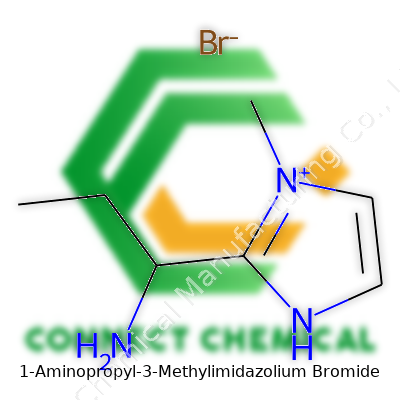

Commentary on 1-Aminopropyl-3-Methylimidazolium Bromide

Historical Development

The journey of ionic liquids started well before they made their mark in modern chemistry labs, and 1-Aminopropyl-3-Methylimidazolium Bromide came along as research directions shifted toward greener, safer compounds. Chemists in the late twentieth century noticed that imidazolium-based ionic liquids could offer strong alternatives to volatile organic solvents. Once early teams discovered that fine-tuning the alkyl chains and functional groups offered unique properties—like non-flammability and impressive thermal stability—the focus turned to making variants with specific use cases. The aminopropyl variant opened new doors thanks to its enhanced reactivity and biocompatibility, sparking studies into catalysis, materials development, and separation technology. As patents rolled out, universities and chemical companies weighed in, pushing the compound from curiosity in the journal margins into focused research efforts. By the 2010s, the synthetic routes had been published and improved, giving researchers that reliable starting point for scaling up or branching into new reaction territory.

Product Overview

1-Aminopropyl-3-Methylimidazolium Bromide attracted attention thanks to a rare balance between a polar framework and a friendly handling profile. You can spot this compound as an off-white solid, a lot easier to store and use compared to some of its dimethyl analogs. What tends to set this product apart is its ability to serve as both a hydrogen bond donor and acceptor. This unique arrangement supports both phase-transfer reactions and catalysis that benefit from tunable polarity. In handling the bromide salt instead of the corresponding chloride, you get differences in solubility that may come in handy for those pursuit-specific reaction schemes. In the commercial sphere, demand comes from folks seeking ionic liquids for sustainable chemical processes, drug formulation, and advanced extraction or purification steps.

Physical & Chemical Properties

Talking about the physical properties, 1-Aminopropyl-3-Methylimidazolium Bromide generally forms a fine white to slightly yellowish powder. It stores pretty well if kept dry, with a melting point that sits noticeably lower than most salts, typically in the range of 60-80°C, making it more approachable for solution-based work. The ionic framework means it dissolves in polar solvents but can manage some water immiscibility, depending on temperature and formulation tweaks. Chemically, the presence of the primary amine group opens the compound to functionalization or reactions with aldehydes and ketones—a feature seldom matched by simple alkyl imidazolium derivatives. The imidazolium ring preserves aromaticity, which supports additional stability in redox reactions and boosts lifespan under practical lab conditions.

Technical Specifications & Labeling

Labels for 1-Aminopropyl-3-Methylimidazolium Bromide supply key data points for quick comparison: molecular formula C7H14BrN3, weighing about 220 g/mol. Purity runs past 98% for research samples, and water content hovers below 0.5% if handled correctly. Often, suppliers publish batch-specific NMR and IR spectra for peace of mind when confirming the product’s identity. Storage instructions recommend cool, dry spaces—no sunlight or high heat—because moisture creeps in and messes with reactivity. Lot numbers and manufacturing dates track stability and ensure traceability during the R&D cycle.

Preparation Method

The most widespread method for synthesizing this compound borrows from time-tested quaternization routes, where 1-methylimidazole reacts with 3-bromopropylamine hydrobromide in aprotic solvents, such as acetonitrile. A steady temperature of 60°C aids the reaction, which can take several hours with regular monitoring. After the mixture cools, filtration removes by-products or excess reagents. Next, recrystallization in ethanol or acetone ensures a cleaner sample and tightens up purity numbers. Some chemists venture off with microwave-assisted synthesis, which can drop the time frame from hours to minutes, but careful attention to temperature control becomes even more crucial here. Once dried under vacuum, the crystalline product lands directly into a properly sealed amber bottle, ready for storage or use.

