance, so analytical confirmation with NMR, IR, and mass spectrometry rounds out the process.

Chemical Reactions & Modifications

On the bench or on the plant floor, users value versatility. In its raw form, 1-allyl-3-methylimidazolium acetate acts as a solvent, but it also jumps into the action as a reaction medium for transesterifications, cellulose derivatizations, and polymerizations. The imidazolium core can take further substitution if special electronic or steric properties are needed. The allyl group can itself join radical or photoinitiated polymerizations. Some labs even explore functionalizing the acetate with isotope labels for tracing in bio-based systems. Blending with other ionic liquids tailors viscosity, polarity, or solubilizing power, expanding what’s possible for specialty applications. Chemical stability under light, air, and mild acids sets it apart in day-to-day use, though strong bases or reactive metals raise the risk for unwanted by-products.

Synonyms & Product Names

In catalogs and literature, you’ll see a string of names: AMIM Acetate, 1-allyl-3-methylimidazolium ethanoate, AMIM Ac, and even just 1-allyl-3-methylimidazolium acetate. CAS number 65501-24-8 usually marks reputable supplies. Synonyms reflect a mixture of IUPAC and practical industrial naming, so cross-checking ensures users order or reference the exact product. These differences in naming often pop up across patent filings, research articles, and supplier lists, so a careful eye becomes vital, especially when comparing data or planning synthesis.

Safety & Operational Standards

Keeping people and equipment safe takes experience and diligence. 1-Allyl-3-methylimidazolium acetate does not give off strong fumes, but skin contact can cause irritation or sensitization. Nitrile gloves, eye protection, and lab coats work as standard barriers. Spills dry slowly and turn sticky, so quick cleanup with absorbent pads and soap cuts handling hassles later. Closed storage in a low-light, cool room stretches shelf life. Disposal follows local rules for organic chemicals—not every drain or incinerator handles ionic liquids the same way. Ventilation helps, mostly for those handling large volumes over extended projects. Regular hazard reviews and proper signage keep mishaps rare.

Application Areas

Looking around research and industry, this ionic liquid unlocks value in places where old-fashioned solvents stumble. In pulp and paper labs, it dissolves high-molecular-weight cellulose, enabling feedstocks for biofuels, engineered fibers, and novel polymers. Chemists lean on it during organic synthesis, where it carries out reactions without contributing volatile emissions, supporting a shift toward greener chemistry. In biorefinery setups, it prepares lignocellulosic biomass for enzymatic hydrolysis, driving down the cost and energy demand tied to extraction and conversion. A few niche fields pursue it as a supporting electrolyte in electrochemistry, where stability and conductivity count for more than just ease of use. This compound’s edge comes from outperforming chlorides or traditional salts in selectivity for target products, as proven in peer-reviewed studies and industrial case reports.

Research & Development

Curiosity and competition both feed the growing literature on AMIM Acetate. Universities and private labs dig deeper, investigating how this ionic liquid lines up against classic solvents in dissolving, processing, and modifying cellulose. Recent multi-year projects compare yields, process energy, and recyclability for bioplastics manufacture, putting hard numbers to claims of sustainability. On the academic side, groups document molecular interactions using NMR and mass spectrometry, painting a clearer picture of how solubility and reactivity start at the nano level. Pilot projects in Europe and Asia show stepwise replacement of more toxic or energy-hungry solvents, turning lab curiosity into plant-scale proof. Downstream, attention shifts to lifecycle and circular economy impacts, opening up pathways for truly sustainable material flows as green chemistry policies take hold globally.

Toxicity Research

Understanding risk starts with hard data, not guesses. Early toxicity screens revealed this compound causes mild irritation in direct skin and eye contact, but its chronic effects—once diluted in process effluent—draw attention too. Bioassays on aquatic organisms register modest, not severe, ecosystem effects compared to halide alternatives. Sub-lethal endpoints, like enzyme inhibition and growth impacts in microorganisms, provide further insight for water treatment specialists. Research keeps building in this area: a few publications from the last five years highlight slower degradation in soil and water, yet see less persistence than some fluorinated solvents. Regulators in the US and EU call for more comprehensive data, especially as larger-scale applications multiply. Responsible companies now run routine ecotoxicity screening on their effluent, and some already invest in closed-loop water treatment to avoid releasing any ionic liquid residue.

