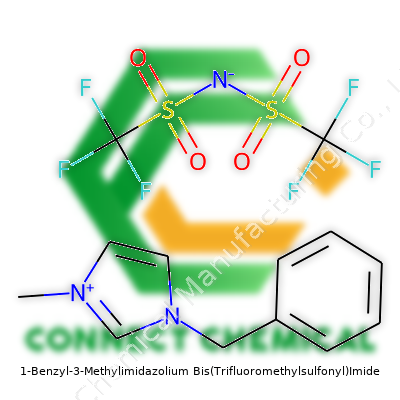

1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide: An In-Depth Commentary

Historical Development

The curiosity for ionic liquids picked up momentum in the late 20th century, as chemists noticed their stability, remarkable solvating abilities, and low volatility. Labs worldwide rallied around room-temperature ionic liquids as alternatives to volatile organic solvents, hoping to break away from many long-standing environmental hazards. 1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide (abbreviated as [BnMIM][NTf2]) sits among these breakthrough compounds. The drive for efficiency and safety in organic synthesis drew scientists to this ionic liquid. It earned a posting in both academic circles and industry, not just for its technical merits but for the vacuum it filled as demands for green chemistry solutions grew louder. Over decades, research communities poured their efforts into characterizing possible cations and anions. Benzyl-substituted imidazolium derivatives made a strong showing, demonstrating balance between thermal stability and process flexibility, especially after the 1990s when sustainable manufacturing took on new urgency.

Product Overview

1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide stands as a salt, but you won’t see white crystals or the dryness seen in common powders. This compound presents itself as a pale yellow, viscous liquid under normal conditions. Typically, labs refer to it by its shorthand [BnMIM][NTf2], or its alternate names such as BMIM-NTf2. The main reason it draws attention is the blend of a bulky, aromatic imidazolium cation with the delocalized, highly fluorinated NTf2 anion. This pairing doesn’t just lower melting points; it reduces tendency to evaporate, so working with it sidesteps headaches linked to more volatile, hazardous reagents. Packaging typically involves airtight containers, as ionic liquids notoriously soak up water. In practical terms, storing and handling goes smoothly in well-equipped facilities, away from strong bases and acids that could degrade the cationic structure.

Physical & Chemical Properties

Looking at its makeup, [BnMIM][NTf2] weighs in at a molecular mass of roughly 502.45 g/mol. Its liquid state kicks in near or just above room temperature, with low vapor pressure and a faint odor—not unlike warm plastic with a tangy kick. Its density hovers between 1.3 and 1.4 g/mL, making it noticeably heavier than water. Because of the imidazolium system, it holds up at high temperatures (decomposition rarely sets in before about 350°C under inert atmosphere), tolerating tough reaction environments where traditional solvents fall short. The dielectric constant isn’t sky-high, but it tolerates polar and nonpolar guests, dissolving both organic molecules and a range of metals. Water content can shift its viscosity and even its conductivity, so those running experiments need to keep it dry if they're after consistent performance. The combination of strong fluorinated anionic groups and aromatic cationic elements shields it against radical breakdown, making it a go-to for demanding chemical engineering protocols.

Technical Specifications & Labeling

Many producers label this compound as >99% pure, which suits it for analytical applications and advanced synthesis alike. Containers highlight the CAS number 174899-66-2, flagging purity, batch data, and expiration. Most suppliers use UN-approved bottles with tamper-proof seals, showing hazard statements that warn about possible skin and eye irritation. Standard specifications spell out water content (often below 0.1%), halide content (usually below 20 ppm), and color (for good measure). Technical sheets include shelf life details and recommend refrigeration below 25°C for long-term storage. In practice, trained personnel should review safety data sheets before handling, as the warnings reflect potential health effects that demand respect for procedural controls—like gloves, lab coats, and eye protection—with every use.

