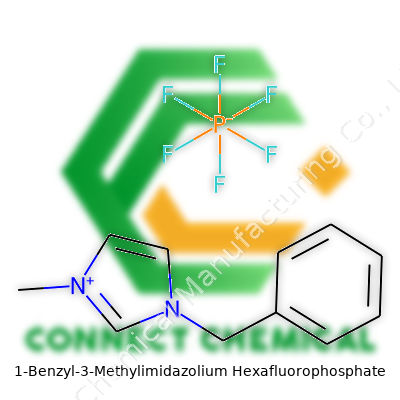

1-Benzyl-3-Methylimidazolium Hexafluorophosphate: A Modern Chemical Story

Historical Roots of a New-Age Salt

Chemists searching for alternatives to traditional volatile solvents started eyeing ionic liquids more closely around the end of the 20th century. The introduction of 1-Benzyl-3-Methylimidazolium Hexafluorophosphate grew from this shift in mindset. Researchers noticed that imidazolium-based salts like this one showed low volatility and strong chemical stability, and a slew of scientists began tinkering with different anions and cations. The pairing of benzyl and methyl groups, wrapped around an imidazolium core, caught on as labs looked for ways to fine-tune melting points and chemical resistance. Manufacturers spread the word about these salts as safer, smarter options for synthesis, catalysis, and electrochemistry, sparking further interest in labs from Asia to Europe.

What the Product Brings to the Table

Benzyl-substituted imidazolium salts aren’t just another chemical. The moment you open a container of 1-Benzyl-3-Methylimidazolium Hexafluorophosphate, you see a crystalline powder or, at higher humidity, a viscous fluid. Manufacturers label the substance for purity (often 98% or higher), and the solid is typically off-white or faintly yellow. The hexafluorophosphate counterion stands out in analytical runs for its ability to suppress unwanted side reactions. The benzyl group brings a tweak to the cation’s size and electronic properties, giving researchers a tool to push selectivity or improve material compatibility, making this salt more than a simple solvent.

Diving Deep: Physical and Chemical Features

With a molecular formula of C11H13N2PF6 and a robust melting point above 80°C, this ionic liquid stands firm under temperature swings. Its density hovers around 1.2 g/cm³, crucial for process engineers working out scale-up plans. Its thermal stability often exceeds 250°C, important in high-temperature transformations or material processing. The salt resists oxidation, and hydrolysis rates slow to a crawl without excess moisture, something I always keep an eye on when working in humid labs. Its distinct solubility in polar organic solvents — acetonitrile, DMSO, DMF, and sometimes water depending on purity — makes it a flexible piece in a chemist’s toolbox.

Technical Details and Labeling Practices

Suppliers ship the compound under multiple grades. Research-grade batches come with tightly controlled impurity profiles, especially moisture and halides, to avoid downstream process issues. Safety labels highlight the hexafluorophosphate group, which, while less reactive than perchlorates, can produce toxic gases in strong acid. Most bottles include hazard pictograms for skin and eye irritation. Storage guidelines stress keeping the product in airtight, moisture-free conditions, far from acids or strong bases, to prevent unwanted decomposition. Batch certificates often provide NMR, IR, and elemental analysis data. The CAS number, 430471-47-3, is standard on every label for regulatory reference.

Stepwise Approach to Synthesis

Lab syntheses follow a clear two-step workflow: generate the cation and perform metathesis. Typically, methylimidazole reacts with benzyl chloride to give the 1-benzyl-3-methylimidazolium chloride salt. Purification through recrystallization or solvent extraction removes excess reagents and by-products. The next step swaps out chloride for hexafluorophosphate by stirring the chloride salt with hexafluorophosphoric acid (HPF6) in a polar solvent or by direct salt metathesis with potassium hexafluorophosphate. Filtration removes insoluble potassium chloride, leaving behind the target ionic liquid. This approach avoids high temperatures and limits unwanted polymerization, which I learned the hard way after a failed scale-up reaction early in my research career.

Chemical Behavior and Modification

The imidazolium cation offers a reactive core for further substitution or ring-modification reactions. Chemists often introduce other functional groups onto the benzyl ring via electrophilic aromatic substitution. Reductive cleavage of the benzyl group gets tricky but remains possible with strong hydride sources. In addition, the hexafluorophosphate anion can be exchanged for other anions — tetrafluoroborate, triflate, or bis(trifluoromethylsulfonyl)imide — to dial in electric conductivity or hydrophobicity, suited for specialty applications. My own work using the salt as a phase-transfer catalyst for alkylations benefited greatly from these modification opportunities.

