Insightful Commentary on 1-Butyl-2,3-Dimethylimidazolium Iodide

Historical Development

The journey of 1-Butyl-2,3-dimethylimidazolium iodide reflects the progress in ionic liquid chemistry that gained real attention in the late 20th century. When researchers started exploring new solvents that defied traditional chemical limitations, they looked at imidazolium-based ionic liquids for answers. Scientists needed safer, less volatile alternatives to regular solvents used in industrial and laboratory processes. Through years of trial and refinement, chemists developed variations with different functional side groups, one of which resulted in this specific compound. The combination of butyl and two methyl groups on the imidazolium ring, paired with an iodide anion, aimed to push stability and solubility into new territory. As demand grew for better electrolytes, more effective catalysts, and environmentally friendlier solvents, this compound found its place in research and industry discussions.

Product Overview

Anyone handling or using 1-Butyl-2,3-dimethylimidazolium iodide gets a product described as a room-temperature ionic liquid or, at times, a low-melting solid. This compound draws interest from synthetic labs and commercial producers keen on ionic liquids. Its robust chemical framework, with the butyl and methyl groups on the imidazolium ring, allows it to offer both stability and relatively low toxicity—qualities scientists and engineers value in processes where regular organic solvents fall short.

Physical & Chemical Properties

Examining the properties of 1-Butyl-2,3-dimethylimidazolium iodide, its pale yellow to colorless appearance feels familiar if you’ve worked with other ionic liquids. Unlike volatile organic solvents, this compound doesn’t evaporate easily or ignite under typical circumstances. The presence of iodide brings high ionic conductivity, letting this material work in electrochemical applications better than many alternatives. Solubility in water and polar organic solvents expands its utility. Density hovers near 1.15–1.20 g/cm³, and its viscosity changes with temperature, making it useful in processes where temperature regulation is crucial. It doesn’t degrade quickly under light or ambient conditions, helping storage and handling.

Technical Specifications & Labeling

Suppliers and researchers expect clear, straightforward technical details—purity above 98%, low moisture content, and precise molecular weight (often listed as 322.21 g/mol for this compound). Labels must communicate handling precautions, expiration dates, and lot numbers. Containers remain tightly sealed in cool, dry storage, usually in amber glass to limit light exposure. Regulations force clear hazard and safety labeling, based on studies of imidazolium iodides and similar compounds.

Preparation Method

Synthesis typically involves alkylation of 2,3-dimethylimidazole with 1-butyl halide, followed by metathesis using sodium iodide or a similar iodide source. The process uses controlled conditions to prevent formation of unwanted byproducts. Purification employs repeated recrystallization and washing with organic solvents. Anyone experienced with bench-scale organic chemistry will recognize the importance of maintaining dryness and exclusion of oxygen for best results. Scale-up demands stable temperature control, adequate ventilation, and reliable separation equipment—for both product quality and worker safety.

Chemical Reactions & Modifications

1-Butyl-2,3-dimethylimidazolium iodide can serve as a base material for making other ionic liquids via anion exchange. Chemists interested in specialized solvents, electrolytes, or catalyst supports often start with this compound and swap its iodide for tetrafluoroborate, hexafluorophosphate, or other functional groups using established ion-exchange techniques. Its imidazolium backbone supports further derivatization, letting labs fine-tune chemical, thermal, and electrochemical behavior. These modifications expand the compound’s reach into new technologies and allow tailoring to specific project requirements.

Synonyms & Product Names

The chemical community uses several names for this compound. Common ones include [Bm2Im]I, 1-butyl-2,3-dimethylimidazolium iodide, or, less frequently, BMIM iodide. Some catalogs use systematic IUPAC names, but most customers and suppliers recognize its shorthand model, with clear abbreviations based on established ionic liquid naming conventions.

Safety & Operational Standards

Direct handling always needs respect for safety standards, drawn from both personal lab experiences and published reports. Standard gloves, eye protection, and lab coats are the baseline. Ventilation prevents inhalation or exposure to vapors, even if volatility is low. Material safety data sheets highlight that, though less hazardous than many organics, accidental ingestion or long-term exposure can cause irritation or health issues. Disposal means following local regulations—flushing down the drain doesn’t cut it. Experience teaches that spills should be cleaned using absorbent materials, not just paper, because residues can react with acids or bases present in labs or process environments.

