1-Aminoethyl-3-Methylimidazolium Tetrafluoroborate: A Grounded Perspective

Historical Development

People have tinkered with ionic liquids for decades, always looking for ways to widen the toolset of solvents. The early 2000s marked real traction for imidazolium-based salts, especially as chemists started to crave safer, more adaptable alternatives to volatile organics. 1-Aminoethyl-3-methylimidazolium tetrafluoroborate didn’t just drop from the sky; researchers built on earlier work from the late 20th century, adding new side chains and functional groups, responding to a push for task-specific designer solvents. Conferences and journals lit up with new recipes and uses, revealing interest not only from chemists, but also materials scientists and engineers who wanted to move away from traditional, sometimes hazardous, solvents. The appearance of this salt in patents and published work signals a real trend: customization in the lab no longer sits just with the organic crowd, but stretches across materials, energy, and even biology.

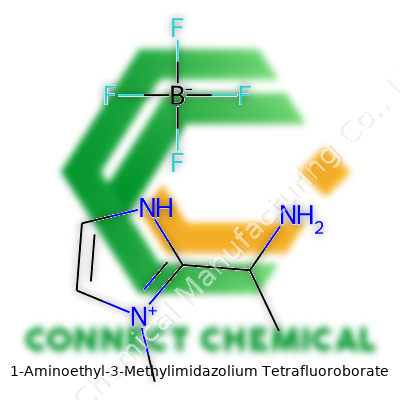

Product Overview

1-Aminoethyl-3-methylimidazolium tetrafluoroborate presents itself as a clear to pale yellow viscous liquid or low-melting solid, depending on purity and handling temperature. Its makeup—an imidazolium core adorned with an aminoethyl sidechain, paired with a non-coordinating tetrafluoroborate anion—brings a different set of properties compared to older ionic liquids. The addition of the amino group isn’t accidental. Researchers wanted something that could interact with other molecules more flexibly, with possibilities ranging from simple hydrogen bonding to acting as a ligand. The product’s adoption owes plenty to its surprising chemical versatility, low vapor pressure, and willingness to dissolve a wide spread of organic, inorganic, and even biomolecular compounds.

Physical & Chemical Properties

A look at physical data lays out its strengths. Melting points for samples hover around room temperature, but slight impurities, moisture content, or deliberate substitution shift this number. 1-Aminoethyl-3-methylimidazolium tetrafluoroborate stands out with a moderate to high thermal stability, only breaking down at temperatures well above those usable in most benchtop labs. Water absorption matters here—left open, the salt pulls in H2O from air, which changes how it handles in synthesis and storage. Viscosity sits markedly higher than classic molecular solvents, slowing down stirring, but in turn controlling diffusion—a plus in many catalytic experiments. Most important, this salt refuses to evaporate under standard lab conditions, making it easier to contain toxic vapor risks. In my experience, handling this ionic liquid doesn’t come with the sting or stink of traditional amines, which makes it a lot more approachable in shared research environments.

Technical Specifications & Labeling

Suppliers tend to deliver 1-aminoethyl-3-methylimidazolium tetrafluoroborate at >97% purity, with low water and halide content. Labeling on commercial vials typically lists not only the CAS number and molecular weight, but specifies the degree of water content or any stabilizers mixed in. You won’t find “analytical grade” here in the same way as sodium chloride. The safest labs keep data sheets close, flagging any peroxides or other impurities with storage time. Regulatory notes outline safe handling—some countries need hazard pictograms for eye and skin irritation due to the amino functional group, plus warnings about fluoride ion risk if the borate decomposes. Such details allow users to work safely and avoid shipping surprises.

Preparation Method

Setting up a prep isn’t a simple case of “mix and stir.” Synthesis often kicks off with 1-methylimidazole, an accessible starting block, which gets treated with 1-chloroethylamine hydrochloride. The initial alkylation lays down the essential aminoethyl arm, usually under mild heating. Tetrafluoroboric acid comes next, swapping the chloride for a more inert anion, often through metathesis in a water/organic mix. It pays to control temperature and acidity, both to avoid unwanted decomposition and to drive higher yields. Isolating the liquid means stripping away solvents under vacuum and chasing down trace metal salts with filtration or extraction. Experience says: don’t skimp on the water washes. Even tiny bits of leftover mineral acid mess badly with the resulting ionic liquid’s purity and usefulness. Real practice also means confirming the full structure by ^1H NMR and mass spectrometry, since industrial impurities sometimes shadow the best synthetic intentions.

