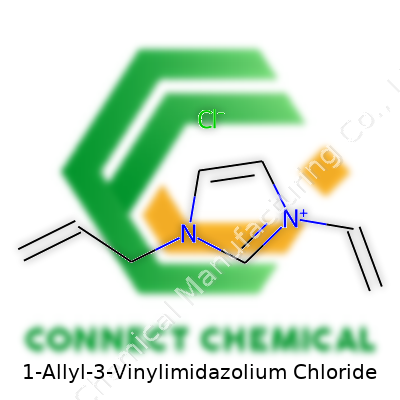

Commentary on 1-Allyl-3-Vinylimidazolium Chloride: Expanding Horizons in Modern Chemistry

Historical Development

Organic salts with the imidazolium backbone emerged as remarkable players in green chemistry after the turn of the millennium. Chemists started searching for non-volatile and non-flammable alternatives to regular solvents, and ionic liquids quickly pulled ahead. Among these salts, 1-Allyl-3-Vinylimidazolium Chloride drew attention because its unique vinyl and allyl substitutions brought extra reaction possibilities compared to older imidazolium compounds. The curiosity around this compound grew as scientific communities in Europe and China raced to develop functionalized ionic liquids that could break through the barriers of traditional process chemistry. In academic labs, coating glassware with this substance quickly felt routine, thanks to its manageable liquid state and pronounced ionic characteristics. The real appeal came when people realized that the simple chloride ion paired with the functionalized imidazolium ring could unlock applications across catalysis, polymer engineering, and electrochemistry.

Product Overview

1-Allyl-3-Vinylimidazolium Chloride looks like a pale to colorless viscous liquid that grips moisture from the air. The formula, C8H13ClN2, has nearly equal allyl and vinyl reactivity mirrored in the overall molecule. Users often need only basic knowledge of organics to handle this reagent; it pours and measures with reasonable ease in a fume hood. It dissolves in water and most polar solvents, though some researchers prefer it neat when exploring polymeric materials. From pilot to bench scale, the compound’s balance between stability and chemical activity drives experimental goals without too many surprises. For small start-ups and established academic teams alike, the main draw lies in straightforward functional group chemistry and the window it opens to customized ionic environments.

Physical & Chemical Properties

Boiling never enters the conversation, as 1-Allyl-3-Vinylimidazolium Chloride decomposes long before, making distillation obsolete. Its melting point remains well below room temperature, locking the product in liquid form for most processes. Strong ionic conductivity, thermal stability up to around 200°C, and a hygroscopic nature set it apart in the expanding pool of ionic liquids. The glass-transition phenomenon shows up prominently for those looking to create hybrid polymers or composite materials. In a typical spectroscopic scan, the imidazolium resonance emerges cleanly, giving clear confirmation of structure. Chemists often comment on its odorlessness, but uninitiated people should think twice before handling without gloves, as the salt clings adamantly to the skin and lab benches. Density and refractive index follow suit with other imidazolium liquids, signaling purity and composition without the need for advanced equipment.

Technical Specifications & Labeling

Manufacturers stamp the bottle with purity—usually above 98%—and recommend storing away from direct sunlight and air to prevent hydrolysis or slow degradation. Labeling always includes hazard pictograms, though most safety sheets remain sparse compared to volatile inorganic salts. Lot numbers and batch records hold water for traceability, especially in regulated labs. Users look for specifics such as water content (less than 1%), residual solvents, and chloride content. Classic 500-gram amber glass bottles dominate the packaging scene, with polytetrafluoroethylene and polypropylene caps standing up to the ionic creep common to many imidazolium salts. Never trust a generic name alone, since dozens of similarly structured salts crowd online catalogs. Clear technical sheets, Material Safety Data Sheets, and reliable lot history spell peace of mind for repeat buyers.

Preparation Method

Most chemists interested in 1-Allyl-3-Vinylimidazolium Chloride start with 1-vinylimidazole and mix it with allyl chloride under gently heated conditions, making sure to stir thoroughly to encourage alkylation at the third position. After the exothermic reaction, the crude product often soaks up water, making careful drying under reduced pressure a crucial step. Impurity removal sometimes includes charcoal filtration or washing with nonpolar solvents, especially when preparing research-grade samples. Large-scale syntheses benefit from continuous-flow pumps and more advanced reactors to handle the heat and sticky by-products. While yield tends to hit a steady high percentage, the tactile process of drying and purifying challenges even seasoned lab workers. Those who shortcut the dry-down or skimp on purification often taste the consequences through off-spec color or erratic behavior in downstream reactions.