Application Area

1-Butyl-2,3-dimethylimidazolium iodide supports efforts in green chemistry, battery technology, organic synthesis, and even some biomedical fields. Its ionic nature and high conductivity mean it gets picked for non-aqueous electrolyte systems in advanced batteries and supercapacitors. In organic synthesis, it replaces volatile, toxic organic solvents in catalytic reactions or separation procedures. Personal experience in academic settings shows demand for such ionic liquids when students want environmentally responsible lab work that doesn’t compromise results. Industrial users leverage its low flammability for safer production lines, especially where solvent loss creates both workplace risks and regulatory headaches.

Research & Development

Scientists continue to push the boundaries of what ionic liquids like this can do. Current research covers use in electrochemical sensors, drug delivery, extraction processes, and renewable energy systems. Labs investigate performance at higher temperatures, under strong fields, or in multistep organic syntheses. The academic literature documents ongoing tweaks to the side-chain groups to increase solubility or disease resistance in biomedical applications. Collaboration between chemists, materials scientists, and engineers speeds up progress, making sure promising advances reach real-world pilot projects and, eventually, market-ready solutions.

Toxicity Research

No research program would be complete without a sharp eye on toxicity. Early studies suggested low acute toxicity compared to classic organic solvents, but chronic or repeated exposure tells a more complicated story. Testing with aquatic organisms and cell cultures shows that even ionic liquids can build up or cause harm over time. Policy and safety circles debate permissible exposure levels and environmental limits, informed by both animal and microbial toxicity results. Working in the lab, I learned that proper disposal and containment, not just PPE, play a critical role both for worker safety and deeper public health.

Future Prospects

Looking forward, the role of 1-Butyl-2,3-dimethylimidazolium iodide in green technology and advanced chemistry is bound to expand. As more industries update their safety standards and sustainability goals, the call for versatile ionic liquids rises. Continued improvement in synthesis, purification, and waste management—paired with smarter design—could make this compound a staple across fields, from electronics to pharmaceuticals. If ongoing research keeps bridging gaps between laboratory discovery and scalable, real-world use, the next generation of ionic liquids just might lead the way to safer and more efficient products throughout the chemical industry.

Stepping Into the Lab: The Basics

Few things connect theory to the real world like building a molecule on paper, tracing each atom until the formula feels as familiar as a street map from your hometown. In the case of 1-butyl-2,3-dimethylimidazolium iodide, these chemical puzzles help researchers open new doors in green chemistry, battery technology, and drug delivery — but the process starts with understanding what’s in the name.

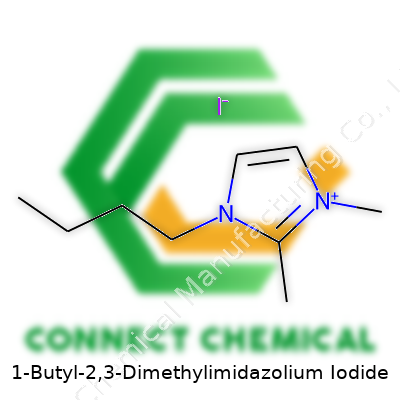

The Core Structure

1-butyl-2,3-dimethylimidazolium tells you this is an imidazolium-based ionic compound. Imidazolium forms the backbone — a five-membered ring with two nitrogen atoms at positions 1 and 3. Attach a butyl chain to nitrogen at position 1, and methyl groups at the 2 and 3 spots, and you’ve constructed the cation. Add iodide as the counterion and the pairing is set.

Breaking that down atom by atom, the core imidazole ring (C3N2H4) transforms:

- Methyl adds CH3 units to both carbon 2 and nitrogen 3—boosting the total

- Butyl (C4H9) chains up on the nitrogen at position 1

Don’t just think of these as names in a book. I spent hours in undergrad organic labs, fingers blackened, getting structures right with ball-and-stick models. Making each swap, picturing the electronic push and pull, was the only way to see why these small shifts matter out in the world—in how the molecule behaves, dissolves, or pairs up in a solution.

The Final Formula

You total up every atom: C for carbon, H for hydrogen, N for nitrogen, and I for iodide. The full sum lands at:

C9H17N2I

That’s chemistry, hands-on. Every letter and number traces back to a specific part—three ring carbons, two nitrogens, two methyls, a four-carbon butyl chain, enough hydrogens to fill out the bonds, and a lone iodide anion waiting to balance charge.

