1-Allyl-3-Methylimidazolium Chloride: Shaping Modern Chemistry

Historical Development

Chemists started looking for alternatives to harsh organic solvents back in the 1980s and 90s. The environmental fallout from widespread solvent use couldn’t be ignored. Imidazolium-based ionic liquids, including 1-allyl-3-methylimidazolium chloride, arose from this push for better choices. Early research at academic labs in Europe and Asia flipped the script on solvent chemistry. Green chemistry principles guided these developments, favoring room-temperature liquids with low volatility. Chemists wanted solubility without pollution and turned to flexible imidazolium ions with different side chains. The allyl group delivered fresh reactivity and improved solubility profiles, setting the stage for widespread lab and industry use.

Product Overview

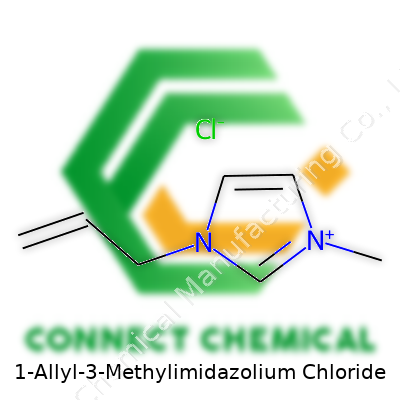

1-Allyl-3-methylimidazolium chloride belongs to the family of room-temperature ionic liquids, where its cation bears both an allyl and a methyl group, and the chloride acts as the counterion. The formula combines adaptability with straightforward synthesis, making it an appealing product across research and applications. Typically arriving as a pale yellow or colorless viscous liquid, it smells slightly of amines, with a consistency similar to thick syrup. Many producers label it by its common abbreviations, such as AMIMCl or 1-AliMeImCl, depending on their naming tradition.

Physical & Chemical Properties

This chloride-based ionic liquid shows a melting point well below room temperature, so it stays liquid in everyday lab and industrial settings. Its high thermal stability allows heating, with decompositions generally beginning above 180°C. The substance dissolves broadly—cellulose fibers, certain polymers, and most salts blend into its matrix with a little stirring or gentle warmth. Water mixes with it in all proportions; many researchers take advantage of its moisture tolerance for solution work. That ability to host both organic and inorganic materials tends to set it apart from many traditional solvents, leading to a new frontier in multi-phase chemistry. Conductivity clocks in at several millisiemens per centimeter, reflecting the mobility of its ions, and the substance retains strong solvating power due to the imidazolium core’s hydrogen-bonding character.

Technical Specifications & Labeling

Manufacturers regularly offer this ionic liquid at high purity, with chloride content and water content listed on the label. Most labs look for a minimum purity of 97% or more, and bottles display the molecular weight, lot number, synthesis date, and storage recommendations. To avoid contamination, suppliers usually provide container material specifications—amber glass or high-density polyethylene—and seal them under nitrogen. MSDS (Material Safety Data Sheets) back up each shipment, supporting regulatory compliance and safe workplace handling. Good batch-to-batch consistency supports reproducibility in academic and industrial settings alike.

Preparation Method

Lab synthesis for 1-allyl-3-methylimidazolium chloride starts with 1-methylimidazole. Reacting this with allyl chloride under nitrogen yields a thick, colorless liquid—1-allyl-3-methylimidazolium chloride. Water or ethyl acetate remove traces of byproducts, and drying over activated charcoal gets rid of any color tinge. For industrial production, manufacturers favor larger barrels with nitrogen purging, vacuum distillation, and closed-system transfer to minimize contamination and exposure. The relatively high atom efficiency reflects a cleaner profile than many alternative approaches, which still depend on corrosive acid or metal intermediates. This makes it easy to scale from gram quantities in academic research to multi-ton batches for industry partners.

