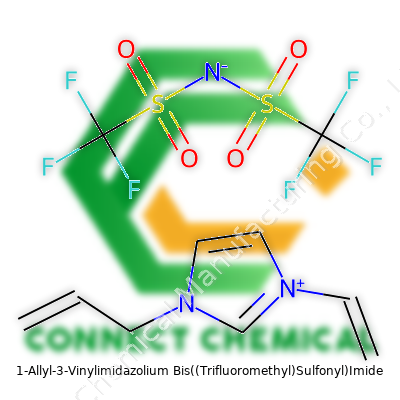

An Article on 1-Allyl-3-Vinylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide

Historical Development

Chemists have been searching for task-specific ionic liquids since the late 20th century, chasing after materials that bring fresh utility to electrochemistry, catalysis, and advanced separations. 1-Allyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide, with its roots in ionic liquid research from the 1990s, marked a breakthrough as both academia and industry scrambled to replace volatile organic solvents. Early studies focused on simple imidazolium compounds, but researchers soon began to see the potential of tuning both the cation and anion, chasing better thermal stability and flexibility. Pioneers like Seddon and Rogers showed the world that ionic liquids could do more than just dissolve hard-to-handle chemicals—they could change the environmental rules of the game. This particular compound built on those foundations, catching the attention of labs focused on safer and greener electrochemical processes.

Product Overview

1-Allyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide lands at the intersection of stability and reactivity. It bridges organic chemistry and materials science, offering a liquid medium with unique solubility for both organic and inorganic substances, and the right cation–anion pairing for customized function. The imidazolium core, familiar for its role in ionic liquid families, links to allyl and vinyl groups, opening doors to polymer science. The bis((trifluoromethyl)sulfonyl)imide anion (NTf2 or Tf2N) helps this compound resist water and heat, which sets it apart from more basic salts. Its commercial forms—ranging from colorless to pale yellow liquids—arrive in tightly sealed bottles, labeled by purity, water content, and batch traceability details.

Physical & Chemical Properties

You can expect this ionic liquid to pour easily at room temperature, thanks to a melting point well below zero Celsius. Low viscosity keeps things moving smoothly, which matters for working in reactors or electrochemical cells. NTf2 never lags behind when it comes to chemical stability—this anion shrugs off hydrolysis, so the ionic liquid maintains performance even in wet environments, a real edge over hexafluorophosphates or tetrafluoroborates. Boiling point sits far out of reach for most experiments; thermal decomposition comes into play before full vaporization. As for conductivity, the cation-anion combination allows reasonable ion mobility, important for batteries and capacitors. Water solubility tilts low, so organic synthesis and material applications don’t run into unexpected dissolving issues, unless you bring in a polar cosolvent.

Technical Specifications & Labeling

Producers usually supply this chemical at a minimum purity above 98%. Critical impurities such as unreacted monomers or water get listed in technical data sheets. Labels detail the correct handling, emphasizing the need for dry, cool storage and careful protection from strong acids or oxidizers. The physical form—liquid, sealed under inert gas—helps minimize water uptake during shipping and storage. Regulatory compliance, including adherence to protocols set by bodies like REACH or the US EPA, plays a part in global distribution. Lot numbers allow for trace-back, which supports both recall management and quality assurance in regulated sectors.

Preparation Method

Most labs approach this synthesis by quaternizing 1-vinylimidazole with allyl halides, such as allyl bromide, in polar aprotic solvents. After the cation forms, they bring in lithium or silver bis((trifluoromethyl)sulfonyl)imide, swapping out the halide for NTf2 via metathesis. Purification usually includes phase separation and drying over magnesium sulfate or similar desiccants, followed by vacuum stripping to get rid of volatiles. The product emerges as a low-viscosity liquid, which gets analyzed by NMR and IR to confirm structure and check for water or halide leftovers.

Chemical Reactions & Modifications

Chemically, this compound gives researchers two reactive handles: the allyl and vinyl groups. You can use radical or ionic polymerization techniques to build poly(ionic liquid)s—materials that anchor the ionic liquid into a solid or gel matrix for electrolyte or membrane work. The imidazolium ring isn’t just a bystander; under the right conditions, ring alkylation or deprotonation happens, though most applications value the ionic liquid for its inertness within the chosen reaction window. Cross-linking, oligomerization, and the formation of block copolymers expand the playground for anyone chasing advanced battery technologies or separation resins.