Alternative Names and Industry Synonyms

This salt travels under several names. Besides its IUPAC designation, chemists call it BmimPF6, [BzMIM][PF6], or, less formally, benzylmethylimidazolium hexafluorophosphate. Catalogs may list “1-Benzyl-3-methylimidazolium hexafluorophosphate” or, for shorthand, simply “benzylmethylimidazolium ionic liquid.” Trade names might pop up depending on the supplier, but the core product structure remains the same.

Operational Hazards and Best Practice Safety

Every time I handle hexafluorophosphate salts, I double-check my PPE. Although not as explosive as perchlorates, PF6-containing materials react in strong acid to make toxic HF gas. Eye goggles, gloves, and chemical-resistant lab coats cut down on risk. Labs follow strict protocols: keep open containers under fume hoods, dispose of waste promptly in segregated bins, and never store large quantities near incompatible substances. Manufacturers add sodium carbonate to accident spill kits to neutralize any leaked acid or PF6. Safety data sheets outline chronic exposure studies, but so far, dermal and inhalation risks remain low for well-managed environments.

Value and Versatility in Real-World Applications

Institutes and companies use BmimPF6 as a non-volatile solvent for green chemistry processes, especially for alkylations, Diels–Alder reactions, and metal-catalyzed cross-couplings. Its ionic properties bring a conductivity upgrade in supercapacitors and batteries, especially where water or volatile organics threaten device longevity. I’ve worked with researchers who use this salt in protein crystallization, finding that its mild solvating properties allow delicate biomolecules to form well-ordered crystals, pushing structural biology projects forward. Its low vapor pressure cuts emissions in scale-up plants, which is a plus from a sustainability perspective.

Research Momentum and Experimental Progress

R&D labs worldwide test BmimPF6 for new roles nearly every year. I see new literature on catalysis under milder conditions and deeper dives into electrochemical windows for battery innovation. Environmental chemists look into its ability to stably dissolve transition metals and rare earths for recycling, which could matter for sustainable electronics. Teams partnering with pharmaceutical companies try using these salts as separation agents for chiral drugs, claiming sharper selectivity and faster process times. Challenges remain in scaling up production while keeping by-product contamination low, which points to continued process engineering efforts.

Questions About Toxicity and Environmental Fate

Toxicity studies kick off when any new ionic liquid starts scaling up. Researchers looking into BmimPF6 find mild irritancy in skin and eye contact, so best practice mandates caution. Chronic oral and inhalation studies in rodents show low bioaccumulation, but environmental breakdown remains slow, raising concerns about persistence in waterways. Hexafluorophosphate can hydrolyze, especially in acidic or basic conditions, to give fluoride-containing byproducts, which are not benign in nature. So, I follow a strict “recover and recycle” rule in lab and encourage industrial-scale systems to install closed-loop handling and incineration units. Regulatory agencies in the EU, US, and Japan monitor large-scale uses closely, yet so far, well-managed facilities haven’t reported environmental incidents.

What’s Coming Down the Line?

Labs and industry partners already test new variants of BmimPF6, swapping anions and adding to the imidazolium core to cut down on environmental persistence and boost conductivity. The push toward “designer ionic liquids” hasn’t slowed — ambitious chemists blend BmimPF6 with biodegradable anions or put fluorine-free replacements through their paces. Process engineers fine-tune recycling protocols and invent ways to reclaim spent ionic liquids from reactor washes or battery electrolytes. In academic circles, the salt remains a model system for studies on ion mobility, solvation, and crystal engineering. The wave of electrification in transportation and chemical manufacture promises fresh markets for salts with the electrochemical performance and safety standards BmimPF6 can provide.

Why Chemical Formulas Matter in a Real-World Lab

People spend years learning to read a chemical formula. For someone working in a research lab, having the precise formula in hand—like C11H13N2+·PF6− for 1-Benzyl-3-Methylimidazolium Hexafluorophosphate—saves headaches, money, and sometimes, lives. Each symbol and subscript tells a bigger story about safety, solubility, and even how this salt interacts inside test tubes and beakers.

I remember an undergrad internship focused on ionic liquids. The first lesson drilled into us: get the formula wrong, and nothing else lines up. If the formula sheet read:

C11H13N2PF6

It's missing the explicit splitting of the cation and anion, which matters when mixing with solvents or calculating molarity. Mess up the stoichiometry, waste thousands of dollars on mismeasured chemicals, and make the supervisor very unhappy.

Breaking Down the Formula

This compound wears two hats: C11H13N2+ as the organic ion, and PF6− as the counterion. The imidazolium part offers stability and solubility, thanks to the benzyl and methyl tweaks. The hexafluorophosphate brings low reactivity—great when organic solvents can burn or degrade less robust salts. Both ions together support a growing green chemistry industry, especially for solvent replacements where volatile organic compounds once dominated.

