1-Allyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: In-Depth Perspective

Historical Development

The journey of ionic liquids in modern science began in the late 20th century, but the family of imidazolium-based salts, particularly 1-Allyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, quickly attracted chemists once their practical advantages became clear. Labs in Europe and Asia moved past clunky, moisture-loving salts and found the chemical flexibility offered by a compound like this could sidestep many headaches of classical solvents. Along these years, incremental advances mirrored what people encounter with new tools: starting out with excitement, facing a few doubts about real-world reliability, then embedding the tool into research routines. Ever since the turn of the millennium, the compound kept shaping investigations into green chemistry, electrochemistry, and polymer engineering with increasing regularity.

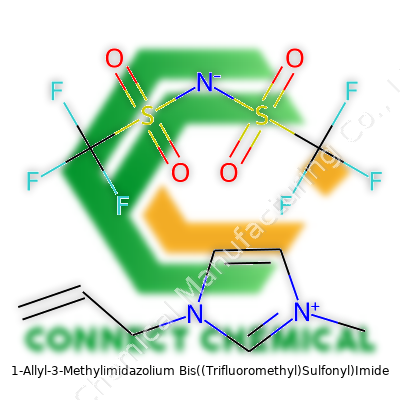

Product Overview

In basic terms, this compound anchors itself among the more versatile ionic liquids, described by chemists as a room-temperature salt with a knack for dissolving organic and inorganic materials. Taking one look at its structure—an imidazolium ring carrying both an allyl and methyl group counterbalanced by a hefty bis((trifluoromethyl)sulfonyl)imide anion—shows it doesn’t belong to the classic concept of salts as gritty crystals. Unlike sodium chloride, this chemical remains a colorless to pale yellow liquid under normal lab conditions, unlocking creative solutions for problems that once seemed unsolvable due to rigidity in solvent selection.

Physical & Chemical Properties

Physical characteristics shape the reputation of every solvent in the lab. This compound stands out with high thermal stability, a melting point far below freezing, and surprisingly low vapor pressure. These qualities mean open containers won’t fill rooms with noxious fumes or dry out over a weekend. The density hovers around 1.3 g/cm³, and viscosity varies based on water content, though it usually flows somewhat more slowly than water. Chemists value the electrochemical window, often measuring upwards of 4 volts, which means engineers and battery researchers can push charge and voltage ratings well past traditional electrolytes. Its hydrophobic character makes it ideal when water-based reactions must be completely avoided, though the imidazolium core still allows solubilizing a range of organic molecules.

Technical Specifications & Labeling

From a practical standpoint, commercial products give clear data on water content (kept below 0.05% for sensitive applications), electrical conductivity, and halide content. Most suppliers classify the compound as ≥99% pure, and include batch analysis for trace metals, chloride, and other aperiodic contaminants. Labels display full IUPAC nomenclature, chemical formula C10H11F6N3O4S2, molecular weight 419.34 g/mol. Storage instructions always stress that containers need protection from humidity and strong light sources, usually sealed with thick Teflon disks or crimped metal caps.

Preparation Method

Synthesis typically starts with 1-methylimidazole, treated with allyl chloride under continuous stirring and mild heat to form 1-allyl-3-methylimidazolium chloride. Next comes a metathesis step, mixing the crude chloride salt with lithium bis((trifluoromethyl)sulfonyl)imide in water or an organic solvent, vigorously agitated to drive ion exchange. The target compound floats out as a distinct phase, which is then separated, extracted, and vacuum dried to yield the pure ionic liquid. Each stage handles scrupulous washing with deionized water to keep halide levels low, since leftover chloride diminishes both electrochemical and physical purity.

Chemical Reactions & Modifications

The reactive allyl group on the imidazolium ring opens paths for further modifications. Researchers exploring polymer chemistry have used this moiety for covalent attachment to polymer chains or surface immobilization onto nanoparticles. Beyond that, the solvent properties enable metal-catalyzed transformations—cross-couplings, cyclizations, even reduction reactions—where other solvents would falter due to instability or volatility. By fine-tuning the cation or replacing the anion altogether, chemists keep discovering new versions adapted to specific reactivity challenges.

Synonyms & Product Names

Vendors ship the product under several labels. Names include 1-allyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide, AMIM-TFSI, or simply [AMIM][NTf2]. Pharmaceutical catalogs and chemical distributors favor CAS numbers for clarity: 324050-44-6. This diversity in naming shows the breadth of inter-industry adoption, ranging from research-grade chemicals in 5-gram vials to bulk-premium material in stainless steel drums.

