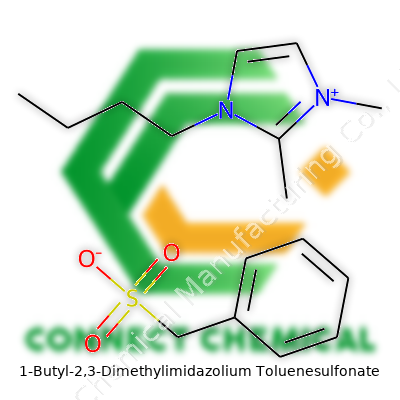

1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate: A Comprehensive Commentary

Historical Development

Interest in ionic liquids caught fire in the late 20th century, with scientists searching for solvents that ditch flammable, volatile properties and stick to stability and low vapor pressure. 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate stands as a testament to this push for safer, more versatile alternatives. The rise of imidazolium-based ionic liquids sparked attention for their broad tuning potential. Toluenesulfonate salts, on the other hand, offered enhanced solubility and chemical resilience. Bringing these features together unlocks a range of applications from green chemistry to electrical engineering. Early research circled around finding anions and cations that do more than sit idle—scientists blended organic and inorganic features, setting the groundwork for materials that resist breakdown and handle tough environments.

Product Overview

1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate forms a colorless to slightly pale liquid at room temperature, featuring a low tendency to evaporate. It dodges the problems of traditional organic solvents, giving labs and industries an edge in controlling emissions. The imidazolium backbone brings thermal and chemical steadiness, while the bulky toluenesulfonate anion prevents cation packing, keeping the compound liquid over a wide temperature range. Producers highlight its use for extractions, catalysis, and pharmaceutical manufacturing. Its stability and solubility profile cut down the guesswork common with older chemical solvents.

Physical & Chemical Properties

Physical attributes define how a chemical fits into your process. 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate has a melting point below room temperature and barely budges until heated well over 200°C, showing serious thermal tolerance. Its density sits higher than water, and its negligible vapor pressure lets you work without the whiff of lost product. The ionic character guarantees strong solvation abilities for polar compounds and a knack for dissolving metal salts. Chemical inertness towards regular acids and bases lets it coexist with plenty of other reactants. The substance refuses to ignite without extreme conditions, giving it a safety edge in busy environments. Viscosity levels can seem high at first glance, a common tradeoff in ionic liquids, but thoughtful temperature control often softens this challenge.

Technical Specifications & Labeling

Regulatory compliance issues grab attention right out of the gate. Detailed labeling matches international regulations such as REACH and OSHA—product names, hazard symbols, lot numbers, and purity percentages land on every delivered bottle. Manufacturers specify water content, residual base materials, and impurities to the parts-per-million. Labels cover recommended storage, showing a preference for cool, dry spots away from oxidizers. Packaging options run from glass bottles to PTFE-lined drums, reflecting sensitivity to leaching and contamination. Documentation keeps buyers aware of shelf life and reactivity issues. Technical data sheets give pH, viscosity, density, and conductivity at varying temperatures. Anyone using these compounds gets a clear window into what they’re working with.

Preparation Method

Creating 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate takes careful planning. The standard path starts with 1-butyl-2,3-dimethylimidazole, which reacts with methyl toluenesulfonate through a metathesis strategy. Dissolved in a suitable solvent, the reaction mixture sees the anion exchange from, typically, a halide to toluenesulfonate—giving the desired product with minimal byproducts. Purification kicks in through repeated washing with non-miscible solvents and drying over molecular sieves, ensuring no moisture or unreacted starting material sticks around. Modern methods run these reactions with a mind on sustainability, reducing waste streams and recycling solvents where feasible. The right process delivers a clear, pure ionic liquid ready for technical and research uses.

Chemical Reactions & Modifications

Applications often demand more than the base compound, so chemical tweaking comes into play. The imidazolium cation readily tolerates methyl and butyl substitutions, boosting hydrophobicity and tuning solubility for specialty tasks. The sulfonate group’s electron-withdrawing nature resists nucleophilic attacks, keeping the ionic pairing steady. Chemists use this stability to support transition metal complexes in catalysis and to act as a template for advanced materials synthesis. It handles functional group modifications, immobilizing catalysts or accommodating biologically active molecules. In electrochemical applications, substitutions on the imidazole ring can nudge conductivity or widen the liquid’s electrochemical window, all without giving up the fundamental liquid property.