Importance for Safety and Innovation

Some chemicals are notorious for hazards, but this salt usually gets picked for its stability and non-flammability. Regulatory bodies—like OSHA in the US or ECHA in Europe—still call for full disclosure of contents and formulas on any lab or shipping labels. I once saw confusion over a wrong subscript on a drum, which led to a week of wasted time as that batch was re-tested for impurities.

The chemical formula clears up confusion between similar-sounding substances. For example, changing just the anion—using BF4 instead—alters conductivity, melting point, and potentially, toxicity. The devil lives in those tiny details. Researchers and chemical engineers need robust, reliable data before starting pilot-scale production.

Addressing Gaps: Communication and Education

One hurdle is knowledge transfer from expert to novice. Universities can help by integrating more practical chemical literacy and stress real-world implications of even the smallest formula error. Industry has a role in demanding transparent, accurate product data and funding open-access resources for up-to-date material safety and technical references. This helps maintain integrity.

Digital tools—such as chemical inventory software—can ease formula entry and flag oddities or conflicts before expensive or unsafe mixing begins. Labs adopting these tools often see fewer mistakes and improved compliance, which keeps both people and budgets healthier.

Looking Ahead

Accurate formulas provide the essential foundation. Everyone, from students to career chemists, benefits when organizations stick with clarity and precision. Mistakes shrink in number, breakthroughs come sooner, and the science moves forward with fewer avoidable setbacks. If science aims to solve tomorrow’s problems, it all starts with those tiny, meaningful letters and numbers.

Why Labs and Industry Turn to “BMIM PF6”

It’s easy to look at a chemical with a name as long as 1-Benzyl-3-Methylimidazolium Hexafluorophosphate and wonder where it fits in everyday research and production. Those working in labs or industrial plants know that specific chemicals often feel like the unsung tools that get essential work done. BMIM PF6 earned its spot on many benches and process lines because of how it performs as an ionic liquid.

Solvent Powers and Green Chemistry

Anyone who’s worked in a wet lab knows the downsides of common volatile organic solvents—fire risks, smells that sting the nose, and waste streams that make environmental staff wince. BMIM PF6 changes that equation. It doesn’t evaporate like traditional solvents, which means it keeps working in a reaction vessel rather than escaping into the air. Since the ‘90s, researchers have leaned on this compound for “green chemistry” pursuits. Faster, cleaner reactions cut down on toxic byproducts and hazardous conditions. In the pharmaceutical industry, where purity and safety carry weight, that matters. It brings the possibility of safer workplaces and easier compliance with environmental regulations.

Electrochemistry and Energy Storage

BMIM PF6 gets heavy use in batteries and capacitors, where the search for stable, conductive, and non-flammable electrolytes never stops. Electrochemists at universities and in clean energy startups use it to push the boundaries in lithium-ion and supercapacitor technologies. Ionic liquids like this one don’t burn easily and allow ions to move smoothly between electrodes, which means better energy efficiency and less risk of fires—a major win compared to traditional organic solvents. The shift toward renewable energy only makes reliable electrolyte materials more important.

Catalysis and Synthesis

Plenty of industrial syntheses don’t move forward until you find the right catalyst or reaction medium. BMIM PF6 acts not just as a solvent but as a partner in tough reactions. Its chemical stability means it doesn’t break down when exposed to strong acids, bases, or even some oxidizing agents. Chemists who focus on fine chemicals or specialty polymers often turn to it because it can dissolve both organic and inorganic reactants. Its recyclability saves on cost and waste, which comes in handy in large-scale runs. From personal experience working on metal-catalyzed cross-couplings, using an ionic liquid like this helped achieve a cleaner, higher-yield product with less mess during purification.

Environmental and Analytical Roles

Separations experts see BMIM PF6 as a game-changer for extraction of metals, especially rare earths and precious metals from mining or electronic waste. Compared to using organic solvents, this compound’s low volatility and tunable properties give more control and lower environmental impact. Analytical chemists sometimes use it in chromatography for separating tricky mixtures—it can reduce tailing and give sharper peaks, saving both time and headaches for lab staff.

Looking At Safer Practices and New Directions

The chemists I’ve worked with will tell you that no solvent is perfect, and BMIM PF6 isn’t free from concerns—hexafluorophosphate anions and their potential for producing toxic byproducts mean handling with care. Researchers keep looking for even safer ionic liquids, but the uses outlined above highlight why BMIM PF6 isn’t going away yet. Solutions include strict waste handling, greener production methods, and recycling processes already in place at many facilities. As regulations adapt, so will the chemical toolbox, but the core demand for safety, efficiency, and sustainability keeps this compound in active rotation.

