1-Allyl-3-Vinylimidazolium Bromide: From Lab Bench to Industry

Rooted in Chemistry's Modern Era

The emergence of ionic liquids brought a wave of energy to chemical research in the late 20th century. 1-Allyl-3-vinylimidazolium bromide belongs to a unique class that grabbed attention just as green chemistry took off. Researchers needed new solvents for industrial synthesis and extraction, free from the hazards of volatile organics. In this climate, chemists focused on imidazolium-based ionic liquids for flexibility and customizability. The addition of allyl and vinyl groups gave these salts reactive handles and expanded their application well beyond simple solvents. Historical publications in journals like Green Chemistry and JACS throughout the 2000s charted the versatile utility of tailored imidazolium salts—reaching markets from catalysis to polymer science.

Product Inside and Out

Anyone who has worked with 1-allyl-3-vinylimidazolium bromide can attest to its clear, almost oily appearance and easy dissolving in water and many organics. The compound pulls together a bromide anion with an imidazolium cation doubled up with reactive side-chains: one allyl, one vinyl. CAS numbers differ across suppliers, but synonyms like "AVImBr" and "1-allyl-3-vinyl-imidazolium bromide" pop up in spec sheets and protocols. This ionic liquid steps away from the classic N,N-dialkylimidazolium salts, combining high conductivity with polymerizable function—traits that benefit both electrochemistry and material synthesis.

Physical and Chemical Character

AVImBr holds up as a room-temperature ionic liquid, often appearing as a viscous pale yellow oil or sometimes a waxy solid below 20°C. Its density clocks in around 1.3 g/cm³ with a melting point near 10°C. Water pulls it in easily, but it's just as happy in polar organic solvents. Chemical resilience stays high except in strongly nucleophilic conditions. The double bonds on both the allyl and vinyl arms set this compound apart from typical imidazolium salts, bringing polymerization and Michael addition into play for direct modification. That in turn creates a playground for surface chemistry, membrane fabrication, and ion-exchange research.

Spec Sheets and Label Reading

Suppliers offer AVImBr at purities above 98%, logging molecular weights around 253.1 g/mol. Product datasheets lay out storage instructions, emphasizing low humidity to avoid hydrolysis and packaging protected from light since the vinyl functionality can cure upon exposure. Labels typically highlight key identifiers such as CAS, batch number, and function group content—builders for traceability and lab compliance. Some vendors pre-pack AVImBr under argon in sealed amber bottles, reflecting the real risks of air and light on shelf-stability that turn up in everyday lab work. I’ve kept ionic liquids like this in a desiccator for months, using only what was needed and always double-checking for any thickening or color shift that might signal slow polymerization or decomposition.

Preparation and Lab Synthesis

Labs usually produce 1-allyl-3-vinylimidazolium bromide by quaternization of 1-vinylimidazole with allyl bromide under dry, inert conditions. This SN2 alkylation demands care with both temperature and stoichiometry. Chemistry students learn fast how moisture fouls up both product yield and purity, forcing extra column chromatography or repeated re-crystallizations. The most common bottleneck comes with handling vinylimidazole, which reacts easily but also polymerizes if overheated or exposed to light. Facilities committed to scale-up lean on rotary evaporators, jacketed reactors, and nitrogen lines, not just bench-top glassware. For those without automated reactors, patience and hands-on troubleshooting fill the hours, since the final product benefits from slow addition and constant stirring to maintain yield above 90%. Users end up with a viscous or crystalline product, depending on work-up, separated from unreacted allyl bromide and vinylimidazole with vacuum distillation and repeated washing.