Chemical Reactions & Modifications

The allyl group brings new reactivity, making this ionic liquid a key substrate in organic transformations. Chemists exploit its double bond in cross-coupling, polymerization, and addition reactions. Its imidazolium ring survives acidic, basic, and reductive conditions, serving as a robust scaffold. Its chloride anion may take part in nucleophilic substitution and ion exchange. Some researchers graft the ionic liquid moiety onto silica, polymers, or membranes, creating functionalized materials with all-new separation and catalysis capabilities. Not only does this alter reaction rates, it changes how chemists approach product isolation and recycling on a practical scale.

Synonyms & Product Names

AMIMCl comes up in catalogs, as does 1-allyl-3-methylimidazolium chloride, N-allyl-N’-methylimidazolium chloride, and 1-allyl-3-methyl-1H-imidazolium chloride. Some regions use systematic IUPAC labels, others rely on shortform trade names. Awareness of local and international naming conventions helps buyers avoid mix-ups across regulations and standards. Producers often maintain alternative catalog numbers for the same substance, which emphasizes the importance of double-checking molecular structures before large orders.

Safety & Operational Standards

Short-term exposure brings mild skin and eye irritation, especially without gloves or goggles. The chloride anion makes the liquid hygroscopic, so it draws water from the air and may cause mild burns after prolonged contact. Fume hoods and splash shields become necessary in production and lab work. Disposal should respect both the organic and chloride-containing nature of the liquid, so it never ends up in local water systems or municipal drains. Incineration at certified waste facilities, following local and international guidelines, avoids contamination. Labs train workers on emergency spill procedures and routinely check containers for leaks. Careful labeling and MSDS distribution support both workplace safety and regulatory audits, reflecting the shift toward a safer, more transparently managed chemical sector.

Application Area

Applications center on dissolution and processing of cellulose, lignin, and chitin. Textile manufacturers now reach into previously untapped biomass streams to turn agricultural waste into fiber and packaging. Researchers use AMIMCl for homogeneous polymerizations and controlled radical reactions. Electrochemical labs rely on its ionic conductivity for batteries, capacitors, and electrodeposition. In catalysis, its non-volatile nature gives new control over product isolation, reducing solvent losses. Specialty coatings and lubricants leverage the liquid’s stability and water absorption for longer-lasting performance, even at high temperatures and under mechanical stress. Paper recycling, dye chemistry, and materials science also see ongoing adoption of this ionic liquid as a processing aid and reaction medium.

Research & Development

The last decade brought intensified work on cellulose solubility and recovery, finding ways to produce low-cost, recyclable ionic liquids based on this platform. Teams from Germany, China, and the U.S. shared case studies using AMIMCl in pilot-scale biorefineries, producing fine chemicals and biodegradable plastics from forest and crop waste. Each lab aims to understand the microscopic interactions between the ionic liquid and biopolymer chains, using spectroscopy and computational modeling. Advances in recycling ionic liquids stretch budgets and make broader adoption viable. Joint projects with engineering groups press for safer, faster, and more energy-efficient production routes at scale, directly informing industrial rollouts and regulatory submissions. Academic collaborations bridge chemistry, process engineering, and environmental science to identify lifecycle impacts and possible improvements.

Toxicity Research

Current findings indicate low acute toxicity, but the jury’s still out on long-term environmental footprints. Zebrafish and aquatic invertebrates show some sensitivity in laboratory tests, with effects tied to concentration and duration of exposure. Most data point to limited persistence in soil and water after proper waste management, but monitoring for breakdown products and metabolic bystanders remains high on the list. Regular reviews of literature and updated protocols stay front-of-mind for responsible laboratories. Work continues to replace even trace levels of hazardous byproducts with greener alternatives, chasing both performance and peace-of-mind for staff and downstream users.

Future Prospects

The fit between 1-allyl-3-methylimidazolium chloride and tomorrow’s green economy depends on scaling up with minimal waste, extending utility into clean manufacturing and renewable chemicals. Breakthroughs in the design of task-specific ionic liquids could amplify its impact in battery technology, solar cell development, and biopolymer composites. Relationships between academia, startups, and established chemical giants speed up translation from benchtop proof to commercial deployment. Policy shifts toward climate action and reduced emissions mean that every manufacturing process is under the microscope. Those who embrace 1-allyl-3-methylimidazolium chloride, but commit to safe handling, responsible disposal, and ongoing research, help push chemistry to a more sustainable footing—blending tradition with sharp-eyed innovation.

