1-Allyl-3-Methylimidazolium Bromide: A Deep Dive

Historical Development

Long before green chemistry became a buzzword, scientists explored new ways to dissolve tough substances without relying on volatile organic solvents. In the late twentieth century, ionic liquids rose as heroes in this quest. Among them, 1-Allyl-3-methylimidazolium bromide (often shortened as AMIMBr) showed up as a promising choice for both research labs and industrial settings. Its structure—a combination of an allyl group and a methyl group attached to an imidazolium ring—paved the way for its inclusion in a wave of studies searching for less toxic, non-flammable alternatives to older chemicals. Over the years, AMIMBr helped shape our understanding of ionic liquids as a group, spurring a surge of patents, pilot projects, and publications that continue to this day.

Product Overview

AMIMBr falls into the family of ionic liquids, with a bromide counterion giving it added utility across diverse applications. People in laboratories know it for its ease of use, versatile solvation power, and relatively straightforward synthesis. Unlike more obscure compounds, AMIMBr finds its spot on chemical supplier catalogs and educational guides, available to researchers and industries with varying purity grades. Thanks to its unique properties, manufacturers and end-users put AMIMBr to work in polymers, biomass processing, organic synthesis, and even electrochemistry. Its adoption highlights the chemical industry’s steady shift towards more sustainable materials that can deliver both performance and a safer work environment.

Physical & Chemical Properties

On the lab bench, AMIMBr typically appears as a colorless to pale yellow liquid. Its melting point hovers around room temperature, which makes handling and measuring a breeze, especially when compared to traditional salts. It dissolves in water, DMSO, and alcohols, broadening its compatibility for many wet chemistry processes. The ionic nature of AMIMBr means it shows remarkable thermal stability up to about 200°C and negligible vapor pressure, all but eliminating fire hazards and inhalation risks seen with volatile solvents. Its density, viscosity, and conductivity change with temperature and concentration, offering ways to fine-tune reaction settings by subtle adjustments, something every bench chemist comes to appreciate.

Technical Specifications & Labeling

A typical AMIMBr sample carries key identifiers: a molecular formula of C7H11BrN2, molecular weight near 203.08 g/mol, and a CAS number for regulatory and logistics tracking. Reputable suppliers describe products in precise language—purity grades, moisture content, appearance, and residual solvents. Quality checks extend past general purity: heavy metal content, halide content, and chromatographic profiles often back the guarantees required by strict laboratories. Packaging usually comes in amber, airtight bottles to protect against light and environmental moisture. Safety data sheets, part of every shipment, break down handling, storage, and disposal needs for on-site compliance.

Preparation Method

Synthesizing 1-allyl-3-methylimidazolium bromide often starts with the quaternization of 1-methylimidazole by allyl bromide, a process run under inert conditions and sometimes with gentle heating. Solvents assist in driving the reaction to completion, after which product separation and purification stand as critical steps to strip out leftover reactants, byproducts, and water. Crystallization, rotary evaporation, and vacuum drying raise purity levels for sensitive applications. Prep methods scale from a few grams for research to tens of kilograms for industry—each scale bringing new engineering tweaks but sticking to similar principles. This straightforward pathway helps labs set up reliable, repeatable manufacturing without specialist equipment.

Chemical Reactions & Modifications

AMIMBr stands out for its chemical reactivity. The allyl group, not common in most ionic liquids, offers a handle for further modification, such as polymerization or crosslinking with other reactive species. Researchers can swap the bromide for other anions through metathesis, unlocking a tailored suite of ionic liquids from a common precursor. In organic synthesis, AMIMBr serves both as a solvent and as a medium that can stabilize high-energy intermediates, especially in transition-metal catalyzed reactions. Other projects use AMIMBr as a component in designing novel materials, like ionic liquid gels, or to support selective cellulose dissolution in biofuel and paper research.

Synonyms & Product Names

Search for AMIMBr in literature, and you encounter alternate names: 1-allyl-3-methylimidazolium bromide, AMIM bromide, or [AMIM][Br]. Bulk suppliers might label it under systematic IUPAC names or shorthand codes, especially as more companies offer bespoke ionic liquid formulations. Regardless of the name, it always refers to the same basic structure, with the allyl group at position 1 and the methyl at position 3 on the imidazolium ring, balanced by a bromide anion.