Chemical Reactions & Modifications

In hands-on lab sessions, this aminopropyl imidazolium compound reacts vigorously with activated acids and electrophiles thanks to the exposed primary amine. It can form Schiff bases or even more complex imine products under mild conditions. A robust property comes from its ability to form salts with organic acids or join polymerization reactions, especially if researchers pursue supported ionic liquid phases in catalysis or chromatography. Adding urea derivatives, acyl chlorides, or N-hydroxysuccinimide esters lets chemists tailor the ionic liquid for specific tasks—like tuning solubility or introducing cross-linking functions in polymer chemistry. These modifiable handles on the imidazolium ring and its side chains set this salt apart from rigid, less reactive ionic liquids.

Synonyms & Product Names

1-Aminopropyl-3-Methylimidazolium Bromide shows up under a handful of names that can trip up someone sifting through catalogs. You may also find N-(3-Aminopropyl)-N'-Methylimidazolium Bromide as an alternative listing. Some product sheets refer to it as [APMIM]Br based on shorthand chemical notation. Recognizing these aliases matters because different language conventions or supplier catalogs could hide the material under another name, causing delays in procurement or confusion about compatibility in a synthetic pathway.

Safety & Operational Standards

Anytime you bring 1-Aminopropyl-3-Methylimidazolium Bromide into the lab, safety gear stays crucial. Even though it avoids the high volatility seen in many old-school solvents, the primary amine group needs attention due to possible irritation and sensitization risks. Direct skin contact can lead to mild dermatitis over repeated exposures, so gloves and long sleeves stand as basic requirements. Fume hoods work best for dusty transfer steps or when prepping reaction mixtures. Eye protection isn’t up for debate, since powder or splashes could trigger inflammation. Waste from this product doesn’t ride down the standard drain—it should be sent to a chemical waste facility with the bromide content marked on disposal logs. Anyone storing or shipping the product has to list the UN number, hazard codes, and safety data sheet entries to square up with transit rules and site safety policies.

Application Area

Research teams turn to this ionic liquid because it avoids some practical issues with both water-soluble and oil-soluble materials. It’s strong in roles such as phase-transfer catalysis, stabilizing ionic intermediates in multistep synthesis, and helping dissolve otherwise stubborn reagents. Pharmaceutically inclined folks explore its biocompatibility for advanced drug formulations or as a carrier for labile compounds. Material scientists use it for templating new hybrid structures or as reaction media in the preparation of nanoparticles and functionalized surfaces. In separations work, the product shines during selective metal extraction from mixed matrices, thanks to ionic selectivity and in-built affinity from the aminopropyl chain. Whenever selectivity and environmental performance count, this compound gives the bench chemist a real edge.

Research & Development

Research moves fast with 1-Aminopropyl-3-Methylimidazolium Bromide. Universities and R&D teams focus on hybrid materials, exploring new catalysts that beat traditional systems on both performance and environmental fronts. For example, projects funded under green chemistry initiatives look to this compound to swap volatile solvents out of extraction workflows, boost yield, and cut post-process waste. Synthesis of task-specific ionic liquids with this salt as a building block led to new anti-corrosive additives and enzyme stabilizers aimed at industries from pharmaceuticals to water treatment. Some of the most exciting studies pair it with switchable solvents, aiming to develop closed-loop chemical processes with lower emissions and recycling opportunities.

Toxicity Research

The push for sustainability forces real scrutiny on safety and toxicity, and 1-Aminopropyl-3-Methylimidazolium Bromide hasn’t escaped this microscope. Studies in aquatic models indicate it displays moderate toxicity toward certain invertebrates and algae, pushing up the need to maintain tight wastewater controls. Toxicological screening in mammals hasn’t flagged severe acute effects at low concentrations, though both inhalation and ingestion over time could spur irritation or systemic stress. Bioaccumulation potential looks low compared to legacy ionic liquids, but environmental pathways—especially through improper disposal—require ongoing monitoring. Researchers evaluate residue breakdown in soil and water, and regulators expect new data as this class of chemicals starts to see increased commercial use.