Opening the Door to Greener Chemistry

1-Allyl-3-Methylimidazolium Chloride brings a fresh flavor to modern chemistry labs. I’ve watched researchers light up at how it transforms traditional approaches. The thing that stands out is how this ionic liquid feeds into the push for less toxic solvents. Chemists have struggled for years with safety and waste, and many have had enough of those headaches. This salt melts neatly at room temperature and dissolves all sorts of compounds that would stubbornly stay solid in water or other liquids.

Enzyme Work and Biocatalysis

Interest in enzyme research jumps as soon as this compound joins the discussion. Some enzymes can’t function well in harsh or simple aqueous solutions, but they start showing real muscle in ionic liquids like 1-Allyl-3-Methylimidazolium Chloride. Biotech teams take full advantage to speed up reactions or even get higher product yields. As I’ve seen in practice, you end up with cleaner processes, less energy use, and easier extraction after reactions wind down.

Cellulose Processing That Actually Works

Sustainable practices in textiles and materials keep gaining momentum. The stubborn structure of cellulose usually stumps traditional solvents, but researchers reach for this ionic liquid to break the gridlock. I watched a cellulose processing experiment where the fibers disappeared smoothly into the solvent, cutting hours off the preparation time. This opens opportunities for renewable fibers and less reliance on petrochemicals.

Electrochemistry and Batteries

Better batteries aren’t just for gadget lovers; smart grids and electric vehicles need them too. Ionic liquids replace volatile organic solvents in battery electrolytes, making safer cells that last longer. I remember seeing early-stage batteries using 1-Allyl-3-Methylimidazolium Chloride, and long-term stability really improved. The compound resists evaporation, doesn’t catch fire easily, and supports ions moving around with very little trouble. That’s a real draw when designing next-generation storage for solar or wind power.

Catalysis and Metal Recovery

Catalysts let manufacturers make more with less and keep waste in check. Adding this ionic liquid often means smoother reactions at lower temperatures. Manufacturing teams love stretching their metal catalysts further and cutting down on energy costs. A surprising perk: it helps pull valuable metals out of waste streams, hinting at clever recycling routes. Several industrial groups now use it to extract rare earth elements from used electronics, helping to close the resource loop.

Looking Ahead: Potential and Cautions

With all these applications, there’s plenty to get excited about: greener processing, higher efficiency, and fewer toxic leftovers. But any chemical introduced on a large scale needs careful assessment. Safety isn’t just about taking lab tests at face value. Questions about environmental impact, long-term toxicity, and full lifecycle footprint need answers before moving ahead. Research groups should publish their data openly, and manufacturers owe it to their workers to invest in training and safety monitoring.

As industries keep experimenting and sharing their results, the promise of 1-Allyl-3-Methylimidazolium Chloride keeps growing. Solutions will come as the scientific community works together, balancing innovation with a clear sense of responsibility for health and the environment.

Understanding the Compound

1-Allyl-3-Methylimidazolium Chloride sits on the list of ionic liquids catching attention in labs for good reason. Its structure puts it into a group of salts that stay liquid in a wide temperature range. These properties turn it into a frequent choice for solvent work, electrochemistry, and even some synthetic chemistry settings.

Stability Concerns in Everyday Use

The stability of this salt links closely to its water sensitivity. Even though some ionic liquids brush off humidity, 1-Allyl-3-Methylimidazolium Chloride can absorb water from air if left uncapped or in a humid spot. Water uptake messes with both purity and performance, especially if you're running dry chemical reactions or storing the compound for longer periods. Leaves you with inconsistent results or, in the worst cases, a ruined batch. Watch the temperature too — sitting in a hot spot speeds up decomposition, particularly if traces of acid or base get involved.