Safety & Operational Standards

Even though ionic liquids avoid flammability and vapor hazards of organic solvents, handling this compound means respecting its ability to interact biologically and chemically. Laboratory standards call for full skin and eye protection, standard fume hoods, and proper respiratory safeguards. Safety Data Sheets warn against prolonged contact and inhalation, and disposal follows hazardous waste protocols to prevent environmental release, given the presence of fluorinated anions known to linger in ecosystems.

Application Area

Field engineers and bench scientists integrate 1-allyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide across electrochemical devices, batteries, and carbon capture experiments. I’ve seen research teams replace volatile organic solvents in pharmaceutical synthesis, benefiting from improved selectivity and reduced emissions. In materials development, the compound acts as a solvent for cellulose and chitin processing, letting researchers bypass the harsh acids and bases once required for biomaterial work. The battery industry leans on it for lithium ion conductivity and chemical stability, which has already shaped prototypes for safer, longer-lasting energy storage devices.

Research & Development

University labs and industry research groups run parallel paths advancing both the chemistry and the applications of this ionic liquid. Academic journal articles detail tuning the cation or anion to fit narrow application windows, like improving CO₂ selectivity or raising energy efficiency in electrolysis cells. Collaborative partnerships with battery manufacturers and biopolymer startups showcase how quickly lab findings shift into practical tools, replacing petrochemical solvents with lower volatility, lower toxicity options. In my own work with graduate researchers, we always end our materials testing with side-by-side comparisons of ionic liquids, giving honest feedback to suppliers about real-world purity and performance versus slick marketing copy.

Toxicity Research

Early hype around ionic liquids painted them as harmless, but recent studies forced a rethink. Tests on aquatic organisms have documented moderate to high toxicity at low concentrations, especially due to persistent, bioaccumulative anions. Chronic exposure damages cellular membranes and disrupts reproductive cycles in lab animals and fish. Ongoing research tracks breakdown products formed after discharge into water or soil; many regulatory agencies demand full toxicological profiles before approving large-scale use. Toxicity reduction becomes part of product design, steering chemists to swap out harmful anions or build in degradable features for new generations of materials.

Future Prospects

The chemical industry looks to this ionic liquid as part of a broader pivot away from traditional solvents that pollute or ignite easily. Persistence in environmental and toxicity studies matters more now, guiding synthetic chemists toward less harmful variations. In the energy sector, new battery chemistries and supercapacitors rely on robust, salt-like solvents to function in wider temperature ranges and higher voltages. Given the drive for greener, safer industrial chemistry, the research community constantly pushes for compounds that blend utility with lower risk profiles. Looking at what I’ve seen both in labs and industrial settings, adoption trends favor those who keep safety data transparent, respond to feedback, and tackle the challenges of scale-up and waste responsibly.

Diving Right In: Why Chemists Turn to Ionic Liquids

It’s easy to overlook just how much the average lab relies on materials that go way beyond basic water and salt. Take 1-allyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide—an ionic liquid chemists love to nickname “AMIM TFSI.” This isn’t just another bottle on the shelf. It can handle serious work, especially where traditional solvents fall short.

Electrochemical Applications: Powering the Future

I’ve seen folks in battery research rave about AMIM TFSI. Its stability at high voltages makes it a favorite for lithium-ion and flow batteries. Where classic solvents might break down, this salt stays steady, helping researchers look for safer, longer-lasting batteries with better energy storage. It brings low vapor pressure to the table, so there’s less risk of fires—always a bonus for facilities prioritizing safety.

Green Chemistry: Doing More with Less Waste

Some people shrug at talk of “green chemistry” as if it’s just a trend, but watch someone try to separate troublesome organic compounds the old way—then watch again as they use AMIM TFSI. The difference is clear. Unlike volatile organic solvents that pollute the air and water, this ionic liquid stays put. It’s reusable. It barely evaporates. Some pharmaceutical labs use it to replace toxic solvents, cutting down on hazardous waste for drug synthesis and purification. Their results look cleaner, and disposal gets a whole lot simpler.