Future Prospects

Based on both lab progress and commercial interest, 1-Aminopropyl-3-Methylimidazolium Bromide stands ready to become even more important in the coming years. The chemists behind next-generation batteries, membranes, and pharmaceutical formulations already test out tailored imidazolium salts for the properties they bring. As regulatory landscapes latch down on solvent emissions and waste, companies look to products like this for compliance and performance. Further engineering of its synthesis—such as drawing on greener, bio-based raw materials or cutting by-product loads—will likely drive down costs and lift broader acceptance. For students, process engineers, and research scientists, this compound sits squarely at the crossroads of safety, function, and innovation in twenty-first-century chemistry.

Breaking Down the Molecule

Anyone who handles chemicals gets used to long names like 1-aminopropyl-3-methylimidazolium bromide. Rather than scare someone off, these big names tell a simple story about how atoms connect. I've spent quite a bit of time in both teaching labs and industry settings, and I see how naming draws a map of a molecule.

1-Aminopropyl-3-methylimidazolium bromide groups together three main features. The first chunk, "1-aminopropyl," shows a chain of three carbons with an amine group at one end. "3-methylimidazolium" signals a five-membered ring built from two nitrogens and three carbons, carrying a methyl group at position three. Bromide hangs around as the counterion. The real magic appears in the way these groups glue together to create an organic salt, known in chemistry circles as an ionic liquid.

The Real-World Impact of Structure

In my own work, the minute details of a molecule’s shape make or break an experiment. For 1-aminopropyl-3-methylimidazolium bromide, the imidazolium ring serves as the main scaffold. Stick a methyl on the third carbon of that ring, and the "3-methyl" tag makes sense. Attach a three-carbon chain at the first nitrogen—add an amino group to that tail—and suddenly, you’ve changed how the molecule interacts with everything from water to metal surfaces.

I remember testing similar ionic liquids for solvent tasks. The presence of an amine group often sparks fresh reactivity. In protein research, amine functions can grab onto peptides or bind with metal ions. For 1-aminopropyl-3-methylimidazolium bromide, the combination brings extra solubility in water and new chances to act as a catalyst. The charge separation between the positive imidazolium center and the negative bromide ion lets this salt flow without crystals forming—always a big benefit where manufacturers want flexible materials.

Why Structure Shapes Use Cases

The structure points to applications in green chemistry. Dropping volatile organic solvents helps both industry and the environment. Ionic liquids like this one bring low vapor pressure and stay liquid under a huge range of temperatures. In the lab, I've seen folks swap out classic organic solvents for these compounds when cleaning up heavy metal contamination. The amine swings into action, grabbing hold of unwanted ions and locking them away.

Newer research picks up on these structure-function connections. Studies show how imidazolium-based ionic liquids break down stubborn cellulose, making biofuel production smoother. Small tweaks at the molecule’s ends, such as the aminopropyl group, unlock brand-new uses in extraction, electrochemistry, and catalysis. According to the Royal Society of Chemistry, the field explodes with possibility, as tweaking the molecular skeleton can fine-tune every feature, from toxicity to conductivity.

Moving Toward Better Solutions

I think back to mistakes I’ve made, where ignoring a small substituent derailed a project. These details aren’t for decoration. Chemists and engineers build on this knowledge to make greener, safer processes. Careful mapping of structure—especially in molecules like 1-aminopropyl-3-methylimidazolium bromide—lets teams pick compounds that work harder, pollute less, and save money. Training the next generation of scientists to read these structures not only sparks curiosity, it drives real change in labs and factories alike.

Anyone interested in sustainability or advanced materials should pay close attention to both names and nuts-and-bolts molecular layouts. One new group, one changed atom, and entire industries pivot directions. That’s not hype, it’s just good science drawn from real-world experience and years spent at the bench.