Safety & Operational Standards

Safety with AMIMBr hinges on standard chemical hygiene and a respect for its reactivity. Direct contact can cause mild skin and eye irritation, though this risk remains modest compared to legacy industrial solvents. Proper lab gear—gloves, goggles, fume extraction—easily covers normal usage. Spill protocols focus on containment and dilution, as AMIMBr dissolves readily in water, easing clean-up. Researchers monitor air quality and inventory records under local and international chemical regulation codes. Waste disposal routes favor jarred collection and handoff to authorized agencies, rather than sewer or landfill dumping, echoing modern commitments to environmental stewardship.

Application Area

With cellulose processing on the rise, AMIMBr wins favor for its capacity to dissolve or swell biopolymers that defy most traditional solvents. Pulp and paper makers, biofuel producers, and plastics innovators rely on it in their push to wring more value from natural feedstocks. Academic chemistry sees AMIMBr as a bridge for catalytic reactions, where its nonvolatility and ion-rich environment boost yields and selectivity. Materials science taps it for creating ion gels and smart membranes, where flexibility and ionic mobility matter. In electrochemistry, its stable window supports the next generation of batteries and capacitors, giving AMIMBr a promising role well beyond today’s energy storage systems.

Research & Development

The research scene keeps AMIMBr near the center of innovation thanks to its chemical adaptability. Groups worldwide examine its impact on swelling and activating cellulose, guiding the shift to bioplastics and sustainable fibers. Electrochemical studies probe its ionic conductivity and electrochemical stability, shaping the pursuit of greener battery electrolytes. Explorations into catalysts and green processes often use AMIMBr both as a medium and as a functional participant, with new methods looking to cut waste, emissions, and operational hazards. With grants and funding following sustainability buzzwords, AMIMBr pitches itself at the intersection of high-performing process chemistry and environmental responsibility.

Toxicity Research

Toxicologists stepping into the ionic liquid field approach compounds like AMIMBr with measured optimism. Published data show AMIMBr’s acute toxicity to aquatic life merits attention, though its low volatility means air pollution concerns take a back seat. Test results steer users to limit releases into waterways, to protect vulnerable ecosystems. Studies on human toxicity suggest low hazards through dermal or inhalation exposure in the short term, but safe handling protocols stay in place, especially during industrial-scale use. Research continues into AMIMBr’s degradation routes, focusing on how time, sunlight, and common microbes break it down, helping policymakers and scientists gauge its environmental fate.

Future Prospects

Looking ahead, AMIMBr faces a world that wants harder-working, safer, and greener chemicals. As manufacturing heads ever closer toward closed-loop, low-waste operations, AMIMBr’s recyclability and low emissions help it stand out. Material scientists eye it for custom ion gels and next-generation polymer composites. Energy researchers model it in advanced batteries, drawn by stability and broad electrochemical windows. Green process engineers look to AMIMBr as a solvent in everything from pharmaceutical synthesis to waste valorization, aiming to slash reliance on older, riskier solvents. Though economic pressures and regulatory questions continue to shape the market, AMIMBr’s track record suggests it will keep drawing attention for those searching out a better blend of performance and sustainability.

What’s Behind This Chemical?

1-Allyl-3-Methylimidazolium Bromide, often found in papers under the label AMIMBr, belongs to the set of ionic liquids that keep finding fresh ground in research. It looks like a jumble of technical words, but the stuff is real — and surprisingly useful. Labs around the globe use it not for flashy, headline-grabbing moments, but for the steady, behind-the-scenes advances that push science forward. Many of us who’ve spent time hunched over benchwork know how valuable these chemical helpers can be.

Taming Tough Substances in the Lab

Research using AMIMBr often starts with a problem: getting stubborn materials to break apart. Dissolving cellulose for biofuel? Extracting rare metals from complicated mixtures? AMIMBr gets called in. Unlike plain water or standard organic solvents, this ionic liquid interacts well with molecules that don’t usually want to mix with anything. I recall going through stacks of solvents for cellulose dissolution and hitting dead ends—AMIMBr cut that search short by gently easing even wild plant fibers into solution. That opens doors for chemists looking to wrangle natural polymers into something workable.

A Solvent with a Cleaner Conscience

Old-school solvents can be rough on the planet and tough to handle safely. Many evaporate easily or leave toxic residue. AMIMBr doesn’t boil away like acetone or gasoline. Labs can recover and reuse it, dodging waste and reducing exposure to the nastier end of the chemistry spectrum. As more funding goes to sustainability, being able to avoid traditional, dirtier solvents counts for something. It won’t turn the whole chemical industry green overnight, but it shifts the culture slowly toward less environmental damage.