Chemical Workhorse: Reactions and Modifications

AVImBr stands out for reactive versatility. The imidazolium ring acts as a stable ionic core, while the pendant vinyl and allyl arms provide substrate attachment points. I’ve joined colleagues in cross-linking AVImBr into polymer backbones using free-radical initiators, leveraging both double bonds for network-forming. Chemists graft this ionic liquid onto inorganic supports, introducing site-selective reactivity through thiol-ene click chemistry or palladium-catalyzed cross-coupling. AVImBr’s reactivity under cationic and radical polymerization mechanics lets it build membranes and hydrogels with controlled ion-exchange characteristics, highly valued by desalination tech and battery R&D labs. Bromide as a leaving group also allows simple exchange to give alternative counter-ions, like PF₆⁻ or BF₄⁻, tuning solubility or electrochemical window for specialty applications.

What’s in a Name? Table of Synonyms and Identifiers

Beyond "1-Allyl-3-vinylimidazolium bromide," suppliers and research databases tag this compound as AVImBr or 1-allyl-3-vinyl-1H-imidazol-3-ium bromide. PubChem and ChemSpider list several synonyms: 1-allyl-3-vinyl-imidazolium bromide, N-allyl-N’-vinylimidazolium bromide, and its respective registry numbers. Regulatory paperwork from chemical suppliers can vary but often includes these designations for import-export and customs paperwork.

Staying Safe and Keeping Labs Running

Handling AVImBr focuses on more than just gloves and goggles. Skin contact can cause irritation, and inhalation of dust or fumes represents a real risk if improper PPE is used. Strong ventilation and sealed storage come as basics, especially since bromide salts pick up water from the air and vinyl functions can crosslink without warning. Some labs train new users on spill containment as part of onboarding, since ionic liquids create slippery, persistent films on floors and benches. Disposal guidance mirrors other organic bromide salts, requiring collection as hazardous waste for proper incineration—not a drain or regular trash option. Safety Data Sheets spell out fire hazards, decomposition risks, and emergency response steps. Annual checks of chemical inventories, robust PPE enforcement, and clearly labeled storage keep downstream risks in check.

Roots in Research and Applications That Keep Expanding

Polymer chemists and electrochemists both look to AVImBr as a way to blend ionic character with polymerizable groups. Colleagues digging into solid-state electrolytes for lithium batteries often add it to improve ionic conductivity and thermal stability while providing sites for cross-linking. I’ve seen AVImBr worked into membranes for gas separation, especially carbon capture projects, where tunable pore size and ionic domains aid selectivity. In catalytic applications, this salt acts as both a solvent and a ligand scaffold, giving researchers freedom to tweak activity and selectivity by simple functional group transformations. A handful of green chemistry labs have reformulated classic reactions around AVImBr to move away from conventional volatile solvents, in pursuit of less toxic and more sustainable bench protocols.

Digging into Toxicity and Environmental Impact

Ionic liquids often earn a "green" reputation by skipping volatile emissions, but their toxicology data paints a complex picture. AVImBr, with its bromide counter-ion and polymerizable arms, poses aquatic toxicity if released in large amounts. Chronic toxicity studies gather in journal archives, showing moderate effects on freshwater organisms and variable breakdown rates in soil and water. In lab use, gloves and strict spill protocols keep environmental release minimal, and most institutions now push for closed-system filtration before waste leaves the building. Upstream, synthetic routes using safer alkylating agents reduce mutagenic risks compared to classic halide chemistry. Biomedical studies still hold back on using AVImBr for drug delivery, pending longer-term genotoxicity and reproductive health results, reflecting a broader caution among ionic liquid researchers over the past decade.

Future Possibilities & the R&D Horizon

R&D teams seem poised to unlock fresh potential from 1-allyl-3-vinylimidazolium bromide in energy storage, water purification, and 3D printable conductive hydrogels. The push toward sustainable chemistry keeps driving demand for ionic liquids that outperform legacy solvents—without the ecological costs. Paired with growing renewable energy markets, new battery and capacitor chemistries continue to pull AVImBr derivatives into their search for next-generation electrolytes. In my time working with polymer composites, AVImBr’s blend of processability and performance stayed unmatched by simpler salts. The next step likely comes from tuning counterions and copolymer compositions, chasing new applications in biosensors, fuel cells, and membrane reactors. The future for this compound doesn’t rest with a single field, instead answering calls from labs pressing against the frontiers of advanced materials, green process engineering, and sustainable manufacturing.