Synonyms & Product Names

Literature refers to this compound under names like 1-ALLYL-3-VINYLIMIDAZOLIUM TRIFLUOROMETHYLSULFONYLIMIDE, 1-allyl-3-vinylimidazolium bis(trifluoromethylsulfonyl)amide, or the terse abbreviation [AVIM][NTf2]. The designation [AVIM][Tf2N] sometimes shows up in technical bulletins or supplier catalogs. Product numbers vary, with chemical vendors using their own proprietary codes; this keeps procurement organized but can create headaches for database searches unless CAS numbers accompany all orders and records.

Safety & Operational Standards

Handling ionic liquids demands respect, even those with low volatility like [AVIM][NTf2]. Safety data sheets advise gloves and goggles; skin or eye exposure still causes irritation, and swallowing any quantity is out of the question. Even though the NTf2 anion offers better environmental profiles than more reactive halides, accidental releases into water should be avoided, given chemical persistence. Labs use fume hoods to avoid slow evaporation or accidental heating, and recommend troubleshooting spills quickly with absorbent pads tailored to organofluorine compounds. Disposal options must align with local environmental rules, which now scrutinize PFAS-type structures for evidence of long-term environmental build-up.

Application Area

The most dynamic uses pop up in electrochemistry, where [AVIM][NTf2] acts as either an electrolyte for high-voltage cells or a material for developing solid-state polymer electrolytes. The vinyl and allyl groups open the door to grafting or copolymerization, which helps in designing membranes for selective ion passage—critical in flow batteries or fuel cells. Synthetic chemists appreciate its ability to dissolve a wide swath of ionic and organometallic compounds, giving them a versatile solvent for transition-metal catalysis or difficult nucleophilic substitutions. Extraction and separation specialists tap its low vapor pressure to streamline the recovery of rare metals from ores or e-waste, bypassing hazards tied to volatile, flammable solvents common in the past.

Research & Development

In my own experience working alongside academic and industrial partners, researchers keep returning to [AVIM][NTf2] for the tweaking potential on both molecular and device levels. Polymerization chemistry explores new ways to fix ionic liquids in swollen networks that conduct ions but block gas or water. Interfacing these materials with metal oxides or carbon allotropes expands their reach to supercapacitors and hybrid fuel cells. Advances in ion transport and membrane formation rely on the tailored polarizability of the NTf2 anion, critical for fine-tuning conductivity without inviting thermal breakdown. Analytical labs trust its purity for method validation in spectroscopy and quantitative electroanalysis. Each research cluster brings a new spin—some aim for durability in flexible electronics, others focus on extracting platinum group metals or lanthanides for sustainable tech.

Toxicity Research

Toxicologists have taken fresh looks at perfluorinated anions, and while [AVIM][NTf2] resists hydrolysis, studies point out potential issues if persistent materials enter waterways. Short-term exposure in small doses shows low acute toxicity in rodents, but bioaccumulation studies call for further investigation. Workers exposed to aerosols, splashes, or contaminated surfaces reported mild skin or eye irritation; no chronic effects stand out yet, but long-term inhalation or repeated skin contact stay off-limits. Environmental agencies watch industrial discharges, since NTf2 shows a tendency to resist microbial breakdown. Labs often run bench-scale tests on aquatic toxicity with zebrafish or daphnia, looking for sublethal effects over periods of days or weeks.

Future Prospects

Looking at evolving trends, [AVIM][NTf2] fits well into the push for safer, greener chemistry and high-performance materials. The ability to modify both the cation and anion means chemists can chase both technical performance and lower environmental hazard in new generations of ionic liquids. If current research succeeds, this could mean batteries and fuel cells that use recyclable, low-flammability components built from elements with lower toxicity overall. Surface modification, 3D-printable gels, or selective extraction processes could become industry standards. That said, the industry needs to balance performance advancements with diligent tracking of environmental persistence, so greener synthesis and robust recycling options warrant strong investment moving forward.

Beyond the Lab: Where This Compound Makes a Difference

Curiosity took me into a few chemistry labs back in college, and there I watched molecules with long, twisting names fuel quiet revolutions. 1-Allyl-3-vinylimidazolium bis((trifluoromethyl)sulfonyl)imide, or [AVIM][NTf2] to insiders, doesn’t hog headlines. But the world leans on chemicals like this for reasons far from obvious: they keep factories running cleaner, batteries pumping longer, and scientists building better medicines.

Charging Ahead with Batteries and Supercapacitors

Rewind a few years—I had a front-row seat to the rechargeable lithium battery boom. The problem: safety, stability, and pushing the charge a little bit further every year. [AVIM][NTf2] steps in here. Because of its chemical makeup, it offers high thermal stability and doesn’t catch fire when pushed. Researchers and battery designers love this, as the push for electric cars and backup grids keeps getting louder. This compound finds its way into electrolytes for lithium batteries and supercapacitors, helping batteries last longer and handle heat.