Preparation Method

Synthesizing [BnMIM][NTf2] typically follows a two-stage route. Starting with 1-methylimidazole, benzyl chloride, and a strong base, chemists stir up 1-benzyl-3-methylimidazolium chloride in a controlled reaction. The intermediate chloride salt is then mixed with lithium or sodium bis(trifluoromethylsulfonyl)imide in water, where anion exchange takes center stage. The [BnMIM][NTf2] forms as an oil, separating and settling at the bottom of the vessel. Multiple water washes remove residual salts and impurities, and drying under reduced pressure finishes the procedure. Labs can scale up production, but sticking to pure reactants and thoroughly removing halide or starting material residues stays crucial for end quality. This preparation, while technically straightforward, still demands vigilance to avoid exposure to both chlorinated intermediates and fluorinated by-products.

Chemical Reactions & Modifications

As an ionic liquid, [BnMIM][NTf2] adapts in many transformations. Its resilience under heat and strong acids or bases (within limits) makes it an attractive host for catalytic processes. Chemists investigate it for metal-catalyzed couplings, such as Suzuki or Heck reactions, where recovery of costly catalysts cuts expenses. Enzymatic steps, often finicky about solvent choice, benefit from its ability to dissolve polar and nonpolar reactants. Modifying the benzyl group or swapping the methyl substituent has allowed researchers to tune solubility or boost compatibility with polymers. In my work synthesizing pharmaceutical intermediates, using [BnMIM][NTf2] sidestepped problems seen with more volatile solvents—lower evaporation losses, less ambient contamination, and easier workups. Additions, substitutions, and organometallic complexes have all been pulled off successfully, leveraging both the stability and the broad range of solubility the ionic nature delivers.

Synonyms & Product Names

Depending on sourcing and documentation, this compound shows up under different aliases: BnMIM NTf2, 1-Benzyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide, and its shorthand [BnMIM][Tf2N] also crop up. Trade catalogs may list it as BMIM-NTf2, following conventions for ionic liquid abbreviations. These alternative names reflect the evolving standards in chemical literature and diversity of international cataloging systems. Any professional searching for it should cross-check all listings, as spelling quirks can trip up database searches, especially in global procurement. My time in multinational research settings has shown how consistency in product naming keeps sourcing headaches down and smooths over communication between teams in different countries.

Safety & Operational Standards

Work with [BnMIM][NTf2] draws sharp lines around personal protection and ventilation. Even though it resists combustion and won’t evaporate like simple organics, it can irritate skin, eyes, and respiratory tracts on contact. The fluorinated anion, if it breaks down, forms by-products that pose environmental hazards. Strict local disposal regulations apply. Labs impose glove, goggle, and fume hood use as standard, and spills need immediate cleanup with absorbent, non-reactive materials. Emergency protocols should be ready for accidental exposure—saline eye washes, and first responders briefed on material hazards. Any operation involving heating, pressure changes, or mixing with other reactive agents should proceed with clear risk assessments and supervision. Documentation and labeling match global GHS harmonization, enabling efficient hand-offs between research, manufacturing, and waste management teams. In my own lab, integrating these standards early on streamlined compliance checks and built good workplace habits.

Application Area

Industries looking for greener chemistry solutions lean heavily on [BnMIM][NTf2]. Its standout thermal and chemical stability finds a stronghold in organic synthesis, electrochemistry, and catalysis. Many pharmaceutical companies have swapped out harmful solvents for it during key synthetic steps. It serves as a heat-transfer fluid in specialty engineering settings, offering safety and process reliability where mineral oil or other organic blends lag. Battery researchers explore it for electrolyte roles, testing conductivity and cycling stability compared to conventional salts. Extractions, especially of rare earth elements or precious metals, benefit from the selectivity of ionic liquids like [BnMIM][NTf2], which finely tunes separation and recovery rates. In my experience, using it for chromatography and analytical separations slashed process times and improved yields, particularly for compounds sensitive to hydrolysis or oxidation.

Research & Development

Academic and industrial labs alike have pivoted to [BnMIM][NTf2] for creative projects—ranging from polymer processing to catalyst recovery. Teams chase after improved recycling methods, hoping to cut back on solvent waste and lower operational carbon footprints. Surface chemistry and materials science have embraced it for self-assembly and nanomaterial dispersion. Since the structure lends itself to fine-tuning, new derivatives emerge regularly from R&D groups seeking custom viscosity or polarity. University research consortia investigate its performance under extreme settings—high pressure, or strong magnetic fields—to push boundaries for batteries, sensors, and even solar technology. Cross-disciplinary projects often bring chemists together with engineers and environmental scientists, using bench-scale experiments as the proving ground for future commercial advancement. On a personal note, working with this ionic liquid opened direct collaborations between my chemistry team and process engineers, speeding up technology transfers and improving lab-to-market timelines.

