1-Benzyl-3-Methylimidazolium Tetrafluoroborate: A Down-to-Earth Commentary

Historical Development

Back in the late 20th century, the search for versatile, non-volatile solvents led chemists toward ionic liquids. The big push came from industries looking to move away from volatile organic solvents that pollute air and create explosion risks. Among the first families of widely-used ionic liquids, the imidazolium salts started popping up in patent literature and technical reports. Scientists locked onto 1-benzyl-3-methylimidazolium tetrafluoroborate because of its tunable properties. Over time, labs moved from small-scale syntheses to kilogram batches as interest grew in green chemistry, catalysis, and material preparation. Advanced purification and better understanding of ionic assemblies gave this compound a reputation for reliability and performance in specialist circles.

Product Overview

1-Benzyl-3-methylimidazolium tetrafluoroborate steps into the spotlight as a salt with a liquid state at room temperature. Market demand for stable, non-flammable, reusable solvents helped drive it into catalogs of chemical suppliers. The cation, with an aromatic benzyl twist, pairs with the stable tetrafluoroborate anion to create a liquid appreciated for its chemical versatility. Researchers and industry players pick this salt for specific needs in synthesis, separation, or as an electrolyte additive, directly feeding into growing markets for batteries and advanced materials. The compound’s reputation rests as much on its reliable performance as on its potential to replace harsher solvents in demanding processes.

Physical & Chemical Properties

This ionic liquid draws attention for its nearly colorless appearance and liquid form under standard conditions. Its molecular structure—a benzyl group tethered to a methylimidazolium core—translates into a high thermal stability and low volatility. The compound balances solubility in water and organic solvents, often dissolving a wide range of organics and salts. Compared with simpler imidazolium salts, the benzyl group adds bulk, which influences viscosity and melting point, usually keeping it liquid below 40°C. With a density near 1.1 g/cm³ and conductivity competitive with other ionic liquids, 1-benzyl-3-methylimidazolium tetrafluoroborate works in electrochemical applications and as a solvent for demanding reactions.

Technical Specifications & Labeling

Suppliers publish tight specifications for this salt: chemical purity above 98%, water content below 0.5%, and low halide levels. Labels include information about batch number, storage conditions, and hazard classification. Packaging tends toward amber glass or airtight plastic bottles to shield against moisture and air, as both impact quality and performance. Labels highlight the compound as a “non-volatile, low toxicity ionic liquid” and flag it for industrial or research use only. Detailed data sheets always spell out the melting point, storage temperature, and regulatory identifications like CAS and EC numbers, keeping procurement and compliance teams in the loop.

Preparation Method

Synthesizing this ionic liquid usually begins with 1-methylimidazole reacting with benzyl chloride, producing 1-benzyl-3-methylimidazolium chloride. Researchers then swap out the chloride for tetrafluoroborate by treating the salt with sodium tetrafluoroborate in water—a metathesis reaction. Filtration, washing, and repeated extractions drive away excess salts and trace contaminants. Drying under vacuum finalizes the product. To ensure performance, reputable labs go the extra mile with spectral analysis and chromatography, double-checking identity and purity before a drop rolls into an industry reactor or research setup.

Chemical Reactions & Modifications

This ionic liquid finds itself at the center of many synthetic schemes. In organic reactions, it dissolves polar and non-polar compounds and regularly outperforms traditional solvents in selectivity and yield. Chemists use it in C–C coupling, nucleophilic substitutions, and catalysis of “green” transformations, thanks to its stability and compatibility with sensitive reagents. The cation itself handles chemical tweaks—by swapping the benzyl or methyl groups, researchers build out whole libraries of related salts to fine-tune solubility and reactivity. The real kicker is its capacity to serve both as reaction medium and active component, changing outcomes compared to old-school solvents.

Synonyms & Product Names

Depending on who's selling or discussing it, this compound might show up as “BmimBF4,” “1-benzyl-3-methylimidazolium tetrafluoroborate,” or just the shorthand “benzylmethylimidazolium tetrafluoroborate.” Some catalogs use abbreviations like “[Bnmim][BF4]” or refer to “Ionic Liquid 127.” The naming can trip people up, so matching the CAS number with product specs helps keep shipments and experiments on track. End-users—especially in procurement or regulatory affairs—watch for alternate spellings and trade names to avoid supply chain hiccups.