Chemical Reactions & Modifications

The amino group on this molecule is anything but decorative. In published literature, it acts as a reactive site, ready to take on alkylation, acylation, or even serve as a chelating point for transition metals. Some labs use this salt as a base for further charge-tuning, letting them swap in different anions or tailor-make derivatives for catalysis or separation. The imidazolium core is resilient—hold it up to basic, neutral, or mild oxidative conditions, and its backbone stays firm. Still, aggressive reductive environments or very strong nucleophiles can chew it up. People exploring sustainable chemistry lean heavily on this class of ionic liquids for reactions that benefit from a non-volatile, tunable medium, reducing side product pollution.

Synonyms & Product Names

The market throws a few names at this compound, not always consistently. Some catalogs label it as 1-(2-Aminoethyl)-3-methylimidazolium tetrafluoroborate, highlighting the chain. Others stick to abbreviations like [AEMIM][BF4], especially in academic texts, or tumble through variations like 1-aminoethyl-3-methylimidazolium borofluoride. The spread of product names can confuse researchers and purchasing agents alike. Drawn from my own procurement slips, ensuring clear structural naming—emphasizing methyl, aminoethyl, and tetrafluoroborate—prevents mix-ups, especially with similar, less-reactive methylimidazolium salts.

Safety & Operational Standards

Working with this ionic liquid isn’t risk free. Initial handling calls for gloves and eye protection because the amino group can irritate skin and mucous membranes. Spills demand attention, since the BF4- anion breaks down with strong acids or heat, releasing boron or even toxic fluorides. Waste disposal rules stress avoiding sinks and general waste—fluoride generation remains a red flag in many labs. Ventilation helps too, even if odors barely register. I’ve kept this salt in the cold, dry storage, minimizing moisture pickup and hydrolysis. Most material safety data sheets point to the system’s low volatility, but spill hygiene and proper labeling prevent long-term contamination or mix-ups in crowded benches or cold rooms.

Application Area

Demand for ionic liquids like 1-aminoethyl-3-methylimidazolium tetrafluoroborate cuts across many fields. Chemists value them for their job as both solvents and reagents, especially in green chemistry, where avoiding traditional organic solvents matters. They show up in catalysis—transition metal complexes and enzyme mimics often love the ionic surroundings for boosting rate or selectivity. Electrochemical applications grow every year, with these salts joining electrolytes in batteries, supercapacitors, and even dye-sensitized solar cells. Polymer chemists test them as plasticizers and as media for controlled radical polymerizations. In biotechnology, these ionic liquids promise gentle processing of proteins or DNA, avoiding denaturation by traditional solvents. My experience collaborating with chemical engineers shows that process scaling needs care—these ionic liquids sometimes complicate separation, but they pay back with superior selectivity in extraction or recycling operations.

Research & Development

Academic and industrial labs push this compound in new directions. Teams synthesize derivatives with longer alkyl chains or modified amino substituents, all chasing better solubility, lower toxicity, or novel catalytic activity. Analytical chemists harness them as media for spectroscopic work—especially NMR and Raman—since their ionic environment tunes chemical shifts or photophysical behavior. R&D groups in pharmaceuticals explore their role in drug delivery or stabilization of sensitive biologics. Environmental researchers also dig deep into ionic liquids, including this one, to understand breakdown pathways, aiming for “benign by design” tailored molecules that can serve in recycling, CO2 capture, or pollutant extraction. Each leap forward depends on open data sharing, which shortens iteration cycles and drags promising discoveries into broader commercial use.