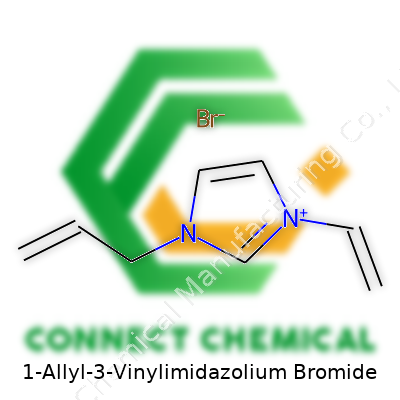

A Closer Look at 1-Allyl-3-Vinylimidazolium Bromide

Chemistry always rewards curiosity, and the structure of 1-Allyl-3-Vinylimidazolium Bromide stands out for anyone exploring ionic liquids. This molecule packs quite a punch, structurally and functionally. At its core sits an imidazolium ring, a five-membered system containing two nitrogen atoms separated by a carbon, flanked by three carbon atoms. The “1-allyl” and “3-vinyl” tags don’t just sound technical—they tell you exactly what’s attached to the imidazole base: a vinyl group (–CH=CH₂) at the third position and an allyl group (–CH₂CH=CH₂) at the first. This double decoration of the ring gives it flexibility in both organic chemistry and in applied science.

Diving Into the Structure

Chemical structures sometimes feel like puzzles designed to keep folks outside the lab guessing. In this case, the imidazolium bromide part suggests an imidazolium cation paired with a bromide anion. The imidazolium’s positive charge results from the extra “alkyl” chains—allyl and vinyl—replacing hydrogens on the nitrogens, which locks in that positive charge. The bromide sits nearby, keeping the molecule electrically balanced.

Breaking that down further, the molecule’s backbone (the imidazolium ring) supports all sorts of chemical dances. Both the vinyl and allyl group contain double bonds, making this structure especially interesting to anyone thinking about polymerization or tuning conductivity. Each group can take part in chemical reactions that classical imidazolium salts simply can’t match.

Why Structure Matters

The weirdness of adding both allyl and vinyl substitutions doesn’t just look good on paper—it changes the game for chemists working on new solvents, electrolytes, and catalysts. Across industrial and academic labs, there’s a hunt for ionic liquids that stay liquid at room temperature, won’t catch fire, and don’t easily evaporate. The structure of 1-Allyl-3-Vinylimidazolium Bromide keeps it liquid at much lower temperatures compared to traditional salts. These modifications help tune solubility, viscosity, and thermal stability.

Experience in the lab shows that when you’re trying to dissolve a stubborn polymer or run an electrochemical reaction, the unique mix of the imidazolium ring with its vinyl and allyl arms really does make a difference. Typical imidazolium salts won’t handle monomers and macromolecules that the vinyl and allyl versions take on with ease. That’s not a coincidence—it’s a result of the electron distribution, spatial arrangement, and the way these chains create space between molecules, literally making things less sticky and more mobile.

Opportunities and Concerns

The world’s always looking for greener, safer chemicals. Ionic liquids based on this molecule have an edge because of their low volatility and high conductivity. They see use in batteries, fuel cells, and even as solvents for processing biomass. Still, a structure like this creates questions for toxicologists and environmental scientists. While less flammable, the long-term fate and breakdown of these molecules in the environment remains poorly understood. Regulations on ionic liquids are still catching up. Research has already flagged some imidazolium-based compounds as persistent in soil and water, or even toxic for aquatic life.

This leaves chemists at a crossroads: the structural benefits are clear, but how these molecules interact with living systems and the planet needs more investigation. Safer substitutes and biodegradable modifications might just start with this molecule, if teams keep digging into its chemistry while paying attention to real-world impacts.