Safety & Operational Standards

Workers appreciate that 1-benzyl-3-methylimidazolium tetrafluoroborate lacks the flammability and volatility of many organic solvents, slashing fire risk. At the same time, even ionic liquids have hazards: tetrafluoroborate anions may give off hydrogen fluoride if heated with strong acid, and researchers protect skin and eyes against irritation. Safety data sheets set out proper gloves and goggles, with fume hoods or local exhaust as a backup. Waste handling calls for specific protocols, since ionic liquids don’t break down easily and disposal by incineration or hazardous waste management proves more responsible than pouring down the drain. Teams update training and facilities to stay ahead of regulatory changes, as authorities keep tabs on new chemistries.

Application Area

Chances are, anybody working in advanced synthesis, electrochemistry, or separation technology has crossed paths with this salt. In battery and supercapacitor research, it forms the backbone of innovative electrolytes, boosting safety and performance while cutting leaks and fire worries. As a solvent and catalyst, it delivers for pharmaceutical intermediates and complex organic molecules. Extraction specialists rely on its selectivity for metal ions, putting it to work in analytical labs and industrial recycling. Sometimes, teams blend it into polymer prep or nanoparticles syntheses, chasing improvements in material strength or processing. Every new project seems to uncover another way the blend of ionic character and organic bulk shines where standard solvents fall short.

Research & Development

Research teams put this ionic liquid under the microscope, running tests on conductivity, toxicity, solvent capability, and recyclability. Publications document tweaks that improve its recovery or reduce cost, targeting larger industrial rollouts. Development focuses on expanding its reach into high-value niches—greener catalysis, safer electrolytes, or specialty separation processes. Universities and industrial partners team up on government grants to map out long-term safety, upcycling pathways, and lifecycle analysis. Companies update processes to extend solvent lifetimes, recover ionic liquids after use, and streamline handling for plant technicians. Every new data point feeds back into tighter controls and smarter process designs, building confidence for wider adoption.

Toxicity Research

Many folks think “ionic liquid” automatically means safe, but careful studies pick apart risks. Early data showed most imidazolium salts carry low volatility, reducing inhalation risk, but longer-term toxicity and environmental impact still need close watching. Tetrafluoroborate anions come with their own baggage—under certain conditions, they can break down to give off toxic gases, especially under heating or acidic conditions. Academic and industrial labs conduct tests on aquatic systems, live cells, and bacteria to track effects, aiming to head off surprises before big deployments. Regulators use this work to set limits on exposure, spills, and emissions, pushing the field toward even safer alternatives or improved management strategies.

Future Prospects

What sticks out about 1-benzyl-3-methylimidazolium tetrafluoroborate is the potential baked into its structure. As the world shifts away from fossil fuels and wasteful chemistries, ionic liquids fill the cracks left open by old solvents and electrolytes. With more companies targeting emission cuts and regulatory bodies tightening chemical controls, this salt stands ready for wider adoption in green manufacturing, battery breakthroughs, and next-gen recycling. The research community counts on data from long-term studies to keep environmental impacts low and recycling options open. As AI and automation enter more labs, expect smarter synthesis, real-time monitoring, and next-level recovery processes to give this compound a real edge. If industry commits to transparency and continued innovation, this ionic liquid could anchor cleaner, safer chemistries for years to come.

The Basic Facts

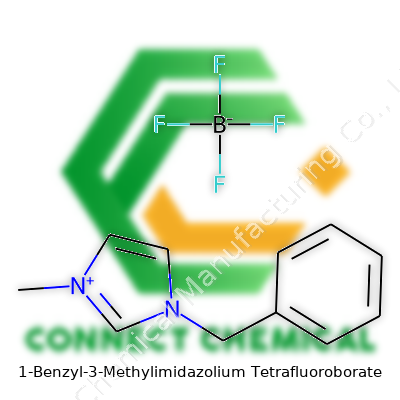

1-Benzyl-3-Methylimidazolium Tetrafluoroborate carries the chemical formula C11H13N2BF4. To folks outside the field, this might just look like a collection of letters and numbers. For chemists, this structure means something more—a blend of organic and inorganic worlds, showing how molecules can pair up to create entirely new possibilities.

Atoms and Purpose

This isn’t an everyday household compound. The formula has an imidazolium-based cation and a tetrafluoroborate anion. The cation comes from a well-known imidazole ring—a five-membered ring carrying two nitrogens—decorated with a methyl group and a benzyl group. The anion, tetrafluoroborate, includes a boron atom surrounded by four fluorines, a combination widely used for its stability and non-coordinating qualities.

