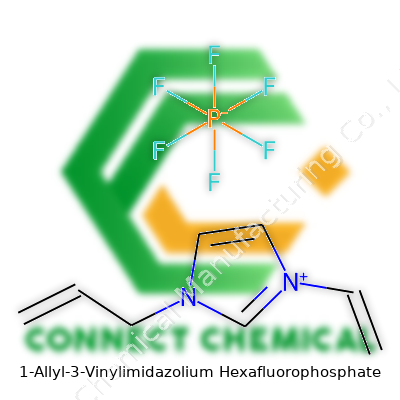

1-Allyl-3-Vinylimidazolium Hexafluorophosphate: A Deep Dive

Historical Development

Research on ionic liquids has drawn global attention since chemists first synthesized room-temperature ionic liquids in the late twentieth century. For a long time, solvents with negligible vapor pressure or high thermal stability sounded futuristic; then, salts like 1-allyl-3-vinylimidazolium hexafluorophosphate came to life. In labs from Tokyo to Berlin, researchers scrambled to cook up new materials to combat the hazards and waste of volatile organic solvents. Looking back, the push to find greener chemistry methods turned ionic liquids from weird curiosities into mainstream lab options. As research budgets shifted toward sustainability, the field saw surges of publications and patents for ionic liquids throughout the early 2000s, each improvement inching the world closer to practical products.

Product Overview

1-Allyl-3-vinylimidazolium hexafluorophosphate belongs to a growing family of imidazolium-based ionic liquids. In my own lab work, I’ve noticed how its unique combination of the imidazolium ring and functionalized alkyl groups brings versatility into play. It comes as a viscous, often clear-to-slightly yellow liquid. This ionic liquid’s cation features both an allyl and a vinyl group, putting reactive chemical handles right into its structure. These handles change what you can do in both laboratory and industrial settings. Many researchers use this compound as a solvent or medium for unusual polymerizations, extraction processes, and catalysis tasks.

Physical & Chemical Properties

Characteristics of this compound bridge classic organic liquids and “designer” solvents of a new era. With a melting point lower than water’s freezing point and a boiling point high enough to laugh off any common lab process, 1-allyl-3-vinylimidazolium hexafluorophosphate gives chemists a wide thermal range to work. Its density hovers just above 1 g/cm³, heavier than most simple solvents but manageable. Most students don't realize its slight hygroscopicity means accidental exposure to air will pull in a bit of moisture, so storage matters. Chemically, the imidazolium core gives this liquid a marked stability against many reagents. But those unsaturated side chains, especially the vinyl group, allow it to undergo polymerization reactions — combining with itself or other monomers in unexpected ways under the right kickstarter.

Technical Specifications & Labeling

Working with this material usually means ordering from a chemical supplier who uses detailed technical sheets. Specs often list purity above 97%, thanks to its applications in sensitive procedures. Some lots ship with precise water content and a warning about trace halide or organic impurities. Labels must flag hazards tied to hexafluorophosphate anions, and the more reputable suppliers meet international labeling rules, like GHS, to keep everyone on the same page about risks. In settings where compliance matters (which should be everywhere), clear labeling ensures proper handling and storage.

Preparation Method

Synthesis of 1-allyl-3-vinylimidazolium hexafluorophosphate usually starts with 1-vinylimidazole mixed with allyl halide. Combining the two brings a classic nucleophilic substitution into play, forming the imidazolium cation. Next, a metathesis reaction swaps the original halide for hexafluorophosphate: treating the crude mixture with potassium hexafluorophosphate does the trick. Proper purification demands multiple washes, often with organic solvents, and drying under reduced pressure. Even minor impurities can affect downstream chemistry, especially for polymer synthesis or electrochemistry work. Careful scientists who’ve seen failed reactions know the importance of these extra steps.

