1-Butyl-2,3-Dimethylimidazolium Hexafluorophosphate: A Practical Look at a Modern Ionic Liquid

Historical Development

Chemists started paying serious attention to ionic liquids like 1-Butyl-2,3-Dimethylimidazolium Hexafluorophosphate in the late twentieth century, searching for alternatives to classic organic solvents that often brought health hazards and environmental damage. The early work on imidazolium-based salts came from European researchers keen to break with traditional, often volatile compounds—a shift fueled by stricter workplace safety laws and an emerging green chemistry movement. Anyone working with volatile organic solvents knows how quickly their fumes take over the bench and how strict the disposal rules can get. As these ionic liquids, which barely evaporate at room temperature, stepped into the arena, research groups on both sides of the Atlantic jumped in. The new salts didn’t just offer safer handling; the unique ability to dissolve both organics and inorganics rewrote old lab protocols.

Product Overview

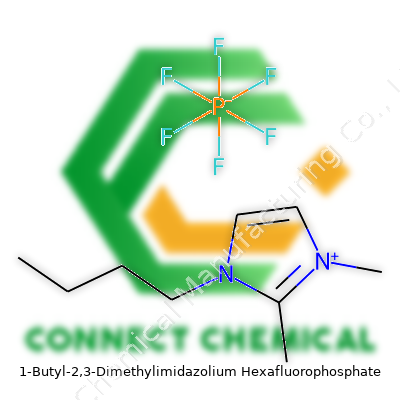

1-Butyl-2,3-Dimethylimidazolium Hexafluorophosphate falls in the family of room-temperature ionic liquids, with a strong reputation for stability and adaptable solubility. Physical scientists regard this salt for its predictably low volatility and high chemical resistance. The structure, consisting of a butyl group and two methyl groups around an imidazolium ring, paired with a hexafluorophosphate counterion, shapes its key features. This combination forms a viscous, often colorless to pale yellow liquid, which resists burning, can stand up to most acids and bases, and barely budges at elevated temperatures. Its unique architecture set it apart from early, more reactive ionic liquid formulations that ran into breakdown problems under basic lab conditions.

Physical & Chemical Properties

This ionic liquid looks almost like thick oil and refuses to evaporate under ambient conditions—no comparison to ether or acetone, which disappear in minutes. Its density hovers well above water, and most users notice the strong electrostatic "feel" when handling it with glassware. Butyl and methyl substitutions on the imidazolium ring modulate melting point, viscosity, and compatibility with solvents and solutes. The hexafluorophosphate anion brings robust thermal and chemical resistance but also raises the bar for proper containment—fluorinated residues never win points in waste management. Common specs include melting points below 25°C, thermal stability beyond 350°C, and negligible vapor pressure, all of which make this material comfortable for bench work, glovebox manipulation, and even pilot plant-scale operations.

Technical Specifications & Labeling

Producers provide detailed labeling for lab and industrial containers, often showing a purity exceeding 98%, traces of water below 0.5%, and specific certification for use in synthesis or electrochemical setups. Robust labeling becomes crucial because confusing one ionic liquid for another—often differing by a single methyl group—leads to entirely different solubilities and hazards. Each bottle carries a unique batch number for traceability, as required under global chemical manufacturing standards. Researchers expect this level of rigor; slight impurities or mislabeling can undermine an entire catalysis study or energy storage experiment.

Preparation Method

Manufacturing typically starts by reacting 1-butyl-2,3-dimethylimidazole with hexafluorophosphoric acid or its alkali-metal salts under strictly controlled, anhydrous conditions. These reagents demand deliberate, careful handling. Any hint of moisture can disrupt the yield and introduce unwanted hydrolysis products—no one wants to deal with hydrofluoric acid risks and lost product in a crowded lab. Most companies running production lines rely on closed systems flushed with inert gas, followed by repeated purification steps such as solvent extraction, drying under vacuum, and filtration. Technicians monitor product quality using NMR spectroscopy and ion chromatography. Unlike slapdash small-molecule syntheses, cutting corners at any stage will quickly show up as loss of stability or erratic physical properties.