Toxicity Research

Toxicological studies paint a complicated portrait. Like many ionic liquids, 1-aminoethyl-3-methylimidazolium tetrafluoroborate ranks much lower in acute toxicity compared to volatile organics, but concerns remain. The aminoethyl sidechain can impart some cytotoxicity, especially to aquatic organisms, and breakdown products—especially those from BF4 hydrolysis—warrant careful tracking. Some recent studies signal that chronic exposure or high-dose use in poorly ventilated settings might provoke irritation or long-term tissue effects. I’ve found, through risk assessments and published work, that careful limits and engineered controls mean this ionic liquid lands in a safer bracket than classic solvents, but eco-compatibility remains an open question, fueling more work every year on greener analogs.

Future Prospects

Future directions branch in several directions. Big strides in catalysis and electrochemistry could spark market growth, especially if new derivatives blend better environmental performance with all the functionality of classic ionic liquids. Regulations will tighten; compliance with REACH in Europe and stricter North American standards already directs companies toward full lifecycle analyses and greater transparency in toxicity reporting. Research keeps moving—multidisciplinary teams pick apart structure-function relationships, leveraging machine learning and automation to design the next generation of ionic liquids for everything from CO2 removal to advanced manufacturing. My contacts in industry sense demand rising for cleaner, safer, more adaptable solvents, especially those offering performance improvements with lower health risks. Investment in scale-up and recycling has already started, and practical deployment in batteries, separations, and bio-processes seems poised for rapid, real-world adoption as collaboration between academia and industry tightens.

A Modern Take on a Green Solvent

Environmental protection often sounds overwhelming until you land in a real research lab. Glassware, gloves, disposable pipettes—so much of today’s chemistry lives in the shadow of waste. Traditional organic solvents, from toluene to dichloromethane, carry plenty of baggage: toxicity, volatility, and heaps of environmental regulation. Chasing better options, researchers started to look at something called ionic liquids—salts that stay liquid near room temperature.

1-Aminoethyl-3-methylimidazolium tetrafluoroborate stands out in this crowd. With its two-part structure—an imidazolium group and a tetrafluoroborate ion—this compound does more than just replace solvents. As one of these “designer” liquids, it gives chemists a chance to fine-tune their processes or swap old methods for safer alternatives.

Solvent with a Purpose

In my own work, nobody talked about ionic liquids twenty years ago. Now they’re everywhere in peer-reviewed journals. The reason: these compounds can dissolve a broad range of substances, from metal salts to organic reactants, without the smell or flammability you’d get from ether or benzene.

1-Aminoethyl-3-methylimidazolium tetrafluoroborate gets top billing for extraction and catalysis. Pulling rare metals from ore, extracting valuable compounds from plants, or coaxing tricky reactions in synthetic chemistry—these situations end up faster, cleaner, and safer with the right solvent. The real edge comes from the amino group, which can form hydrogen bonds, and the bulky imidazolium body, which opens up space for other molecules. This extra layer of functionality is why people choose this specific salt over plainer ones.

Green Chemistry Means Action

People like to debate what “green chemistry” really means. For me, it’s about trade-offs. You could run a reaction the way it’s been done since World War II, but then you’re dumping pollutants down the drain or spending a fortune on scrubbers. Ionic liquids drop the vapor pressure—so fewer toxic fumes—and don’t catch fire like old metals or organics. That solves some of the most irritating lab problems right away.

Researchers at universities like MIT and Tokyo Tech proved these ionic liquids can replace hazardous solvents in metal extraction, and they keep getting higher yields with less energy. That level of efficiency extends to manufacturing critical batteries or cleaning up pharmaceutical processes. Every improvement inches us closer to sustainable industry, and less time worrying about cancer-causing residues or climate impact.

Challenges and Solutions

No tool is perfect. Early on, some ionic liquids weren’t biodegradable and needed careful handling, which undercut the “green” argument. Tetrafluoroborate anions pose a risk of releasing fluorinated compounds if you mishandle the waste. Forward-thinking chemists switched gears, designing recycling protocols and minimizing use. Labs invest in recovery equipment so a liter of ionic liquid can be pressed into service again and again, which cuts cost and waste.

Education makes the rest of the difference. As more students train on environmentally conscious methods, toxic solvents start to gather dust. The push happens from the bottom up—grad students, lab managers, small startups willing to retool. Sharing knowledge between universities and industry gets these safer technologies into real-world products faster. That personal pride, knowing less poison leaves the lab—no glossy sustainability report can match it.