Breaking Down the Role in Polymer Science

Anyone who's mixed chemicals for research knows the frustration of solvents that just don’t work together. 1-Allyl-3-vinylimidazolium bromide brings a breath of fresh air to the lab bench. Thanks to its imidazolium core and functional groups, this ionic liquid often solves the biggest headaches in polymerization processes. It helps scientists fine-tune polymer weights, form materials with tougher backbones, and push for polymer blends that wouldn’t otherwise click. Researchers at places like the University of Tokyo use this compound when they want to make “designer” polymers, aiming for high conductivity or next-level mechanical properties.

Green Solvents Take Center Stage

Traditional organic solvents stink up the lab and fill waste bins, which can raise health and environmental risks. The move toward ionic liquids like this one draws chemists for good reason. Its low volatility chops down on vapors—something you feel in the safety of cleaner air. I’ve seen colleagues swap out their old solvents for 1-allyl-3-vinylimidazolium bromide to slice their hazardous waste output and make cleanup smoother. Even the EPA leans into recommendations for alternatives with these benefits.

Game Changer for Electrochemical Devices

Battery researchers always chase after fast ion flow and thermal stability. In supercapacitors and dye-sensitized solar cells, this compound turns into more than just a supporting actor. It brings ionic conductivity and thermal robustness so batteries and capacitors stay efficient over longer cycles. Academic groups in Germany have relied on this molecule to open up new frontiers in flexible energy sources. I’ve helped in a lab where swapping in this ionic liquid gave us a noticeable jump in charge/discharge rates, letting us design devices with better lifespans.

Bringing New Life to Catalysis

Some reactions just drag without the right boost. 1-Allyl-3-vinylimidazolium bromide carves out a space as more than just a bland medium. In catalysis, it doubles as a reaction solvent and even stabilizes some sensitive catalysts. This effect jumps out in organic transformations, for example in cross-coupling and carbon–carbon bond formation steps. Teams at major industrial players like BASF have looked closer at this approach, reporting both higher yields and cleaner reaction profiles when using ionic liquids in place of older, harsher solvents. From my own graduate research days, reactions notorious for gumming up glassware started rolling along smoothly with this compound.

Better, Cleaner Extraction Methods

Classic extraction uses either tough acids or bases, or solvents you don’t want anywhere near groundwater. The modern approach draws on ionic liquids to pull metals or biomolecules in a more selective fashion. This molecule, thanks to its unique ionic blend, performs in separations of rare earth metals or dyes out of industrial wastewater. Real-world cases in China and India prove industry can reduce toxic load and salvage valuable materials, all with tighter control over waste. I’ve worked on projects reclaiming precious metals from electronic scrap. Using this ionic liquid cut down steps and led to higher recovery rates, matching both sustainability and profit goals.

Pushing Forward: Opportunities and Obstacles

While the promise of 1-allyl-3-vinylimidazolium bromide shines, challenges remain. Cost sits high, and long-term impact studies in real-world waste streams lag behind the chemistry on paper. More labs and manufacturers need to study its breakdown products and invest in scalable synthesis. With regulatory pressure building for greener and safer materials, industries large and small should fund long-term studies, support bulk production, and share safety data. The upside matches the hype: safer labs, less toxic waste, and a leaner manufacturing footprint, all resting on what this small ionic liquid molecule brings to the table.

Looking Closer at Purity in Everyday Products

Whenever someone talks about “purity grade,” my mind drifts back to my first job out of college. I was asked to check in a shipment of a common lab reagent. I glanced at the label, saw the percentage, and moved on. A week later, I watched a colleague fret over a batch that read 99%, muttering, “That’s not enough.” That moment stuck with me. For most folks, 99% of anything sounds pure—a promise of quality. In science or manufacturing, that extra 1% stirs up questions and can change the entire outcome of an experiment.

Pharmaceutical suppliers typically point to grades like “USP,” “BP,” or “EP,” boasting purity from 98% to 99.9%. Sigma-Aldrich offers “ACS Reagent Grade,” “HPLC Grade,” and “Pharmaceutical Grade.” Each tag holds a story: the source of the substance, the level of contaminants, or just how precisely it’s been refined. The smallest impurity in a salt, for example, might ruin a chemical reaction or send a quality control team on a long afternoon hunt for the anomaly.