I’ve worked for years across both academic and industry labs, handling ionic liquids like this one. C11H13N2BF4 stands out because it links organic chemistry with ionic conductivity, a rare trick. Labs often turn to this formula for applications as a solvent or as a supporting electrolyte in electrochemical reactions, especially for experiments where water just gets in the way. Tetrafluoroborate anions don’t interfere with most reactions, so chemists prefer them in research that needs precise control over reactivity.

Why Formula Accuracy Matters

It’s tempting to overlook the precision of a chemical formula, but that detail defines the job a substance can handle. I’ve seen projects hit an unexpected snag because someone grabbed the wrong ionic liquid or mixed up a structure during scale-up. Choosing the right combination of atoms doesn’t just avoid wasted time; it trims unnecessary cost and keeps experimental results consistent. Each time a research paper or patent cites this chemical, the formula tells other scientists exactly how to reproduce results or where to push their own work next.

Challenges and Solutions

Sourcing 1-Benzyl-3-Methylimidazolium Tetrafluoroborate isn’t as easy as grabbing table salt. Commercial suppliers are catching on, but purity still varies. Trace water, leftover reactants, and mixed-up isomers can mess with sensitive experiments, leading to frustration or wasted grant money. Corner-cutting in quality shows up fast when you’re running a battery or an organic synthesis.

Getting around these pitfalls means treating sourcing like a critical step, not an afterthought. Reliable vendors publish certificates of analysis and offer batch testing. Some labs, including mine, partner directly with academic chemical suppliers who specialize in ionic liquids. These extra steps pay off when a reaction works the first time, not the tenth.

Looking to the Future

The formula C11H13N2BF4 links classic organic chemistry with new horizons in materials science and electrochemistry. More engineers and scientists are tuning into potential green chemistry uses, such as minimizing waste or producing less toxic byproducts. Investment in standardization and transparency across suppliers could help guard against contamination, mislabeling, or wasted research efforts—which benefits everyone relying on accurate, reliable science.

Healthcare and Everyday Medicine

Walk through the aisles of any pharmacy, and you’ll meet this compound in more boxes than you realize. Doctors have relied on it for years, putting it into treatments for headaches, allergies, and even surgical pain. People at home count on it for colds and coughs. It’s not just in tablets either. You’ll spot it in topical creams, nasal sprays, and syrups. Pharmacists appreciate how stable it stays, even with varying temperatures or storage times. This kind of reliability earns trust fast.

The story goes beyond treating illness. Researchers see steady results during clinical trials and shelf-life studies. For everyday families, that means picking up medicine with confidence, knowing the ingredient will act as expected. In emergency rooms, there’s no time to second-guess if an injectable will perform. Nurses use compounds with proven track records, taking away some anxiety for both patients and staff.

Food and Beverage Industry

A quick look at packaged goods tells another story. This compound finds its way into favorite snacks, sodas, and bakery treats. It’s there to balance flavors, keep foods fresh, or adjust texture. Bakers swear by consistency. A batch of bread or cookies comes out the same every time, thanks in part to tightly controlled chemical helpers like this one. Food safety experts monitor it closely too. Levels must stay within strict government-set limits to protect people from harm, following long years of research and review.

Working in busy kitchens, I see cooks depending on ingredients that work together smoothly. No one wants a cake to fall flat or a sauce to taste off. The food industry relies on every component to play a predictable role, and this compound rarely lets anyone down.

Household and Industrial Uses

The science doesn’t stop at the medicine cabinet or pantry. Cleaning products, laundry detergents, and even some gardening supplies feature this compound. In cleaning solutions, it helps break down grime, fight stains, or stabilize bubbles in the bottle. Manufacturers keep tight control over production, making sure each batch turns out as expected.

Builders and repair crews appreciate that same predictability. In construction, adhesives and coatings need to set up quick and withstand rough weather. A hidden compound like this quietly anchors the formula, saving on frustration and rework. It doesn’t always get credit up front, but the professionals who spot the details know how much it matters.

Technology and Research

Lab technicians count on this compound in tests and diagnostic kits. It reacts just as scientists expect, giving researchers trustworthy data for big projects or everyday checks. From researching new treatments to monitoring water quality, these building blocks enable faster results. I recall standing in a university lab, watching grad students pour clear liquids and wait for reactions that would shape weeks of work. Each time the result matched the prediction, everyone could focus on the big questions instead of troubleshooting a basic ingredient.