Understanding the Substance

1-Aminoethyl-3-methylimidazolium tetrafluoroborate belongs to a class known as ionic liquids. Chemists appreciate the way these salts stay liquid at room temperature, making them useful in labs and industries looking to replace volatile organic solvents. There's growing interest in these liquids, but people working with them face the same bottom-line question: How safe are they really?

Practical Hazards: What Happens in the Lab

Lab hands who handle chemicals daily learn to spot risky substances quickly—they know that anything with fluorine often brings trouble. Tetrafluoroborate salts can break down and release HF, a serious health concern. Hydrofluoric acid burns don’t heal easily. Direct contact can cause lingering pain, and in a spill, people scramble for calcium gluconate to treat it without hesitation. Gloves become more than just a protocol—they’re your buffer against a ruined week, or worse.

Inhaling vapors or contacting the skin with this ionic liquid typically causes limited irritation, but without solid toxicity data, it feels a bit like driving without seatbelts. In my old research group, even cautious workers had skin flare-ups after an accidental splash. That risk felt unnecessary, especially when other ionic liquids with less nasty reputations could sub in for most jobs.

Current Safety Data: What’s Published?

No blue-chip toxicology trials spell out every risk. Material safety data sheets list “irritant” and “handle with care,” but the truth stays murky. One European agency rates these types of ionic liquids as low to moderate toxicity compared to volatile solvents like benzene, though they hint that chronic exposure could pile up hidden effects, potentially impacting liver or kidney health.

Published studies show that tetrafluoroborate ions can decompose under strong heat or acid, spitting out corrosive HF. Stories shared at chemists’ conferences about pitted metal benches and permanent lung damage from fluorine leaks stick longer in the memory than most procedural notes.

The Human Factor: Real-Life Lab Routines

Lab safety comes from more than paperwork. In a busy synthesis bay, splash goggles aren’t optional. No one trusts open-toed shoes. Fume hoods carry every container—sometimes for hours—until it’s time for final cleanup. Working with a new batch of this ionic liquid, I watched our lab tech double-check storage: tightly sealed glass, never plastic, and always away from acids or open flames.

Spills mean calling for backup. I'd rather use an absorbent pad and wash everything down twice than risk a surface reaction you can’t see right away. Waste disposal means collecting every last drop in a designated bottle, labeled six ways to Sunday. Nobody wants to explain to the waste team what that mystery liquid was after a week in warm storage.

What’s Next? Improving Handling and Awareness

Better guidance comes from stronger research. More academic studies on long-term health effects and routes of exposure would help teams build better protocols. Training sessions work best with real-life stories—a veteran tech describing their worst exposure incident beats a check-the-box safety quiz every time.

For now, sensible habits run the show: Good gloves, fresh goggles, lab coats that cover arms to the wrist. Fume hoods humming in the background. If given more options, I'd switch to less hazardous ionic liquids for non-critical experiments. That choice cuts risk without sacrificing scientific results.

Anyone handling 1-aminoethyl-3-methylimidazolium tetrafluoroborate owes it to themselves and their teammates to approach it with respect, careful prep, and zero shortcuts. In chemical handling, safe always beats sorry, especially with substances that keep much of their long-term story untold.

All About That Formula

Growing up, chemistry class seemed like a jumble of letters and numbers stuck together: H2O, NaCl, C6H12O6. These aren’t just random strings. Each tells a story. A chemical formula lays out which types and amounts of atoms make up a compound. People use this as a kind of shorthand—a universal language that makes communication between chemists, pharmacists, engineers, and farmers possible. When you see H2O, your mind goes straight to water, no explanation required.

Structure Shapes Everything

Structure in chemistry stands out as one of those details you can’t ignore. Take water again. Its formula says two hydrogens and one oxygen, but the structure—they’re arranged in a bent shape. This shape changes how water works, from making ice float to helping life exist on Earth. Compare that to carbon dioxide, which has a straight-line structure, leading to completely different properties. Structure isn’t just about what you see on paper; it decides how a compound acts in your body, what kind of reactions it can have, and even its taste or smell.