Catalysis: Speeding Up Reactions and Saving Money

In industrial chemistry, time means money. AMIM TFSI plays well with a variety of catalysts, letting reactions run smoother and sometimes with less heat or pressure. This not only trims energy bills but also helps companies meet stricter environmental standards. I’ve read reports about certain alkylation and polymerization processes where yields jump just by swapping in this ionic liquid, shrinking the footprint for both waste and energy.

Separation Science: No More Pesky Cross-Contamination

A friend of mine in analytical chemistry swears by AMIM TFSI for separating tough-to-purify compounds. In liquid-liquid extraction, it can “pull” specific chemicals out of a mix, almost like a magnet. Labs dealing with trace levels of pollutants or rare molecules see a big boost in efficiency this way. And because the solvent itself doesn’t evaporate like a regular organic solvent, sample loss shrinks—good news for anyone working with precious or expensive materials.

AMIM TFSI in Materials Science

Move into the world of new materials, and you see AMIM TFSI showing up yet again. It’s handy in the synthesis of novel polymers and composites, helping researchers master the interface between organic and inorganic phases. Thin films, coatings, and high-performance fibers all benefit. With interest growing in solid-state electrolytes for next-gen batteries, AMIM TFSI is turning into a surprise contender for both flexibility and ionic movement.

Facing the Challenges: What Comes Next?

Anyone working with AMIM TFSI learns you can’t ignore the cost or the need for careful handling. While it solves some problems, procurement teams face price hikes, and safe disposal still requires proper protocols. Some researchers are already adapting production methods to recover and recycle ionic liquids better, bringing down long-term expenses and shrinking environmental impact. Universities and industry players collaborate to tighten regulations and standardize best practices—something that protects workers and gives our communities more peace of mind.

Digging Into Chemical Identification

If someone asks, "What’s the chemical structure and formula of this compound?" they’re not just splitting hairs. Scientists, researchers, and students all run up against this question. In the laboratory, knowing exactly what something is, down to the atoms and bonds, isn’t just a nice-to-have—it keeps people safe and helps research stay on track.

A chemical formula is more than a set of letters and numbers. For water, we read H₂O and picture two hydrogens and an oxygen. The story doesn’t just stop there. That trio binds together at a specific angle, which gives water its famous liquid character. Same formula, but if the atoms sat differently, we’d have a totally different substance.

Health, Safety, and Honest Communication

In the medical field, getting the structure right can mean life or death. Medication manufacturers and pharmacists depend on correct formulas to prevent accidental mix-ups. Sometimes, two compounds can share the same formula (like C₂H₆O for both ethanol and dimethyl ether) but have wildly different effects. One helps preserve organs for transplant, the other works as a fuel or cleaning solution. Trusting the formula alone doesn’t cut it—structure nails down the true identity.

During my years in undergraduate chemistry labs, the structure of even the “simple” compounds forced me to slow down and double-check. I remember messing up an experiment just because I drew the benzene ring wrong—six carbons in a ring, alternating double bonds, not just a hexagon. That little difference spelled chaos for the reaction I tried to run.

Complex Molecules in the Real World

Out in the world, not every substance gets handed to you with a neat label. Take common plastics or drugs—pharmaceuticals are often built around core ring structures with all sorts of side groups. The antibiotic penicillin—its core is a beta-lactam ring. Swap a few atoms in the ring, and you get a different drug altogether. Biomedical researchers track small shifts in structure, since those lead to either healing or harmful side effects.

Industry-watchers see this play out in agriculture too. Herbicides, for example, use molecules tweaked for rugged weeds. Change a single chlorine for a fluorine on the “backbone” and the EPA demands a whole new series of safety tests, even if the difference seems minor.

Why Accuracy Fuels Progress

Public confidence in science depends on clarity. During chemical spills or food recalls, knowing whether a factory leaked sodium chloride (table salt) or sodium cyanide makes the difference between a routine announcement and a health emergency. Regulators rely on chemists who get formulas and structures right. This trust builds up over years, backed by millions of data points and careful communication.

To push things forward, open databases help. Services like PubChem or ChemSpider list thousands of chemicals alongside visual structures. Anyone can double-check what they’re working with. Schools need to teach this approach early—let students draw structures and tie them to real consequences, whether it’s breaking down pollution or designing a new flavor for a sports drink.

Getting the chemical structure and formula right isn’t just a chemistry exam question. It’s a building block for health, safety, law, and trust. I’ve seen lab groups go from confusion to teamwork, just by sharing clear drawings and formulas. Solutions come from accuracy—on the board, in the lab, and out in the field.