Key Uses in Green Chemistry

Most people outside a chemistry department don’t hear much about ionic liquids, but 1-Aminopropyl-3-Methylimidazolium Bromide often pops up in labs pushing greener methods. This compound usually steps in as a solvent for chemical reactions, especially where reducing environmental waste matters. Labs favor it because of low vapor pressure, cutting down on potentially hazardous emissions. I’ve seen researchers swap out traditional organic solvents for this ionic liquid, and the group managed to recover and use it multiple times with no drop-off in performance. This cuts down on constant solvent purchases and disposal fees—great news for both finance and the environment.

Improving Catalysis

Many chemists look to squeeze more out of every reaction. With this ionic liquid, catalysts have a friend that helps keep them in the mix and working longer. For example, palladium-catalyzed reactions often get a boost, both in terms of higher yields and cleaner isolation of products. Academic work shows that some catalysts can be recycled several times in this medium without losing their punch—helpful for anyone running multi-step syntheses and looking to scale up without burning through rare metals. In a chemical engineering course I took, a group looked at economics of recovery, and ionic liquids like this one helped keep expensive catalysts in play instead of in the waste bin.

Contribution to Electrochemistry

Another useful side of 1-Aminopropyl-3-Methylimidazolium Bromide shows up in batteries and sensors. Its stable nature and the way it helps ions move make it a valuable ingredient in electrolytes. Groups working on lithium-ion battery research sometimes turn to ionic liquids to push for improved safety—less flammable than the standard carbonate-based liquids. While the costs can slow industry uptake, the push for safer storage and transport of energy stands as a real motivator. In one project on supercapacitors I followed, small tweaks in the liquid composition led to more consistent results over hundreds of cycles, which hints at possible breakthroughs down the road.

Potential in Biomass Processing

Transforming plant materials into fuels or chemicals often gets bogged down because lignocellulose resists breaking apart. Labs have experimented with 1-Aminopropyl-3-Methylimidazolium Bromide, finding that it helps dissolve tough plant fibers. This means more of the useful sugars get released, which could feed directly into fermentation or further upgrading. There’s published proof that these ionic liquids can help “unlock” new pathways for making biofuels or biodegradable plastics. In my brief stint working with bioenergy startups, companies showed serious interest but struggled with the cost and recycling of the ionic liquid. Finding cheaper production routes and better ways to pull it out after use would widen its role in this area.

Next Steps and Opportunities

As new applications open up, issues like cost, toxicity and large-scale recovery need more attention. Regular scrutiny from research groups and regulatory bodies keeps everyone on track. Getting more affordable ways to make ionic liquids, plus new purification methods, may tip the scales for these compounds in wider industry. Academic collaboration and transparent reporting of negative results also help weed out hype and validate practical success stories. Since sustainability is no longer a luxury, but a must, attention on versatile tools like 1-Aminopropyl-3-Methylimidazolium Bromide will only grow.

The tasks in a chemical lab never really feel routine. Every day seems to bring a new bottle with an odd name and a strict set of rules attached. 1-Aminopropyl-3-methylimidazolium bromide is one of these—sounds almost like it belongs in an advanced textbook, but it pops up anywhere work with ionic liquids takes place. Some folks pay close attention to expensive equipment and advanced synthesis, yet ignore the basics: how safe storage influences both day-to-day safety and research outcomes.

Real Risks: Moisture, Heat, and Light

1-Aminopropyl-3-methylimidazolium bromide brings real potential for worry if moisture gets in. Like many salts and ionic liquids, it hungrily pulls water vapor from the air. One time in a university dry room, I opened a fresh reagent only to find the crystals soft and sticky after just a weekend in the wrong cabinet. Water changes the characteristics of these chemicals in a real way—shift in melting points, reactivity jumping through the roof, everything you don't want in an experiment. Facts back this up. Peer-reviewed studies highlight contamination issues in imidazolium-based salts when left exposed.

Forget about leaving this stuff on a standard shelf under fluorescent lighting. Heat and UV light creep into the compound over time, sometimes triggering degradation not visible to the naked eye. Even mild sunlight leads to color changes and potentially unstable decomposition products, based on incidents reported by chemists handling imidazolium derivatives. Physical changes signal a chemical problem that creeps into your results later.