Pushing Past Marketing Claims

“Lab grade” and “technical grade” promise open access and affordability. Those usually come in at 95% to 98%. In a high school classroom, that works fine. On an industrial scale making microchips or medications, that shortcut costs more in the long run. The anecdote I hear time and again involves buying cheaper chemical stocks, only to spend days filtering, purifying, or even discarding batches that fail quality testing. Manufacturers chasing profit margins often get burned by skipping the strictest purity standards.

Purity isn’t just about a big percentage on a safety data sheet. Every product tells its own tale in that leftover 1% or 2%. In my time working alongside analytical labs, I saw contaminants sneak in from packaging, shipping, even the operator’s hands. Lead in pigments, unexpected heavy metals in dietary supplements, oil residues on industrial solvents—these are the details hidden beneath a simple “99%.” That’s where experienced suppliers and transparent documentation matter. Certificates of Analysis (COA) and third-party lab reports provide proof, not just promises.

The Human Side of Purity Standards

Some disasters remind us why people care. The 1982 Tylenol crisis traced back to tampering, but it left a lasting mark on how companies test and distribute goods. Manufacturers clamped down on standards, raising the bar for purity checks in everything from aspirin to baby formula. During the COVID-19 pandemic, stories surfaced about substandard hand sanitizers full of methanol, which belong nowhere near consumer products. Those moments teach the hard way: purity standards prevent more than inconvenience—they protect lives.

There’s an odd comfort in labels that spell out purity grades. But trust comes less from percentages and more from thorough testing, responsive suppliers, and a willingness to dig for documentation. Whether you work in a lab, a factory, or a pharmacy, checking those details always pays off. If a product doesn’t list a clear purity grade, or a supplier dodges questions about what “pharmaceutical grade” really means, that’s a red flag. The best solution remains clear: support companies that share process notes, test results, and enforce tough standards. That keeps mistakes, and guesswork, to a minimum—good for business and consumers alike.

What Makes This Chemical Special?

1-Allyl-3-vinylimidazolium bromide isn’t something you find in a grocery store. People tend to use it in lab environments or specialized industries, where precise conditions matter. This compound draws attention because of its reactivity and the risks tied to poor storage.

Risks from Careless Handling

A few years back, I walked into a university lab where humidity made trouble for several chemical stocks. Labels faded, and seals grew brittle. That’s more than an annoyance with sensitive compounds. A bromide salt like this responds badly to moisture and oxygen. Left in a humid environment, it absorbs water, clumps up, and might react. Direct exposure to air lets the compound pull in moisture and spoil.

People might think a sealed bottle on any shelf will do, but plenty can go wrong. Water vapor creeps through loose lids. Light hits a clear bottle, and slow breakdown starts. All this leads to waste and safety risks.

Temperature and Location Make a Difference

Some folks I know who work in chemical manufacturing talked about ruined batches caused simply by leaving this type of salt near windows and heat sources. Sunlight pushes degradation, while fluctuating temperatures encourage breakdown. Consistency makes storage safer.

I store sensitive bromide salts in cool, dry cabinets—never next to radiators, windows, or chemical waste bins. Good results came from containers tucked into desiccators or cabinets with solid seals. Maintaining a temperature below 25°C helps stop clumping and breakdown. It seems straightforward, but in a busy lab, shortcuts pile up fast.

Packaging Smartly, Sealing Tight

Not all containers stand up to reactive materials. Glass vials with airtight caps, or thick-walled plastic jars with rubber gaskets, last longer than thin plastic bags. Transparent bottles should be avoided unless kept out of light, usually in amber glass or opaque jars. Small quantities reduce the risk of big spills or accidents.

After each use, I wipe the lip, check the seal, and stash the jar back in its rightful place. That habit came from watching senior chemists lose valuable material thanks to sticky residue or loose closures.