Synonyms & Product Names

This compound often goes by multiple labels, which sometimes hinders clear communication. Suppliers list it as 1-Butyl-2,3-Dimethylimidazolium p-Toluenesulfonate, [BMMIm][OTs], or simply BMMIM OTs. In chemical catalogs, it may show up under CAS Registry Number 799283-63-1. Each name focuses on a slightly different structural feature—the cation’s substituents or the sulfonate anion—making it important to double-check documentation before ordering or running regulatory checks.

Safety & Operational Standards

Safety rules remain strict around any chemical, especially with relatively new ionic liquids. Although non-volatile, 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate does not escape the need for gloves, goggles, and fume hoods. Long-term exposure studies are still a growing field; so far, toxicity trends lean lower than many analogs, but it pays to work cautiously, assume the need for cleanup protocols, and keep monitoring for skin or respiratory irritation. Ventilation and spill kits stand ready in any well-run lab. Training covers safe disposal, which means not pouring into regular drains. Material Safety Data Sheets (MSDS) offer guidance on firefighting measures, accidental release, and health effects. Facilities dealing with this chemical often take cues from green chemistry, reusing or recycling product when possible, cutting down on environmental loading.

Application Area

Widespread uses reveal the versatility of 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate. In synthesis labs, it tackles specialty extractions, catalyzing organic transformations, and serving as a medium for polymerizations that do not tolerate volatile solvents. Its solvation power for rare earth and transition metals makes it a choice material in recycling electronics and designing new batteries. Pharmaceutical researchers turn to it for difficult separation challenges, benefiting from its thermal stability and lack of contamination risk. Electrochemists value its wide voltage window and solid ionic conductivity when assembling prototype supercapacitors and new-style fuel cells. In biomass processing, its ionic nature breaks down lignocellulosic material, cutting through what normal solvents cannot touch. These practical results drive ongoing investment in production technology and regulatory assessment.

Research & Development

University and industry labs both chase answers about how to squeeze the most from this ionic liquid. Current lines of research probe new catalysts, seeking how modified versions speed up hydrogenations, oxidations, or C–C coupling without deactivation. Studies track how alterations in the imidazolium core influence viscosity, ionic mobility, and compatibility with polymers or proteins. Some work focuses on immobilizing enzymes in the liquid, hoping for greener reaction conditions or better selectivity than traditional solvents. Research papers report on separating precious metals, treating spent catalysts, and removing persistent pollutants using the unique solubilizing power of the compound. Industry partners monitor how scaling up impacts purity, batch consistency, and cost structure. The biggest lesson? Forward progress means talking honestly about impurities, operational hazards, and recycling strategies—not just research breakthroughs.

Toxicity Research

Safety data for 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate continues to evolve. Early animal and cell studies report relatively low acute toxicity, but experts urge caution about chronic impacts and breakdown products. The imidazolium ring sometimes raises eyebrows for its biological persistence, underlining the importance of responsible procedures from day one. Fish and plant toxicity studies suggest low bioaccumulation compared to more hydrophobic analogs, though aquatic impact assessments demand more complete life-cycle data. Scientists recommend closed-loop handling, robust personal protective equipment, and air monitoring in larger facilities. Discussions about waste treatment keep pushing for incineration at high temperatures, not landfill or water disposal. These steps reflect a recognition that even promising materials need a watchful eye.

Future Prospects

Industrial shifts toward greener, more sustainable chemicals put 1-Butyl-2,3-Dimethylimidazolium Toluenesulfonate in a bright spot. Production processes grow more efficient, aiming to trim cost and environmental impact at the same time. Next-generation battery and electronic applications look to these ionic liquids for higher safety and better temperature performance compared to legacy materials. Work in pharmaceuticals targets its unique dissolving power to streamline extractions or purifications currently burdened by flammable solvents. Regulatory and safety advances soon may open broader global markets, provided that environmental standards and end-of-life recycling keep pace. As the chemical landscape adapts, ongoing feedback from users, process engineers, and regulators shapes which innovations stick and which modifications fall by the wayside.

What This Compound Brings to the Table

People in labs and on factory floors know that solvents do more than just hold other chemicals. 1-Butyl-2,3-dimethylimidazolium toluenesulfonate stands out as one of the so-called “ionic liquids.” It stays liquid at room temperature and doesn’t evaporate the way water or alcohol does. This means you barely lose any of it to the air, helping keep both costs and air pollution in check.