Future Prospects

Looking ahead, interest in 1-allyl-3-methylimidazolium acetate shows no sign of stalling out. International pushes for decarbonization and bio-based manufacturing keep demand high for powerful yet environmentally manageable solvents. Researchers probe its blending behavior, seeking even better solutions for recalcitrant feedstocks. Startups and established firms alike target closed-system recycling, aiming to recapture value from used liquid without sacrificing quality. As regulations tighten on solvent emissions and waste, companies that already switched to ionic liquids like this one report fewer compliance headaches and better long-term feasibility. Curiosity will shape what’s next: whether it’s advanced composite processing, smart drug delivery, or new battery chemistries, the search for more intelligent, agile liquids keeps this compound in the innovation spotlight. Every advance here stands to multiply across sustainable chemistry, making 1-allyl-3-methylimidazolium acetate a name worth learning and understanding for years to come.

Pushing the Boundaries of Biomass Processing

Every year, mountains of plant material get left behind after harvest. Breaking down tough cellulose fibers into simpler sugars sets the groundwork for new types of fuels, plastics, and chemicals. This is where 1-allyl-3-methylimidazolium acetate steps in with its unique ability to dissolve cellulose—something water and many other chemicals simply cannot achieve. Researchers and industry players use this liquid as a solvent to unlock plant cell walls. A study from the Journal of Physical Chemistry highlights how this compound swells and splits apart cellulose, turning stubborn straw, wood chips, or even newsprint into liquid or gel forms. These mixtures allow enzymes to reach the inner sugars for bioethanol or biodegradable plastic production. By making this initial step efficient, more communities can turn local waste into something valuable, not just something to burn or landfill.

Shaping Green Chemistry Solutions

Our world faces a plastics problem, and the hunt for greener manufacturing methods becomes more urgent. As someone who’s worked in a lab with ionic liquids, I’ve seen how traditional solvents can pollute waterways and endanger workers. 1-allyl-3-methylimidazolium acetate brings a new mindset. Chemists use it to replace harsh chemicals like dimethyl sulfoxide or chloroform in many synthesis reactions. This liquid’s low volatility and high solvating power mean fewer toxic fumes and less impact on workers’ lungs or ecosystems. Whether making specialty plastics, resins, or pharmaceuticals, more labs consider this alternative as both safer and more efficient.

Boosting Material Science Innovation

Scientists keep finding new uses in the field of materials. By dissolving cellulose, chitin, or raw silk, this liquid shapes new fibers, films, and gels. These materials show promise for everything from wound dressings to strong, light packaging. Researchers mix cellulose dissolved by this ionic liquid with other biopolymers, crafting blends with surprising toughness or flexibility. This would be nearly impossible using regular solvents. At conferences I’ve attended, university teams show off how even simple filtration membranes or packaging wraps can gain strength without heavy use of fossil fuels—all thanks to ionic liquids.

Improving Enzyme Reactions in Industry

Industrial biocatalysis feeds on innovation. Enzymes often struggle to access large molecules or need an optimal environment. Many companies now use 1-allyl-3-methylimidazolium acetate as a reaction medium. Studies show it promotes enzyme activity in certain cases, especially where water hinders efficiency. This can cut costs in making flavors, fragrances, and fine chemicals. A good example comes from biofuel startups tweaking the preparation of cellulose for enzyme conversion, reporting up to 30% higher yields after switching to this solvent.

Looking Ahead

Adapting new chemicals comes with hurdles. Cost still limits the spread of ionic liquids to big industrial scales, and disposal or reuse remains under study. Still, as more eco-friendly factories rise, alternatives like 1-allyl-3-methylimidazolium acetate become too promising to ignore. Steps forward could include better recycling systems for used solvents, and partnerships that lower the price point. Investment in research offers a realistic shot at reducing pollution and creating more sustainable materials—making this compound more than just another laboratory curiosity.