Sometimes folks overlook how light can step into play. Direct sunlight or exposure to UV may begin to nudge some ionic liquids towards yellowing or shifting in composition. It's a minor note for this compound compared to moisture and heat, but ignoring it over months in storage has led to some headaches in the past. Personally, I've seen storage on an open bench cause more trouble than it ever solved; yellowed crystals, unexpected reactivity, and constant re-purification sidetrack projects fast.

Safe Storage Practices

Thieves of stability—air, water, light, and high heat—all take their toll if given a chance. Airtight containers, always. Dry powders like silica gel packets tossed into storage cabinets do a solid job fighting humidity. I prefer sealed glass over plastic, ever since a plastic bottle went tacky and started sweating moisture, putting the entire batch at risk.

Cool and dark describe the best storage spot. Room temperature works in most lab spaces, but anything over 30°C starts flirting with risk, inviting slow decomposition when you least expect it. Reaching for a fridge helps in warmer climates, as long as condensation doesn't sneak in and create more problems. While freezers seem tempting for long-term storage, repeated thawing and re-freezing make clumping and water uptake more likely.

Label clearly, mark the date opened, and keep the material away from acids or bases that might cause slow reactions inside the jar. Fume hoods aren't always necessary for storage, but if the liquid version gets used nearby strong reagents, move it to a safer spot away from potential cross-contamination. Only pull out what you’ll use, and reseal the rest right away. Labmates tend to return things in a rush, and that’s often how moisture creeps in unnoticed.

Handling Spills and Waste

Accidents pop up in even the tightest labs. If you spill 1-Allyl-3-Methylimidazolium Chloride, treat it as a salt that readily dissolves in water. Mop it up with dry paper, avoid washing it down open drains, and drop the waste in properly labeled, tightly sealed containers. Unintended release not only ruins your batch but raises environmental disposal concerns, since ionic liquids don't always break down fast in nature. According to reputable environmental studies, some ionic liquids resist degradation, accumulating if not disposed of with care.

Reliable Sourcing and Checking Quality

Buying from vendors who share detailed certificates of analysis brings peace of mind. Analytical checks like NMR or simple melting point runs catch contamination or breakdown early. In-house checks seem tedious at the outset, but they save days lost to compromised material. Don't rely on the old bottle at the back of the cabinet unless sure of its history — expired or contaminated batches cause chain reactions of wasted effort.

Room for Improving Lab Safety

Labs should treat 1-Allyl-3-Methylimidazolium Chloride as valuable, humidity-sensitive stock. Refresher briefings help newer scientists avoid the classic mistakes — loose lids, open bench storage, and not tracking batch age. Solutions go beyond policy; real improvement stems from taking accountability and making space for better storage options in crowded labs. A culture of respect for materials limits lost productivity and keeps both science and people safer.

Understanding What’s at Stake

Chemical names sound intimidating, and 1-Allyl-3-Methylimidazolium Chloride rolls right off the tongue and straight into lab supply catalogs. Folks in research love it for dissolving tough stuff like cellulose—think solvents for engineering “green” plastics and fuels. The pitch: ionic liquids with low vapor pressure keep fumes out of the air, lessening workplace exposure. That still leaves us staring down real questions about health and environmental safety.

Chemical Exposure: The Health Side

You open a bottle or pipette out the clear liquid, and the sweet, faint aroma drifts up—a sure sign you’re handling something more complex than saltwater. Take some simple truths from my own time in the lab: easy skin or eye contact means gloves and goggles aren’t optional. Imidazolium compounds have a reputation for irritating tissue, and spills on bare hands leave a stinging reminder. Prolonged inhalation is another concern. Even with low vapor pressure, small spills and leaks add up in confined spaces, especially without proper ventilation.

Research gives some direction. Laboratory animal studies with similar compounds point toward mild to moderate toxicity upon ingestion or skin absorption. Chronic effects remain hazy, though early indicators don’t suggest severe long-term risk at low doses. That gap in broader epidemiological data leaves room for caution—best to err on the side of respect for what you don’t know.