Role in Materials and Catalysis

Chemists don’t just use AMIMBr to break things down — they use it to build new stuff. Some teams have let it serve as a reaction medium for catalysts, letting challenging reactions run at milder temperatures or in shorter timeframes. In my own work, seeing a sluggish reaction speed up in the presence of AMIMBr made the difference between a week-long wait and getting results before lunch. High-value fields like battery research or drug development keep looking for that kind of practical edge.

Where Are the Roadblocks?

Given all its upside, AMIMBr faces practical hurdles. Cost stays high compared to bulk, commodity chemicals. Scaling up from grams in a beaker to tons for manufacturing pulls researchers into a world of shipping, purity checks, and regulatory hoops. AMIMBr also requires clear handling protocols — not everyone in a plant or startup lab has deep knowledge of the quirks that come with ionic liquids. Getting better training and developing broader safety data can keep users from run-ins with unexpected side effects.

Steps Toward Progress

Producers have started looking for easier synthesis methods, which can push prices down and open the door for small companies to experiment with AMIMBr. Educators at the undergraduate and graduate levels now squeeze ionic liquids into courses, prepping new scientists for hands-on work with these modern solvents. Real use cases keep growing — from studies on extracting valuable compounds from food waste to developing flexible electronics. As more real-world successes hit journals, AMIMBr becomes more than lab curiosity. It’s part of a movement pushing safer, cleaner chemistry from idea to industrial reality.

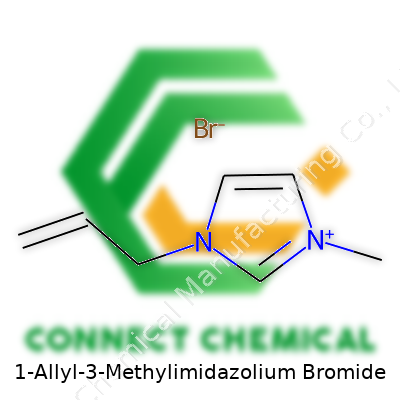

Chemical Formula and Core Structure

1-Allyl-3-Methylimidazolium Bromide carries the chemical formula C7H11BrN2. Its structure builds on the imidazolium ring—a five-membered heterocycle packed with two nitrogen atoms and three carbon atoms. To break it down, the third position features a methyl group, making it “3-methyl”, and the first nitrogen picks up an allyl group, which brings in three more carbons arranged as CH2=CH–CH2–.

The positive charge sits on the imidazolium ring due to the nitrogen atoms, which means every molecule includes a bromide anion (Br-) to keep things balanced. Chemists draw this molecule often by outlining the ring as a pentagon, attaching a CH3 to the third carbon, and linking the allyl group directly to one of the nitrogens. The whole setup looks streamlined, but its properties set it apart.

Why the Structure Matters

My own experience in a university research lab brought a rapid appreciation for the quirks of ionic liquids like this one. The imidazolium ring gives 1-Allyl-3-Methylimidazolium Bromide a strong capacity for dissolving stubborn compounds, including certain organic and inorganic materials.

Chemists gravitate toward this salt for its low volatility. You can heat these ionic liquids, and they don’t just vanish into thin air. As a result, the risk of inhalation hazards drops. Many find the structure stable enough for setups that need a wide liquid range, stretching well beyond water’s boiling point on both ends of the thermometer.

Applications That Draw on Its Nature

The unique structure means this compound doesn’t simply sit in bottles on dusty shelves. Industrial labs turn to it for processes that need solvents capable of breaking tough chemical bonds. For example, 1-Allyl-3-Methylimidazolium Bromide steps up in cellulose processing or in making advanced polymers. This makes recycling plant waste a bit more practical—an important shift as stricter sustainability standards start guiding business decisions worldwide.

Researchers exploit its ionic properties in battery development, especially as safer, non-flammable electrolytes. Imidazolium rings can help shuttle ions back and forth in electrochemical cells, making them an attractive option for building better batteries that are less likely to spark or cause damage.

Addressing the Waste and Toxicity Challenge

Handling ionic liquids comes with responsibility. Studies point out that although these compounds offer advantages, they can pose toxicity risks if released into the environment. The bromide anion and imidazolium cation need proper containment and disposal. Responsible labs design containment and recycling systems, treating spent liquids before disposal and seeking greener alternatives. Research now focuses on tweaking the imidazolium ring itself, adding functional groups that break down faster in the environment or cause less harm to non-target organisms.

Getting the chemistry right has direct consequences for people and the planet. The more we respect the intricacies of 1-Allyl-3-Methylimidazolium Bromide’s structure and reactivity, the greater the benefits—and the safer the experience for scientists and end-users alike. Open communication and evidence-based research strengthen safety protocols, ensuring innovation follows ethical tracks without leaving a chemical mess behind.