Chemical Reactions & Modifications

This compound’s dual unsaturated side chains let you steer its chemistry toward radical or ionic polymerizations. Take the vinyl moiety: under the right catalyst, it slips into growing polymer chains and builds materials with entirely new properties. The allyl side, with its slight electron-rich character, helps in cross-linking and fine-tuning solubility. Teams have modified this ionic liquid to introduce more functional groups, or to anchor it onto solid surfaces, expanding its range in catalysis. In electrodeposition, it can help shape unique metal nanoparticle patterns, proving the value of functionalized ionic liquids in advanced material science.

Synonyms & Product Names

You might spot this compound in catalogs under names like 1-allyl-3-vinylimidazolium hexafluorophosphate, or its slimmer moniker: [AVIm][PF6]. Sometimes translations or repackaging introduce alternate terms—1-allyl-3-vinylimidazolium PF6, or even its CAS number for those who need clear tracking. From personal experience, I know mix-ups in ordering can happen, so double-checking synonyms ensures you receive the right compound for your project.

Safety & Operational Standards

Hexafluorophosphate salts like this one need more care than most people realize, especially in undergraduate labs. PF6- ions have a nasty habit of releasing HF, a toxic gas, if the compound gets too hot or acidic. Standard operating procedures insist on gloves, goggles, and good ventilation. Emergency protocols must cover handling spills—since its viscosity makes cleanup tricky—and steps for HF decontamination. Compliance with regional safety standards, like OSHA or REACH, helps keep more experienced chemists and new researchers equally protected. The best labs refresh training often, because skipping safety may lead to disaster.

Application Area

This ionic liquid pushes into polymer chemistry, where its structural features support living polymerizations and tune solubility of monomers or polymers. Electrochemists use it as a solvent or electrolyte in supercapacitors, ionic transistors, and battery prototypes, since its conductivity and stability outperform many classic electrolytes. My own colleagues test such liquids for extracting metals from ores—green chemistry at work—and for dissolving cellulose and other tough bio-based feedstocks. The ability to tweak its structure makes it valuable in separation science, where custom task-specific ionic liquids change extraction efficiency overnight. Pharmaceutical researchers eye it as a potential aid for drug formulation or purification, though mainstream medical use remains at arm’s length for now.

Research & Development

Ongoing work explores how structural tweaks to the imidazolium core or side chains shift physical and chemical behavior. Development focuses on engineering task-specific solvents, smarter polymeric materials, greener extraction processes, and cost-effective electrochemical devices. Scientists collaborate across continents, swapping data on modifications that boost stability, conductivity, or recyclability. Each year brings clusters of studies around environmental impact, cost analysis, and creative application fields. As teams seek ways to scale production, industry links with academia—the kind I’ve seen at conferences—speed up the bench-to-market journey.

Toxicity Research

For all its promise as a “green” chemical, the hexafluorophosphate anion raises eyebrows. Researchers conduct in-depth toxicity tests, measuring effects on aquatic life and studying breakdown pathways in soil and water. Hexafluorophosphate’s potential to release persistent pollutants or break into more toxic species, particularly hydrogen fluoride, keeps authorities on alert. In vitro studies suggest moderate cytotoxicity to some human cell lines, so no one’s racing to put this compound in consumer products just yet. Regulatory bodies monitor and reassess exposure guidelines as studies build on one another. Real-world data motivates shifts toward anions and cations with improved safety records.

Future Prospects

Looking ahead, demand for cleaner, safer alternatives to conventional solvents and electrolytes remains strong. As society expects industries to shrink environmental footprints, research turns toward ionic liquids that combine high performance and better end-of-life profiles. Teams strive for less toxic anions, bio-derived building blocks, and processes that recycle these liquids rather than discard them after use. As researchers unlock new reactions that hinge on the unique environment enabled by 1-allyl-3-vinylimidazolium hexafluorophosphate, interest will only grow. The next step comes from cross-disciplinary work—chemists, engineers, and toxicologists aiming for breakthroughs that sidestep both environmental and economic hurdles.