Practical Storage Steps That Work

Experience teaches caution, so I rely on sealed containers. Air-tight glass jars with solid screw-tight lids work best. Polypropylene sometimes works for short-term storage, but it never keeps out moisture as well as glass. For anyone serious about keeping their stocks dry, toss in a few fresh silica gel packets. They soak up what the compound misses.

Temperature matters just as much as humidity. Stick with cool, stable spaces away from workbench chaos and sunlight—dark cabinets or fridges (at 2-8°C) serve this purpose well. I watched a batch degrade after two months in a warm, sunlit prep room, while another batch survived a year in a cold, closed drawer. Staying out of direct sunlight matters more than many realize.

Labeling matters just as much. Details on opening dates and storage conditions help track changes at a glance. Too many times someone shoves the container back without a label, and everyone spends the next week trying to figure out if the contents are trustworthy. Records of storage temp changes don’t just save time; they prevent dangerous, wasteful mistakes.

What Happens If It All Goes Wrong?

Failing to fight off moisture and heat makes these substances unpredictable. Impurities multiply, anyone relying on purity for calculations gets burned, and no one enjoys a failed experiment caused by something this basic. Regulatory bodies already cite storage failures as the cause for environmental and lab accidents. If a spill or leak happens, gathering loose powder means dealing with messy, sticky waste—a clean-up headache that stretches into hours instead of minutes.

Better Habits Mean Fewer Problems

Teaching proper storage as part of everyday lab culture goes further than buying the latest instrument or running another calibration. Keep these compounds dry, cool, dark, and tightly sealed. Share protocols openly and keep checking the logs. These habits do more than impress a safety inspector; they make the lab a place where chemistry works—consistently and safely.

A Personal Lens on Safe Chemical Handling

Work in a lab or a chemical plant for any stretch of time and you learn quick that every substance deserves a careful approach. 1-Aminopropyl-3-Methylimidazolium Bromide, used in all sorts of modern chemistry, looks nearly harmless at a glance—powdery, maybe a crystal. The truth: even the chemicals you don’t smell or see in the air demand respect.

Protecting Skin and Eyes: Frontline Defense

Splash or spill this compound on your hands and odd symptoms show up—you’re risking redness, itch, maybe irritation you’ll regret. Standard nitrile gloves go a long way here; some prefer doubling up on layers. Face shield or at least snug-fitting goggles turns splashes into ‘no big deal’ moments. In my own work, I’ve been grateful for that plastic “barrier” more times than I can count, especially after watching a colleague fight through a chemical burn simply because he skipped eye protection.

Ventilation and Breathing Easy

Open windows or a whirring fume hood may not get much notice until you’ve taken a breath of something caustic. Even though 1-Aminopropyl-3-Methylimidazolium Bromide barely wafts an odor, the fine particles threaten lungs if they become airborne during measuring or mixing. Fume hoods aren't just a box with a window—they move that invisible mist away from your face. Dust masks, or better, a particulate respirator, help for short tasks if a full hood isn’t an option.

What Storage Can Prevent

Keep this imidazolium salt in a tight-sealed bottle. Humidity in the air likes to sneak in and cause lumps or altered chemistry. A desiccator comes in handy, cutting down the risk. Store the chemical well away from acids and oxidizers. I once saw an entire shelf cleared out after a leaky cap mixed with the wrong bottle beside it—cleaning can’t undo all the risk once something goes wrong.

Clean Hands, Clear Conscience

Hand washing isn’t just a habit. Contamination runs all over door handles, notes, and lab tools. Even time at the cafeteria table can turn dicey without a proper scrub. Soap and running water—twenty seconds takes less effort than dealing with hives or a rash. I recommend washing up before and after any handling, no matter how busy the day gets.

