Exploring 1-Butyl-3-Ethylimidazolium Chloride: A Deep-Dive Commentary

Historical Development

Back in the late twentieth century, researchers started looking for safer options to replace volatile organic solvents. The hunt for ionic liquids began then, mostly in labs exploring “green chemistry.” The early progress led to the synthesis of numerous imidazolium compounds, with 1-butyl-3-ethylimidazolium chloride earning attention for its performance in catalysis and as a medium in chemical processes. Mainstream chemists noticed that this salt had a melting point low enough for practical liquid-phase applications. The economic and regulatory pressures to rethink industrial solvents only drove deeper interest, steering both public and private research funds toward improving and understanding this compound.

Product Overview

1-Butyl-3-ethylimidazolium chloride stands as a member of the imidazolium-based ionic liquid family. In my own experience working with complex synthesis, researchers favor this salt not just because it dissolves a wide variety of organic and inorganic materials but because it doesn’t release irritating fumes. The chemical structure, with the butyl and ethyl groups attached to the imidazolium ring, creates a product that presents unique solvation characteristics. Large industrial suppliers deliver this chemical for applications ranging from material synthesis to electrochemistry. Names for this salt often switch depending on the vendor, but the essential properties remain consistent.

Physical & Chemical Properties

Most users notice right away that 1-butyl-3-ethylimidazolium chloride appears as a crystalline solid at room temperature, sometimes forming a viscous liquid above 60°C. The salt offers remarkable thermal stability, often persisting up to 250°C before decomposing. Solubility in water and select organic solvents makes it handy for multi-phase reactions. Conductivity stays decent thanks to free-moving ions, making it suitable for electrochemical systems. Unlike traditional solvents, there is no dangerous evaporation and almost no bulking volatile vapor pressure. The ionic liquid’s polarity, tunable by changing the side groups, lets researchers interact with polar and nonpolar substances more smoothly than with classic solvents.

Technical Specifications & Labeling

Producers label this product with clear CAS and EC numbers (CAS 342573-75-5; EC 609-514-2), often specifying purity levels between 98% and 99%. Packaging remains straightforward: resistant bottles or lined barrels guard against water absorption, which can affect weight and reactivity. The product arrives marked with hazard pictograms and handling recommendations, following regulations set by agencies such as OSHA and REACH. In the lab, chemists recognize it by its faint color and characteristic ionic scent. Labels point out any batch-specific impurities and note the recommended shelf life, an important detail for consistent research results.

Preparation Method

The mainstream approach to synthesizing 1-butyl-3-ethylimidazolium chloride involves a quaternization reaction. Chemists start by mixing 1-ethylimidazole with 1-chlorobutane, stirring with heat and continuous removal of byproducts. The reaction proceeds under nitrogen or argon to cut back on unwanted oxidation or hydrolysis. Some industrial reactors now employ microfluidic systems, wrapping up synthesis with less risk and more repeatable outcomes. Several groups then purify the product by washings and drying under vacuum conditions. The product can scale up reliably, allowing researchers and manufacturers to supply large quantities for industry applications.

Chemical Reactions & Modifications

Although the imidazolium core seems stable, the chloride anion offers room for chemical creativity. Halide exchanges swap out chloride for larger or more reactive anions, giving chemists control over the liquid’s hydrophobicity and solubility. With catalytic systems, the cation itself sometimes participates in stabilization—changing the speed or direction of a reaction. In my experience with functional material synthesis, 1-butyl-3-ethylimidazolium chloride often partners with metal salts to coax out nanostructures or specialized complexes. Pairing with reactive gases, this salt can support specialized carbon capture or act as a phase transfer agent for stubborn transformations. This flexibility has helped build its reputation beyond just a solvent.

Synonyms & Product Names

Depending on the supplier or country, the chemical may show up on purchase lists as [BEIm][Cl], 1-butyl-3-ethylimidazolium chloride, or with shorthand like BEIM-Cl. While some catalogs specify trade names, most researchers keep it simple for clarity in documentation—especially as the international chemistry community relies on consistency. These synonyms matter for sourcing, as labs need dependable communication across language barriers and regulatory systems.