Chemical Reactions & Modifications

Modification begins with either the vinyl or allyl group—each acts as a convenient handle for further chemistry. Polymer chemists draw lines to classic radical copolymerization, easily roping this ionic monomer into hydrogels, conductive polymers, and new membrane materials. Crosslinking across the vinyl group brings about swelling gels invaluable for controlled-release formulations. Some teams choose alkylations, hydroformylations, or even click chemistry on the allyl group to graft new side chains or anchors. Electrochemists like its ability to stabilize charged intermediates for transition-metal catalysts. In catalysis, the chloride counterion supports ligand exchange, helping deliver control in processes that depend on ionic strength and conductivity. The real world widens as organic, inorganic, and polymer scientists vie to capitalize on the dual-reactive structure, discovering pathways that regular imidazolium salts seldom allow.

Synonyms & Product Names

In product catalogs, 1-Allyl-3-Vinylimidazolium Chloride comes up under several trade names and synonyms: AAEM Cl, 1-Allyl-3-(ethenyl)imidazolium chloride, N-allyl-N-vinylimidazolium chloride, and CAS number 249279-52-1. Some vendors use European-style spellings or alternate ordering of substituent names, so search results often demand close inspection. On bottles, the full IUPAC name stretches across labels, sometimes with even more detail, such as “Hydrochloride” appended on non-English safety sheets. Academic journals refer to the salt in short form (AviImCl in shorthand), especially in polymerization and ionic liquid specialist circles. Consistency in product naming relies on both vendor integrity and consumer vigilance, since close analogs and counterion swaps change properties dramatically.

Safety & Operational Standards

Handling 1-Allyl-3-Vinylimidazolium Chloride calls for chemical-resistant gloves, goggles, and well-ventilated fume hoods. Most users stash it out of direct sunlight, capping bottles tightly after each use to limit water gain. Direct contact leaves a soapy residue that stubbornly resists simple washing; cleanup needs soap, copious rinsing, and occasionally acetic acid. Waste containers specific to ionic liquids work best for disposal, as regular halogenated waste can react or become unstable when mixed. Laboratories that adopt strict inventory systems rarely lose track of this reagent, but smaller teams sometimes face issues with ethereal fumes from accidental heating. On the regulatory front, authorities in the European Union and United States require updated SDS sheets and full compliance with REACH and OSHA labeling protocols. Safety culture strengthens each cycle, shaped by trial, error, and a few minor spills retold at conferences and seminars.

Application Area

Organic electronics, surface coatings, and ion-conductive membranes all welcome this versatile ionic compound. Energy researchers throw its name into fuel cell discussions, where its stability and conductivity outperform many old-school electrolytes. In polymer labs, the monomer powers the design of antifouling agents, sticky adhesives, and next-generation networks for controlled swelling or release. High school and undergraduate chemistry demonstrations now sometimes include ionic liquid preparations as green chemistry showcases, also showcasing its capacity for dissolving otherwise stubborn biomolecules. Biomedical engineering teams test gels made from this salt for their wound-healing and drug-delivery tricks. In advanced sensors and batteries, the unique balance of vinyl and allyl groups can tune both mechanical and electrochemical stability, pushing innovation in flexible devices and soft robotics. It’s the ability to leap between disciplines that makes this salt a key ingredient in both basic research and commercial prototypes.

Research & Development

Research groups keep searching for ways to optimize synthesis, tweak purity, and uncover new applications. Breakthroughs crop up when combining this ionic liquid with nanoparticles and hybrid organic-inorganic frameworks. I’ve seen teams unlock performance jumps in lithium-ion batteries by introducing this salt as part of the electrolyte mix. Others grind out new membrane materials that tackle desalination and gas separation using the unique reactivity of the imidazolium center. Grants pour into studying its use in carbon dioxide capture, where tailored functionality could drive costs down for large-scale emissions controls. Polymer scientists pursue reversible networks and self-healing gels, finding that the careful dance between allyl, vinyl, and imidazolium groups writes the rules for long-term stability. Patent filings trickle in, especially in the field of printable electronics and new energy storage. The engine of discovery keeps rolling, energizing both academic ecosystems and industry research benches with challenges and fresh questions.

