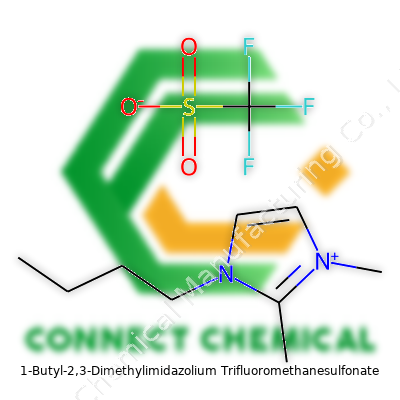

1-Butyl-2,3-Dimethylimidazolium Trifluoromethanesulfonate: A Deep Dive

Historical Development

Back in the early days of ionic liquids, researchers sought new alternatives to classic organic solvents. Their reasons ranged from environmental concerns to the strict rules about emissions. In the 1990s, interest in imidazolium-based ionic liquids picked up—not just among academic labs but in industry, too. Chemists began exploring structures with longer alkyl chains and new substitutions to tackle issues like viscosity, stability, and solubility. The birth of 1-butyl-2,3-dimethylimidazolium trifluoromethanesulfonate (also called BM₂ImOTf by some labs) was a direct result of these efforts. It didn’t make waves overnight, but those who worked with it started seeing how its specific composition solved problems commonly faced in both analytical chemistry and production-scale processes. Its use spread quietly through communities looking for materials that allow stricter process control, even in tough regulatory climates.

Product Overview

1-Butyl-2,3-dimethylimidazolium trifluoromethanesulfonate stands as a single-component ionic liquid that doesn’t evaporate quickly and brings stability in both air and under mild humidity. It looks like a clear, slightly viscous liquid at room temperature. You’ll often spot it stored in amber glass bottles since light can eventually yellow it over time. Its melting point sits far below water’s freezing point, so it keeps liquid characteristics under most lab conditions. Its major draw comes from combining an imidazolium cation’s flexibility with the outstanding coordinating strength of triflate. This gives it the power to dissolve challenging salts and complex organic molecules, handy in synthetic chemistry, catalysis, and extraction science.

Physical & Chemical Properties

1-Butyl-2,3-dimethylimidazolium trifluoromethanesulfonate brings a high thermal stability, usually not degrading below 280°C. Its low vapor pressure means it won’t escape from open beakers, helping users keep a tidy lab and reduce waste. The compound typically has a density close to 1.3 g/cm³ at room temperature—heavier than water, which signals stronger intermolecular interactions. Its viscosity measures higher than many conventional solvents, though small changes in temperature cause big shifts in flow. Chemists value its broad electrochemical window, which stays stable from strongly reducing to moderately oxidizing potentials. This range opens the door to advanced battery, electroplating, and electrosynthesis experiments. Its trifluoromethanesulfonate anion resists nucleophilic attacks and keeps the salt inert in most simple reactions, though it will play a part in specialized functionalizations.

Technical Specifications & Labeling

Chemical suppliers list BM₂ImOTf with a purity often above 98%. Lots vary by residual water content, so every batch carries a moisture analysis certificate. The chemical’s registry number (CAS 869295-33-0) shows up on its label, alongside recommended storage instructions—typically cool, dry, and away from acidic vapors. Most lab users order it in amounts ranging from 25 g to 500 g. Its identity check often comes through NMR and IR spectra, available on request. Reliable brands offer documentation on heavy metal screening, specifically for applications in catalysis or sensitive spectroscopy.

Preparation Method

Labs often start with 1-butyl-2,3-dimethylimidazolium chloride, made by reacting 1-chlorobutane with 2,3-dimethylimidazole under basic conditions. Following purification steps, they introduce sodium trifluoromethanesulfonate in water or methanol, allowing the two components to exchange halide for triflate. After thorough washing with non-polar solvents, the ionic liquid gets dried under vacuum. This route leaves very little inorganic contamination, crucial when the end product sees use in sensitive chemical reactions. Some production lines shift toward continuous flow methods, especially when scaling for industrial uses like specialized coatings or electrolytes.

Chemical Reactions & Modifications

Among the key strengths of BM₂ImOTf lies its backbone, which resists most nucleophilic and electrophilic attacks under normal lab conditions. The butyl and methyl substituents block most simple degradations and give the liquid an edge in resisting unwanted polymerization. At the same time, the imidazolium ring lets scientists design new derivatives—switch methyl for ethyl, swap anions for others like hexafluorophosphate or bis(trifluoromethylsulfonyl)imide. This flexibility opens endless custom solvent blends for extraction work or reaction design. Some teams have tested it as a phase transfer catalyst, promoting unusual heterocyclic syntheses and yielding access to products not easily managed with classic solvents.