Safety & Operational Standards

Safety often shapes every interaction with this salt, even though it looks tame on the bench. Chemical safety sheets highlight the dangers of skin or eye contact, which can cause irritation. While the liquid is non-volatile and less flammable than many organics, gloves and goggles come out for every use. Disposal relies on established protocols for ionic liquids—special waste collection avoids soil and water contamination. Labs and plants follow inhalation guidelines, as chronic exposure remains under investigation. Standard ventilation, chemical aprons, and prompt cleanup of spills provide a straightforward playbook for daily operations, based on a mix of regulatory guidance and community best practice.

Application Area

Research teams and industrial chemists work with this chloride salt in fields as diverse as organic synthesis, catalysis, electrochemistry, and separations. I’ve seen the biggest impact in rechargeable battery research, where this ionic liquid helps suppress fires and extend the lifespan of electrodes. Some colleagues use it as a reaction medium to avoid hazardous solvents, letting them recover catalysts or reuse solvents with less fuss. It plays a strong role in material science, too—coating nanostructures or supporting membranes for advanced separation tasks. Even in the pharmaceutical sector, formulation specialists experiment with ionic liquids for solubilizing unusual actives or designing slow-release drugs.

Research & Development

Universities and commercial labs steer efforts into understanding structure-activity relationships involving 1-butyl-3-ethylimidazolium chloride. Published studies probe how tweaking the side groups or switching anions might yield stronger catalytic effects or safer handling. Instrument manufacturers test new electrode coatings using ionic liquids derived from this foundation. Real-world R&D now chases after biotech and environmental cleanup, measuring the salt’s breakdown pathways and long-term presence in soil or water. Some development programs aim at commercial scale synthesis, hoping to bring costs down further, opening new doors in energy storage and green chemistry.

Toxicity Research

Toxicologists dig into both acute and chronic effects of exposure to this chloride. Short-term tests point out irritation on skin and mucous membranes, making good PPE and prompt cleanup essential in every lab. Researchers push further with bioassays on aquatic life, since some ionic liquids don’t break down easily and can build up in the food chain. My own reading of industry and academic results shows gaps in knowledge, especially in understanding what long-term trace exposure does to complex ecosystems. Regulatory agencies look to close these gaps, calling for standardized reporting and more transparent data sharing on lab accidents—both for workers and environmental safety.

Future Prospects

1-Butyl-3-ethylimidazolium chloride lines up for a long future, especially as the world pivots toward cleaner and safer chemical technologies. If production costs drop further, more manufacturers could shift away from hazardous solvents toward ionic liquids. The drive to electrify transportation and expand renewable energy storage also connects to innovations in battery electrolytes based on this salt. At the research frontier, molecular engineers might keep adjusting the imidazolium core to squeeze out extra performance, looking at improved recyclability or lower toxicity. As green chemistry takes stronger hold in regulations and lab culture, the value and versatility of this compound only look set to grow.

Opening Up Chemical Doors

Chemistry has always fascinated me for how it sometimes finds creative shortcuts to make tough tasks much easier. Take 1-butyl-3-ethylimidazolium chloride, for example. The name’s a mouthful, but the work it pulls off in the lab sticks out. This ionic liquid has turned into a bit of a star in research groups, factory benches, and even pilot plants because of its forgiving nature with temperature, salt, and water. I’ve spent years messing around with solvents, and you rarely find something that juggles so many tough jobs at once.

Solvent for Cellulose and Biomass

Every time scientists hit a wall with cellulose’s stubborn structure, this ionic liquid slides in to help. Regular solvents give up, but 1-butyl-3-ethylimidazolium chloride can break up cellulose straight from untreated plant material. This trick matters for biofuels and biodegradable materials. By dissolving tough plant fibers, this chemical opens the door to making fuels, plastics, and even textiles from things like straw or sawdust. In my old lab, we struggled with dissolving raw cellulose. When we switched to this ionic liquid, we stopped wasting weeks on endless pre-treatments. I saw first-hand how a single compound can clear bottlenecks in renewable chemistry.

Catalyst and Reaction Medium

Lab notes from universities and companies both keep circling back to 1-butyl-3-ethylimidazolium chloride as a reaction medium. It’s not just about dissolving things—it changes how molecules move and bump into each other. For certain organic reactions, like alkylations or couplings, this chemical creates a friendlier playground for atoms. Because it holds both positive and negative charges right in one molecule, it often removes the need for extra salts or additives.

Since I started out testing simple organic reactions in glassware, I noticed fewer headaches and higher yields by swapping out traditional solvents for this one. It keeps air and moisture troubles at bay. That’s a rare find in practical chemistry, where humidity and sloppy seals mess up results.