Why This Matters in Research

Researchers using this compound in the lab aren’t working with obscure doodles. Ionic liquids like this one actually show up in real industrial processes and alternative energy work. They cut down on toxic solvents. They help chemists separate compounds cleanly, recover valuable metals, or shuttle ions in solar cells and rechargeable batteries.

A solid chemical formula gives scientists a shared language. A journal article posting data on C9H17N2I lets a lab anywhere in the world match techniques or troubleshoot with confidence. Knowing your starting composition means fewer bottlenecks and less waste.

From Paper to Purpose

I’ve learned that these details — not just the formula, but the logic behind it — drive the field forward. Teaching or building curriculum, transparency about chemical structure connects work at the bench with safer industrial use and sharper environmental awareness. One real solution is open sharing of structural logic and reliable data, supporting not just labs, but whole service and manufacturing chains relying on cleaner processes.

Chasing down the right formula isn’t just busywork. It’s the doorway to innovation, letting us design better compounds, lower safety risks, and speed up discovery on problems that matter far beyond the classroom or the lab.

What Makes This Compound Unique?

1-Butyl-2,3-Dimethylimidazolium Iodide doesn’t sound like something you’d bump into at the supermarket, but it earns its spot in advanced labs and high-tech industries. The structure—featuring an imidazolium ring tweaked with butyl and methyl groups, paired with iodide—turns it into more than just a mouthful. It’s what chemists call an ionic liquid, and that brings all kinds of benefits: low volatility, pretty high thermal stability, and a knack for dissolving stubborn compounds.

Solar Cell Innovation

Some of the biggest changes in renewable energy tech happen on the nanoscale. Take dye-sensitized solar cells (DSSCs), for example. These may look unassuming, but their performance often hangs on the fine details of their electrolytes. Researchers turn to ionic liquids such as 1-Butyl-2,3-Dimethylimidazolium Iodide for a reason: its iodide helps shuttle electric charge between electrodes, which improves efficiency, and the whole mix often resists evaporation over time.

A lot of the reliability in these cells can vanish if the electrolyte starts leaking or breaking down, and that can happen fast with basic organic solvents. I’ve seen data showing how switching to ionic liquids—especially ones like this—doubles or even triples device lifespans. If we want solar to go mainstream in places with crazy temperature swings, breakthroughs like these help bridge the gap.

Electrochemical Devices and Energy Storage

Talk to anyone who works with batteries or supercapacitors, and they’ll tell you that the hunt for better electrolytes never ends. Standard choices often mean trade-offs: high flammability or quick degradation. Ionic liquids offer a way out. The composition of 1-Butyl-2,3-Dimethylimidazolium Iodide lets it support fast-moving ions without turning into a safety hazard, something that matters in electric vehicles and large-scale grid storage.

In the lab, I’ve seen this compound mixed with other salts and adjusted for improved conductivity, which means charging and discharging batteries at faster rates. The lower vapor pressure also keeps accidents at bay. For anyone who's seen battery recalls due to leaks and fires, the draw of ionic liquids like this becomes obvious.

Organic Synthesis and Green Chemistry

Chemical manufacturing still faces pressure to clean up its act. Many labs still rely on volatile organic solvents, adding cost and risk. Ionic liquids like 1-Butyl-2,3-Dimethylimidazolium Iodide step up as alternatives. Their stability under heat offers room for new reactions, cutting down on toxic byproduct formation.

Green chemistry in practice doesn’t always feel like a revolution, but small tweaks—like swapping a hazardous solvent for an ionic liquid—add up over time. I’ve seen case studies where substituting these compounds slashed hazardous waste generation and protected workers’ health. That’s progress you can track not just on paper, but in the air quality and waste barrels in any facility.

Room for Improvements and Next Steps

No single solution fits every challenge. Cost and sourcing of ionic liquids can hold back broader adoption. More recycling and manufacturing research could drive prices lower, which would open up more applications. Collaboration between universities, startups, and regulatory agencies can push safer chemicals from small-scale to industrial use. Safer, more robust materials will mean better batteries, cleaner factories, and solar panels that keep going strong.

Room Temperature Isn’t Always Reliable

People often assume every compound’s fine at room temperature. In practice, a “room” fluctuates. In the summer, my home office will drift up to 28°C, just from sunlight. Small changes like that can speed up decomposition or kick off a chemical reaction nobody wants. Pharmaceutical data shows some drugs degrade ten times faster at 30°C than at 20°C, even if they look the same.