I’ve watched this compound get a lot of attention in chemical processing. Teams will use it as a replacement for toxic organic solvents in reactions that make pharmaceuticals, plastics, and specialty chemicals. There’s a real need out there for greener, safer processes, mostly because older solvents put so much strain on both people and the environment. By ditching those, workplaces often get safer not just for lab techs but also for anyone living nearby.

Making Chemical Separations Easier

Some jobs depend on pulling apart complicated mixtures, like separating out fine chemicals, metals, or oils from waste streams. Many places stick with water or harsh organics for this, but they run into trouble with efficiency and safety. Here, ionic liquids like this imidazolium salt come in handy. Since they don’t mix easily with certain solvents and have low flammability, technicians get more control. Companies recover valuable materials that would otherwise be lost—and that puts money back in the budget.

Electroplating and refining also depend on high-performance solvents. Ionic liquids support consistent current flow and steady plating, so finished products look cleaner and last longer. For some specialty metals, this compound helps reduce defects by keeping conditions stable. Less waste means less money spent cleaning up or fixing rejected batches.

Role in Green Chemistry

Sustainability drives a lot of innovation now. In my experience, regulators and customers push for greener ways to make things. 1-butyl-2,3-dimethylimidazolium toluenesulfonate helps there, too. Companies aiming to run reactions at lower temperatures or swap out fossil-derived ingredients rely on it as a solvent or even a catalyst. Researchers find that its stability at higher temperatures expands the range of new reactions they can try out.

Teams exploring biomass conversion and enzyme-driven chemistry count on this solvent, especially for tricky plant materials or recycling plastics. The compound lets folks run processes that don’t work in water or in regular organics. More value comes from local waste, and there’s less pressure on oil.

What Still Needs Work

None of these benefits come for free. One thing that always matters is the long-term environmental footprint. Evidence shows many ionic liquids last a long time once they leave the plant, and their breakdown products can be tough to predict. I’ve seen research teams work on ways to recover and recycle these chemicals so they don’t end up in the environment—but it takes commitment and new infrastructure.

Cost and availability still limit widespread use. The upfront spending on new solvents and training can slow progress. Firms and universities that share real performance data give everyone a better shot at adopting safer, more sustainable tools. As demand rises, manufacturing methods will streamline and prices should come down.

As the chemical industry pushes for processes that lower risk and waste, 1-butyl-2,3-dimethylimidazolium toluenesulfonate has already earned a spot on the shortlist for greener, safer solutions.

Why Proper Storage Makes a Difference

Walking down any supermarket aisle, you see the same warning printed on everything from milk to medicine: “Store in a cool, dry place.” It seems simple enough, but there’s real science behind it. Every item, whether food, medicine, or even hardware, reacts to its storage environment. Heat, light, moisture—these elements break down ingredients, reduce shelf life, and, in some cases, even cause harm.

A few years ago, I left a chocolate bar in my car during summer. By the afternoon, it had turned into a sticky mess. That’s a basic example, but the impact climbs when products are sensitive. For instance, life-saving insulin loses potency quickly if it gets too hot. Some vitamins will degrade quickly if kept in humid kitchens. Once quality slips, users won’t always know right away. Efficacy drops, and so does safety.

Understanding Labels and Real-Life Storage Challenges

Labels say a lot, but not every household sticks to the recommendations. In my own kitchen, I used to keep my spices above the stove, thinking it was convenient. Over time, the colors faded and flavors dulled. Heat and moisture from cooking wreak havoc quietly over weeks. Manufacturers don’t put these storage guidelines on packages as an afterthought; ignoring them truly wastes money and product.

Let’s take medicine as another example. The U.S. Food and Drug Administration (FDA) reports that storing drugs outside recommended conditions leads to a spike in expired or less effective medication. People often keep bottles in steamy bathrooms for convenience, yet that environment raises risks—those pills may lose potency, or worse, break down into unwanted byproducts.

Food can spoil or lose nutritional value. Flour attracts pests when left in humid places. Nuts turn rancid in the heat. Cosmetics develop bacteria if forgotten in damp bathrooms. Small lapses add up across millions of homes and businesses. The result: waste piles up and people risk using products that don’t work as promised.

Simple Steps to Protect Quality

Manufacturers and safety agencies agree: most products benefit from steady temperatures, low humidity, and low light. Dry pantries protect grains. Refrigerators slow bacteria and mold growth for perishables. Medicine cabinets outside of bathrooms keep temperatures more stable.

For more sensitive products, take it a step further. Insulin often needs proper refrigeration. Art supplies, like certain glues, dry out unless sealed tightly after use. Even seeds for the garden germinate better when stored with care through winter.