Synonyms & Product Names

You might spot it sold as [BM₂Im][OTf], 1-butyl-2,3-dimethylimidazolium triflate, or plain “imidazolium triflate ionic liquid” with varying methylation described, depending on the supplier. Scientific papers alternate between these, but the CAS number acts as a clear identifier regardless of origin or packaging.

Safety & Operational Standards

Long-term studies on imidazolium salts push for strict lab hygiene—gloves and eye protection form the basics. Even if BM₂ImOTf rarely gives off noticeable vapors, splashes irritate skin or mucous membranes, so every bottle ships with hazard warnings. Waste should go to chemical disposal, as triflate-based ionic liquids can persist in the environment. Labs working with larger quantities follow step-by-step risk assessments, especially in academia where less skilled hands may spill or misuse the liquid. No major chronic hazards have turned up in published toxicity screens, but as with all new materials, teams stay cautious, gathering more data before authorizing larger-scale uses outside enclosed labs or regulated process lines.

Application Area

BM₂ImOTf shows up in fields driven by the need for robust, non-volatile media. Electrochemists praise its high conductivity and stable window, using it in supercapacitor development and lithium battery prototypes. Extraction technicians lean on its strong solvating power to separate rare earth metals from electronic scrap or nuclear waste streams. Catalysis research often features it as a green replacement for legacy solvents, helping reduce hazardous byproducts and simplify recovery. Its low flammability leads to use in high-temperature industrial reactions, where fire risk poses a problem with other media. The constant expansion of microfluidics and green engineering projects keeps pushing demand, as engineers look for substances that don’t bring new environmental headaches or worker safety problems.

Research & Development

Growth in R&D for ionic liquids accelerates thanks to global efforts targeting eco-friendlier chemical routes and higher energy efficiency. BM₂ImOTf draws interest thanks to its resistance to decomposition under electrical or thermal stress. Academic publications deepen understanding by mapping its interactions with biomolecules or polymers, searching for ways to fine-tune properties for drug delivery or smart materials. Collaborations between universities and industry investigate real-world uses, from safer reaction vessels to recyclable battery electrolytes. The volume of work keeps growing, reflecting how researchers see beyond classic solvents and keep pursuing more sustainable operations across sectors.

Toxicity Research

Data from cell studies show imidazolium-based ionic liquids like BM₂ImOTf act as mild irritants, though their exact mechanism in living tissues stays under investigation. Researchers have found that triflate anions don’t easily bioaccumulate, but metabolites formed in the body or ecosystem still spark caution. Most evidence to date comes from studies at concentrations much higher than would show up in workplace air or water, so real risk remains low under tight controls. Regulatory agencies recommend limiting open handling and ensuring strong ventilation just to stay ahead of any yet-unseen health concerns. Further animal studies continue, mostly to pin down thresholds below which exposure would carry no risk for full-time workers.

Future Prospects

BM₂ImOTf stands ready to ride demand as sectors shift toward green chemistry and high-tech material sciences. Research keeps highlighting new uses in hydrogen fuel cells, next-generation sensors, and hybrid organic-inorganic interfaces. Projects underway aim to recycle the liquid in closed-loop systems, just as electronics manufacturing moves away from toxic, volatile solvents. Its ability to support multi-phase catalysis and resist thermal breakdown puts it on the shortlist for future industrial standards. The key lies in continued investment in safety research—both for workers and the planet—coupled with transparent communication between suppliers, users, and regulators. As technologies adapt, 1-butyl-2,3-dimethylimidazolium trifluoromethanesulfonate looks set to unlock faster, safer, and cleaner chemistry across scientific and manufacturing landscapes.

What’s Pushing 1-Butyl-2,3-Dimethylimidazolium Trifluoromethanesulfonate into the Spotlight?

Chemicals with long, tongue-twisting names rarely get attention outside research circles, yet 1-butyl-2,3-dimethylimidazolium trifluoromethanesulfonate, often shortened in lab slang to a manageable “ionic liquid,” finds its way into more applications than most folks realize. This isn’t another yet-to-be-proven compound — labs already use it in meaningful ways. My own early days in synthesis involved poking at salts and solvents that left more headache than answers. This liquid stuck around because it solved problems fast.

The Real Power of Ionic Liquids

Traditional solvents evaporate, create pressure, and carry health hazards. Back in my first job mixing organometallics, keeping the air clean required fans, extractor arms, and unending caution signs. Ionic liquids like this one flip the script. They bring ultra-low volatility and stability under air, making bench work safer and less wasteful. The trifluoromethanesulfonate anion helps the compound handle strong acids and bases, which made some tricky steps in catalysis less stressful for me.