The Enemy: Moisture and Oxygen

Some powders or liquids hate humidity. Over the years, I’ve opened bottles labeled “keep dry” and found hard cakes or faint smells that weren’t there before. Water in the air finds its way in, and some chemicals clutch to it, changing their structure. That often ruins purity. Oxygen can be worse. It reacts with metal salts, vitamins, and plenty of lab staples, sometimes with just a brief whiff. I’ve thrown out more than one bottle of ferric chloride that turned to rusty sludge long before its shelf life ran out.

Science Gives Clear WarningsStudies out of the CDC and organizations like the International Pharmaceutical Regulators Forum repeat the same advice: Desiccators and tightly sealed vials cut down those risks. One study tracked antibiotics kept in humid conditions; less than half the expected dose remained after six months. Mistakes like that cost money and trust.

Light Brings Its Own Problem

Some compounds react to light far faster than they react to air. For example, vitamin B2—riboflavin—breaks down in sunlight and even fluorescent light. Growing up, my dad always wrapped some of his laboratory’s samples in foil. I used to see that as overkill. Instead, he was following guidance out of pharmacology texts: brown glass and cool, dark shelves stretch shelf life, simple as that. I later learned researchers at the University of Tokyo found that antibiotics exposed to hospital lights for just a week lost measurable potency.

These stories sound fussy, but if you depend on a chemical—maybe it goes into patient care, agriculture, or manufacturing—every bit of careful storage saves money, effort, and reputation.

Good Storage Starts on Paper

Best practice: figure out what the compound hates most. If a manufacturer says “store at 2-8°C”—that’s not a suggestion for fun. Fridges at hospitals, food labs, and research facilities aren’t for employee lunches but for sensitive stock. I’ve worked in places where freezer inventory lists grew longer than the active experiment lists. It took time to set up cold monitoring, since a single freezer shutdown could cost tens of thousands.

Labels matter just as much. I keep a habit now of writing the open date on every new container. If a bottle sits for months, I know exactly when it hit room air. If light’s a threat, it gets covered. If humidity matters, it goes in with silica gel or another desiccant. My strategy is simple: whatever the label says, do a bit more. If it says dry, I double-seal. If it says cool, aim for the low end for safety.

Room For Simple Solutions

Manufacturers and suppliers have a role, too. The least confusing labels boost compliance. Clear graphics, instructions in common languages, even QR codes for more data have made things easier. Schools and smaller businesses still lose money and materials from minor mistakes like leaving a bottle by a window or failing to check a fridge. Asking local experts or reading up can save a lot of headaches.

The best labs aren’t just the best equipped—they treat their supplies like investment. A little time spent getting storage right pays off, every single time.

Understanding What’s in the Bottle

1-Butyl-2,3-Dimethylimidazolium Iodide carries a name long enough to trip over, but under the jargon sits an ionic liquid. That has made it popular for battery research, solar cells, and other high-tech uses. People outside labs won’t bump into it much, but the folks who do need to know what they’re holding. The cheery assumption that an ionic liquid always stays friendly isn’t right. Rules and habits borrowed from working with standard lab salts don’t always fit with ionic liquids.

Why the Details Matter

My experience with chemical stocks taught me that even if you’re not splashing hydrofluoric acid, you can find surprises in the bottle. Take 1-Butyl-2,3-Dimethylimidazolium Iodide—researchers use it for its low volatility and high ionic conductivity, but being easy to handle on paper doesn’t mean you can ignore risks.

The Material Safety Data Sheet (MSDS) for this compound doesn’t list it as acutely toxic, but the document doubles down on basic precautions. The substance can irritate the skin and eyes. Accidentally getting it on your hands or breathing dust in a poorly ventilated space can be more than a minor nuisance. In a shop that respects safety, you’d see this stuff stored with regular labels, in sealed containers, away from sunlight and moisture. I’ve seen senior chemists get a rash after wiping down benches where an imidazolium salt spill wasn’t properly cleaned up.

Rethinking “Safe Enough”

Chemical handling has a pecking order, but complacency creates new hazards. Sometimes people get lured in by unfamiliar names and slip into casual routines. One year, I saw a pile-up of gloves in the lab sink. Most were still dusted with unknown powders. In a group email, the safety officer reminded everyone that strong hygiene cuts real exposure, even for so-called “mild” salts.