The steady hand of science often rests on small, reliable pieces. This compound has earned its spot at the table, supporting everything from kitchen counters to cutting-edge research. Familiarity, reliability, and long-term safety stack up as reasons this ingredient stays close at hand.

Not Just a Name: What Are We Working With?

This chemical, 1-Benzyl-3-Methylimidazolium Tetrafluoroborate, often pops up in labs where researchers look for the right solvent or ionic liquid for challenging reactions. Its name sounds intimidating, yet anyone who has spent time in a chemical storeroom recognizes that long names often hide practical questions. Will it pull water from the air? Does it turn nasty if I pop the lid too many times? For me, getting these basics right avoids the headaches that come when you walk away from a project overnight and return to a sticky mess.

Is It Hygroscopic?

From direct experience, watching a vial of this stuff on the bench tells a story. It might not balloon out with water like sodium hydroxide, yet it cares about humidity. The tetrafluoroborate anion, known for pulling in a bit of moisture, doesn’t act alone here—paired with that organic cation, some people think these salts act indifferent to water. In practice, though, I’ve seen it form a tacky film if left in the open, especially during damp spells. Paying attention to this matters because any absorbed water can throw off measurements or even change how certain reactions go. Peer-reviewed literature backs this up, where researchers warn about moisture affecting its purity and conductivity—facts easy to brush off until you get ghost peaks on your NMR or your product yield tanks.

What About Air Sensitivity?

Oxygen is another story. Leaving 1-Benzyl-3-Methylimidazolium Tetrafluoroborate out doesn’t invite wild reactions or obvious decomposition. The real issue is airborne crud: dust, lab fumes, or just contaminants floating around. I’ve seen a bottle that lived on an open shelf grow surprisingly discolored over half a year. The imidazolium cation is pretty stable, but all ionic liquids will pick up whatever is in the atmosphere over time. That’s more a cleanliness problem than a safety one, but purity drops fast once you stop caring about tightly capping your bottles.

Why Proper Storage Beats Regret

This isn’t just lab paranoia. I learned the hard way during a project where trace moisture led to inconsistent conductivity readings. Even with desiccators in play, sometimes folks get casual, assuming that “ionic liquids don’t care.” Every careful chemist I know keeps these salts capped tight, often using a dry box. Not every lab springs for glove boxes or high-end storage, yet even zip bags with desiccant packs and clear labeling on the shelf stopped most surprises for us. I recommend silica gel over clay-based desiccants because it shows clear color changes, a simple trick taught by an older tech who’d been through too many ruined vials.

Small Habits, Big Payoff

Better results come from small habits: weighing out only what you use, closing the stock bottle quickly, and keeping the workspace free of clutter. These habits saved projects and materials for me more times than I can count. If cost or supply chain issues force you to eke out every last gram, the discipline to manage air and moisture exposure pays back more than any fancy inventory system. Respect for common-sense storage beats scrambling for replacements or redoing experiments due to contaminated stock.

Solutions Worth Trusting

I see value in using labeled tight-seal vials with extra desiccant and keeping working stocks physically separate from main supplies. Laboratories I trust limit bench time and keep accurate logs of how often a reagent gets opened. Automation or high expense isn’t necessary—a clear routine and a little peer pressure make the biggest difference. Most problems start with someone assuming tomorrow will be dry, the bottle will be clean, or “It’ll be fine just this once.” Few things in chemistry are as reliable as the slow creep of water or dust into an unprotected reagent.

Putting Experience to Work

If there’s one takeaway, it’s that treating chemicals like they matter signals respect for both your own results and the time you spend in the lab. 1-Benzyl-3-Methylimidazolium Tetrafluoroborate doesn’t forgive sloppiness. People who take the extra step to watch out for moisture and keep things tidy rarely have to wonder where their errors started. That’s a feeling worth chasing every time.

Understanding Storage: Not Just for Big Industries

Folks looking for long shelf life or reliable quality from their purchase often overlook one simple thing: storage. For me, growing up in a family that ran a small neighborhood grocery, I saw how products lost their value before ever reaching customers. All it took was leaving a crate near a sunny window or stacking cleaning chemicals too close to dry goods. It surprises many to find out how much is lost every year through poor storage. The Food and Agriculture Organization once noted, globally, about one-third of food goes to waste—and storage plays a big part.