Separation and Extraction Processes

Every lab or plant that handles metals or organics eventually faces the tedium of extracting something valuable from a mess of leftovers. The rise of ionic liquids such as this one boosted new forms of separations—metals, drugs, even dyes. In many cases, 1-butyl-3-ethylimidazolium chloride lifts out heavy metals from waste streams, just by convincing the metal ions to leave an aqueous phase behind. I once watched a wastewater treatment pilot reclaim nickel and copper faster than older systems, just by adding this liquid and spinning it in a centrifuge.

Challenges and Ideas for Progress

Any tool with as much promise as this also creates worries. Ionic liquids don’t break down in the environment like water or alcohol. Researchers, including myself, have spent long hours sketching out safer ways to reuse or recycle them. Some teams have found that immobilizing them on surfaces or inside membranes makes cleanup less of a chore. Others are investing effort into designing new ionic liquids with gentler lifespans.

Another angle comes from optimizing how much of this chemical gets used in each process. By dialing in exact amounts or pairing it with renewable feedstocks, labs find ways to cut waste. The challenge lies in making scalable changes rather than sticking with small, batchwise fixes. Whenever I’ve seen industry and academia talk, the most excited voices always push for reusability, cleaner production, and easy recovery.

One thing is sure: tools like 1-butyl-3-ethylimidazolium chloride push science forward, but they also demand responsibility. Solving big problems often means refining these tools until nature can keep up with our curiosity.

A Real-World Look at a Lab Chemical

1-Butyl-3-ethylimidazolium chloride pops up in labs that push boundaries with new solvents. Chemists like myself often see it on shelves with other so-called ionic liquids—the kind used for their low volatility and high thermal stability. You might think a compound with a long name like this would command careful thought. Experience teaches me it does. Safe handling is not just about ticking boxes during safety orientation.

The Risks in Plain Terms

Just because this compound doesn’t boast a skull-and-crossbones label, that doesn’t mean it’s totally benign. Some ionic liquids have drawn attention for possible toxicity—even at low levels. The chloride component can trigger corrosive effects if it lands on bare skin or comes into contact with eyes. People with sensitive skin often notice irritation after touching even small drops that splash during routine pipetting. It’s tough to remember how often skin oils and micro-scratches become a pathway for lab chemicals.

This compound isn’t known for inhalation hazards under normal storage, but working in a warm, poorly ventilated room can change things quickly. Vapors rise if someone spills it or heats it for a reaction. Personally, I’ve seen enough chemical burns and allergic reactions over the years to adopt the habit of using gloves any time containers open. That’s not paranoia—it’s a respect learned from seeing what skin contact with ionic liquids can do.

Precautions That Work

Gloves are a must. Not thin garden ones, but nitrile gloves—the kind that sits snug and doesn’t let liquids seep through. Some colleagues double up if a session runs long. Goggles stay nearby. People skip those at their own risk, but after dealing with one emergency eyewash drill too many, I keep them on anytime bottles open. Lab coats protect against accidental spills that run down the sleeves or splash onto regular work clothes.

Ventilation matters more than most people appreciate. I learned early, working under strong fume hoods trumps breathing in unknown vapors. The main reason—some solvents with similar chemical structure can trigger headaches or even long-term health effects. Cleanup after spills involves more than a paper towel: absorbent pads, followed by approved disposal ways for any waste.

People storing 1-butyl-3-ethylimidazolium chloride keep tightly sealed bottles, away from heat, in places with clear chemical signage. Dry areas work best, since water can speed up reactions that make the mixture more corrosive. Sticky residue on gloves signals poor technique. Good labs put eye wash and safety showers in traffic areas, not tucked in some storage closet. Easy access encourages people to actually use them if things turn bad.

Safer Labs by Design, Not Accident

Clear labeling, strong training, and a culture that takes safety drills seriously—these build confidence with challenging chemicals. I’ve guided younger chemists through slow and steady lab technique. One slip-up teaches lessons that textbooks skip. There’s value in knowing exactly what’s inside a bottle and having real steps for accidents. Regulatory agencies track evolving science on toxicity, so staying updated on new guidance helps everyone avoid unexpected harm.