Chemical Reactions & Modifications

This compound doesn’t just tolerate a broad range of conditions; it enables a suite of chemical transformations. 1-Butyl-2,3-dimethylimidazolium hexafluorophosphate serves as a non-coordinating solvent in transition metal catalysis, where it often increases yield or selectivity compared to classic media like acetonitrile or dichloromethane. Synthetic chemists have attached functional groups to the alkyl chains or swapped out the PF6 anion for alternatives like BF4 or NTf2, tuning solvent properties for custom needs. Some research groups have demonstrated electrochemical applications, exploiting the wide electrochemical window. Chemistry with this ionic liquid goes beyond swapping containers—its reactivity can shift entire research directions.

Synonyms & Product Names

Firms and catalogs rarely agree on a single name; you’ll see entries for [Bm2im][PF6], BM2IM-PF6, or even 1-butyl-2,3-dimethylimidazolium hexafluorophosphate, making CAS numbers essential checkpoints for sourcing or review. This variety creates confusion, especially in international research settings where US, European, and Asian suppliers list the same compound with subtle variations—one misplaced digit or letter quickly derails a project’s materials order. Long experience with purchasing tells me it pays to verify the full structural formula plus batch analysis every time.

Safety & Operational Standards

Safety protocols require gloves, eye protection, and fume hood use, since small but real risks come from both the imidazolium cation and the hexafluorophosphate anion. Inhalation or direct contact rarely happens under normal lab operations, thanks to the compound’s low vapor pressure, but chronic exposure concerns still call for engineering controls and careful waste management. International agencies such as REACH and OSHA guide the handling, labeling, and disposal procedures, but every workplace shapes rules based on their own risk audits. Over the years, more research has shifted toward ionic liquids with less persistent or toxic breakdown products, but labs still see regulatory site visits focusing on disposal routes for fluorinated waste. Experienced chemists organize secondary containment, air monitoring, and staff training—not as a bureaucratic headache, but as a way to keep workplace injuries and accidental releases off the incident log.

Application Area

Companies and universities draw on this salt for uses spanning energy storage, catalysis, electrochemistry, pharmaceutical formulation, and analytical separations. Electrochemical researchers prize its broad voltage window and non-flammability when pushing lithium or sodium batteries past the limits of safe traditional solvents. Organic synthesis groups appreciate the ability to run greener reactions without losing product yield. Environmental scientists look to ionic liquids like this for extracting metals or pollutants from water, hoping to cut down on organic solvent discharge downstream. The pharmaceutical sector explores these solvents for dissolving stubborn active ingredients, aiming for new ways to deliver drugs. Each application brings separate regulatory hurdles, but every successful project with this compound chips away at the old dependence on toxic organics.

Research & Development

Today’s R&D efforts fixate on stability, reactivity, and lifecycle impacts—no one can ignore environmental costs or regulatory limits anymore. Collaborative efforts between academia and industry have produced entire families of analogous ionic liquids by tweaking alkyl chains or swapping counterions, aimed at customizing performance for selective extraction, lubrication, or nanomaterials synthesis. Researchers check compatibility with metal catalysts or battery chemistries; others study its resistance to bacterial and fungal growth for use in sensitive manufacturing zones. Funding goes more readily to those who can prove both effectiveness and a route for closed-loop recycling or safe degradation—government agencies and competition between labs see to that.

Toxicity Research

Toxicologists and regulatory scientists continue to investigate decomposition products, especially concerns about the release of free fluoride or persistent imidazolium fragments into water or soil. Early work raised flags over hexafluorophosphate breakdown under strong acid, base, or heat, and some in the field push for tougher regulation or outright substitution with less hazardous anions. Those of us handling these materials always treat spills and waste as hazardous, ensuring thorough containment, labeling, and disposal via licensed facilities, not the local drain. Newer studies test aquatic toxicity, seeking levels where environmental discharge begins to cause problems, and set the bar for allowable use as governments re-examine industrial discharge licenses. Until consensus develops, most workplaces stick with “better safe than sorry” as a foundation for their chemical hygiene plans.