Why Purity Levels Directly Impact Performance

Growing up, my dad worked in water treatment. He understood that purity wasn’t just a buzzword, but a matter of safety and reliability. If a chemical in his plant fell short of its purity claims, pipes corroded, filters clogged, and workers faced real risk. That memory sticks with me whenever purity levels come up. It’s not only about technical specs—it’s about trust in how that product is going to perform, day after day.

What Specifications Really Mean

A purity level on a label should always match rigorous testing. That number—whether it says 99.5%, 98%, or something lower—is more than a sales pitch. It tells you how much of the main ingredient you’re actually getting. Anything lower could mean extra contaminants hitching a ride, and those can really throw off the intended effect. For instance, in pharmaceuticals, a small impurity can turn a confidently prescribed medicine into something far riskier. In electronics, a slight deviation in material specs can lead to short circuits or full-on device failures. Results like this make me double-check technical sheets before recommending or using any product.

How Standards Shape Expectations

Major industries use strict standards for a reason. Groups like USP, ISO, or ASTM don’t just publish rules—they create trust networks. When I worked in a quality control lab, every shipment arrived with its certificate of analysis. If numbers didn’t match the agreed range, we sent the batch back without hesitation. That data made our decisions fast and gave us confidence in the product’s behavior. Without that baseline, troubleshooting would turn into shooting blindfolded at night.

The Hidden Costs of Ignoring Real Specifications

Some businesses try to save money with cheaper substitutes, ignoring subtle changes in purity. That shortcut rarely pays off in the long run. Upfront cost savings vanish the moment a product underperforms—about as much use as a car that stalls on a busy highway. Customers notice quickly if a paint pigment loses vibrancy or a cleaning agent leaves behind stains. Over time, this erodes brand reputation and drains resources fixing problems that clearer specs could have avoided in the first place.

Solutions That Actually Work

Buyers should always ask for full specs and traceable proof of testing before placing any order. A reliable supplier never hesitates to provide detailed purity data, including impurities down to the parts per million. Lab transparency builds trust and ensures both sides can track down issues if anything shifts during storage or shipping. These steps can be reinforced by spot-checking new batches internally. Even small, regular audits keep everyone honest.

Clear, plain-language specs also help users avoid mistakes during application. Not every buyer is a scientist, and dense jargon can lead to confusion or accidents. Explaining what those numbers mean, and why the values matter, helps users get the most out of every package.

As new regulations emerge, transparency will only become more important. Suppliers who take the time to educate, rather than just sell, set themselves apart in a crowded marketplace.

Knowing the real purity and specs of any product doesn’t just protect the bottom line. It’s about setting clear expectations and building long-term trust. That’s how industry relationships last—one verified shipment at a time.

Getting Real About This Ionic Liquid

Anyone working with chemicals knows a fancy name doesn’t mean a simple job. 1-Allyl-3-methylimidazolium acetate, despite being a go-to ionic liquid for cellulose processing, acts with the same unpredictability and risk of anything else in the lab that could sting your skin or cloud up your lungs. Building habits around safe handling isn't about ticking boxes, but keeping yourself and your work area out of trouble.

Staying Out of Harm’s Way

I’ve noticed that wearing safety goggles and gloves seems like chemical handling 101, but it’s easy to slip into old habits, especially when a substance looks as harmless as a bottle of slightly viscous water. This compound won’t show off with a strong odor—nothing to remind you that it can mess with your skin, eyes, and sometimes lungs if misty vapor gets airborne. Nitrile gloves stand up well to most ionic liquids, and lab coats keep splashes where they belong—off your arms and torso.

People skip fume hoods if the stuff isn’t pungent. Don’t. Some acetates release irritating vapors, especially when heated. If you don’t want to test how cough-inducing or lingering those vapors feel, keep all open work under a properly running sash with good air draw.