Spill Response—It Pays Off to Prepare

Spills cause panic only if there’s no plan. I keep plenty of absorbent pads, a bucket of sand, and an extra set of gloves nearby. Scooping up dry compound without stirring it into the air makes a huge difference. Label everything you use and pitch it into a proper hazardous waste bin. I learned from a past mistake—the cost of disposal is nothing compared to a visit to the ER.

Training: Knowledge Over Guesswork

New technicians sometimes shrug off the safety training videos, but real stories stick. A mistake with this compound could mean minor irritation one time, or a major health scare another. Running drills, reviewing chemical safety sheets (the SDS), and regular reviews keep everyone sharp. For my team, asking questions and sharing small mistakes builds stronger habits together.

Accountability in Safety Culture

Every measure, from wearing gloves to labeling a shelf, builds a safer space for everyone. It’s easier to prevent problems than fix disasters. If you see a coworker working without gear, call it out—better an awkward moment than a trip to urgent care. Hard lessons make long memories, and real vigilance keeps accidents from finding you twice.

Digging Into the Science

Science doesn't always show up in big headlines, but small breakthroughs sit behind many changes in everyday tech. Ionic liquids, especially those based on imidazolium like 1-aminopropyl-3-methylimidazolium bromide, stand as a good example. Solubility in water figures high among practical questions chemists and industry folks bump into. Most ionic liquids with imidazolium rings show a big affinity for water because of their charged nature, their salt-like structure, and the bromide anion. Here, the bromide ion plays a role, as do the hydrogen-bonding abilities built into the imidazolium ring and the aminopropyl group.

What Practical Experience Tells Us

Graduate students and lab techs who work with ionic liquids often groan when someone spills a bottle—cleanup always means lots of water. In many cases, 1-aminopropyl-3-methylimidazolium bromide dissolves well in water, creating a clear, almost syrupy solution. No gritty clumps left floating around, just a swift shift to a single phase. The polar structure ramps up the dissolving process, with water molecules crowding around the ions and breaking ionic bonds with ease.

One of the biggest signals comes from research in green solvents. More than a decade of laboratory trials, peer-reviewed reports, and patents prove this chemical’s value as a water-miscible medium. Chemists chase such compounds because they drive reactions faster and cut down on waste. Solubility forms the backbone for applications ranging from extraction processes to drug delivery studies—always underpinned by reliable phase mixing.

Why Solubility Matters

Pure science gets things moving, but the bigger story hits when you look at what solubility makes possible. Water-soluble ionic liquids have cleared pathways in catalysis, separation science, and organic synthesis. The point isn’t just academic curiosity. These substances step in to replace volatile solvents, reducing fire and health hazards in the workplace. During my own research, the sharp contrast between old-school, smelly solvents and these new ionic solutions drew a line between safety goggles and simple gloves. People handling these compounds can feel more confident about avoiding accidental exposure to toxic vapors.

In scale-up chemistry, where labs hand recipes off to factories, water compatibility helps with wastewater management. Waste treatment teams feel less heat about releasing byproducts or needing mountains of additional chemicals for cleanup. Better solubility also opens doors for recycling solvents, a crucial step when cost and sustainability push to the front of boardroom discussions. Investment in greener chemistry isn’t just talk—regulators often look for measurable reductions in environmental footprint, and water-based systems get plenty of attention.

Addressing Practical Hurdles

No chemical story leaves out the bumps in the road. Some ionic liquids, though friendly with water, can cause issues downstream. Excessive solubility leads to contamination in reaction products or the need for sophisticated purification setups. If too much ends up in process streams, treatment costs climb fast. Researchers and plant managers have turned to tailored extraction protocols and selective membranes, tools designed to finely balance the right amount of solubility without unwanted residues.

Open communication between academic labs and industry partners pushes improvements forward. Clear reporting on solubility data, full disclosure of risks, and commitment to safer procedures keep science rolling in the right direction. People want straightforward answers about chemical properties, especially as regulations shift and demand for evidence-based decisions grows.

Everyday chemistry isn’t splashy—most of it runs on reliable, reproducible data. Knowing how a specific ionic liquid dissolves in water shapes decisions far outside the glass beaker, sparking change in manufacturing, medicine, and environmental management.