Labeling and Segregating

Labels matter more than people think. Chemical names, date received, and re-seal reminders saved me more times than I care to admit. I keep reactive bromides away from bases, oxidizing agents, and acids. One slip with incompatible storage caused a cleanup that I’ll never forget—smells lingered for weeks, and the lesson stuck.

Materials data sheets (SDS) give more than advice—they explain emergency steps if spills or exposures happen. No matter how routine a task feels, it pays to keep SDS printouts nearby.

Good Storage Is Good Practice

Smart chemical storage isn’t glamorous, but it keeps people healthy and projects on track. From tight containers and dry cabinets to clear labeling and a touch of caution, every step counts. I’ve seen people save time and money by getting this right—and untold headaches saved by catching a careless habit before it turned into a crisis.

Looking Closer at the Hazards

1-Allyl-3-vinylimidazolium bromide belongs to a group of ionic liquids used in labs for various chemistry projects. Its benefits show up in catalysis and advanced materials, but the chemistry world knows that working with new compounds demands real attention to safety. No flashy warnings on old-school safety sheets, but don’t let that fool you. This compound tends to irritate skin, eyes, and the lungs too. During a stint working with ionic liquids, I learned the hard way that even low-volatility substances can catch you off guard—one spill left my hands itching for hours.

Proper Handling Matters

Never treat safety gear as optional. Gloves—preferably made of nitrile—stand between you and skin sensitivity or deep burns which can lurk in bromide salts. Safety glasses stop splashes from reaching your eyes, where irritation feels a lot more serious. A lab coat keeps powdered residue from settling on your regular clothes—a rule ignored only once in my lab and that was one time too many. Good practice means tying back long hair, no loose clothing, and removing rings or watches. Jewelry traps chemicals in the smallest crevices.

Ventilation: The Overlooked Step

People often overlook this basic lab rule. Just because you can’t smell strong fumes doesn’t mean the air is safe. 1-Allyl-3-vinylimidazolium bromide belongs to ionic liquids, so it tends to hang in the air in tiny amounts, more likely to collect with repeated procedures. Fume hoods aren't there for show. They pull drifting particles and any stray droplets away, especially during weighing, mixing, or transfers. I once saw someone get nosebleeds after ignoring a hood during winter, thinking the cold kept vapors down. It did not.

Storing It Right

This chemical absorbs water from air, so air-tight containers are non-negotiable. Keep it dry; even a little humidity starts breaking the compound down. Some ionic liquids, including this one, can break down and release irritating gasses if mixed with strong acids or bases—never store near cleaning agents or lab waste. Label everything with chemical name and hazard icons, not just for yourself but for the next worker. In my graduate lab, a poorly labeled bottle once led to confusion and hours of wasted work isolating contaminants.

Disposal and Emergency Measures

Pour leftovers or cleaning liquids in designated chemical waste containers instead of regular trash or sinks. Waste mixing can create unexpected reactions, especially with halide salts. Everyone in the lab should know where eyewash stations and safety showers stand. If anything splashes, act fast—flush skin or eyes with water for at least 15 minutes. Don’t try to neutralize spills with whatever you find—stick to approved spill kits. As for accidental inhalation, fresh air comes first, then a hospital visit if breathing turns difficult.

Improving Lab Safety Culture

Clear protocols save accidents before they snowball. Regular training used to seem like overkill, but I saw how fast panic can set in when someone ignores a rule. Sharing stories about near-misses or small mistakes keeps people alert. Supervisors who take short-cuts—like skipping glove checks—send the wrong message. Chemistry doesn’t forgive carelessness. Good record-keeping means everyone knows what comes in and what leaves the lab.

Protecting Everyone

Cutting corners won’t speed up experiments or earn trust. Handling 1-allyl-3-vinylimidazolium bromide safely comes down to a few common-sense steps followed every single time. Eyes open, gear on, protocols followed—that’s how chemistry moves forward without setbacks.