Toxicity Research

Safety reviews for [BnMIM][NTf2] flag the need for careful handling, as with most engineered chemicals. Animal studies suggest low acute oral toxicity, but repeated exposure links to moderate skin and eye irritation. Chronic toxicity research still lags behind; researchers warn about possible environmental impact, especially via breakdown of the bis(trifluoromethylsulfonyl)imide anion. Its high stability means natural breakdown happens slowly in soil or water, which raises questions about long-term ecological fate. Regulations push for closed-loop processes, limiting environmental releases wherever possible. Incineration or specialist waste management facilities stand as best practices for disposal. Consulting up-to-date safety data and ongoing toxicology reports guides how companies and organizations should handle risk, both for worker exposure and ecosystem impact. Increased transparency on publication of toxicity studies has helped inform responsible practices at every stage from lab notebook to large-scale manufacturing.

Future Prospects

The growing push for sustainable chemistry hands [BnMIM][NTf2] and its peers a strong future. Companies continue searching for high-performing, recyclable solvents. Demand for batteries, renewable energy, and low-footprint materials keeps the pressure on research teams to boost efficacy and slash toxicity. As regulatory controls grow, innovation follows: improved synthesis methods aim to cut unwanted by-products; product modifications target specific pain points for manufacturers. In the broader context, the reputation for process safety and technical flexibility sets this compound apart. Ongoing collaborations between industrial labs and academic researchers spell out a likely evolution—more focused derivatives, tailored for advanced applications in energy, biochemistry, and green engineering. In my work mentoring the next generation of chemists, introducing these compounds has meant not only new scientific challenges but a chance to contribute to a safer and more responsible scientific culture.

Stepping Into the Lab: Where This Chemical Actually Matters

Few names in chemistry turn heads like 1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide, often a favorite among chemists who deal with ionic liquids. This compound brings something new to the table. Growing up in a family of chemists, I heard stories about the pain points of solvents—flammability, stink, evaporation, and the constant cleanup after each experiment. Modern ionic liquids, like this one, show real progress compared to solvents that barely behave.

Batteries Get a Real Boost

Lately, anyone watching the push for better batteries runs into challenges around safety, power density, and lifespan. Lithium-ion batteries remain the workhorses for many devices, from phones to electric cars, but flammable solvents in them bring risks. This chemical steps up with non-flammability, low vapor pressure, and strong conductivity. Researchers have used it to make battery electrolytes safer and more stable, tuning the liquid’s properties for specific energy storage needs. The focus on extending battery lifetime matters for consumers and manufacturers trying to reduce waste and avoid recalls.

Green Chemistry: Living the Promise

Environmental impacts of traditional solvents continue to bite. Volatile organic compounds harm air quality and expose workers to long-term health risks. Stories of chemical spills and chronic headaches during grad school lab work stuck with me. 1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide, in liquid form at room temperature with a wide electrochemical window, fits the call for sustainability in modern labs. Experiments in catalysis, extraction, and separations benefit from this stability. It helps clean up reaction pathways and reduces toxic waste at the end of each run. Environmental standards are growing tighter every year, and labs look for greener ways to keep up.

Organic Synthesis: Getting the Job Done

Everyone who tries organic synthesis knows the agony of purification. Removing unwanted byproducts or solvents often eats up hours, and some older solvents leave their mark everywhere. 1-Benzyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide does double duty as both a solvent and a reaction medium that supports unique catalyst activity. The ability to reuse or recycle it can trim down project budgets. This benefits more than just academic labs—industrial-scale synthesis aims for cuts in operational costs without sacrificing product purity.