Toxicity Research

Toxicologists focus on both the immediate risks to lab workers and long-term environmental effects. Early data show that, compared to classic solvents, this ionic liquid tends to display lower vapor pressure and fire risk. Skin and eye irritation come up first in occupational studies, with strong evidence for both acute dermatitis and longer-term sensitivity in case of repeated exposure. In the environment, its persistence and resistance to breakdown drive ongoing debate. Some test models hint at aquatic toxicity, particularly to microorganisms, though data remain limited outside model ecosystems. Industry guidelines stress proper containment, labeling, and prompt cleanup after any spill, since soluble salts can migrate through wastewater streams and influence plant growth or aquatic health. Regular updates to the European REACH registry and American EPA inventories ensure new batches and imports remain traceable and accounted for. Testing for chronic exposure in rodent studies continues, as industry groups weigh risk management against green chemistry promises.

Future Prospects

With each new research cycle, the field spots more opportunities for innovation. 1-Allyl-3-Vinylimidazolium Chloride already plays a part in reshaping the way energy, water, and biomaterials are handled in labs and industries. The growing focus on sustainable chemistry and renewable materials looks set to push this ionic salt deeper into high-value manufacturing, especially in flexible electronics and green catalysts. Some see the evolution of printable polymers and hybrid electrolytes as the next leap, made possible by the compound’s dual functionality. Regulatory environments nudge producers to tighten purity, reduce impurities, and ensure full lifecycle analysis, increasing trust for those delivering large-scale solutions. More analytical work on environmental persistence and bioaccumulation will help shape labeling and disposal standards. For students and newcomers, learning to wield this molecule wisely could set the tone for a safer, more adaptive chemical industry that prizes sustainability and innovation in equal measure.

Taking a Closer Look at Its Role

1-Allyl-3-vinylimidazolium chloride doesn’t usually show up in casual conversation, but lots of researchers and tech companies have their eyes on it. This compound belongs to the family of ionic liquids, a set of materials that flip the script on what most folks know about liquids: they don’t evaporate easily, and you won’t catch them catching fire like alcohols or gasoline. My first real encounter came during some postgraduate lab work, where we used it to keep tricky reactions running smoothly, especially the ones that regular solvents couldn't handle. That experience gave me more than a passing interest; it showed me how one new chemical tool can reshape an entire workflow.

Putting It to Work in Polymer Science

Research teams, especially in universities, turn to 1-allyl-3-vinylimidazolium chloride for polymer production. With two reactive groups, the molecule becomes a building block for specialty polymers. Unlike basic plastics, these polymers might end up in films that block out oxygen or water. Picture high-end food packaging or medical storage that depends on reliable barriers—this is the sort of application where a specialty monomer can change the outcome completely. During industry collaborations, I’ve seen chemists hunt for higher performing packaging, testing candidates that come from new ionic monomers like this one. Facts matter here: studies from journals like Polymer Chemistry outline how imidazolium-based materials boost flexibility and chemical resistance in the end product.

Driving Innovation in Electrochemistry

Electrochemists have plenty of praise for 1-allyl-3-vinylimidazolium chloride as well. Its ionic nature helps move electric charge inside experimental devices, making it valuable for designing batteries and supercapacitors. My colleagues working in battery labs try out all kinds of ionic liquids, aiming to squeeze extra life or power from the cells. Using this compound as an electrolyte component helps prevent evaporation and melting, giving devices more durability under stress. Scientific reports, including those from Electrochimica Acta, back up what I’ve heard in person—these materials push performance where others fail due to heat or harsh chemical conditions.

Solving Environmental and Industrial Challenges

There’s a greener side to this compound too. Unlike many industrial solvents based on petroleum, ionic liquids such as 1-allyl-3-vinylimidazolium chloride show low volatility and can be recycled. Industrial labs now explore ways to replace toxic solvents in catalytic reactions, aiming for less waste and fewer emissions. In visits to specialty chemical companies, I’ve seen pushback against old, hazardous chemicals drive this kind of innovation. Some catalysts can dissolve in the ionic liquid, making reactions run at lower temperatures—this saves energy and sometimes lets the entire mixture re-enter the process for another round. Not every solution fits every need, but companies recognize that shifting away from traditional solvents offers a real path toward safer manufacturing.