Stepping Away from Ordinary Solvents

Ask anyone in the lab about solvents, and the conversation turns quickly to reliability and safety. Traditional solvents bring headaches—literal and regulatory. 1-Allyl-3-vinylimidazolium hexafluorophosphate has shown up as something fresher. As an ionic liquid, it refuses to evaporate off into the air or catch fire easily, changing the way chemical reactions get done. I remember trying to keep a reaction at bay under a fume hood, worrying about the usual cloud of toxic vapor. This stuff sidesteps that drama. It acts as the medium for organic syntheses, letting complex molecules come together more cleanly. That honestly makes late nights in the lab a little less stressful.

Tough Tasks in Electrochemistry

Moving electricity through a liquid can turn raw materials into batteries, fuel cells, or tools for electroplating metal. 1-Allyl-3-vinylimidazolium hexafluorophosphate brings wide electrochemical windows and serious stability. Fact-checking through recent research, it pops up in efforts to craft better lithium-ion battery electrolytes, adding life to devices people rely on daily. My phone’s charge seems to vanish faster every year, so advances here hit home. Ionic liquids like this bring better thermal and electrochemical endurance; high temperatures or energetic voltage swings stop being such a deal-breaker.

Shaping Catalysis in Greener Directions

Being on the receiving end of environmental lectures nudges chemists to cut waste and look for non-toxic methods. This substance becomes the backbone for catalytic processes where it holds metal catalysts together and stabilizes them during tough reactions. The vinyl and allyl pieces in this liquid help adjust reactivity, fitting unique reaction needs. I’ve sat in seminars about “clean chemistry,” and the appeal comes down to real-life payoffs. Less hazardous byproducts end up in wastewater or landfills, which matters for everyone—not just people in white coats.

Cleaning Up and Pulling Apart Complex Mixtures

Purification isn’t just about making things shinier; it protects products and ecosystems. Ionic liquids like 1-allyl-3-vinylimidazolium hexafluorophosphate help pull selected molecules from stubborn mixtures. In my own work, I watched researchers use these substances to extract rare metals from e-waste piles that otherwise sat in dumpsters, slowly leaking into soil. Selectivity means less mess left behind, and more money saved recovering valuable bits. This sort of process fits right in as recycling gets more attention and regulations tighten up worldwide.

Challenges and Paths Forward

No tool is perfect. Collection and disposal bring their own headaches. The hexafluorophosphate piece gives strong performance but flags safety and cost questions due to lingering toxicity and environmental persistence. Safety training matters as much as high performance here. Factoring in green chemistry, future work pushes toward similar compounds with less environmental baggage. Some labs hunt for recyclable versions, others focus on breaking down these liquids safely at the end of their useful life.

The Role of Experience

After years of juggling different chemicals and processes, it’s obvious that 1-allyl-3-vinylimidazolium hexafluorophosphate shows promise when safety, separation, and performance count. The best route lies in combining careful handling with new innovations. As more organizations pay attention to energy efficiency, waste reduction, and recycling, the push for better alternatives—including improving this class of ionic liquids—continues to pick up speed.

Looking Beyond the Label: Stability in Practice

Nobody working with 1-allyl-3-vinylimidazolium hexafluorophosphate wants a nasty surprise halfway through a synthesis. This ionic liquid, with its unique mix of allyl and vinyl groups coupled to a robust imidazolium core, draws interest from folks running electrochemical studies, solvent work, or specialized catalysis. Hexafluorophosphate as the counterion was chosen for a reason—it hands out a runway of stability against hydrolysis compared to some other candidates, especially those based on halides.

Research groups and industrial teams have seen that these ionic liquids, despite looking like saltwater in a fancy bottle, carry vulnerabilities. The imidazolium ring itself holds up pretty well, but that can’t offset careless handling.

What Stresses the Molecule

Moisture creates the biggest headache. The moment water vapor enters, PF6- starts splitting into corrosive hydrofluoric acid (HF). Even a whiff of humidity, over time, means gradual breakdown, strange precipitates, or stubborn corrosion stains on glassware. If this pops up in analytical results—unexpected fluoride peaks or a sour smell—it usually means the original container didn’t remain tightly sealed, or someone skipped the desiccation step.