Getting Real About Lab Safety

Every scientist remembers the moment they realized that some chemicals deserve real respect. Not every clear liquid means it’s safe. 1-Allyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide, often labeled as an “ionic liquid,” cuts across that line. It looks like nothing unusual—no strong odor or eye-catching color. Without a good look at the safety data, someone might treat it like water. I learned, through training and hands-on work, that skipping the details always backfires.

Known Risks with This Ionic Liquid

Working with chemicals at the university, I picked up the habit of skimming material safety data sheets before even uncapping a bottle. Imidazolium-based ionic liquids, especially those with bis(trifluoromethanesulfonyl)imide as the counterion, demand caution. Manufacturers warn that skin and eye contact can cause intense irritation. Besides, even a splash could trigger reactions that aren’t visible at once but can build up, especially if exposure happens daily. Toxicity data on this class of chemicals often stays incomplete, yet published studies flag concerns like mutagenicity or longer-term environmental harm.

Environmental Impact and Disposal Concerns

Disposing of this material down the drain—bad idea. The ions in this compound break down slowly in water and soil. Some lab studies show they stick around, raising flags for aquatic life and even posing a challenge for modern water treatment. I’ve seen teams forced to spend thousands cleaning up stubborn residues in wastewater because they didn’t treat these chemicals with enough care.

Practical Safety Measures in the Lab

Dealing with this chemical safely needs a practical approach, not just theory. Lab coats, gloves made out of nitrile, and solid goggles form the main shield. Standard latex gloves might not protect against this chemical family—nitrile or butyl materials work better. Fume hoods help keep vapors or accidental splashes contained. Training staff to check labels and confirm PPE before starting any job makes a bigger difference than review meetings ever could.

If Something Goes Wrong

Spills or splashes happen, no matter how much care you take. I once knocked over a beaker after getting distracted by an unexpected reaction. Turning off panic mode, washing affected skin under cool running water for at least 15 minutes, and reporting the incident without hiding it—that approach limits damage. Quick access to eyewash stations and showers helped me more than I’d like to admit.

Better Protocols and Team Habits

Relying on habit and peer checks works well. In our research group, sharing each accident openly stopped others from repeating the same mistake. Tracking near-misses improved our container labeling routines and made people less likely to cut corners.

Looking Forward

Manufacturers and chemical suppliers should keep updating their guidelines, as ongoing research uncovers new risks. Lab managers ought to push for regular refresher training instead of just one-off orientation sessions. As science dives deeper into ionic liquids for green chemistry or battery tech, the urge to treat new chemicals with healthy skepticism won’t fade. Real safety means keeping focus not just on the exciting results but on the routines that keep everyone whole.

Why Melting Point Says So Much

Growing up, I watched my dad cook on weekends. Watching a block of ice melt on the counter or a stick of butter soften on a summer day, I sometimes wondered what set apart one melting experience from another. Turns out, the temperature at which something changes from solid to liquid—the melting point—speaks volumes about its stability, use, and storage. For example, take table salt and sugar: salt stays solid in regular kitchens even in hot climates because its melting point sits much higher than sugar's. That means you won't find sweaty bags of salt, but chocolate bars can soften fast without air conditioning.

Scientists check melting point to spot impurities, too. Chemists use it as a kind of fingerprint. Pure compounds show sharp melting points. Something off, like a mix-up or contamination, usually lowers or broadens the temperature range. Drug makers, candy factories, metal smiths—all need this number dialed in just right before recipes go to scale. If a chocolate melts too soon or a pill breaks down on a humid shelf, the end user notices. A lot of trial and error goes into finding the right blend, partly just to keep the goods intact.

The Big Deal With Solubility

Solubility—how much of something dissolves in a liquid—shapes everything from cleaning solutions to prescription drugs. Take coffee in the morning. Hot water pulls flavors and caffeine from the grounds because those molecules dissolve well at higher temps. Try the same trick with cold water and most flavor stays behind. At home, I've cursed when sugar wouldn't disappear into iced tea as quickly as into hot. That's chemistry in action, governed by solubility.

This property means life or death for some medications. A pill swallowed whole has to break down and dissolve in stomach fluids or the bloodstream can't carry it where it needs to go. If solubility drops too low, the medicine doesn't work. Diagnostic labs spend years tweaking molecular structures or inventing additives—called excipients—to push the right level of dissolving. Food companies dance a similar tune, hoping the end product stirs smoothly into sauces or beverages instead of leaving clumps behind.