Practical Barriers and Paths Forward

No material is perfect. Issues with purity, pricing, and large-scale production hang over research compounds like this one. Outreach with process engineers always turns up the same worry: can any lab-scale innovation stay affordable or consistent once you scale up? Open data from pilot projects suggest some ionic liquids make the jump, but pricing still slows widespread adoption. Continued investment in synthesis methods and recycling strategies look promising. If enough teams share their tricks and keep the conversation going, these next-generation materials stand a real chance to move out of the lab and into the tools and products we use every day.

Looking at What this Chemical Demands

1-Allyl-3-Vinylimidazolium Chloride stands out in lab settings for its use as an ionic liquid and advanced solvent. Anyone handling it should know how a lapse in storage can cause waste, safety problems, and poor lab results. To keep projects steady and safe, the right storage isn’t up for debate.

Respecting Moisture Sensitivity

Labs that have some experience with imidazolium compounds often learn this lesson early: moisture turns them unstable, causing clumps, unpredictable reactions, and sometimes full-on degradation. A dry, airtight container, such as amber glass, blocks humidity. After each use, screw the lid down tight. Silica gel or similar drying agents inside a secondary container give extra insurance against sneaky dampness. Keeping a small batch in use and storing the bulk away pays off in less waste and more reliable results.

Temperature Control for Steadiness

Heat doesn’t only break glass; it also encourages chemical change. My first job in a small research lab drilled this point home. Even a week at 10 or 15 degrees above room temp left ionic salts looking brownish, with odd-smelling fumes. A fridge around 4–8°C strikes a balance—cold enough to slow changes, not so cold that stock turns syrupy or forms ice. Avoiding freezer storage helps, since freezing can harm container seals or force the chemical out of solution.

Blocking Out Sunlight

Some chemicals shrug off sunlight; 1-Allyl-3-Vinylimidazolium Chloride does not fall into that group. UV rays set off side reactions, giving inconsistent outcomes and tempting fate with new decomposition products. Dark storage—ideally amber or opaque bottles placed away from direct light—crucially extends shelf life. Store it in a closed cupboard with other light-sensitive reagents.

Keeping Safe Air Practices

Imidazolium salts don’t smell much, but open them up in a drafty lab, and small amounts of vapor can find their way into the air. Anyone who’s worked around open bottles in warm labs recognizes the irritation a careless whiff can bring. Using the chemical inside a fume hood or in a well-ventilated room reduces exposure. A good set of PPE—nitrile gloves, goggles, and a lab coat—keeps your skin and eyes protected from accidental spills.

Labeling and Good Practice

Sharp labeling skips drama later on. Write the date received, date opened, and concentration (if making a stock solution). This helps with tracking shelf life and rooting out mistakes before they grow into hazards. Segregate from acids, oxidizers, and reactive metals—mixing can invite unwanted reactions or breakdown. Keep incompatible materials apart on separate shelves or bins.

Risk From Poor Housekeeping

Letting expired or spilled material stack up risks lab fires, health exposures, or ruined research. One research building I worked in had a forgotten corner full of old ionic liquids and degraded salts. It took just one knock-over to prompt a full evacuation. Regular inventory checks, clear labeling, and safe disposal tie the whole process together, keeping labs safer long-term.

Wrapping Up Good Habits

1-Allyl-3-Vinylimidazolium Chloride rewards those who treat it with respect. Dry, dark, cool, and labeled—these habits cost pennies but save plenty. Careful storage sends a message that the team doesn’t just chase results but values safety and reliability too.

A Chemist’s Perspective on Solubility

A curious question comes up for many who bump into ionic liquids like 1-allyl-3-vinylimidazolium chloride for the first time: what happens when you toss it into water? Classic chemistry tells us that chloride salts of imidazolium cations have a reputation for playing well with water. My earliest encounters in a research lab—back in the days of graduated cylinders and cracked wooden benches—involved watching these clear crystals dissolve almost before the stirring rod finished its first circle.

The secret comes down to the charged nature of 1-allyl-3-vinylimidazolium chloride. Water is a polar solvent, meaning it has a partial positive charge on one side and a negative charge on the other. These partial charges love to snuggle up to the positive imidazolium and the negative chloride. This relationship lets water molecules wrap around the ions, prying apart the ionic bond and tucking each component safely into solution. Not every ionic compound is so obliging, but imidazolium salts often dissolve with little resistance—especially when small, strongly hydrated anions like chloride join the party.