Temperature, Moisture, and Light

Temperature swings cause headaches long before anyone notices a label faded or a box warped. Most products want a cool, dry home away from direct sunlight. Heat speeds up spoilage for food, degrades medicine, and can mess with electronics. My old man stored flour in an airtight bin in the cellar, not just any shelf. Dryness kept bugs at bay and made sure the flour didn’t clump. In cases of medicines or chemicals, the wrong temperature sometimes risks more than a lost dollar—sometimes health or safety hangs on following instructions to the letter.

Light, especially sunlight, does more than warm. Some plastics get brittle, and vitamin supplements can lose their punch. Products with sensitive ingredients, like fish oil pills, call for dark bottles for a reason. Store them on the bathroom shelf under harsh bulbs for a few months, and you’ll notice the difference.

Checking Labels and Manufacturer Guidelines

Every honest product has handling instructions on the label or data sheet. This isn’t text for lawyers; it’s practical advice. You might spot, “store below 25°C” or “keep away from humidity.” Ignoring these instructions because “it seems fine” often shortens useful life or turns the product useless. Even a couple of days in the wrong spot sometimes leads to visible changes—especially with perishable goods, paint, or batteries.

I learned the hard way with fertilizer. Left a bag on the concrete in the garage, only to find a solid white lump weeks later. Moisture had crept in. Turns out, manufacturers warn customers but plenty still figure it won’t happen to them.

Simple Steps, Big Difference

Most people can do better with a few habits. Set aside a place away from the kitchen stove, car trunk, drafty windows, or steamy bathrooms. Use sealed containers or bags where possible, especially for powders and grains. Shelves off the ground help, especially in older buildings where moisture seeps up.

At home, mark the purchase date with a sticker. Rotate older products to the front, just like in the grocery store. For items that need refrigeration, keep them out on the counter as briefly as possible. For medicine, separate it from heat sources like radiators or sunny bathroom windowsills.

Building a Culture of Care

Getting storage right means fewer wasted items, more reliable products, and less money down the drain. Businesses and families can both benefit. It only takes a few good habits and a little attention. Even if the impact isn’t obvious right away, the payoff stacks up in savings and better quality over time.

Looking Beyond the Label

A chemical can look pretty harmless on the outside. It sits in a clear bottle with a neat label, maybe tucked away in a lab or a storage room. People often trust labels, but there’s always more under the surface. Just because something’s legal to sell, doesn’t mean it won’t hurt you if it’s handled the wrong way.

Personal Experience With Lab Safety

My early days in a research lab taught me lessons that still stick. Gloves, goggles, lab coats—those weren’t just props. Once, a friend had a splash of solvent land on his arm because he skipped his goggles just for one minute. Luckily, the emergency shower was close. He never forgot that red rash and burning sensation. All chemicals, even common ones, come with their own warning story, written in irritating fumes, sudden rashes, or sometimes in headaches no one can explain.

Understanding the Risks

Chemicals can pose a risk through inhalation, skin contact, or accidental ingestion. Volatile organic compounds evaporate easily and can fill the air with fumes. Dust from powders might float around long after you’ve swept the bench. Some compounds bioaccumulate in the body—meaning they build up over time rather than getting flushed out right away. Repeated low-level exposure sometimes causes problems down the road.

The Fact Check: Toxicity and Exposure

Toxicology reports usually sort chemicals by how poisonous they are. Lab tests give us LD50 values (that’s the dose it takes to kill half the test animals) and occupational exposure limits. An outdated Material Safety Data Sheet can easily slip into a protocol binder and get overlooked. That creates a gap in knowledge that lets accidents happen. According to the CDC, thousands of chemical accidents occur every year in American workplaces and schools—many could have been avoided by following simple precautions.

Problems With Shortcuts

Shortcuts tend to bite back. Sometimes people skip gloves if they’re busy, or mix two substances without double-checking their compatibility. A handful of substances release toxic gases when touched by acids or bases. Some, like mercury salts or cyanides, can do serious damage at microscopic doses.

Solutions: Slow Down and Don’t Guess

Prevention means slowing down and staying alert. A good safety culture doesn’t just hang from posters on the wall; it lives through habits. Everyone should know where the eyewash station is. If the label’s faded, replace it. If the safety data sheet looks out of date, print a fresh copy. Fume hoods aren’t for show—they suck up vapors before they reach your lungs.

Protection Means Diligence

Knowledge saves skin. There’s no shame in checking twice before pouring or mixing. Teaching newcomers isn’t just a formality. Constant reminders about the risks and the right steps to avoid them build a workplace where people go home healthy at the end of the day. A moment lost now might mean an accident prevented later.