Room for Improvement, and Practical Solutions

While this ionic liquid offers solutions to old problems, price and sourcing stay in the conversation. In my experience, chemists build trust in materials by sharing trial data in open journals and making process tweaks together. Industry partnerships, bulk synthesis facilities, and open communication bring down price barriers and open possibilities for broader use. Efforts to create supply chain transparency and train younger scientists in handling and recycling ionic liquids spark optimism.

A Resource for Progress

The shift toward safer, more sustainable chemistry isn’t just a slogan. Watching research teams switch to ionic liquids when seeking better performance and safety, I see clear benefits for labs, factories, and the environment. Every bottle of this compound represents a step toward a world where chemical reactions don’t compromise safety or sustainability.

Understanding Chemical Stability

Stability means more than just sitting on the shelf. It decides if a product still works, stays safe, and meets quality promises over time. I’ve seen plenty of labs where an unstable compound goes from top performer to useless—sometimes overnight. Moisture from the air, a bit too much sunlight, or just a nudge of heat, and the product changes. That’s not just an inconvenience; it can wreck careful research or, worse, put people at risk.

Every chemical carries a unique fingerprint. Some react fast with humidity. Others quietly break down after weeks in the wrong container. A few, like sodium hypochlorite, lose muscle just by being left open. In high school, we learned to keep hydrogen peroxide in dark bottles for a reason: light turns it into water and oxygen. It's the little chemistry lessons that stick with you in real life, especially in workrooms full of reactive materials.

Factors Affecting Shelf Life

Shelf life isn’t just determined by date stamps. Temperature swings, light exposure, and contamination ruin good inventory every year. Take vitamin C powder—it looks innocent enough, but humidity or air will break it down. The same goes for certain antibiotics, plant extracts, or diagnostic reagents. Seeing a trusted product fail means more waste, frustrated staff, and safety headaches. Each weakened batch is a missed opportunity and a blow to trust in the supply chain.

Product labeling usually hints at the trouble spots. “Keep dry,” “Store in a cool place,” “Protect from light”—these aren’t just legal cover. They point out real-world threats. Cutting corners or brushing off those instructions can turn a reliable product into a risk. One expired batch in a pharmacy can trigger expensive recalls. In a teaching lab, it can throw off an entire semester’s work.

Fact-Based Risks and Safety

Ignoring storage rules leads to dangerous situations. Chemicals like peroxides, if left unsealed or in sunlight, can form dangerous crystals. Certain acids eat through plastic or metal containers if not separated. I once saw a storeroom with unlabeled bottles; most had degraded labels and odd-colored liquid. That’s how accidents happen. The U.S. Chemical Safety Board and similar agencies record hundreds of incidents caused by mishandled storage each year.

Practical Storage Recommendations

Sticking to basics goes a long way. Store chemicals in the original containers, out of direct sunlight, away from heat sources. Check the label for temperature ranges—most stable compounds prefer 20–25°C, but check the specifics. Tighten caps every time and keep an updated inventory list, noting the opening date. Shelves above eye level spell trouble. Use secondary containment for liquids, especially on lower shelves, to catch leaks.

Humidity brings big problems. Use desiccators or silica gel packets for powders and moisture-sensitive products. Refrigeration helps, but only for substances that tolerate cold—some crystallize or settle if chilled. Never store chemicals next to food or drink. Mixing incompatible substances in the same cabinet spells disaster.

How Good Habits Pay Off

Years in the lab have taught me an old saying: “A place for everything and everything in its place.” Good storage protects people, research, and reputations. Reviewing stock often, discarding expired material, and training new staff all feed into safety and reliability. Mistakes do more than waste money—they endanger health and public confidence. For anyone serious about safe and effective work, chemical stability and clever storage deserve real respect.

Real World Chemistry Risks

Too many lab accidents start with something simple—a mistaken assumption that a compound behaves the way you expect in familiar solvents or containers. All those neatly labeled bottles and shiny instruments rely on more than theory. A bottle of sodium metal tossed in water leads to fireworks; storing strong acids in the wrong plastic ends with leaks. Lab safety stories fill volumes because chemistry doesn’t make exceptions.