Getting Practical About Chemical Storage

Working with chemicals day in, day out, I’ve run into my share of headaches. A simple oversight in storage can mean ruined product, health troubles, or even a hurried sprint to the eyewash station. The difference often comes down to respect for the compound—recognizing that one wrong move creates bigger problems than just a spill on the floor.

Humidity and Temperature Control in Chemical Storage

Some compounds have a real problem with moisture. Even a brief door propped open on a humid day invites clumping, spoilage, or unexpected reactions. In my lab, desiccator cabinets with clear silica gel indicators kept us honest. Keeping chemicals in a cool, dry spot wasn’t just a line from the label—it saved us from ruined batches more times than I could count.

Heat brings its own risks. Chemical bottles too close to a heater or left in direct sunlight sometimes led to pressure build-up, warped seals, or even leaks. Every year, incidents get reported from chemicals that cooked on loading docks or in poorly ventilated stockrooms. Best practice—store away from direct heat sources, check the recommended temperature range, and always rotate stock to use older supplies first.

Ventilation: Keeping the Air Clean

It’s easy to forget that not every container seals perfectly. I’ve walked into supply closets where fumes hung thick in the air simply because someone cut a corner on ventilation. That type of air can put your health at risk without you knowing it. Mechanical ventilation or dedicated chemical cabinets solve this headache before it starts.

Personal Responsibility: Labeling and Segregation

Labels have to be big, clear, and impossible to miss. In shared spaces, unreadable labels create confusion and mistakes. It stunned me how often a faded label caused panic—no one likes guessing what’s in the jar. Always use standardized labels, replace damaged ones immediately, and note the purchase or opening date.

Not all chemicals get along. Acids shouldn’t live near bases. Oxidizers don’t belong next to organic solvents. Stories of explosive reactions from unsuitable neighboring bottles aren’t rare—they make the news every year. Segregated storage prevents disaster. Simple color-coded shelves or bins practically shout warnings before a risky mix reaches the counter.

Tools and Containers: The Right Gear for the Job

I’ve learned that not every scoop or jar is fair game. Some compounds chew up plastic, others rust metal, and a few leach through glass over time. Follow the manufacturer’s storage recommendations exactly. Only use tightly sealed, chemical-compatible containers. Good-quality containers cost more upfront, but they prevent leaks and protect shelf life.

PPE and Emergency Planning

No one feels invincible in a spill. Goggles, gloves, and lab coats weren’t up for debate in my old department—they were as essential as the chemicals themselves. Spill kits sat within arm’s reach, and everyone knew the drill for neutralizing and cleaning up trouble. Teams ran drills, so small accidents didn’t turn into serious harm.

Making Safety a Habit

What works in industry trickles down to classrooms and garages. Written protocols, regular safety reviews, and ongoing training build a culture where everyone keeps an eye on safety—no exceptions. Better habits across the board keep people out of the emergency room and safeguard every investment in research or product development.

Real respect for a compound means steady routines: dry, cool storage; proper ventilation; solid labels; compatible equipment; and serious PPE. Cutting corners carries a cost, while straightforward care sets everyone up for success.

Understanding the Chemistry

With a name as long as 1-Benzyl-3-Methylimidazolium Hexafluorophosphate, most folks might expect it to act in unusual ways right out of the gate. This compound belongs to the family of ionic liquids, with a structure that includes a bulky organic cation and a fluorinated anion. Chemically, ionic liquids often intrigue chemists because their melting point sits surprisingly low and their solubility trends stray from typical salts.

Solubility in Water

From my own experience doing bench research, folks often try to mix new ionic liquids with water, hoping for full dissolution. The hexafluorophosphate anion stands out: it resists water far better than more familiar salts like sodium chloride. Here’s what stands out—1-Benzyl-3-Methylimidazolium Hexafluorophosphate doesn’t blend well with water. Try to mix it, and most will settle at the bottom or float in cloudy globules, barely breaking apart.

Science backs up that observation. Multiple studies show that hexafluorophosphate-based ionic liquids fall into the hydrophobic camp. They won’t dissolve easily; the numbers point to milligram-scale solubility per hundred mL of water. Some even call these compounds “water-fearing” because their molecular pieces simply refuse to bond with water. That means chemists can often use this material to separate compounds out of water—good news for certain kinds of extraction.