Some studies show that its use can improve ionic conductivity, which just means electrons zip around more easily. That leads to faster charging and longer battery life. It’s not a magic bullet for cheap, sustainable power—but it gives engineers another reliable tool.

Green Chemistry in Industry

Factories chew through gallons of toxic solvents every day. Replacing them isn’t simple, but [AVIM][NTf2] offers a safer path. It’s an ionic liquid, so it barely evaporates and doesn’t add much pollution. Green chemistry circles have been buzzing about using it in place of harsh solvents for making pharmaceuticals or separating rare metals.

I’ve spoken with process chemists who see this as a way to protect workers and reduce waste, thanks to the compound’s low volatility. It can help strip out impurities without dangerous fumes. With regulators tightening the screws on emissions and chemical safety, interest in alternatives like this keeps growing.

Materials for the 21st Century

Advanced materials catch my attention—especially the ones that wind up in solar cells, sensors, or medical devices. Researchers turn to [AVIM][NTf2] for polymerization, which is a way of stringing molecules together to make tough, functional plastics. The vinyl group in this compound acts as an active site where new materials are built up, brick by chemical brick.

One engineer explained how these ionic liquids let labs tune the surface properties of a material—change how it sticks, how it repels water, or how conductive it is. This approach produces membranes that filter water, coatings that prevent corrosion, or films that pull electricity out of sunlight. This modularity means cleaner and longer-lasting products.

Challenges and What Comes Next

No one believes any single compound solves every problem. Cost still runs high, making industrial adoption slow. Long-term environmental impacts need more study—even the greenest solution on paper can surprise after a few years of mass use. But as manufacturers chase cleaner energy and safer production, the role for materials like [AVIM][NTf2] keeps expanding. Open conversations with engineers, environmental scientists, and regulators can help chart a safe course. If investment keeps pace, expect to see this molecule in places you don’t even notice—yet.

Trust, Experience, and Common Sense

A lot of tasks at home or on the job involve materials you don't think twice about, but the moment something looks out of the ordinary—strange powder, suspicious canister, substance with a warning label—you get that gut feeling. Relying on instincts as much as instructions can make all the difference. Failing to respect chemicals or ignoring safety manuals, whether for industrial cleaners or simple solvents, often brings trouble. I learned early on: trust warning labels and your nose. Unusual smells, tingling sensations, or colors signal caution.

Basic Protective Gear Isn’t Optional

Standard advice for handling unknown or hazardous stuff comes down to a few bedrock rules. Gloves, safety goggles, and masks don’t overcomplicate things—they’re baseline. More jobs could be done safely with a thirty-second check and grabbing the right gear. Splash-proof goggles, thick nitrile or latex gloves, solid shoes, and—if the instructions call for it—a respirator prevent injuries that last a lifetime.

Many exposures happen because a person skips protection “just for a few seconds.” For example, household bleach can burn skin, and strong acids do much worse. Even some common powdered chemicals release dust that damages lungs and can irritate the eyes. Forty million workers in the U.S. deal with hazardous materials. Most accidents happen to experienced hands who let their guard drop.

Ventilation and Handling Gimmicks

Some substances build up fumes—paint thinners, glues, strong cleaning agents. Working in the back of a dark garage or a closed bathroom raises risks fast. Good airflow tops the list of engineering controls that experts like the CDC and OSHA recommend. Just opening windows or setting up a small fan can stop headaches, chemical burns to nasal passages, and longer-term harm.

Keeping chemicals off your skin means more than slipping on gloves. Avoid eating or drinking where you work. Tools and containers pick up residue. Capping bottles when not in use, using scoops or dispensers, and labeling everything clearly keeps surprises away. Inside shops or labs, buddy systems and communication save lives—if you get a strong reaction, you need someone who knows the first aid steps immediately.

Get to Know Emergency Procedures

Nobody wants to use the eyewash station or emergency shower, but knowing their location brings peace of mind. I keep the poison control number and basic first-aid posters handy in my garage. Swallowing, spilling, or inhaling something toxic can quickly turn serious. Immediate rinsing with water, removing contaminated clothing, and calling help proves more effective than guessing.

Fire danger rides along with many chemicals. Having extinguishers nearby and knowing the type—ABC for most purposes, Class D for metals—helps contain small accidents. Never pour water on burning oil or solvent; smothering works better.