Future Prospects

Forward-looking researchers and entrepreneurs push to overcome the cost and lingering toxicity hurdles, steering toward greener ionic liquids with benign counterions. Successful substitutes for widely used organic solvents could transform pharmaceuticals, electronics, and advanced materials manufacturing. Progress will come from open collaboration between universities, industry, and policymakers, along with independent monitoring of environmental impacts. Ongoing investment in process safety, real-world toxicology studies, and end-of-life solutions will shape how these compounds carve a place in tomorrow’s labs and factories. The hope is to combine high utility with safety and responsibility as public awareness and regulatory oversight grow.

What’s This Chemical Doing In the Lab?

Beneath the tongue-twister of a name, 1-Butyl-2,3-Dimethylimidazolium Hexafluorophosphate stands out as an ionic liquid that gets real work done. Scientists often reach for it because it stays liquid at room temperature, dodges the volatility headaches that come with traditional solvents, and does not light up at the first sign of a spark. I’ve gone through more than a few research papers where its role was less about mystery and more about solving the practical challenges that crop up in modern chemistry.

Electrochemistry: Making Batteries and Supercapacitors Work Smarter

Walk into any research lab working on energy storage and the chances are good you’ll see bottles marked with this stuff. The appeal is simple: cells using lithium and other metal ions crave high stability, a broad voltage window, and minimal evaporation, especially during long tests or at odd temperatures. Traditional battery fluids often degrade, leading to lower life cycles and safety concerns. By offering a wide electrochemical window and resisting decomposition, this ionic liquid lets researchers push for better capacity and longer battery life cycles. The numbers from published data back up these claims—higher safety ratings and longer operation times show up again and again in studies using it.

Green Chemistry: Cleaner Solvents for Tough Jobs

Green chemistry keeps gathering steam, and many folks see ionic liquids like this one as part of the solution. Manufacturers and researchers don’t want solvent leaks, explosive hazards, or endless headaches from recycling and waste treatment. One common hurdle I’ve seen in organic synthesis is extracting or separating products after a reaction without losing half your batch or spending all day venting toxic fumes. This chemical comes in handy for those extra-stubborn separations, especially with polar molecules. Its low vapor pressure sharply cuts down workplace exposure and pollution. Instead of battling clouds of solvent or shelling out for intricate ventilation systems, you stay safe and still get high purity yields.

Catalysis: Helping Reactions Run Smoother

Mixing oil and vinegar doesn’t work, and many chemical reactions are just as fussy. The industry wants media that can dissolve both salts and organic molecules. Here again, this ionic liquid serves as a middle ground, pulling in molecules that would otherwise refuse to mingle. Real projects—such as transition metal-catalyzed transformations or certain pharmaceutical syntheses—see higher reaction rates, cleaner separations, and fewer pesky side products. Statistics from recent process chemistry research highlight efficiency jumps of more than 20% compared to standard solvents, supporting its practical edge.

Challenges and the Road Ahead

Nothing comes without trade-offs. Waste disposal remains tricky; the hexafluorophosphate part brings up environmental red flags if not treated with respect. Cost also drives decisions—commercial processes look for ways to recycle these liquids or design less expensive alternatives. The chemical industry sits on stacks of data about the toxicity and persistence of fluorinated chemicals, and it’s right to ask tough questions about what happens after use. Responsible laboratories work to capture and reuse the ionic liquid, cutting raw material use and avoiding the risk of accidental release.

From energy research to safer workspaces and cleaner processing, 1-Butyl-2,3-Dimethylimidazolium Hexafluorophosphate holds its own. Getting the most from it and sidestepping pitfalls means leaning into research about reuse and letting the facts drive decisions, not old habits.

Understanding What You’re Dealing With

Chemists and engineers chase performance, but handling new compounds can introduce risk nobody bargained for. 1-Butyl-2,3-dimethylimidazolium hexafluorophosphate stands out among ionic liquids as a solvent and electrolyte. Shielded by a name you’d never try pronouncing twice, this stuff makes waves in research labs for its impressive ability to dissolve stubborn materials. Yet, every convenience comes at its price, and, frankly, a hexafluorophosphate means the hazard conversation cannot get skipped.