Oxygen brings its own baggage. Vinyl and allyl side chains allow interesting chemistry, but they also want to take part in radical reactions, especially if strong light or high heat gets involved. Most labs working with these salts keep light exposure at a minimum, using amber bottles, foil wraps, or simple dark storage drawers.

Safe Storage: Simple Rules and Real Tools

The best solutions often stick to the basics. Store 1-allyl-3-vinylimidazolium hexafluorophosphate in a tightly capped, chemically resistant container—polypropylene or glass with a solid PTFE liner beats most alternatives. Sodium-based or activated alumina desiccants help trap any stray water vapor before it hits the liquid. A dedicated desiccator, either vacuum- or gas-purged, makes for a smart investment in any laboratory handling moisture-sensitive salts.

Direct sunlight should stay off the table. Even if polymerization seems unlikely under mild indoor lighting, consecutive handling under bright overhead lights or on a sunny bench can create byproducts no one wants to track down later. Short-term room temperature storage works if humidity remains low and the cap stays shut. For longer-term storage or if someone can’t vouch for consistent room conditions, refrigeration between 2°C and 8°C extends shelf life without freezing out the salt or introducing condensation risks.

Lessons from the Bench

A few years of working with these materials teaches simple lessons: take moisture control seriously, use protective gloves and safety goggles since PF6- hydrolysis products pack a punch, and never store this salt next to open acid bottles or caustic bases. Uncapping outside a glove box or dry box invites contamination, especially during humid days.

Disposal brings another round of responsibility. Product breakdowns leave behind HF and other toxic fluorinated materials. Neutralizing leftover samples with calcium carbonate (not sodium or potassium salts, which stay soluble and risk leaching) traps released fluorides safely. Always double-bag solid waste and label containers for hazardous pickup.

Chemistry rarely forgives complacency. A keen eye, a dry shelf, and airtight seals keep useful ionic liquids like this one from turning into regrettable messes.

Getting to Know This Chemical

1-Allyl-3-vinylimidazolium hexafluorophosphate shows up in labs working on ionic liquids, material synthesis, and electrochemistry. The name might sound complicated, but its main use comes from its ability to dissolve a wide range of compounds and serve as a catalyst. Anyone who’s handled ionic liquids before knows they aren't always as green as their reputation claims. Some can cause problems if people ignore the safety data sheets.

Why the Hazards Are Real

Hexafluorophosphate compounds don’t play around with safety. The "PF6" part can break down in the presence of moisture, releasing toxic gases like hydrogen fluoride. Since hydrogen fluoride eats through glass, skin, and even some metals, it earns a healthy dose of respect in every lab I’ve worked in. Breathing in these fumes or getting the substance on your skin doesn’t end gently. Eye damage, severe burns, or even systemic fluoride poisoning can follow careless contact. Studies in chemical safety journals point out that hexafluorophosphate-based ionic liquids, unlike their less reactive cousins, demand much tighter controls.

PPE and Ventilation Aren’t Just Optional

My time in chemical development shaped some hard rules: gloves, eye protection, and lab coats go on before the cap comes off the bottle. Nitrile gloves work best for these ionic liquids; latex gives up too easily. Labs that treat air as an afterthought invite risk. I learned early the value of proper fume hoods. Good airflow makes all the difference. Reports from workplace incidents often show a lack of proper ventilation as a key factor in exposure incidents. Spills, even small ones, can linger in the air and cause issues if rooms stay closed up.

Storage and Disposal: Lessons from the Field

Leaving 1-allyl-3-vinylimidazolium hexafluorophosphate on just any shelf brings trouble. Sealed containers kept dry and away from acids, bases, and water sources protect both the chemical and the people around it. Moisture triggers decomposition and toxic gas release. Colleagues once stored vials alongside water-based reagents—clean-up from the resulting mess taught the whole team a lesson about using dedicated, labeled storage cabinets. It isn’t just about the mess; it’s also about the dangerous gases no one saw but everyone could have inhaled.