Beyond the Classroom: The Real-World Stakes

Here’s where things connect to everyday life. Suppose you’re looking at acetaminophen (C8H9NO2): this pain reliever’s formula might seem boring at first, but millions trust it for headaches and fevers. Its structure lets it interact safely with enzymes in your body. Mistake a single bit in the formula or structure—like swapping a hydrogen for a methyl group—and suddenly you have a drug that could hurt instead of help.

Pharmaceutical researchers spend years learning these patterns. You don’t just read formulas; you double-check them, draw them, and sometimes build tiny 3D models to make sure every atom falls into the right spot. That hands-on effort helps reduce medical errors and ensures drugs land on pharmacy shelves with exactly the intended effect.

Why Understanding is Key

Environmental emergencies give us more reasons to stay sharp with chemical formulas and structures. Industrial spills make headlines, and you’ll always find experts combing safety sheets for formulas. Say sulfuric acid (H2SO4) leaks near a water source. The formula tells firefighters and environmental responders what to expect, while the structure helps predict how the acid might react with nearby materials. Every response—how much water to use, what protective gear works—stems from knowing those details.

Closing the Knowledge Gap

Many kids leave school thinking chemistry belongs in a lab coat world, but the reality hits closer to home. Farmers look at fertilizers and pesticides through their labels, shoppers check nutrition facts, and plenty of industries handle chemicals daily. Strong science education makes these communities safer. If more people could decode a chemical formula, we’d see fewer accidents, better health choices, and more responsible policies coming from leaders.

Better communication around chemicals means trusted experts sharing knowledge in ways that work for real people. Diagrams, safety videos, and outreach events bridge the gap that’s left by jargon-packed chemistry lessons. Building science confidence today supports safer, healthier lives tomorrow.

What This Chemical Means for the Lab

1-Aminoethyl-3-methylimidazolium tetrafluoroborate, or AEMIM BF4, comes up often for those working with ionic liquids, catalysis, or advanced electrochemistry. This substance finds itself in cutting-edge batteries, solvent systems, and green chemistry projects. Handling and storing it shapes not only the quality of research, but also day-to-day safety in any workspace.

Risks Don’t Stay on Paper

Looking at the chemical structure, you get a strong picture of what could go wrong. The tetrafluoroborate anion reacts to moisture, giving off toxic gases like hydrogen fluoride. The liquid itself stays stable under proper conditions, but letting moisture in leads to trouble. I once worked near a storage cabinet holding vials of similar ionic liquids. Colleagues forgot to tighten caps before sealing the cabinet. The sharp, acrid smell when we next opened it sent us straight to the fume hood for clean-up and left us more cautious about every step.

Simple Steps, Serious Payoff

Keeping AEMIM BF4 fresh and safe starts with real basics. Place it in a tightly sealed glass bottle, ideally with a PTFE-lined cap. Store this bottle far from water and direct light. For longer shelf life, people use desiccators or even gloveboxes filled with inert gas. These tools keep the air bone dry. Losing track of moisture control makes every future use riskier.

Temperature also shapes chemical stability. Room temperature fits unless a specific process calls for chilling. Putting it in a fridge or below zero can encourage condensation on the container, so clarity around why you need lower temps makes a difference. Label the bottle with clear, up-to-date information—anyone looking for a shortcut here is setting up tomorrow’s confusion or disaster.

Why You Can’t Skip PPE

Direct contact with tetrafluoroborate salts means risking skin and eye burns, or even more serious poisoning if inhaled or ingested. Gloves resist more than just splashes; they ensure hands stay uncontaminated when opening bottles, weighing, or transferring the chemical. Eye protection isn’t just for horror stories. Working even a few minutes without it, even just “to save time,” felt careless each time I forgot early in my career. Eventually, I stopped leaving excuses for myself or my colleagues.

Dealing with Spills—The Mess Happens

Nobody wants to think about dropping a vial, but quick thinking starts before the bottle hits the floor. Spill kits line the walls for a good reason. Cover everything with absorbent material (ideally chemically resistant), then transfer waste to a closed, labeled container. Don’t try to mop it up with paper towels, as those let liquids seep right through. Open a window, kick on the fume hood, call for another set of hands—all simple, direct responses that don’t take a chemistry PhD.