The Hazards Hiding Behind a Long Name

Ask anyone who's spent time with chemicals: the ones packed with fluorine sit up there with the most stubbornly dangerous. This molecule packs a phosphorus atom with six fluorine buddies, creating a pretty nasty situation if something breaks apart. Hydrolysis or high heat can send clouds of hydrogen fluoride (HF) gas into the air. Even tiny puffs of HF leave burns that keep on burning, because HF keeps digging into you and can reach your bones if you let it.

That’s only part of the story. Many think, “ionic liquids–nonvolatile, safer, less flammable,” but this approach glosses over messy realities. The imidazolium ring, especially with butyl and methyl groups attached, doesn’t come with a safety card. Skin absorption and accidental splashes linger in the practical memory of many lab workers. These organic salts sneak through gloves faster than you’d expect, and once they touch skin, irritation lingers much longer than you hoped.

Research Findings and Real-World Experience

Turning toward research, trusted agencies like the European Chemicals Agency signal caution here. Data points to toxicity for aquatic life and lasting harm to water systems. Labs that vent waste into sinks create slow-moving chemical time bombs for their local ecology. Publications have reported moderate toxicity if inhaled or swallowed. Nobody calls it acutely toxic in the same league as cyanides, yet the chronic effects add up because of how persistent this chemical stays both in your body and in the environment.

Reading a safety data sheet for this compound tells more about worry than comfort. Serious eye and skin irritation get mentioned straight away. Inhalation risks may seem lower due to low volatility, but accidents involving spills or reaction byproducts can turn airspace dangerous quickly.

Staying Safe Means Changing Habits

Some take these warnings as a cue to double-glove and work with the fume hood at full blast. In practice, that’s not quite enough. Remember the stories about nitrile gloves failing after a short time—switching out gloves more often beats relying on labels. Spills rarely give much warning, so it pays to have calcium gluconate gel ready, since that’s the first aid for HF exposure.

Disposal gets overlooked a lot—this isn’t acetone down the drain. Strong containment, careful labeling, and hazardous waste pickup are non-negotiable. The lab next door might not want to share an air vent with you if HF ever gets loose.

Everyone working with modern ionic liquids needs honest conversations—not just the promise of “green chemistry.” The price of pushing innovation means respecting the invisible, long-term dangers some materials hide. Keeping the workspace safe comes through shared vigilance, plenty of trial and error, and zero shortcuts on personal protection.

Finding Answers and Setting Hard Limits

Nobody wants a new solvent turning into a new hazard. Campus EHS officers, supplier-provided SDS forms, and peer-reviewed studies should be stapled to your bench before the bottle even gets cracked open. If you run a research group or industrial team, treat this compound with the same care you’d give any known hazardous chemical—and don’t let budget or schedule “efficiency” erode those standards. Pushing for better training, running drills for spills, and investing in disposal resources all cut future regrets off at the knees.

So, yes, 1-butyl-2,3-dimethylimidazolium hexafluorophosphate delivers unique chemistry, but every drop needs respect. In lab and industry, only teams with a healthy dose of caution will keep both their people and the environment out of harm’s way.

Everyday Risks and Simple Solutions

Ask anyone who works in a lab, and a story about ruined experiments or safety scares pops up fast. Storing chemical compounds in careless ways causes more than inconvenience. Left out in the wrong temperature, moisture, or light, many chemicals lose their punch or even turn dangerous. Just last year, I watched an expensive reagent degrade on the shelf, all because the lid wasn’t tight and the air in the room ran just a bit too humid. A whole week of prep vanished with a little mold fuzz blooming at the top of the bottle.

Keeping things straightforward works best. Cool, dry, and dark. These three words covered almost every kitchen pantry and most lab benches, too. It takes a lot less energy to maintain, and the drop in waste always catches the eye of anyone with a budget. According to the CDC, humidity and heat drive decomposition and sometimes feed unwanted chemical reactions. If a staff member doesn’t pay attention to a bottle sweating in the sun on a windowsill, dangerous fumes or even a fire result if the substance is flammable or reactive.