Email, Green Chemistry, and Next Generation Batteries

What makes this ionic liquid stand out isn’t paper claims about “greener chemistry” — it’s actually changing how chemists develop reactions and materials. Teams trying to replace old-school organic solvents in pharma or plastics now turn to these salts. In drug discovery, for instance, I saw how ionic liquids replaced DMF or DMSO for cleaner extraction and purification. The result: fewer toxic by-products, easier recycling of reagents, far less environmental burden. Researchers working with lithium-ion and sodium-ion batteries — especially those focused on high-energy storage — have added this compound as an electrolyte. It boosts ionic conductivity and stability, helping cut down on flammable electrolyte risks I witnessed as real safety issues.

Catalysis: Moving Beyond “One Size Fits All” Solvents

In the hunt for efficient catalysts, this compound shapes reaction selectivity. Think about hydrogenations or coupling reactions that need precise temperature and pH control. Conventional solvents forced chemists to play a balancing act between stability and speed. Using this ionic liquid meant we could add oddball catalysts and sensitive organics without fear of rapid decomposition. Studies from groups in Japan and Germany back this up — showing higher yields and better purity when swapping in ionic liquids in place of volatile solvents.

Electrochemical Devices—Supercapacitors and Sensors

Laboratories advancing supercapacitor tech or pushing boundaries in biosensors use this material for its durability in harsh environments. Unlike water-based solutions that degrade or corrode electrodes, this ionic liquid stays stable over hundreds of cycles. The viscosity, conductivity, and non-flammability opened up new designs that survived months of repeated charging, which had been a weak point in older prototypes I saw tested.

What’s the Roadblock?

Results from my own bench work and industry reports show that sourcing and cost still hold these compounds back from mainstream adoption. Synthesizing pure ionic liquids isn’t as straightforward as fetching off-the-shelf solvents, and price tags add up fast. In a competitive sector like battery research, these factors matter big time.

Looking Forward: Breaking Silos and Lowering Costs

Open data on production, sharing know-how across the chemical industry, and scale-ups from pilot plants may finally make ionic liquids like 1-butyl-2,3-dimethylimidazolium trifluoromethanesulfonate part of standard lab toolkits. Large manufacturers starting to step in with supply chain solutions, and collaboration between university labs and industry has begun lowering prices and boosting confidence. For anyone working in green chemistry, electrochemistry, or advanced manufacturing, keeping an eye on these changes could mean quicker, safer, cleaner problem-solving at scale.

Why Chemical Stability Matters

Anyone who's ever forgotten old painkillers at the back of the medicine cabinet knows products don’t last forever. Chemical stability plays the biggest role here. It means a product keeps its intended structure over time. Imagine a bottle of vitamin C tablets. Coupled with moisture in the bathroom, that vitamin C can break down into useless crumbs. Most active ingredients have a shelf life for this reason. Once that window closes, you stop getting real benefits—and product safety could slip too.

What Influences Degradation

I’ve seen firsthand how small things speed up spoilage. Exposure to oxygen, sunlight, or heat can break down chemicals faster than we realize. My grandmother once stored aspirin next to her stove. The tablets clumped and the smell changed, all because of warmth and moisture. Chemical bonds start to break with enough energy. Some compounds react almost immediately with light or humidity; others degrade slowly, but no less surely.

Manufacturers test how long their products last using rigorous studies—accelerated aging, checking reaction byproducts, monitoring performance. Acidic or basic materials can shift product stability, so niche additives or buffers sometimes end up in the ingredient list specifically to slow down those unwanted changes. Every component faces scrutiny because even the container matters. One pharmacist shared how plastics can actually leach into a liquid medics over time, especially if the wrong temperature hits. That’s a big deal for drugs, supplements, lab solutions, and even cosmetics.

How Shelf Life Affects Real People

Shelf life isn’t just a number on a label. A lapsed expiry date can mean reduced potency or side effects no one wanted. When my daughter had antibiotics left over, my doctor warned against saving them for later. Not just because of resistance, but because degraded chemicals can produce new, unpredictable reactions in the body. Sometimes consumers might think they’re saving money by keeping old products, but those risks can far outweigh the benefits. Household cleaners, pesticides, and even sunscreens all share this same hidden cycle of breakdown.

What Can Be Done

Clear communication helps. People need honest labels that state both the production date and the realistic shelf life. Storage instructions should be front and center. I’ve seen rescue medications packed in foil with warning cards to avoid bathroom storage or direct sun. That simple move prolongs their effectiveness and keeps people safe.