Looking After the Bottle and the Bench

It may not explode the way some reactive chemicals do, but this liquid soaks up moisture in the air much faster than you’d expect. I’ve watched someone lose an expensive sample in just an afternoon by leaving a cap loose. The stuff pulls in water so fast that the concentration and, as far as the experiment is concerned, the purity get wrecked. Dry atmosphere matters. Tighten bottles before you move away from the bench, and, if your lab owns a desiccator, store it in there to keep air contact to a bare minimum.

Leaving a substance like this in a scrap polyethylene squeeze bottle is asking for trouble. Manufacturers usually offer it in tightly sealed amber or high-density containers for a reason—UV light and oxygen have a way of starting unwanted side reactions, which can slowly degrade quality or even produce unknown byproducts. Brown glass tucked away from sunlight and strong lights keeps things predictable.

The Facts: Safety Data and Real-World Incidents

No one enjoys sifting through safety data sheets, but that’s usually where facts hit hardest. 1-Allyl-3-methylimidazolium acetate carries health warnings: irritant, possible organ toxicant if inhaled or ingested, maybe harmful for the aquatic environment. In my circle, spills just once led to a sticky bench covered with ruined notebooks, and it took days to actually wipe away the last traces. Quick action with absorbent pads and plenty of water helps, but better yet—work in trays or over disposable liners.

Most injuries with liquids like this emerge from small, repeated exposures. Skin dryness, mild rashes, or headaches happen before the more dramatic stuff. Professionals in industry often install spill kits and eye-wash stations close by and run annual training, and every school or startup with less funding deserves the same mindset—even if the room looks calm, the risks aren’t zero.

Solutions That Stick: Simple Steps to Safer Labs

Label everything you decant. Sharpie fades, so relabel as needed. If you don’t recall what’s in the flask, assume it needs a glove and a fume hood. Regular auditing of chemical stores and disposal areas uncovers damaged bottles before they develop leaks. Most importantly, keep a culture where people admit to spills or near-misses early. Catching a mistake together prevents repeating it alone.

The bigger picture isn’t just about following the playbook—it’s about respecting the science and not letting a shortcut today create a disaster tomorrow. With a little discipline, chemicals like 1-allyl-3-methylimidazolium acetate become valuable tools, not accidents waiting to happen.

Choice Drives Buying Decisions

Walking into a store, most people expect options. That’s not just about brand or style, but also about getting the right amount for a specific need. Families often need bigger packs to cut down on trips, while someone living alone might prefer a smaller version. This simple point keeps coming up in everyday shopping. If you like cooking at home, you know how frustrating it is to find a seasoning only offered in jumbo tubs or a sauce that only comes in a single-use sachet. It often leads to either waste or not buying at all.

Why Offering Different Sizes Makes Sense

Companies often roll out a single size or package to test the waters. If demand grows, different sizes usually follow. Consumers notice this; complaints about wasted product or budget woes pile up when there isn’t enough flexibility. When toothpaste started coming in travel tubes, it solved two problems—folks could bring it on flights, and those with smaller budgets could spread out spending. Studies from the National Retail Federation show customers actually spend more in total over time when offered right-sized packaging.

Environmental and Economic Effects

Every extra bit of packaging means more trash. On the other hand, packing everything in bulk sizes can lead to spoilage, especially with perishable items. I’ve tossed out half-full bags of salad or boxes of crackers, just because I couldn’t finish them in time. It stings a bit, both for the wallet and the trash bin. More packaging size options help shoppers buy what they need and cut down on waste. A 2022 report from the Environmental Protection Agency pointed out that reducing packaging waste isn’t just good for the planet; it lowers disposal costs and helps keep store shelves tidy too.

Barriers Brands Face

Not every producer finds it easy to split products into more sizes. Machinery and warehouse changes cost money. Small companies often can’t afford the setup costs until there’s enough pressure from bigger retailers. It happens a lot with imported goods; imported snacks in only one or two sizes because that’s what the exporter can handle. The retail supply chain runs smoother with fewer packaging types. Too many options, especially for slow movers, tie up storage and clog restocking. This is where careful market research before launching extra sizes makes a big difference.