Labeling seems basic, but too many places skip this step and pay for it later. More than one safety incident starts with a plain white container with faded marker ink. You can’t treat a bottle right if you don’t know what’s in it. Writing the date, concentration, and hazards in permanent ink saves more than time, it protects people. It also means there’s a quick way to check on expiration and match usage with the original safety data sheet.

Temperature’s Big Impact

Many organic solvents, acids, and salts hold up best in the cool range, around 2–8°C, which matches fridge and cold room storage. Others solidify once chilled, shrinking shelf life or making retrieval tough. Some metal compounds and pharmaceuticals barely notice cool air but get touchy above 25°C. Check the guidelines – they exist for a reason. The World Health Organization ran data on medicine shelf life and found up to a 10% drop in effectiveness for every 5°C rise above a recommended storage level.

One trick that always pays off: grouping chemicals by compatibility, not alphabet soup. Acids with oxidizers? Disaster waiting to happen. Most modern labs keep up-to-date digital inventories that flag unsafe mixes automatically. In home or classroom settings, a simple printed compatibility chart on the door makes a big difference. No one wants to learn the hard way what happens when ammonia and bleach share a shelf.

Moisture and Light: Silent Destroyers

Water vapor acts like a thief in the night for many powders and salts, especially those with hygroscopic tendencies. Even a cap off for a minute brings enough humidity to clump or change chemical properties. Storing desiccants in containers, preferably with tight-fitting lids or even in vacuum-sealed bags, keeps powders crisp and ready to use. Different from humidity, UV and visible light kick-start breakdown in medications, dyes, and even some metals. Amber glass bottles and opaque cabinets take just a bit longer to fetch supplies but save endless headaches later.

Building Better Habits

Everyone in the building benefits when storage isn’t an afterthought. Smart rotation—oldest compounds up front, new stock in the back—reduces waste. Routine checks, monthly reviews, and documented audits do more than tick boxes for safety inspectors. They create a culture where compounds don’t get left to chance. Experienced lab techs share tricks with green interns, and the entire team works faster, safer, and with more pride in their results.

At the end of the day, safe storage builds trust: in the result, in each other, and in the science or products being built. No one likes surprise explosions, tainted data, or wasted dollars. Get back to basics, label what matters, check the rules, and chemicals do what they’re meant to do.

Navigating How This Ionic Liquid Behaves in Solvents

1-Butyl-2,3-dimethylimidazolium hexafluorophosphate, sometimes abbreviated as [BMMIM][PF6], showed up on my radar during a project where finding a truly hydrophobic ionic liquid made all the difference between a functional separation and a budget-busting rerun. It’s a mouthful to say, but its place in green chemistry and extraction is clear. One reason? Its relationship with water tells you exactly where it stands among the newer crop of organic solvent alternatives.

In practical terms, this ionic liquid refuses to dissolve much in water. Peer-reviewed literature points toward a solubility around 10-100 mg per liter at room temperature—so vanishingly small that it’s effectively immiscible. I remember loading a vial with both water and [BMMIM][PF6], giving it a solid shake, then watching the two layers settle back apart. No cloudiness, no mixing. You see a crisp line: water above, ionic liquid below. That clear boundary isn’t just academic; researchers need immiscibility for things like solvent extraction and waste minimization in industrial processes.

This lack of water compatibility can be traced back to the molecular structure. The hexafluorophosphate anion brings a level of hydrophobicity, and the butyl plus dimethyl groups crowd around the imidazolium core, making it even less willing to interact with polar molecules like water. Some ionic liquids make compromises between water compatibility and organic solubility. [BMMIM][PF6] doesn’t budge.

Organic Solvents in the Mix

Now, drop the same compound into organic solvents, and the scene changes quickly. In my own lab runs, I watched this ionic liquid blend effortlessly with dichloromethane and acetone. It slides right in with acetonitrile, and even gives good results with ethyl acetate if you run an ultrasonic bath or put in gentle heating. Polar aprotic solvents get along the best; polar protic solvents like ethanol do the job, but with less enthusiasm—think sluggish but not stubborn. Compare this to any simple salt, and the versatility stands out.