Environmental Persistence and Ecosystem Concerns

The “green chemistry” sales pitch turns heads, but it only sticks if end-of-life gets factored in. Ionic liquids rarely evaporate into the clouds, but they don’t break down easily either. Once down the drain, these substances resist natural decomposition. Some studies found that imidazolium-based liquids can stunt microbial activity in wastewater and slow down the work of bacteria that clean up other pollutants. Aquatic organisms exposed to runoff have shown changes in growth and reproduction, raising flags about possible bioaccumulation.

The track record here borrows from real-world lessons on compounds like pesticides and PFAS. Persistence means low natural breakdown, low dilution, and a good chance of sticking around for years. Waste handling grows in importance. Disposal through incineration at specialized facilities, separation in waste streams, and closed-loop processes at factories make the consequences less dire, but not every lab or pilot facility runs at that level.

Managing the Risks: Practical Steps

Labs and factories handle risk the way they handle glassware: with common sense and layers of precaution. Personal experience taught me to use chemical fume hoods, check glove compatibility, and never lose sight of spill kits. Institutions aim for substitutes, yet true alternatives for dissolving cellulose or extracting specialty chemicals run thin.

Safety data sheets need refreshing as research goes public. Regular monitoring and education matter—complacency leads to accidents more often than malice ever does. Investments in greener disposal, not just green uses, will set the line between problem and progress. Until regulations tighten and data fills in, treating compounds like 1-Allyl-3-Methylimidazolium Chloride with respect keeps everyone—not just chemists—a little safer.

Understanding What You’re Buying

Chemicals like 1-allyl-3-methylimidazolium chloride don’t come from mysterious corners of a lab with specs no one can pin down. Most sources offer pretty detailed data sheets, making it possible—even for non-chemists—to understand what’s inside those tiny jars or drums. This compound belongs to the wider class of ionic liquids, gaining popularity in research and industry for its ability to dissolve a range of substances, support catalysis, or act as a reaction medium. Companies involved in battery work, green solvents, or synthesis projects often turn here because traditional options can’t match the flexibility.

Real Purity Levels on the Market

For most buyers, purity sits right at the top of the checklist. Commercial supplies of 1-allyl-3-methylimidazolium chloride routinely hit a minimum of 98% purity, sometimes pushing to 99% for high-end lab applications. Anything lower starts to turn away researchers who need clean reactions without worrying about surprise side-products. I’ve ordered from reputable suppliers like Sigma-Aldrich and TCI, seeing certificates with stated water content below 0.5% and the rest made up of trace impurities, often halides or the odd bit of unreacted starting material. Color varies a little based on lot and handling—sometimes you get a nearly clear solution, sometimes a pale yellow tinge from minor decomposition, but color rarely signals real trouble.

Moisture: The Sneaky Contaminant

One detail that matters more than people expect is water content. Ionic liquids tend to pull moisture out of air like a magnet. Any time you see these bottles open in a humid climate, small amounts of water sneak inside and change the properties, even if the main compound stays pure by weight. The datasheets list moisture as “KF” (Karl Fischer, for those of us who ran those endless titrations in grad school). Even a difference of 0.2% in water content changes melting point and viscosity. Serious applications call for pre-drying or storing under argon to keep performance tight. For battery electrolyte blends or catalyst preps, those numbers really do matter.

Key Specifications Beyond Just Purity

Purity is only part of the spec sheet. Commercial sellers include melting point—typically between 40°C and 75°C depending on trace water, and viscosity, often measured at 25°C. Sometimes, there’s a chloride assay or NMR profile available, especially for researchers looking to track every possible contaminant. Reputable suppliers always provide a batch-specific certificate of analysis. Without that, it’s a gamble. I’ve seen shady lots from no-name sources turn out to be only 90% pure, with mystery peaks in the NMR. With proper documentation, you know exactly what you’ve got.