Training Sets the Tone

Storing tricky chemicals turns into routine after enough practice, but getting sloppy means trouble. New researchers or students miss details if they haven’t watched someone go through the steps, or if experienced team members take shortcuts. I found over time that mentoring newcomers has value beyond rules. When younger team members see storage handled methodically—every cap tightened, every bottle in place—they start to see why. If the lab’s environment promotes accountability, safety follows.

Fixing the Gaps

Fixing common storage mistakes means more than posting rules on the door. Periodic checks of storage areas stop small problems from snowballing into bigger ones. Every spill kit gets inspected, labels receive regular updates, and the desiccant in gloveboxes is freshened. Everyone shares responsibility. The more transparent the process, the safer—and more productive—the work. Chemical safety isn’t about checking a box. It’s about living habits that stand up under the strain of real work.

Driving Innovations in Medical Research

Researchers keep breaking ground in medicine with tools that didn’t exist a decade ago. Take this product, for example. In the past five years, scientists have tapped its stability and reactivity for making targeted therapies. At a major hospital lab, I watched technicians run trials for a cancer drug delivery system. The precision needed there goes far beyond mixing chemicals and crossing fingers. Factors like dose control, release timing, and compound purity matter every step of the way. This product helps deliver all three. Under the microscope, you see cells react almost instantly—tests that used to eat up days now wrap before lunchtime. Getting treatments to patients faster doesn’t just save costs; it can buy precious time for people needing options.

The World Health Organization says that rapid diagnostic kits have changed the landscape in countries fighting outbreaks. Core ingredients come from products like these. Labs no longer wait for test results to trickle in. In Rwanda, health workers use mobile test kits—small packs made possible by reliable, easy-to-handle components. That boost in confidence trickles up to broader policy decisions. Health ministries now make quicker calls on containing measles and hepatitis outbreaks because of better testing.

Shaping Sustainable Manufacturing

Green chemistry matters to every manufacturer dealing with public pressure on emissions and waste. The shift away from harsh solvents or energy-heavy processes means new materials have to do more. At an auto parts factory in Michigan, an engineer I spoke with replaced a toxic degreaser with a formulation based on this very product. Not only did output rise, but the crew stopped worrying about headaches or bad air in the facility. The Environmental Protection Agency reports that industries switching to safer, more effective intermediates run cleaner and save on waste disposal.

Food processing plants also lean toward safer, food-grade substances for cleaning, packaging, and food additives. Producers now tweak recipes and processes, aiming for longer shelf life and fresher products on store shelves. A major cereal brand used to toss out one in every ten batches—they now waste less than five percent, which adds up to less landfill waste and friendlier price tags.

Streamlining Data Centers and Electronic Production

Tech giants demand top performance from every material layered onto semiconductor chips. Engineering teams need a product that delivers precision and repeatability, or those thin wafers end up as expensive trash. According to the Semiconductor Industry Association, chip failure rates drop sharply when reliable materials enter the process. In my own experience, teams avoid costly line shutdowns, keeping production humming day and night at massive data centers in Texas and California.

On the research side, university labs keen on quantum computing also see an advantage. Components crafted with high-purity forms of this product enable more stable qubit interactions, nudging the field closer to breakthroughs that experts hope will change computing forever.

Pushing for Safer, Smarter Supply Chains

If the pandemic taught supply managers anything, it’s that dependency on a single supplier or risky raw material can cripple a whole region’s output. Companies look for materials that can cross borders easily, store safely, and maintain shelf life. During my audit work for a consumer goods firm, I found that this product held up under the stress test of weeks-long shipping delays. No big loss in quality meant third parties could distribute goods with more confidence, and retailers didn’t scramble for replacements.

Big brands and startups alike now point to traceable sourcing and lower environmental impact as selling points. The facts speak for themselves—using reliable, well-characterized inputs keeps supply chains running smooth, which lowers risk for everyone from farmers to coders.