Solubility in these solvents opens doors for advanced reaction systems. You see chemists shifting away from volatile organics for the sake of worker safety or environmental demand, and ionic liquids offer a middle path: solvent extraction, phase transfer catalysis, and even electrochemical applications. For [BMMIM][PF6], ease of use in organics means you can dissolve transition metal catalysts or design biphasic systems where waste streams stay tight and manageable.

Why Practical Solubility Matters

Solubility isn’t just about what disappears. It’s about designing actual processes, balancing worker safety, and hitting sustainability marks. Water immiscibility means handling spills or waste requires more than just a rinse—special collection steps keep everything in check. On the flip side, full miscibility with polar aprotic organics makes it possible to swap out more hazardous reagents in catalysis or to recover valuable solutes without leaving behind persistent pollutants.

Curiosity drove much of my own work. Knowing the fine points of a liquid’s solubility means anticipating lab pitfalls—like phase separation glitches, or incomplete extractions. Chemists find room for innovation in these details: using ionic liquids for tough separations in pharmaceuticals, or running greener extractions of rare earth metals. The key comes down to straightforward properties like solubility, paired with the right safety and recovery strategies. And industry or academia, you never forget to value a liquid that tells you clearly where it belongs: away from water, right at home in the organics.

Real World Hazards Lurk in Small Labels

Most folks, including me, have grabbed a new spray, cleaner, or gadget off the shelf with hardly a glance at the label. It seems like overkill, all those caution signs. But after seeing my uncle end up in urgent care with a chemical burn from a grill cleaner, I realized that the warnings aren’t there just to tick boxes. They’re direct results of plenty of people getting hurt in everyday situations.

Your average cleaning spray, for instance, often contains bleach or ammonia. Alone, they deal with stains and grime, but mixed together, they create toxic gas that sends hundreds to the ER every year. Even simple air fresheners can aggravate respiratory conditions or trigger allergic reactions. I’ve talked to a mother whose child broke out in hives after a heavily perfumed plug-in filled the living room.

No Step Skipped: Why Small Steps Matter

Companies don’t test for fun. Product safety instructions are there because missing just one—wearing gloves, opening a window, not eating or drinking nearby—has led to real harm. Swiveling fans look harmless until hair or jewelry gets tangled. Personal heaters that seem reliable have caused house fires when left operating near curtains. Even mounting a heavy TV with the wrong anchors can send it toppling onto a child or pet. Safe use boils down to paying attention to the details on that tiny leaflet inside the package, and seeing those warnings as hard-won wisdom, not paranoia.

Clear Steps Everyone Can Take

Start by reading the guide that comes with anything unfamiliar, not just the shiny features on the box. Store chemicals away from kids and pets, especially in high or locked cabinets. Wear the gloves and goggles. If the item recommends ventilation, work in a room with windows wide open. For electronics, double-check cords for fraying, keep water far away, and unplug before cleaning. These steps slow you down, but they address the main causes of home accidents.

Outside, tools deserve respect. I’ve met so many who thought a lawn mower guard was optional until a stray rock shot out and shattered glass or injured a bystander. Gasoline-powered gear carries risks of explosion if stored next to pilot lights or inside a closed garage. know where the nearest fire extinguisher sits. Never assume that since you "got away with it last year," the same shortcut will work again.

Learning From Real Incidents—And Sharing the Wisdom

Mistakes happen, but every accident teaches something. Community programs that demonstrate correct product use cut accident rates because people trust stories from neighbors more than faceless warning labels. Online forums and social media put recall alerts front and center—sign up and stay informed.

Companies should speak plainly: use big, bold warnings, easy pictures, and straightforward language. Too often a label drowns people in fine print, and the real point gets lost. Home safety isn’t just about avoiding lawsuits or ticking regulation boxes; it’s about families not having to rush to the ER or start over after a fire.

From my own family’s mishaps and neighbors’ close calls, I know ignoring safety advice writes a blank check for disaster. Glancing through instructions and taking simple steps protects your health, your home, and everybody under your roof.