Why Solubility Matters

Dissolving a compound in water unlocks all sorts of useful chemistry. I’ve seen teams spend weeks struggling to work with more hydrophobic ionic liquids, only to light up when a water-soluble version allowed for greener reactions, easier product separation, or softer conditions. Environmental impact shrinks because researchers can skip organic solvents, a massive win given the health hazards associated with many alternatives.

Industries lean into this, too. Water-based systems cut costs and lower risks. In batteries, water-soluble ionic liquids contribute promising electrolytes without the flammability and volatility of old-school organic solutions. I remember working on small-scale electrochemistry projects where swapping an insoluble ionic liquid for a water-loving one let experiments run safer, smoother, and cheaper.

Challenges and Honest Limitations

Something gets lost in translation from paper to lab. Not all samples behave the same way. Purity, temperature, and even old glassware can throw unexpected twists into the mix. I've seen supposedly “highly soluble” salts leave cloudy suspensions behind if the vendor cut corners or if the humidity in the lab crept up. Facts suggest that most 1-allyl-3-vinylimidazolium chlorides hit high marks for water solubility, but preparation methods and storage conditions deserve attention, too.

Residues or polymerization—often a risk with the reactive vinyl group—can spoil a good solution. Additives or stabilizers from manufacturing sometimes muddy the waters. Keeping things cold and sealed improves shelf life, and vetting suppliers to avoid mystery impurities makes a difference. Reliable certificates of analysis have become just as essential as safety goggles.

What Could Improve the Landscape?

Solubility opens the door, but reproducibility keeps it from slamming shut. Labs can run simple, published solubility tests on bulk purchases instead of assuming uniformity. Industry groups could push for tighter standards and clearer labeling. Open sharing of “failed” results encourages honest conversation, rather than hiding away exceptions.

Chemists, academic and industrial, gain more when they treat solubility as a process—testing, confirming, troubleshooting—rather than a simple property. Tools like spectroscopy, visual inspection, and even smartphone photos help catch red flags early. At the end of the day, science moves forward with a combination of facts, curiosity, and a little bit of skepticism, even for something as seemingly simple as dissolving salt in water.

Understanding the Molecule: The Basics and Beyond

Every time I read about new ionic liquids, 1-Allyl-3-Vinylimidazolium Chloride pops up as a unique figure among its peers. Its chemical structure brings together two unsaturated hydrocarbon chains—an allyl group and a vinyl group—attached to an imidazole ring, capped off with a chloride ion for balance. The imidazole core forms the backbone, and both the allyl and vinyl groups hang off the ring at separate nitrogens. To keep it grounded: if you picture the imidazole as a five-sided table, the first seat holds an allyl chain (-CH2-CH=CH2), the third seat cradles a vinyl chain (-CH=CH2), and chloride ion hovers outside, carrying the negative charge.

I remember the first time I worked in a university lab with an imidazolium salt—handling it required no glove drama, but once in the reaction, the impact on solubility and reactivity was immediate. Ionic liquids like this can dissolve a wild variety of substances, reaching beyond the normal rules most solvents play by. Some textbooks might get lost in jargon, but at the bench, the presence of both vinyl and allyl sticks out. Both groups invite further chemistry: polymerization, coupling, grafting.

Real-World Impact: From Green Chemistry to Advanced Materials

What sets this salt apart relates to its structure. The dual unsaturated groups make it highly tuned for reactions that create network polymers or tailor-make hybrid materials. Researchers at the University of Tokyo documented better thermal stability and tunable electrical conductivity using similar imidazolium-based ionic liquids. Industry notices these qualities. Big pushes toward greener solvents—fewer volatile organic chemicals, safer working conditions—lean on structures like this one.

Just last year, I saw a project replacing traditional volatile solvents in electrode manufacturing with 1-Allyl-3-Vinylimidazolium Chloride. The structure gives it a melting point below 100°C, sticking to a liquid state for most lab work, even when the room is cold. Its chloride counterion, while basic, makes it play well with metals, enhancing its use in electrochemical setups.