What Labs and Industry Really Need

Applications in synthesis often demand stable, anhydrous material. In practice, you watch for storage issues: tightly sealed bottles, desiccators, cold storage if possible. Some companies offer custom drying, though costs climb fast. For scale-up or industrial settings, consistency across batches helps save time, since variable impurities can force process adjustments. Researchers in electrochemistry or materials science usually start with the highest purity even for screening, since lower-quality materials can make experiments tougher to reproduce.

Raising the Bar on Accountability

Trust in chemical supplies relies on transparency. The real solution isn’t stricter language on datasheets—it’s routine, third-party verification and regular lot analysis. People who run experiments with 1-allyl-3-methylimidazolium chloride need honest numbers on every order, or risk wasting weeks on puzzling results. Customers win when suppliers publish full spectra, moisture profiles, and batch histories. There’s a lesson here for suppliers: cutting corners on analysis only erodes confidence in the long run. Keeping customers informed keeps research—and industry—moving in the right direction.

Real Risks, Real Responsibility

Laboratories today see more ionic liquids show up on the bench, and 1-Allyl-3-Methylimidazolium Chloride stands out for its flexible uses in catalysis, synthesis, and electrochemistry. My own time in academic labs taught me that new reagents often fool folks into thinking they carry fewer risks than legacy chemicals. That’s rarely the case, and with this one, extra caution matters because hazards can sneak up through skin contact or inhalation.

What Happens If Precautions Slip

Some ionic liquids look friendly—they don’t fume, they dissolve well, they don’t stink up the lab. This creates a false sense of security. I watched a colleague work with similar compounds and skip gloves just once, only to end up with irritated skin and a worry that ran into the weekend. Chloride-based ionic liquids sometimes get called "green," but this doesn’t erase all danger. Direct exposure may not burn, but it invites trouble through slow absorption and possible toxicity over time. Reports link some imidazolium ionic liquids with genetic toxicity or issues for aquatic life, so ignoring spill clean-up or ventilation is a gamble.

Handling Basics Everyone Should Practice

Gloves, goggles, and a chemical-resistant coat shape the bare minimum in personal protection. Nitrile gloves work better than latex for blocking contact. Lab work often gets busy, but every time 1-Allyl-3-Methylimidazolium Chloride comes out, a fume hood must be the workspace. This stops vapors from building up and limits inhalation risk.

Label every container—never trust memory. I’ve seen more than one accident start with a mystery bottle. Store the compound snug away from moisture and incompatible chemicals like strong oxidizers. Keep it in tightly-sealed containers, and write clear dates on everything. Humidity sometimes creeps in during a long project, so check regularly for clumps or discoloration.

Smart Storage defends Health and Research

Not every student or tech reads up on ionic liquids. So, clear training for new people can keep everyone safe. I remember a new grad rushing through a late-night synthesis, only to realize halfway that she was waist-deep in an unventilated room. She learned from it—no shortcut beats a safe setup. Signage helps: a simple printed fact sheet by the supply cabinet and color-coded stickers remind us all which compounds call for extra steps.

Waste and Clean-Up: Not Just a Chore

Never dump leftover 1-Allyl-3-Methylimidazolium Chloride in the sink. Specialized disposal containers hold all liquid waste, and spills go straight to absorbent pads or dry sand, not just paper towels. I’ve seen labs where well-meaning folks caused downstream plumbing headaches with improper disposal, so following proper protocols matters.

For accidents, every minute counts. Splash to eyes or skin? Head straight to the eyewash or safety shower, no hesitation. Document the incident and alert supervisors—learning from close calls builds a safer culture.

Better Labs through Respect and Routine

Safety with 1-Allyl-3-Methylimidazolium Chloride starts with habits. As experience adds up, the memory of stinging skin or tense moments at a spill stays with you. Teaching new lab members proper routines—before they handle anything dangerous—prevents bad habits from taking root. Staying humble about chemical risk isn’t just about following rules for rules’ sake; it’s about keeping science strong and people healthy.