Better Storage Means Lower Waste

Small changes add up over time. By following storage instructions, you stretch a product’s lifespan and reduce unnecessary waste. Families spend less. Companies see fewer returns. The environment takes less of a hit. Too many people shrug off the importance of dry shelves, tight lids, or cool corners, thinking it’s fussy or unnecessary. In reality, every product in a home or workplace comes with an unspoken expectation: take care of it and you get full value.

Storing things right isn’t complicated; it just requires a bit of attention. Reading labels, understanding warnings, and setting up smarter storage spaces protects not just the products, but the people who rely on them. The benefits pay off—quality holds, waste shrinks, and the chances of harmful surprises drop. There’s a real return from that little extra effort.

What Is This Chemical and Why Does It Matter?

Science often introduces new compounds that promise more efficient processes or greener results. 1-Butyl-2,3-dimethylimidazolium toluenesulfonate, a type of ionic liquid, has popped up in lab work meant for advanced manufacturing and chemical synthesis. Some chemists like its low volatility and how it can dissolve a wide range of materials, from cellulose to metals. None of that means it’s risk-free.

Safety always has to come first—just look at the long history of chemicals once hailed as breakthroughs, like asbestos or leaded gasoline. Glance at the safety data sheets for this one and you’ll notice warnings about skin or eye irritation. The toluenesulfonate part, derived from toluene, raises eyebrows right away. Toluene itself is flagged for its ability to harm the nervous system if mishandled.

Examining the Toxicity

Switching from theory to the trenches, researchers and lab techs want to know if they can handle this stuff without worrying about major health impacts. Here’s the truth: there just isn’t much published research specific to 1-butyl-2,3-dimethylimidazolium toluenesulfonate. Some studies on similar ionic liquids show that they don’t vaporize easily, so you probably won’t breathe them in by accident, which is a plus.

Still, contact with skin or inhalation of dust could trigger reactions. Animal tests on the family of imidazolium-based ionic liquids sometimes indicate moderate toxicity and issues for aquatic life if spilled. A study from the Journal of Hazardous Materials reported that ionic liquids with similar structures harmed water fleas and algae at certain concentrations. Nothing benign about that for ecosystems.

Handling the Chemical in the Real World

In research labs, nobody takes those gloves and goggles off lightly. Any time I’ve dealt with ionic liquids, the golden rule holds: avoid direct exposure, and keep everything contained and labeled. I remember a colleague who assumed an imidazolium salt was as benign as tap water—but a splash to her skin led to a long day flushing with water and filling out incident paperwork. Even minor accidents feel major if you aren’t prepared.

Disposal matters too. This chemical should never go down a regular sink. Collect waste in labeled containers and make sure the facility can process it safely. University labs in Europe and the US now require anyone using ionic liquids to pass environmental and safety quizzes. The effort helps new researchers realize that “green” doesn’t always mean “harmless.”

What Should Happen Next?

We need more direct research into toxicity, breakdown products, and how these chemicals behave outside the lab. I’d like to see chemical manufacturers and academic journals collaborate on more thorough hazard testing before new compounds reach broad use. Small steps make a difference: regular hazard communication, safer lab practices, and equipment designed for spills.

At the community level, public databases should keep up with the risks to waterways or soil. Environmental monitoring can catch issues before they become disasters. If we treat every new compound with caution, fewer people get hurt, and fewer ecosystems pay the price. A little skepticism and care go a long way in chemical safety.

What Purity Levels Actually Mean for Chemical Work

Purity tells the story of a chemical before anyone starts their work. Lab technicians, pharmacists, and engineers all treat that number—sometimes as high as 99.9%—like a badge. Street-level chemistry might sound distant from most people’s lives, but these numbers shape everything from basic science to the medicine in someone’s cabinet.

In college lab days, professors drilled into our heads: always check the purity stated on the bottle, because buying the wrong grade throws off months of work or can even leave lingering dangers. Research chemicals often land in the 98%-99.9% range; pharmaceutical intermediates tend to be higher, sometimes demanding nearly absolute purity. Drop to “technical grade,” and you’ll see something closer to 90%-95%.

Small Numbers, Big Consequences

Quality matters a lot more than jargon makes it seem. It’s the difference between a reliable batch and a failed experiment. High-purity reagents cost more for a reason: those extra fractions of a percent mean that the product works as promised and won’t create surprise reactions. Minute levels of contamination can wipe out a whole project. I remember a failed experiment in graduate school—all due to an off-brand solvent labeled “pure,” but really loaded with invisible impurities. That single shortcut meant weeks of troubleshooting and extra spending.