Industry and regulators must continue to improve testing and update shelf life regularly, using data from real-world conditions. For example, vaccines face temperature swings on their way to clinics. Data loggers and smart packaging are helping everyone track stability from warehouse to pharmacy fridge.

Educators and medical professionals need to reinforce the importance of appropriate disposal for expired products. Some pharmacies and police stations host take-back days for household chemicals and drugs. This gives consumers a practical option to avoid accidental poisonings or misuse.

Reliable Information for Everyday Decisions

People rely on products every day—whether for health, cleaning, or routine living. Reliable shelf life information, plus safer packaging and smarter storage, all add up to peace of mind and better results. That’s not only a benefit for patients or consumers, but a badge of accountability for manufacturers and regulators alike.

Understanding Product Risks

People often ask about the safety of new products, especially with items that claim to solve problems or make life easier. Each time I try something unfamiliar, my mind drifts to all the labels I’ve read over the years. From strong adhesives to cleaning agents and even food packaging, there’s always more beneath the surface than a glossy ad or quick start guide tells us. How you handle a product — not just what’s inside it — can affect your health and the people around you.

Looking at the Label Isn’t Enough

I once ignored a glove warning on a can of sealant, figuring it was only a guideline. By the end of the afternoon, some residue ended up on my skin and left behind irritation that took days to clear. According to the U.S. Consumer Product Safety Commission, more than 200,000 emergency visits each year are linked to consumer chemical products, mostly due to unexpected exposure. Many accidents happen exactly like mine: someone skips a step or assumes the warning sounds too cautious.

Personal Experience Builds Better Habits

From paint thinners to household cleaners, I’ve learned to pay extra attention to symbols and pictograms, like skulls or flames, which signal real hazards. Not all risks jump out at you with bright colors or big warnings. Sometimes it’s a tiny note near the ingredients list, mentioning “corrosive” or “may irritate eyes.” Small print can pack a punch if ignored. My own family adjusts home routines, like opening windows and storing containers in cabinets that kids can’t reach. Even reusable products, like storage bins treated with antimicrobial coatings, can release fumes right after unpacking. Sometimes it just takes a reminder from a friend or health professional to rethink old habits.

Key Safety Steps That Make a Difference

Every product needs a tailored approach. For cleaning supplies and solvents, manufacturers recommend gloves, eye protection, and good ventilation for a reason. The American Association of Poison Control Centers notes consistent increases in calls related to improper storage or accidental mixing of products. Storing materials in original packaging and away from heat or moisture prevents chemical reactions and protects children or pets who get curious. Reading a safety data sheet — usually linked on a manufacturer’s website — gives a full run-down of risks, first-aid advice, and disposal instructions.

One overlooked practice is watching for product expiration. Old chemicals break down, affecting their safety profile. For example, expired disinfectants can develop fumes or reduced effectiveness, opening the door to harmful bacteria. Most local municipalities hold hazardous waste collections, giving households a safe way to offload outdated or empty containers.

Solutions That Work at Home and in the Workplace

Better labeling with clear language and larger symbols would help consumers spot danger quickly. I’ve seen workplaces add posters and quick-reference charts in areas where harsh products get used, and it helps everyone — not just the newest employee. At home, we check labels and swap stories about accidents to keep each other sharp. Making it a habit to read about risks before opening something new saves time and trouble in the long run. Asking questions at the store or online, and not assuming a product is harmless just because it looks familiar, closes the loop on safety.

Getting Practical with Lab Chemicals

I’ve seen plenty of labs overlook small details—little things that might seem minor, but they could mean the difference between a smooth protocol and a costly mistake. Chemicals like 1-butyl-2,3-dimethylimidazolium trifluoromethanesulfonate don’t call attention to themselves, but trust me, improper storage can turn a tidy bench into a mess, or worse, endanger the folks working beside you.

Respect for Stability and Compatibility

This compound sits in the ionic liquids family, often praised for low volatility and good thermal stability. Don’t get too relaxed about it. Store it in tightly sealed containers—glass or HDPE it won’t react with. Humidity sneaks in, so keep it somewhere cool and dry. Refrigerator shelves away from food make good sense if the facility allows it. Keep it away from shelving dedicated to acids, bases, and especially strong oxidizers. These trifluoromethanesulfonate compounds react if given the wrong conditions. I once saw a careless chemist mix up shelf locations, and the aftermath involved more phone calls to maintenance than anyone wished for.