Looking at Solutions

One solution comes from collaboration. Retailers and producers sharing data can spot patterns in what shoppers actually use and want. Grocery delivery services do well with flexible packaging—there’s a reason meal kits come with single-use spice packets or precise portions of cheese. Customization with digital printing and modular packing machines has started lowering the barrier for offering variety, cutting time and costs on the production line.

Labeling transparency helps, too. It’s not just about selling the sizes, but letting people easily spot differences—number of servings, price per ounce, or recyclability. I’ve noticed local stores testing “bulk wall” concepts, letting you scoop your own amount, which works especially well for things like coffee or rice. It puts the power in your hands, literally.

Building Trust through Options

Offering different quantities gives shoppers more say in what they take home. It shows the company isn’t only chasing bigger margins but paying attention to how people live and spend. Over time, that practical respect builds loyalty. In markets where budgets tighten and awareness around waste is growing, having packaging variety doesn’t just meet a demand; it reflects a genuine understanding of real-world habits.

The Realities of Working Around Hazardous Chemicals

I remember walking into my first high school chemistry lab, feeling the weight of the safety goggles on my face. Our teacher told a story about a student who ignored the rules and ended up at the nurse’s office with burns. That stuck with me. Chemicals can seem harmless if you don’t see an immediate reaction, but the danger often hides in the invisible: fumes, skin contact, even the dust in the air.

One key lesson I picked up: never trust your eyes alone. The most dangerous exposures happen before you realize it. Acids, bases, solvents—many of them act fast. Some effects take years to show up, like cancers linked to repeated formaldehyde exposure. It’s not about overreacting. It’s about respecting the risk and knowing what you’re dealing with. Even the everyday routine—mixing, storing, cleaning up—matters.

Simple Steps That Make a Real Difference

Chemical safety depends on a few basics: know the substance, use the right protective equipment, and respect proper storage. Reading the Safety Data Sheet (SDS) isn’t just red tape. The SDS tells you if a chemical irritates skin, causes lung damage, or explodes in sunlight. It lays out fire risks and gives first aid steps. Skipping it can be the difference between a scare and an emergency.

Gloves, goggles, and lab coats keep the skin and eyes protected from splashes and spills. Good ventilation matters; fumes shouldn’t fill the room before you realize it. I’ve seen people open bottles of volatile liquids too close to their face, take a breath, and regret it. Respect the smell—your body reacts quickly to strong chemicals, sometimes with headaches or worse. Use fume hoods if you have them, and never lean right over an open container.

Storing chemicals away from heat sources, sunlight, and incompatible materials also prevents accidents. I once saw a storage closet where acids sat next to bleach. One leaky bottle could have meant toxic gas. Double-check labels and keep things organized. Lock up anything with a skull and crossbones, especially if kids share the space. Even the best precautions slip if tired hands grab the wrong bottle at the end of the day.

The Bigger Picture: Long-Term Exposure and Environmental Impact

Many people worry about the big accidents—the fires, explosions, chemical burns. Chronic exposure gets less attention, but it does real harm. I worked once with someone who’d handled solvents for decades, and only then learned his persistent cough came from years of breathing fumes. Employers sometimes cut corners or assume old habits are safe, but that’s not an excuse. It’s up to everyone to insist on safe conditions.

Chemical spills don’t just endanger the user. Runoff finds its way into water, dust coats the air, and small leaks add up. Proper disposal means following local laws, not pouring liquids down the drain or tossing powder in the trash. I’ve had to clean up spills more than once. Every time, I wished someone had just labeled things better or checked the lids.

Personal Responsibility and Speaking Up

Chemical safety only works when everyone on the team pays attention and speaks up. If something smells off, feels odd, or looks dangerous, trust your instinct and check. Self-advocacy matters. I’ve watched new lab techs hesitate to report a near-miss. Instead of blaming mistakes, encourage questions and double-checks. Safe habits pay off for years to come.