Solvents: Not All Bottles or Chemicals Mix

Acetone cleans glass perfectly, yet it chews through some plastics like polystyrene. Chlorinated solvents like dichloromethane turn certain rubbers sticky over time. As a grad student, I remember the day ethanol managed to extract plasticizers from cheap pipettes, clouding my sample and wasting hours. Every chemist hits that wall—experiment ruined by a container chosen in a rush. It’s not just about purity, but about surprises that only happen once a flask, a cap, or a seal is under stress.

The Hidden Influence of Lab Materials

Looking at a shelf lined with chemicals, each one seems tamed by its bottle. PTFE (Teflon) resists pretty much anything except molten alkali metals or fluorine. Glass works for most acids, but hydrofluoric acid eats right through it. Some compounds—peroxides or nitrites—turn dangerous if stored in light-sensitive containers or near incompatible substances. Human error happens, but sometimes a supplier swaps an old cap for a new one, and things go south because nobody realized the O-ring material won’t last a month with the solvent inside.

Solubility Can Trick Even Pros

Solubility charts don’t answer every question. Some compounds dissolve in a solvent, only to slowly degrade or react unexpectedly. I once watched a perfectly clear solution go yellow after a day in DMF—a hidden side reaction nobody spotted in the references. Organometallics in ethers work, unless traces of water sneak in and create a mess. NMR tubes sometimes dissolve with heavy organic solvents, generating mysterious peaks no one can explain. Skipping a materials check guarantees headaches and surprises, especially with sensitive syntheses.

Solutions: Straightforward but Not Always Obvious

Memory tricks and checklists help, but they only go so far. Cross-referencing compatibility charts is a start. Reading current safety data sheets—not the outdated photocopies in the drawer—gives facts that keep labs safe. Asking a colleague who ran a reaction last year often saves days. Small scale tests are king. Drop a bit of solvent into a vial made of the new plastic and let it sit before committing precious samples.

Quality lab work comes from respect for the unpredictable. Double-check those container materials before storing reactive stuff overnight. Keep a healthy distrust of unfamiliar solvents in new settings. Chemistry rewards caution with clear data and safe working environments. In my experience, time invested up front saves effort, worry, and risk in the long run.

Knowing Your Material Saves Trouble

Curiosity about ionic liquids has led to big strides in green chemistry, battery tech, and even pharmaceuticals. They can look tame—sometimes they don’t even smell, and they don’t ignite easily. That’s where a real risk lies. Just because something doesn’t shout “danger” like the reek of ammonia doesn’t mean you can ignore precautions.

A few years ago, I worked in a lab that explored various solvents for recycling electronics. Some ionic liquids felt safer than classic flammables like acetone, but labs reported burns, breathing issues, and unexpected corrosion when folks ignored safety sheets. I always tell new researchers: every liquid has a story, and you don’t want to learn the hard way.

Lab Setup: No Corners to Cut

Start with the right gear. I’m talking about goggles—not glasses—and gloves that actually resist the liquid you plan to handle. Standard nitrile often works, but specific types of ionic liquids can eat right through or soak in. A chemical splash apron and closed shoes create a barrier you’ll appreciate if a spill happens.

Fresh air means fewer headaches and less risk of lung damage. Even if an ionic liquid hardly vaporizes, a fume hood gives peace of mind. Some liquids can become more dangerous if they break down or react with water. Ventilation is cheap insurance against mysterious headaches or chronic issues down the line.

Spill kits should sit within arm’s reach. The right absorbent material soaks up a spill without turning toxic or reacting. I always check the kit’s instructions for compatibility twice—never rely on a dusty mop or old towel. Some labs even keep neutralizers on hand, but only for trained folks who understand potential reactions.

Respect the MSDS—It’s Written in Blood (Figuratively)

Safety data isn’t just paperwork. It comes from hard lessons—fire, hospital trips, sometimes worse. Find your liquid’s SDS and read it before opening any bottle. Does skin exposure mean a rash, or does it mean deep tissue burns? Some ionic liquids attack nerves or disrupt breathing, quietly building risk over repeated contact.

Even common ionic liquids like EMIM BF4 or BMIM PF6 demand different precautions. Research from the American Chemical Society shows some are toxic to aquatic life for weeks, so sinks and drains never count as disposal points. Bag waste and label it clearly. Ask your safety officer or environmental health team before sending anything down the line.