Any time new technology brings a fancy reagent into play, like 1-butyl-3-ethylimidazolium chloride, safety sits front and center not because it’s trendy, but because those lessons are learned up close, often the hard way.

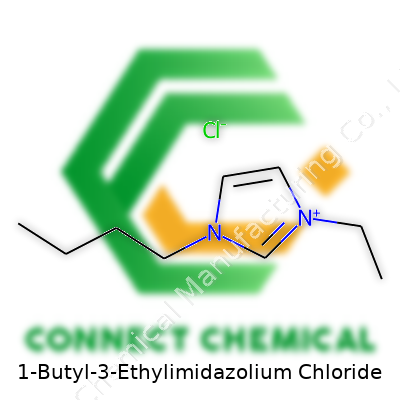

Looking at the Structure

1-Butyl-3-Ethylimidazolium Chloride, usually written as [BEIM]Cl, catches a chemist’s eye because of its unique makeup. Its chemical formula comes to C9H17ClN2. You start with an imidazolium ring—a flat, five-sided affair that carries two nitrogen atoms in its framework. Chemists attach a butyl group to one nitrogen atom and an ethyl group to the other nitrogen. The setup brings a flexible, almost tail-like butyl chain and a shorter, punchier ethyl chain—very unlike what you see in most simple salts. The chloride ion hangs outside this organic structure, drawn in by the charge difference but not covalently bound.

Why This Structure Matters

This compound isn’t just a stack of atoms. The imidazolium center allows the molecule to act as an ionic liquid at room temperature. That means it doesn’t look or behave like table salt lying in a pile. It brings low melting points, sometimes even below room temperature, and keeps a liquidity that makes it a favorite in labs. The structure allows easy dissolving of organic compounds and a pretty wide range of inorganic substances, including metal salts.

I worked in a chemistry lab that needed a stable, low-volatility solvent able to handle sensitive reactions without catching fire or evaporating away. Most organic solvents have flammable tendencies or strong, headache-inducing odors. Every time we cracked open a bottle of [BEIM]Cl, the lab stayed much safer and cleaner. Its viscosity takes some time to get used to, but it makes up for that by not dissolving plasticware or fogging up the air with toxic fumes.

Real Benefits—Not Just for Scientists

Beyond the structure, the real draw comes in what [BEIM]Cl can do. Researchers turn to this compound for its ability to dissolve cellulose, which opens up environmentally friendlier ways to work with plant fibers. Textile processing, wood pulping, and even battery development use ionic liquids exactly like this one to reduce reliance on harsh chemicals. I’ve seen teams run electrodes in these media without watching their results degrade, since the imidazolium chloride bath resists breaking down under electrical current.

Tackling Some Drawbacks

As much as I appreciate [BEIM]Cl’s upsides, making and disposing of ionic liquids asks for care. Waste streams, if not handled properly, risk harming waterways and soil. Manufacturing the compound itself pulls in non-renewable materials and can create byproducts in need of careful disposal. These issues aren’t someone else’s problem. Labs, factories, and universities need strict, upfront waste protocols and recycling programs. Switching to green synthesis routes—using less energy, making fewer toxic leftovers—offers a real step toward sustainability. Researchers are chasing these goals by exploring less inherently toxic ionic liquids and recycling spent compounds instead of throwing them away.

Looking to the Future

The chemical structure behind 1-Butyl-3-Ethylimidazolium Chloride isn’t simply clever molecular architecture. It stands as an example for chemists hunting better solvents, cleaner manufacturing, and new ways to process materials. I expect future students and professionals to build off this foundation, setting cleaner trends with the lessons learned from both its breakthroughs and its limitations.

Understanding Why Storage Matters

1-Butyl-3-Ethylimidazolium Chloride comes up often in laboratories focused on catalysis, battery research, or green chemistry. Anyone who has handled specialty chemicals knows how a lapse in storage methods results in more than just wasted product—safety often takes the hit. From personal experience, overlooking proper storage guidelines costs both time and money. It pays to get it right from the start.

Recognizing The Risks Involved

This ionic liquid holds several perks over traditional organic solvents. It's less volatile, meaning it won’t evaporate away on a warm day. Still, some might get a false sense of security and leave it out on an open bench for “just a few days.” Don't. Moisture spells trouble in ionic liquids, and this one is no different. If you leave it open to air, especially in a humid lab, you’ll probably notice clumping or discoloration. That sign says the chemical has absorbed water from the environment. Even small amounts undermine purity and affect future experiments.