Respect the Risks

Every time I take a shortcut to save time, I remember stories of people who didn’t walk away. The MSDS (safety data sheets) posted online give clear info about handling, storage, and hazards. Printing these or having them in a visible spot in shared spaces arms everyone with facts—not just the pros. The more you respect both the substance and the process, the safer your work or home stays.

The Right Environment Matters

Products change over time, and so much of that has to do with the space where they land after leaving the factory. Anyone who’s seen milk left out on the counter too long knows temperature runs the show. Too warm, and most things—whether they’re drugs, food, or even cosmetics—start to lose their edge. For medication, storing at room temperature doesn’t mean a stint near the stove or inside a steamy bathroom. Instead, a cool, dry spot—ideally somewhere with steady temperatures between 20°C and 25°C—keeps things stable. That’s because constant shifts, even if it feels like just a degree or two, can cause active ingredients to break down before you ever twist off the cap.

Humidity Opens the Door to Trouble

It doesn’t take a science degree to notice what happens to crackers in a humid kitchen—they go stale quickly. Medications act much the same. Too much moisture can turn tablets mushy and make powders clump. Worse, it might even fuel mold growth in worst-case scenarios. In my own pantry, I’ve learned that high humidity ruins any hope of a snack lasting through the week. Medicine holds no special immunity here. A tightly sealed cap and storage apart from bathrooms keep excess humidity at bay, making sure products don’t end up contaminated or degraded.

Light Packs a Punch

Direct sunlight belongs in the garden, not streaming onto a box of medication or a container meant to last. Ultraviolet rays can break down chemicals before their time, especially those that keep their good qualities by sticking to darker bottles or opaque jars. Vitamin supplements often arrive in brown glass for a reason. Leaving that same bottle near a sunlit window shortens its life, sometimes without obvious clues.

Investing in the Right Containers

Original packaging holds more importance than people often imagine. Manufacturers do their homework to find bottles, blister packs, or bags that fend off moisture, air, and sunlight. Swapping out original packs for convenience—like dumping pills into plastic organizers—may look tidy but risks a faster slide into uselessness. Hard lessons from personal mistakes have taught me it’s wiser to trust the packaging science instead of shortcuts.

Details That Save

Check the label before putting anything away. Storing insulin, for example, demands cooler temperatures—usually a refrigerator, not the freezer or the back seat of a hot car. Some ointments keep best in the fridge because warmth speeds up separation, making them gritty. Keeping the information where it’s easy to find—on the box or a clear sticker—prevents guesswork when the label rubs off over time.

Solutions That Work

Maintaining lower moisture at home comes down to using simple tools like silica gel packs or small dehumidifiers. A shelf up high—away from light, heat, and reach of pets or children—works better than a cupboard above the stove. For situations where cold storage is needed, a standard kitchen fridge gets the job done if positioned away from freezing coils.

Making the effort to follow storage guidelines builds trust with producers and, more importantly, protects your investment and well-being. The details feel tedious at first, but every time a product lasts, the payoff becomes clear.

A Closer Look at Purity

Purity isn’t just a regulatory number on a certificate. For anyone who’s worked in a lab or tried to scale up a process, even a small drop in percentage means something. In chemical supply, folks expect to see purity levels sitting at 98% or higher for most technical or industrial use products. You move up to 99% and above if the work touches food, pharmaceutical, or anything regulated tightly for health. I remember during my time in analytical testing, anything less than 99.5% would set off a discussion—would it make the product fail? Would it change how the material behaves in synthesis? The reality is every percent counts, and even trace elements like metals or chlorides can make or break a process.

According to the US Pharmacopeia and several ISO standards, high purity specifications exist to keep outcomes predictable. In fact, the difference between “technical grade” and “reagent grade” comes right down to these decimal points. Technical grade works for large-scale manufacturing or things like cleaning, but not for research or patient-facing products. When ordering a product, certificates of analysis back up these numbers, showing results from titrations, chromatography, or spectroscopy.

What to Expect in Physical Form

After you’ve checked purity, the next surprise often arrives in the package. Powder, granule, or crystal—producers usually stick with what’s easiest to weigh, pour, or dissolve. For many common chemicals, a fine, free-flowing powder is the default, usually packed in airtight bags or drums to keep out moisture. Granules show up more in bulk orders or materials that clump together too quickly. Liquids also ship for some specialty chemicals, often sealed in bottles or drums with tamper-proof seals.