Challenges and Solutions for Practical Use

Every lab has its concerns. The same unsaturated bonds that make this compound versatile can bring shelf-life issues. Oxygen, light, or heat could trigger unwanted side reactions, so proper storage means no window ledges or steamy benches. I’ve seen colleagues run freshly-distilled samples for sensitive work—those who skip this step usually end up puzzled with inconsistent results. Purity matters, and so does verifying the absence of peroxide species before large-scale synthesis.

Toxicity gets less press but deserves more attention. The imidazolium structure is generally more benign than common organic solvents, but people sometimes overlook its handling protocols. Proper PPE and well-ventilated fumehoods still rule. Industrial processes must ensure effluent is treated, minimizing chloride runoff. Some studies, such as a 2021 paper out of ETH Zurich, suggest using derivatization or swapping the chloride for less environmental-sensitive anions where possible.

Looking Forward

Anyone aiming to innovate in materials science, electrochemistry, or even green catalysis benefits from a grounded grasp of this structure. By not only knowing each atom’s role, but also the real influences this arrangement creates in everyday applications, labs and production facilities can design safer, more effective pathways. 1-Allyl-3-Vinylimidazolium Chloride represents the crossover between creative chemistry and functional utility—something that, in my own experience, usually points to lasting relevance in both research and industry.

Respect for Chemicals Starts with Knowledge

Getting up close and personal with unfamiliar chemicals often means facing risks you didn’t expect. 1-Allyl-3-vinylimidazolium chloride, for example, finds use in specialized labs and sometimes in research tied to ionic liquids and polymerization. Not a household name, but the safety routines followed around this salt often draw on both standard chemical hygiene and unique experience working around reactive or unfamiliar compounds.

Physical Contact

Skin doesn’t just shrug off these compounds. Gloves that resist permeation, like nitrile (not latex, which sometimes breaks down around chemicals), protect your hands. In my lab days, I watched more than one student skip gloves for “just a minute” only to see redness or learn after the fact how sensitizing some chemicals can be. Splashes sometimes travel farther than you think, so long sleeves, closed-toe shoes, and even a face shield add layers of protection, especially during transfers or mixing.

Inhalation Hazards

Breathing in dust or vapor from this sort of chemical isn’t about immediate burning in your nose—it can have slower, subtle effects. A researcher I knew told stories about minor symptoms showing days later. Fume hoods aren’t optional in labs for chemicals like this, since they capture airborne particles and keep your personal breathing zone clear. If you’re working outside a hood, you bump up the risk.

Storage and Spill Response

Humidity and air sometimes react with chemicals, setting off decomposition or creating sticky messes worse than the original spill. Airtight, properly labeled containers save headaches. I’ve walked through storerooms with stains from old leaks—reminders of past mistakes. A chemical like this shouldn’t share space with acids or strong bases, since incompatible materials make accidents more likely.

Spillage happens, even for careful technicians. Absorbent pads, neutralizing agents, and plenty of water (not just a dry cloth) change the outcome. Immediate cleanup, not waiting for someone else to notice, keeps the workplace safe. I recall seeing a minor spill left overnight crust over and degrade nearby labels, which added risk for everyone.

Fire Safety and Emergency Measures

Not every lab chemical goes up in flames easily, but you never want to find out when it’s too late. I keep a mental checklist near: location of extinguishers, what type can be used, and how fast emergency services can arrive. Drinking coffee in the lab break room once, a chemist described a near-miss with a reactive spill and praised the fast grab of a carbon dioxide extinguisher.

Training and Procedures

Learning these hazards can seem dull compared to the rush of discovery, but only those with steady habits avoid major incidents in the long run. Every place I’ve worked, annual refreshers on material safety data sheets ran alongside hands-on drills. Up-to-date training—never “just once, years ago”—prevents the biggest mistakes.

Making It Safer for Others

Labels matter. Anyone who handles chemicals without clear labeling puts others at risk. It’s easy to think a quick experiment isn’t dangerous, but tomorrow you can come in tired and forget which clear powder goes with which project. Smart laboratories post clear signage and keep local antidotes or eyewash stations within reach. In crowded workspaces, courtesy extends beyond cleaning—double-checking containers and returning tools saves time and health for everyone in the room.

Sharing Solutions and Building Culture

Talking about these experiences together—especially when things almost went wrong—builds a stronger safety culture. Colleagues who swap tips or stories about near-misses spread real lessons better than many manuals. It’s not only about ticking boxes on a form; it’s about getting everyone home in the same shape they arrived.