Interaction with Organic Solvents

The situation flips when swapping water for organic solvents. The structure, stuffed with benzyl and methyl groups, loves to play with nonpolar or slightly polar liquids. Drop 1-Benzyl-3-Methylimidazolium Hexafluorophosphate into acetonitrile, acetone, or dichloromethane and watch it disappear rapidly, forming clear solutions.

During my work with green solvent technologies, nearly everyone in the lab experimented with these substances in hope of dissolving tricky organic compounds. These experiences mirror what the literature supports: hexafluorophosphate ionic liquids melt into most organic solvents, especially those used in pharmaceutical and catalysis work. This preference for organic media often draws researchers searching for safer, more tunable alternatives to harsh chemicals.

Implications for Industry and Research

The poor solubility in water and strong affinity for organic solvents shape how this ionic liquid gets used. In the pharmaceutical world, this offers a safer solvent choice for difficult syntheses or separations. Environmental scientists eye these liquids as replacement for volatile organic solvents, though the question of long-term toxicity and degradation has yet to find a solid answer.

The chemical structure awards unique properties: researchers can take advantage of selective solubility, using the ionic liquid as a medium for extraction or as a phase in special reactions. In routine organic synthesis, this means smoother workflows, less evaporation, and at times smaller environmental impacts.

Moving Toward Practical Solutions

Scientists and engineers interested in using 1-Benzyl-3-Methylimidazolium Hexafluorophosphate should look beyond simple solubility tables. Small pilot tests show how these ionic liquids can streamline difficult separations or catalysis projects. Equipment compatibility checks help avoid corrosion or fouling, since the hexafluorophosphate ion occasionally reacts with moisture, producing problematic byproducts like hydrofluoric acid.

Continued research should focus on safer disposal, toxicity reduction, and greater insight into long-term effects—key points for anyone aiming to move beyond lab-scale work. By pairing knowledge from hands-on experimentation and the scientific record, new applications and safer processes will follow.

Purity: The Real Value Factor

People don’t buy chemicals or ingredients just for the label. Most folks working in labs or industries know that purity shapes everything—the accuracy of results, safety, and often the bottom line. Take pharmaceutical-grade substances, for example. Buyers expect at least 98-99% purity, often hitting even higher percentages. Lab reagents go under tight scrutiny too, usually ranging from 95% up to “ultra pure” grades approaching 99.999%. Lower-purity batches find their place in industrial or agricultural settings, where a decimal point less doesn’t spell disaster.

The threat from impurities isn’t just abstract: Heavy metals, for example, even in trace amounts, can distort lab results, clog machine parts, and trigger costly recalls in food or drug production. So, paying for higher purity often means avoiding headaches, equipment damage, or legal trouble.

Appearance: More Than Just Looks

Most buyers hope the product looks like the datasheet says it should. For chemicals, powders typically show up white or off-white. Sometimes, slight color hints emerge from tiny impurities—the kind you spot only after years in a lab. Clear, fine crystals or uniform granules suggest careful processing and solid quality control.

Liquids tell their own stories. A clear, colorless solution usually means few unwanted extras. Cloudiness or a strange tint can spell trouble: contamination or poor storage. Some oils and resins arrive yellowish or amber—normal for their type, but buyers learn to watch out for unexpected changes. One time, I opened a drum of what should’ve been white powder, only to find damp clumps tinted gray. Turns out, moisture had sneaked in somewhere along the supply chain, cutting shelf life and making dosing impossible.

Regulations and Trust in the Supply Chain

Companies serious about their reputation lean on documentation—spec sheets, certificates of analysis, and sometimes even third-party testing. Industry veterans check batch numbers, question anything odd, and avoid deals that seem too good to be true. Regulations don’t just pile up for fun. For some ingredients, like food additives or pharmaceutical precursors, a consistent appearance and guaranteed purity protect not just businesses but everyone who might use the end product.

I watched a neighbor’s small food company once order what they thought was high-purity citric acid from a discount source. Box came in looking slightly yellow and clumpy. Their customers quickly noticed an off taste, and complaints flooded the inbox within a week. That single batch nearly cost them a wholesale contract—an expensive lesson about sticking with trusted vendors, even if the price tag seems higher.

Smarter Buying and Clear Solutions

Solid buying starts with understanding the risks. Always inspect batches up close before running full-scale production. Labs can run spot checks for critical impurities. Building relationships with reliable suppliers pays off in the long haul. Large buyers may even perform their own third-party checks or visit supplier warehouses.

At the end of the day, purity and appearance serve as first warnings. If something looks or tests off, stopping early prevents bigger losses down the road. People can be tempted by cut-rate offers, but real value—and safety—grows from sticking with quality-focused suppliers.