A bad experience with caked-up powders or inconsistent blends can ruin a day’s work, and anyone in the lab has seen what happens when you try to weigh a product that sticks to every surface. Most suppliers add anti-caking agents or ship products under nitrogen for products that are extremely sensitive to oxygen or water. I once received a shipment of material that had absorbed so much water on the journey that its properties had changed completely.

Troubles and Solutions

Nothing ever goes perfectly from the plant to the bench. Contamination creeps in through bad sealing or careless storage. At the user end, opening a can in a humid room can drop purity within minutes, especially for hygroscopic salts or acids. That’s why real-world users don’t just look at the certificate; they check the appearance and even run spot tests. Many buyers request smaller, vacuum-packed bags—even if they’re more expensive—just to keep the remaining material from reacting with the air every time the drum is opened. One lesson from years in the field: splitting orders into smaller units saves a lot of heartache.

Communication helps. Ask for a full analysis profile, not just a one-line purity figure. The packaging details matter. Some manufacturers also offer custom particle sizing or blending, so it’s worth a conversation if your process needs something different. For the best outcomes, establish a trusted relationship with suppliers who not only meet the grade but also listen to feedback and act quickly when issues crop up.

Keeping an eye out for these details means fewer surprises, less waste, and a smoother run, whether the product’s going into a pilot reactor or a small classroom setup.

More Than Just Another Solvent

Ionic liquids get chemists excited. Their melting points refuse to budge even past 100°C, showing a liquid state where many salts would still cling to their solid form. This strange resistance opens up a door to fresh thinking in both polymerization and electrochemical work. My own attempts at making tough, durable polymers usually involve old-school solvents that smell awful and demand careful handling for fire and toxicity reasons. Swapping out these for ionic liquids often changes the process entirely. These compounds bring chemical stability and very low vapor pressure, helping minimize dangerous fumes. As health and safety rules tighten, finding solvents that avoid headaches—literal and regulatory—pushes more labs to experiment with novel liquids.

Unlocking Control in Polymerization

Polymer scientists face a simple problem: how to control the growth of chains. Ionic liquids provide a toolkit that traditional solvents simply can't offer. Viscosity, polarity, and ion content all tune the process. During one project on radical polymerization, using an ionic liquid halted runaway reactions that would normally spoil a batch in regular solvents. High ionic conductivity lets reactions finish efficiently without overheating. Plus, the right ionic liquid can suppress side reactions, leading to better product consistency. Some even show antimicrobial behavior, which keeps the final polymer cleaner from the start—handy in medical or food packaging. A few industrial teams have shown that swapping in ionic liquids during step-growth polymerization helps build materials that are both lightweight and less brittle, avoiding the endless struggle between strength and flexibility.

Changing the Game for Electrochemical Devices

The world leans hard on rechargeable batteries, supercapacitors, and flexible electronics. Traditional electrolytes often dry out, catch fire, or perform badly under heat or cold. Ionic liquids come with no flammable fumes, and handle high voltages without breaking down. During a summer internship, I watched a team tweak lithium-ion cells using an ionic liquid. Cycle life shot up and battery swelling dropped off, making the cells safer—even after repeated charging. Electroplating labs enjoy how ionic liquids let them lay down metal at lower temperatures or create surfaces that resist corrosion. No need for heavy, dangerous acids in the bath; ionic liquids keep metal ions dissolved and stable. In fuel cells, performance jumps thanks to non-volatile ionic liquids that curb unwanted side reactions at the electrodes, pushing up efficiency.

Tough Hurdles and Real Solutions

The main challenge stays cost. Ionic liquids don’t get produced at the same scale as classic solvents yet, so their sticker price shocks budget-minded technicians. Some are even harder to recycle cleanly. Still, advances in synthesis have trimmed costs year by year. Open communication between research labs and manufacturers can accelerate this drop. Toxicity also needs scrutiny. Not all ionic liquids are benign, especially with odd cations or large fluorinated anions in the mix. I have seen teams switch formulas after toxicity screens flagged risks in aquatic environments. Consistent, transparent risk testing and regulatory collaboration make sure “safer” choices reach the factory floor. Open access to environmental fate and transport data would help entire industries make informed decisions. Small startups and university labs set examples here, posting test results for peer review.

Shaping Tomorrow’s Materials

For anyone building the future—longer-lived batteries, medical-grade plastics, greener manufacturing—ionic liquids promise a reset on how many chemical processes work. Balancing performance, safety, and sustainability remains a group effort. Wider adoption will depend on reliable cost data, tough safety studies, and honest results. The shift toward ionic liquids in polymer and electrochemical fields signals a break with past limitations, steering materials science into new territories.