Labeling Is Just Good Practice

You only need to work in a multi-user lab for a month before realizing that clear, dated, waterproof labels prevent all kinds of confusion. I’ve pulled unlabeled vials from the fridge and had no clue what was inside—a situation you don’t want to sort out under time pressure. Mark down the full chemical name, date of receipt, your initials, any necessary warnings, and the source, so no one has to guess.

Tracking Down Hazards

The safety data sheet lists the hazards; always glance at it before bringing a new chemical into the lab. Even ionic liquids—though often hailed as greener solvents—can irritate skin or eyes and release toxic fumes if mishandled. I’ve tried short cuts in the past: grabbing from an open shelves, even when I knew proper storage called for a sealed secondary containment. That mistake made for a stinging clean-up and tossed-out gloves. Take the extra minute. Store in a sturdy, airtight container, placed in a chemical storage cabinet, preferably with a spill tray beneath it.

Thinking About Spills Before They Happen

Too many people think spills only happen when big bottles fall over, but fickle caps and worn-out vials leak too. Keep absorbent pads or spill response materials nearby, and don’t hesitate to train new students on how to handle leaks properly. I always keep a log nearby to document any issues. Tracking spill incidents helps everyone spot problems faster.

Compliance Is About Protection

OSHA and similar organizations set their guidelines for good reason. Ignoring them doesn’t just put your project at risk; it can jeopardize your colleagues’ safety and the lab’s reputation. Frequent audits, checklists, and peer reminders go further than stern posters. During inspections, labs with tidy, properly labeled chemical storage draw less unwanted attention. This carefulness keeps everyone confident about the next experiment.

Solutions for Real-World Storage

Invest in dedicated chemical fridges or lockers if possible. Rotate stock, so older material gets used first—chemical aging leads to stability issues. Don’t trust memory; keep inventory records. Choosing the right container, creating a solid habit of labeling and dating, and giving newcomers proper walkthroughs will sidestep most avoidable trouble. All these actions keep both the scientific results and everyone’s safety on solid ground.

Understanding Purity in Daily Life

Purity touches a lot more than just science labs and pharmaceuticals. Whether it's gold jewelry, drinking water, or the baking soda in your kitchen, we care about how much is the real deal and how much is something else. A gold ring advertised as 24 karat can’t have copper or nickel sneaking in, or it won’t shine and last as promised. Purity isn’t only about being fancy – it keeps products safe and honest.

The Real World Impact of Impurities

I remember buying some “organic” honey at a local market. A few weeks later, news broke that several batches of honey in the area had been cut with sugar syrup. You pay extra thinking you’re helping bees and your body, but what you get is diluted, less nutritious, and possibly unsafe. Stories like this explain why purity means more than taste or looks. In pills or supplements, small changes in what’s inside can cause big health problems. Impurity sometimes means allergies, sickness, or useless medicine for people depending on it.

How We Actually Check for Purity

Checking purity usually calls for specialized tests. In metals, jewelers use acid tests, magnets, and sometimes X-ray instruments to spot cheap mixes or imitations. Some folks bite gold coins on TV, but experts rely on solid chemical tests. For food, there’s a mix of chemistry and gadgets. Lab teams will often use chromatography and spectrometry, breaking down samples by chemical makeup and reading what’s really there. My friend works in a food lab where they test olive oil to catch false labeling – using machines that can spot even tiny amounts of other cheaper oils.

In medicine, laboratories pay even more attention. High Performance Liquid Chromatography, for instance, separates each chemical piece for a look under the microscope. Even a small hint of contamination in pharmaceuticals gets flagged, because people trust these pills with their well-being. In the water industry, daily or weekly reports tell us whether water companies are keeping out bacteria, metals, and other stuff that shouldn’t be there. It’s common to find government regulations forcing everybody to double-check these results and post them publicly.

What Happens When Purity Slips

Half the scandals in consumer goods stem from people cutting corners. The melamine-tainted milk episode in China made thousands of kids sick, just from a few suppliers sneaking in a cheap chemical to fake higher protein measures. Consumers, left in the dark, end up paying the price. When purity turns into just a marketing term, trust suffers and sometimes so does public health.

Fixing the Problem: More Honesty, Better Science

Strong rules can help. Requiring public labs to review products before sale, punishing fraud, and pushing for stricter, transparent labels gives shoppers tools to protect themselves. Brands turning to third-party testers attract trust. The easy availability of low-cost test kits for water or gold lets buyers insist on proof before they pay. Open information and real consequences keep manufacturers honest.

People only trust what they can check. With more spotlight on product origins and tighter checks at every step, raw deals and health risks shrink. Whether it’s food in your fridge, a ring on your finger, or pills in your cabinet, purity checks keep us safe, informed, and satisfied with what we buy.