Getting rid of the waste means using trained chemical waste handlers. Pouring this compound down the drain or tossing it in a regular trash bin violates most environmental and safety rules. Waste companies treat ionic liquid disposal as a special category, referring to regulations from agencies like the EPA or the European Chemicals Agency. A friend in industry described expensive setbacks that followed mishandling this category of waste; no one wanted a repeat incident.

Improving Everyday Safety

Routine training and clear signage change culture. I’ve seen labs where safety data sheets sit on every bench, and newcomers must review them before handling new materials. Labs hold biannual drills for handling spills and exposures. People feel safer, and actual accidents drop. Fact-based awareness replaces complacency. Many organizations employ specialized monitoring systems to check for air quality and chemical releases—insurance policies that pay for themselves over time.

Sensible Solutions and Community Voice

No one should assume that a compound’s label as an ‘ionic liquid’ means it behaves itself. Much of the harm comes from underestimating the risks. Chemists, lab managers, and students all share the job of respecting this category of materials. As someone who’s seen both close-calls and best-practice successes, I push for teams to treat chemicals like 1-allyl-3-vinylimidazolium hexafluorophosphate with a proven recipe: knowledge, protective gear, good ventilation, careful storage, responsible disposal, and ongoing training. That’s the toolkit that saves skin, sight, and lives—in every lab that wants to stay out of the news for the wrong reasons.

Getting a Grip on the Science

1-Allyl-3-vinylimidazolium hexafluorophosphate—bit of a mouthful, but this salt often pops up in research labs exploring ionic liquids and green chemistry. With both an imidazolium ring and those big hexafluorophosphate anions, you’d expect some interesting behavior in solvents, and that’s exactly what happens. Solubility, one of the most important properties to gauge real-world usability, guides choices from purification methods to reaction designs.

Water Versus Organic Solvents: Big Differences

Forget easy dissolving in water. Due to the non-coordinating, hydrophobic PF6- counterion, this compound barely mixes with water. Researchers report that salts like these produce cloudy suspensions rather than forming a homogenous solution. Measurements back this up, putting solubility in pure water as barely above a trace—often under 1 gram per 100 milliliters. That’s not much.

Organic solvents tell a different story, especially those without hydrogen-bonding character. Acetone, dichloromethane, acetonitrile, and even some chlorinated solvents easily dissolve 1-allyl-3-vinylimidazolium hexafluorophosphate. My own work in an advanced organic synthesis class proved this. We struggled for ages trying to wash out PF6- ionic liquids with water and watched beads of undissolved material float around. The minute we poured some acetonitrile or acetone in, everything went clear. Fast, too.

Common literature points to this compound reaching solubility values well past 10 grams per 100 milliliters in acetonitrile and acetone. This stands out for anyone hoping to use it in homogeneous catalytic systems or as a charge carrier in solvent-based batteries. The switch from water to something like dichloromethane flips how these ionic liquids behave.

Why Solubility Drives Application

Solubility isn’t just a technical footnote. Too much undissolved salt in water jams up attempts at green extraction or phase-transfer catalysis, both popular goals in sustainable chemistry. If your target is renewable solvents, the hydrophobic, non-coordinating anion works against you. This limits attempts to “green” these materials by shifting toward water-based systems. From personal experience, projects that counted on ionic liquids dissolving easily in water turned out heavier than expected, slow, and hard to filter.

In contrast, if your process involves polar organic solvents, the situation flips. Processes—from electroplating to organic separations—play to the salt’s strengths. Researchers have even tuned the cation/anion combination in these salts to maximize performance in non-aqueous media, drawing from data that consistently shows organic solvents winning out.