1-Butyl-2,3-Dimethylimidazolium Iodide sits in a space between nastier halide salts and the “innocent” table salt. No one should ignore basic protections—nitrile gloves, goggles, lab coat. Rushing cleanup leads to residue smears, which come back as hand eczema or eye irritation days later.

What Scientists and Workers Can Do

Putting care into material training pays off. New lab workers need to know more than just the “do not eat” rule. Trainers should walk everyone through the proper setup: designate a well-ventilated bench, keep a spill kit nearby, and never pour unused sample back into the stock to avoid cross-contamination.

Waste handling can’t get sloppy either. Many ionic liquids take a long time to break down in the environment, and the iodine component in this compound adds another environmental consideration. Local regulations nearly always require sealed waste containers and accurate labeling. During my time in battery research, I knew one team that tracked every gram used and every gram disposed. It was overkill to some, but it saved them from trouble during audits.

Focusing on Proven Steps

1-Butyl-2,3-Dimethylimidazolium Iodide doesn’t bring drama to the lab, but familiarity breeds carelessness. The best move is to handle it like any other specialty chemical: treat it with respect, use solid protective gear, and don’t wing it with cleanup or disposal. Rely on routine, not just luck. Mistakes might not lead to crisis, yet steady good habits build trust and keep work safe, especially where students or new researchers learn by example. Proven, not performative, safety works every time.

The Real Factor: Purity for Results

Purity means everything for those using 1-Butyl-2,3-Dimethylimidazolium Iodide in any lab or manufacturing process. Purity affects reaction yields, consistency, and even safety. In my own work in research labs, the difference between “reagent-grade” and a batch barely above technical grade has stopped good ideas dead. Labs and companies demand a compound that contains as few impurities as possible—ideally above 98%. For high-impact work, folks seek levels greater than 99%, usually confirmed by chromatographic analysis or NMR. If a supplier advertises 99.0% purity on a certificate of analysis, with water and halides tightly controlled, anyone using this specialty salt can feel a lot more confident about what will come out at the end.

Pitfalls of Poor Specification

Even a slight drop in purity causes headaches. Research articles often report that unlisted contaminants change the results or make reproducibility impossible. In my graduate years, I watched projects derail from low-specification reagents—especially with ionic liquids that soak up moisture or trap unreacted starting material. For this compound, iodide contamination means more than failed tests. Traces of other imidazolium ions, solvents, or even halides can skew cost calculations, poison catalysts, or alter conductivity in an electrochemical cell. Just one supplier failing to list actual contaminant levels pushes careful scientists and engineers to keep searching elsewhere.

Demanding More: Transparency and Documentation

Smart buyers ask for certificates of analysis listing the main compound’s assay, the moisture content (Karl Fischer is a favorite for water), halide content, and, if possible, trace metal analysis. Companies following strict quality assurance methods like ISO 9001 will often be far more willing to share their testing regime. That matters most in regulated industries—think pharmaceuticals or battery R&D—where knowing every impurity can change the outcome for safety, compliance, or patent claims. I’ve seen regulatory reviews grind to a halt when purity or documentation was “marketing speak” instead of cold, hard analytical data.

What Actually Works

To find a supplier worth trusting, I always look for full disclosure. A certificate stating “>99%” using HPLC, NMR, or mass spectrometry, plus detailed breakdowns on water and volatile organics, beats an empty phrase like “high purity.” In practice, the best sources share production batch records, sometimes even forward analytical test results for current batches. Talking to the manufacturer can help. A real technical expert will explain methods used and back up claims, while vague statements are a red flag. This holds true for any specialty chemical supplier—especially one offering compounds as niche as 1-Butyl-2,3-Dimethylimidazolium Iodide.

The Drive for Better Standards

Within the broader chemical industry, higher expectations around purity create demand for third-party inspection. Some suppliers get certificates from independent labs or use globally recognized purity standards (like ACS or pharmaceutical grades). As a researcher, I appreciate those extra steps and always check for actual numbers, not just words on a website.

Action Steps for End Users

Anyone sourcing this compound should keep three things in mind: insist on a complete certificate of analysis, look for actual impurity breakdowns, and check how the material is stored and shipped. Drying, airtight packaging, and traceability make a big difference. Speaking from experience, investing time upfront in quality verification saves a lot of trouble down the line—and helps ensure results are both reliable and respected.