Respecting the Chemical for What It Is

In the world of chemicals, 1-Allyl-3-Methylimidazolium Bromide doesn’t carry the headline hazards of some more notorious substances, but you ignore basic precautions at your own risk. This particular salt draws a following in research labs for its ionic liquid properties and role in green chemistry processes. Still, if you don’t keep storage in check, you run into unnecessary headaches—think ruined batches, unwanted water absorption, and accidental mixing with the wrong agents.

Moisture and the Enemy Within

Anyone who’s ever opened a chemical bottle after a humid season knows moisture becomes the quiet spoiler. 1-Allyl-3-Methylimidazolium Bromide likes to pull water from the air. I learned that the hard way two summers ago—tiny clumps, sticky powder, loss of confidence in purity. Hygroscopic compounds, this one included, really stress the subtle power of air exposure; what started as a perfect white powder quickly takes on a gummy texture if left in a careless spot.

Desiccators are the trusty friend to any chemist dealing with this salt. Throw in some silica gel packs or another drying agent, snap the lid, and you cut down moisture trouble. Room temperature often does the trick, but some labs keep the salt a few degrees cooler—a matter of personal risk appetite and batch size.

Choosing the Right Container

Plastic jars can seem convenient, but not all plastics are created equal for chemical storage. Glass bottles with tight poly-seal lids make life easier. Some folks say you can get by with screw-top plastic, but over time, vapors find their way out or in more than you’d like. I always favored borosilicate glass, mostly because it handles sudden temperature swings and doesn’t leach anything into the sample. Write the opening date right on the label. Nobody regrets good record-keeping three months down the line.

Watching Out for Contamination

Cross-contamination pops up even in well-organized spaces. It pays off to dedicate tools—spoons, spatulas, and weigh boats—to the single compound. I made the mistake of pinching pennies once, weighed a few similar salts with the same spatula without a proper cleaning, and spent the next week troubleshooting strange results. Small steps, big difference.

Location: Safe, Dry, and Away from the Curious

Not every shelf in the lab or stockroom meets the grade. Keep your ionic liquids like 1-Allyl-3-Methylimidazolium Bromide on a high, well-marked shelf in a low-traffic area. Some students see a long chemical name and think it's harmless. A locked, labeled cabinet shuts down that temptation. Accidents don’t discriminate. If kids or visitors enter your space, pick isolation over convenience every time.

Right Approach Reduces Problems

Every supply of this salt comes with a safety data sheet—some folks skim, others study. I keep a printed copy by the storage area just in case. Ventilated rooms and clear personal protective equipment guidelines matter just as much as desiccators. Gloves and goggles hang by the storage shelf, not hidden away in some mystery drawer. If the salt ever gets on your skin, don’t hesitate; rinse, rinse, and rinse.

In the end, storing chemicals belongs more in the discipline zone than the deep science zone. Moisture, contamination, wandering hands, and laziness draw out more trouble than most realize. Keeping 1-Allyl-3-Methylimidazolium Bromide stable starts with respect and ends with a little day-to-day vigilance. Simple habits go further than fancy gear.

The Clear Picture on Chemical Safety

I have spent years working around chemicals in university labs and industrial settings, and every compound has its own story. Some earn a reputation because of immediate danger. Others fly under the radar until a close call changes our perspective. 1-Allyl-3-Methylimidazolium Bromide, widely used in research as an ionic liquid, gets questions because folks want to know if they’re risking health or safety by coming into contact with it.

What the Science Says About Toxicity

Laboratory chemical safety data shows this compound isn't among the most notorious toxins in the world, but that doesn’t mean you can treat it like table salt. Like many ionic liquids, 1-Allyl-3-Methylimidazolium Bromide struggles with breakdown in the environment. Scientists call this low biodegradability. It tends to hang around, and that lack of easy decomposition can spell trouble for aquatic life.

Direct, credible studies on the toxicology show that this chemical can irritate the skin, eyes, and respiratory system. Testing points to moderate toxicity toward certain organisms—not among the deadliest, but not gentle either. Its bromide component and the imidazolium ring both can stress freshwater ecosystems. You can see fish displaying abnormal behavior and slower growth rates if this stuff seeps into waterways at high enough concentrations.

Inside a lab, gloves and goggles shield from most exposure. I have seen a few cases where folks underestimated irritation, especially with tiny, unnoticed splashes on arms. The warning comes later, not immediately. Most concerning are accidental spills where someone neglects to clean up promptly, and the vapor or mist spreads. It pays to be quick and thorough with cleanup—anyone who’s spent time in a wet chemistry lab learns that lesson fast.