Looking for Solutions

Anyone chasing water compatibility for these salts faces an uphill climb. Chemists turn to tricks like swapping the PF6- for more hydrophilic anions, like tetrafluoroborate or even halides. These efforts aren’t just academic; they open the door to safer, easier recycling and greener synthesis. Some newer studies suggest mixing small amounts of co-solvents can boost water compatibility, though that’s far from a perfect solution. Ultimately, chasing water solubility with this exact PF6- salt usually trades away other benefits, like stability or volatility.

For now, the reality stands out clearly: 1-allyl-3-vinylimidazolium hexafluorophosphate fits best in systems built for organic solvents, not water. Tailoring process design around that fact not only saves time, but also heads off headaches in purification, recovery, and waste management. The chemistry world keeps moving, and with some creativity on the anion side, maybe a breakthrough for water compatibility waits just ahead.

Real-World Expectations in Chemical Purity

Researchers working in advanced material science or catalysis often pay close attention to the purity grade of any ionic liquid they plan to use. Labs push hard for rigorous results, but without the right chemical grade, projects can stumble. I remember one trial in an academic lab where the entire batch of catalysts failed simply because the ionic liquid contained trace contaminants that were not disclosed in the specification sheet. That underlined how critical high purity is, especially for chemicals like 1-Allyl-3-Vinylimidazolium Hexafluorophosphate.

Main Specifications in Detail

This compound carries the CAS number 875595-66-9 and falls under a growing family of ionic liquids. In terms of specifications, suppliers frequently offer it as a crystalline or highly viscous liquid, sporting a faint pale color. Most reputable suppliers list a minimum purity between 98% to 99%, and that’s a grade trusted for both research and pilot manufacturing environments.

Actual laboratory sheets list trace metal analysis by ICP-MS. Residual water content should check in under 0.5%, with some vendors running Karl Fischer titration reports as proof. Chloride ions, a persistent impurity in many ionic liquids, typically test below 100 ppm in high-quality batches. Organic residue, especially from unreacted imidazole or its derivatives, should rank below 0.5% by mass. Whenever I checked these specs before ordering, I found it helpful to get the raw NMR or HPLC data from vendors—requesting spectra or chromatograms not only built trust but dodged a lot of headaches.

Why Purity Matters in Research and Manufacturing

Ionic liquids like 1-Allyl-3-Vinylimidazolium Hexafluorophosphate aren’t just chemicals, they’re tools for cutting-edge science. Their uses stretch from electrochemistry setups, cellulose processing, and even fine-tuned separation applications in the pharmaceutical industry. Lower grade samples, tainted by water or halides, can kill the performance of sensitive processes like electrodeposition or catalytic conversions. Even a slight shift in impurity content has led me to waste weeks deciphering mixed results, only to find out the commercial batch I received didn’t match the stated purity.

Those working in fields like battery research or organic synthesis should double-check not only the label claims but also the analytical reports. For those scaling up, gas chromatography and ICP-MS data will spotlight impurities that could tweak reaction rates or poison catalysts. A one-off purchase from a discount supplier can seem like a bargain, but consistency, batch-to-batch, ends up mattering more—especially after factoring in downstream project costs.

Supporting High Standards and Safer Handling

The United States Pharmacopeia and the European Pharmacopoeia don’t cover this specific ionic liquid, so companies and universities often lean on ISO 9001-certified vendors with transparent quality control. I learned the hard way that clear communication with the supplier to understand quality assurance protocols saves time. Many now provide certificates of analysis with every shipment, outlining moisture, halide content, and organic byproduct levels.

Since hexafluorophosphate anions bring some risk of slow hydrolysis and release of HF, good safety standards matter on top of chemical grade. I always store open vials of this compound under argon or nitrogen and keep desiccants nearby to avoid breakdown or accidental exposure.

What Labs and Buyers Can Do

Demanding a certificate of analysis for each new batch helps keep research on solid ground. Experienced labs check not just for purity percentages but for all the small things—trace metals, water content, halides, and residual solvents. A consistent supply chain and a willingness to pay for high-quality chemical stocks pay off over time, both in reliable data and safer working environments.