In the environment, solubility patterns decide if a pollutant will sit in soil or end up in drinking water. Pesticides designed to protect crops sometimes wash off in rainstorms, partly because they dissolve in water and move with it. Scientists keep hunting for cleaner, smarter ways to coax these molecules to behave—playing with their composition, designing safer alternatives, or capping how much ends up in the wild.

How This Shows Up in Real Life and What Can Change

Melting point and solubility might sound technical but they shape what you see on grocery aisles and pharmacies every week. Durable chocolate coatings, long-lasting deodorants, or stain-proof fabrics—they exist thanks to careful tweaking of these properties. Fresh food, sturdy plastics, quick-dissolving tablets, even winter road salt—everyday choices depend on controlling melting point and solubility.

Better testing tools and computer models help cut costs and reduce mistakes in every field. Recycling teams mix plastics with care so old plastics blend together smoothly instead of becoming brittle. The next generation of medications takes aim at illnesses once thought impossible, partly thanks to smart tweaks in how and when drugs dissolve. Consumers can chip in, too. Storing products properly—keeping chocolate out of cars or following directions on medicines—keeps properties in their best range so items work as promised.

Why Care About Storage?

Taking care of materials like this imidazolium salt often gets lost in the shuffle, but that can be a recipe for trouble. It’s a salt, sure, but that doesn’t mean it’s only as risky as kitchen table stuff. Fluorine and sulfonyl groups change the equation, including how it interacts with containers, the air, and whoever handles it.

I’ve learned that trying to skimp on specialized containers or skip climate control because “it looks solid enough” never pays off. One small spill or a little exposure to heat, and you’re spending hours cleaning or explaining safety slipups.

Conditions to Watch Close

1-Allyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide is known for good thermal and chemical stability compared to some other ionic liquids, but that doesn’t mean you can store it in just any spot. Moisture is a real issue—left in a humid area, this salt can start taking on water from the air, which might not look dramatic but could mess with purity and make later work much messier. With many ionic liquids, water sneaks in everywhere, changing viscosity and reactivity, sometimes even causing slow breakdown.

If you ever spent time cleaning out sticky, unusable chemicals from jars because a lid wasn’t tight, you know why seals matter. The right call is always a well-sealed glass bottle, not a lightweight plastic one that ends up brittle. Some plastics, even if they start strong, let these chemicals leach out or react at the surface over time. Storage in a cool, dry cabinet, out of sunlight, keeps conditions steady.

Transport Practices That Matter

Moving chemicals brings up other stress points. Rushed packing or loose labeling can turn a standard transit into hours of paperwork or even an emergency. From personal experience, regret always follows shortcuts during chemical shipments.

Packing with secondary containment—using cushioned, leakproof backups—makes a difference. Simple double-bagging, absorbent liners, clear hazard labeling, and secure closures have saved more than one shipment from disaster, especially if something does get jostled or leaks. Truck cabs and shipping bays both get unexpectedly hot; so reliable temperature control isn’t just a “nice to have.” Road stops and customs checks get easier and faster if documentation, hazard warnings, and MSDS sheets are on hand and legible.

Why Trained Eyes Help

Seasoned lab staff spot container flaws or labeling errors that beginners miss. During audits, I’ve caught unapproved containers or ambiguous labeling, which could have led to regulatory issues or health risks. It always pays to have someone double-check packaging before shipping and someone else receive and check the product on arrival. That little bit of extra supervision heads off problems.

Anyone handling or storing it should know the basics of chemical hygiene—gloves, proper lab attire, clear labels, and a spill kit close by. One quick call to environmental health and safety folks is better than dealing with workplace injuries or expensive cleanup later.

Room for Solutions

Shifting to RFID inventory tags and regular audits helps companies keep tabs on sensitive stock. Building shared checklists among staff for storage conditions or using remote sensors for temperature and humidity make staying in spec less guesswork. Investing in tighter training up front—teaching the why, not just the how—reduces mistakes, waste, and long-term risk.

Keeping a chemical like 1-allyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide safe doesn’t rest on a single step. Using sturdy bottles, shielding from water, tracking conditions, and supporting good habits are what make the job truly secure. Anyone dealing with these materials owes it to colleagues, and the environment, to get it right every time.