Training Builds Good Habits

Comfort breeds carelessness. After hundreds of safe uses, routines get sloppy—bare hands, chemical containers left open, vent hoods ignored. I once watched a seasoned researcher forget gloves, only to rush to the eyewash station moments later. Every lab needs regular training, reminders posted on the wall, and a culture that welcomes questions.

Peer-reviewed studies and my own experience agree: sharing stories of real incidents makes the danger stick in your mind better than rule lists ever could. Bring up close calls in group meetings so lessons travel through the team.

Solutions: Build a Culture and Track Each Step

A checklist beats memory every day of the week. I keep mine taped above my bench—goggles, gloves, splash resistance, fume hood ready, backup spill materials set, label visible, waste plans clear. Encourage quick reporting of all mistakes, even near misses. You don’t just protect yourself; you set a standard for anyone who comes after.

When dealing with any chemical—ionic liquids included—habits save skin, eyes, lungs, and careers. It’s not paranoia, it’s respect born from knowing how easy, and how painful, a slip can get.

Understanding What ‘Purity’ Really Means

Let’s talk about product purity. Every industry deals with the questions: “How pure is your product?” or “What’s the grade?” People who haven’t worked in production might not realize just how much this single number can impact everything, from the price on an invoice to the safety warnings on a label. My years working in manufacturing taught me that purity isn’t just a bragging right—it’s a baseline that shapes safety, cost, and even trust.

Most buyers see purity as the percent of a substance that’s actually what the label claims. In chemicals, that might be 98% pure or higher for “technical” or “reagent” grade items. For food or pharmaceuticals, the standards get stricter—think 99.9% and above, often with a required absence of specific contaminants. I remember one client in the food sector who would send products back over a 0.05% variance, no matter the cost. It sounds obsessive until you realize that trace impurities can mean health risks or failed quality audits. The bar sits high because there’s no room for error when people’s health is on the line.

Challenges That Manufacturers Face

Getting consistent, high-grade purity takes a lot more than fancy equipment. I’ve seen entire batches scrapped over a decimal point’s difference. Even with frequent lab checks, impurities sneak in—dust in a plant, leftover residue from a previous run, or something as simple as contaminated water. Without sharp process controls and routine validation, even one small slip risks the whole run. Data from the U.S. Pharmacopeia show that most product recalls for ingredients come from purity concerns.

The cost pressure gets real, too. Raw materials with higher purity often carry big markups. A jump from 95% to 99% can mean doubling the cost. This hits smaller processors the hardest, especially in fields like supplements or foods. Many get caught between customer demand and what their budgets allow. I’ve helped negotiate supply contracts where purity grade nearly tanked the deal—we ended up running extra rounds of filtration, watching profits shrink just to keep the client.

Facts That Can’t Go Ignored

Regulations dictate the minimum required purity for specific uses. In the U.S., the FDA demands strict testing and certification for food and pharma. ASTM and ISO standards set the tone for chemicals and industrial goods. Industry audits often go further: some will test every batch, compare it to certificates of analysis, and check for possible fraud. There’s a world of difference between a lab that holds itself to ISO 17025 and one that cuts corners for speed. In 2023, the European Chemicals Agency flagged more than 150 products from Asia for failing purity tests—proof that the paperwork doesn’t always match reality.

Trust gets built on transparency. Brands that publish their test results or open their processes have an easier time attracting long-term partners. Community watchdogs, like independent labs, also keep things honest—these are the groups that discover when shortcuts get taken, and they often set the stage for a recall or investigation.

Solutions for a Cleaner Supply Chain

It isn’t always about running more tests or buying higher-priced raw stock. The best improvements I’ve seen come from staff training and smart processes—keeping equipment spotless, reducing cross-contamination, and using robust lot tracking. Working closely with reliable suppliers makes a huge difference. Digital product passports, now adopted in the EU for certain chemicals, help track quality and trace issues back to the source.

In a crowded market, purity and grade stand as more than numbers on a spec sheet. They shape reputation, safety, and every transaction that follows.