Medicine brings the stakes even higher. The FDA and similar agencies don’t cut corners with pharmaceuticals. Tablets get manufactured under strict conditions, starting with chemicals that often hit 99.5% purity, if not better. Even a hint of impurity sometimes makes a product unusable or dangerous; cancer drugs, for example, have set the bar especially high. Those numbers don’t just protect science, they protect lives.

Looking Past the Label

It’s easy to see “pure” as a guarantee, but there’s always a footnote: not all impurities work the same way, and every supplier has a different way of measuring. The best labs trace every batch with certificates of analysis, showing exactly what’s in the mix. That’s the clearest way to avoid risk. Sometimes, these impurity profiles reveal critical details that a single “purity” number can’t cover, especially when trace metals or specific byproducts could still sneak past standard testing.

Quality thinkers in manufacturing never rely only on product claims. They ask questions, run their own spot-checks, and demand transparency from suppliers. Real oversight protects against errors slipping through—or, worse, fraud. Documented cases exist where suppliers sold “pure” chemicals that turned out to contain harmful levels of other substances. These lapses don’t just upset research, they can lead to large recalls or public health scares.

Building Trust and Raising Standards

Improving chemical purity means investing in better equipment, trained staff, and reliable supply chains. The payoff is clear: safe medicines, consistent food additives, dependable research supplies. Transparency and traceability back up every claim, helping workers and consumers trust that what’s on the label matches what’s in the bottle. In my work, the best results came from partners who provided detailed analysis with every shipment—backed not just by words, but real, verifiable data. Setting that bar higher, every time, means fewer errors and safer outcomes for everyone.

Why Safety Isn’t Optional

Mistakes in chemical handling have real consequences. I’ve watched someone dismiss safety goggles for “just a quick pour,” only to end up rushing for an eyewash station. No bulk of paperwork makes up for even a minor chemical splash or unexpected release. The compound on your bench might seem harmless—until you realize how easily fumes or spills can trigger long-term health issues, fires, or environmental harm.

Direct Steps Backed by Experience

A solid understanding of a chemical’s hazards comes before anything else. The Material Safety Data Sheet (MSDS) offers clear warnings about toxicity, reactivity, and safe limits. I check these details every time, not just for the obvious threats, but for less visible dangers like chronic inhalation or persistent residues.

Let’s talk about containment. Rushing a transfer job, using an old funnel, or choosing a cracked beaker can cost you and your team. I store volatile or corrosive compounds away from heat, light, or incompatible materials—never in reach of food or office supplies. Labels must stay readable. Permanent marker on tape works better than trusting memory or smudged stickers.

Personal Protection Isn’t Just a Sign on the Wall

Some compounds look innocuous in the bottle. Still, a pair of nitrile gloves, chemical splash goggles, and a lab coat have spared me countless troubles. I go a step further: for powders and strong acids, a face shield and fume hood convince me I’m not rolling the dice. Regular checks for holes in gloves or filters in respirators save on regret.

For spills, waiting around breeds problems. Small spills get covered with absorbent pads or suitable neutralizers, then scooped into waste bins designed for hazardous materials—not down the drain or in regular trash. After cleaning, I wash hands with soap and water, no shortcuts.

Disposal: The Details Matter

Disposal instructions in the MSDS or local environmental regulator’s guide take priority. Once, I saw a colleague flush a solution that later triggered alarms at the wastewater plant. It cost us hours and a hefty fine.

If the compound is organic and harmful (such as solvents or heavy metals), I place waste in labeled, tightly sealed drums or bottles. The contents, hazard class, and date must all appear clearly. For acids, I neutralize only after consulting protocols and verifying that the end product is safe.

Partnering with a certified hazardous waste disposal contractor closes the loop. At one job site, regular audits from outside experts caught weaknesses in storage and labeling, which gave everyone a wake-up call. Talking to local environmental health authorities helps keep our practices sharp and legal.

Responsibility Extends Beyond the Lab

Chemical stewardship heads off disasters that stretch far beyond workplace walls. Fish kills, poisoned soils, and unexpected air releases often tie back to half-baked handling or disposal. My role isn’t just following the rules; it’s setting a safer path for colleagues and anyone downwind or downstream.

Real improvement comes from training—refreshers on the realities behind each label and symbol, clear signage, and a culture where anyone can call out a sloppy setup. In the end, it’s not about getting through the day. It’s about sending everyone home safe, every time.