Why Long-Term Safety Matters

All too often, chemicals like this one get greenwashed because they help with cleaner processes or boost performance over old-school solvents. That’s not untrue—ionic liquids can replace more toxic, volatile solvents. Yet, green doesn’t always mean safe for every living thing. This is a hard lesson I picked up talking with environmental health researchers. Any chemical’s lifecycle deserves scrutiny, especially once it enters water, soil, or possibly food chains.

Most manufacturers and academic suppliers classify this one as hazardous. That label doesn’t only sound official—it comes with responsibility. If a researcher or technician ignores disposal instructions or skips ventilation, risks mount quickly. Some countries list it under watch for chemical disposal protocols. The importance of reading Safety Data Sheets goes beyond box-checking. The fine print about toxicity and handling can save someone from health issues down the road.

How to Lower the Risk

Safe habits beat overconfidence every time. Always use personal protective equipment in the lab, keep chemicals sealed, ensure ventilation, and stick to established waste procedures. Training new students or workers can’t take shortcuts—stories of accidents are more common where folks rushed or tried to cut corners. Clear instructions, proper storage, and prompt spill response build a culture of respect around every bottle.

At the research level, reevaluating the need to use 1-Allyl-3-Methylimidazolium Bromide helps too. Substitute with safer options if possible, and monitor any discharges carefully. Peer-reviewed studies can shed more light on long-term effects, so supporting that work makes sense. Staying proactive, reading new research, and sharing safety stories keeps everyone in the loop. Real safety grows from shared experience and honest dialogue, not just rules on paper.

Pushing for High Purity Standards

Scientists, chemists, and manufacturers often judge chemicals by their purity, and 1-Allyl-3-Methylimidazolium Bromide gets no exception. This compound supports various research and industrial applications, from catalysis to advanced materials. Most labs expect at least 98% purity, and some suppliers push this up to above 99%. High purity really matters. Impurities in chemicals throw off reactions, make data unreliable, and can add hidden risks to projects.

I remember working on a polymer project in graduate school. We once tried to cut corners with a lower purity reagent. The result? Unexpected side reactions that wasted whole weeks. That memory sticks with me every time I see a chemical label. You pay up for purity, but you pay even more for mistakes that come from impurity.

Packaging Sizes in the Real World

Shops and suppliers don’t set a single packaging standard for this chemical. Academic buyers tend to prefer smaller bottles, often 5 grams, 10 grams, and sometimes up to 25 grams. Research runs small, both to save money and to manage hazards. For example, a team synthesizing special ionic liquids for sensor work may only need a few grams at a time.

Companies tackling scale-up need more. Tech firms and specialty manufacturers ask for larger units, sometimes 100 grams, 250 grams, or even by the kilo. Industrial clients sometimes negotiate even bigger deals where multiple kilograms arrive in robust HDPE bottles with air-tight seals. During my time working at a contract research lab, clients often called in with their own ideas for packaging, which told me that flexibility really helps bridge the gap between producer and end user.

Safety and the Role of the Supplier

Quality isn’t only about chemical composition. Reputable sellers clearly state the purity, batch number, and traceability. Labels should include a Certificate of Analysis. Tougher regulations and supply chain transparency push this further. Counterfeit and contaminated chemicals still circulate, especially from sellers that don’t prioritize quality.

Big names like Sigma-Aldrich, Alfa Aesar, and TCI regularly list purity and offer customer support. They track and trace chemicals and provide certification and support, giving peace of mind. Less established vendors often skip these steps, and that introduces risk.

Unsafe packaging causes its own set of problems. Strong chemicals need bottles that seal tight, resist corrosion, and don’t leach. And even in the world of ionic liquids, some bottles crack or leak if the wrong polymer meets the wrong chemical. We once opened a delivery that reeked of solvent — a telltale sign of mishandling and the wrong kind of container. This kind of error creates risk at every step, from shipping to storage to daily use.

What Could Change?

Demand grows for clear product data, tamper-evident seals, and transparent sourcing. Adopting honest labeling and publishing third-party testing results would set a higher bar for everyone. Researchers and industrial chemists can push back by asking for certifications, clear labeling, and real support before buying. Regular audits, open customer reviews, and supplier listings filtered by reliability could close the gap further.

As more industries shift toward specialized ionic liquids, better norms for both purity and packaging serve everyone downstream. The more we raise expectations now, the safer and more productive the work becomes.