Choosing The Right Container

Forget using thin polyethylene bags or lightweight vials—glass or high-quality plastic containers seal out air and moisture much better. A screw-cap bottle with a PTFE liner does a solid job. In one project, we reused a poorly capped bottle for a supposedly dry ionic liquid and spent days troubleshooting wonky results before realizing atmospheric moisture had crept in. There’s no shortcut here. Take the time to check the seal.

Temperature Really Matters

Ionic liquids typically don’t freeze until you hit pretty low temperatures, and they rarely boil off at room temp. Still, heat changes their chemistry. If storage happens in a hot storeroom, breakdown or impurity buildup increases. Most reference data, including the safety data sheet for this compound, points to storage at room temperature, ideally in a dry cupboard away from direct sunlight or heat sources. During summers, I’ve seen labs move their collection of ionic liquids to interior closets just to avoid the effect of sunlight through a window.

Keep Water and Acids Far Away

Mixing with water, even in the atmosphere, often creates a headache. I’ve been in labs where cross-contaminating chemicals led to weird colors or smells popping up overnight. In worse cases, acids sitting on the same shelf cause corrosion of the lids; it’s smart to keep reactive chemicals fully separated. Any acid vapors or traces of moisture could compromise not just one bottle but an entire shelf of chemicals.

Track Shelf Life, Not Just Storage

Some people think ionic liquids “last forever.” Over the years, I've learned otherwise. Write the date on every container as soon as it comes in. Check for shifts in color or viscosity every month or so. If you start seeing crystals, especially along the rim, it’s time to run a purity check or replace your stock. Making a habit of labeling and regular checks saves much bigger hassles down the line.

Safer Storage Means Smoother Research

Chemicals like 1-Butyl-3-Ethylimidazolium Chloride make it possible to push into exciting areas of electrochemistry and synthesis. Their perks only shine when storage is handled with care and thoughtfulness. Think beyond the manufacturer’s label—treat each container with the respect you’d give your most valuable equipment. In the end, every researcher benefits from a chemical shelf that’s dry, organized, and as cool as the science that happens nearby.

Why Purity Means More Than Just a Number

In chemistry circles, talk about 1-butyl-3-ethylimidazolium chloride (BEIM-Cl) mostly revolves around purity. No two labs work quite the same, but just about anyone who handles this ionic liquid keeps an eye on purity levels. A product clocking in at 98% or even 99% purity might look nearly spotless, but even that one percent makes a world of difference for solvents, electrolytes, or catalysts. If you’re mixing for battery research, surprise traces from a lower grade can sideline an entire round of results. Working on enzyme applications myself, I learned the hard way that contaminants—even in slivers—skew activity measurements, or worse, shut down reactions altogether.

Producers know this, so purity is usually backed up by documentation. Certificates of Analysis with details like water content and impurity profiles show that suppliers aren’t just guessing. Analytical data from trusted labs, such as from C NMR or HPLC, helps keep everyone honest. While government regulations for lab chemicals push for transparency, it’s clear that once you move closer to pharmaceutical or food applications, purity specs only tighten.

Packaging Choices Shape Handling and Storage

I’ve worked with chemical vendors who send BEIM-Cl in everything from crinkly 100-gram foil sachets to sturdy plastic containers holding a full kilogram or more. Each type serves its own purpose. Lightweight sachets make sense for small-scale experiments or quick screening. It’s less exposure to air and moisture, which matters because ionic liquids can pull in water from the air. For kilo-scale reaction runs, you need something tougher—tightly sealed HDPE jars or amber glass bottles, sometimes double-packed to cut down on light exposure and keep the product dry.

Bulk buyers—think pilot plants or companies running larger processes—often bring up custom drums and lined carboys. There’s a practical reason for it. Transferring from a drum means fewer chances for product loss and less contamination from handling. During my time setting up a pilot reactor, we chose drum packaging with a nitrogen blanket. That extra step kept the product in shape for weeks, not days, and made the folks on quality control relax their shoulders a bit.

The Real Costs of Getting it Wrong

Anyone who’s ever had to return a poor-quality batch knows lost time grates on everyone. A purity level that matches your process saves money in the long run—there’s less cleaning out reactors, fewer repeat tests, and better results with sensitive syntheses. For businesses, repeat purchases depend on reliability. I’ve seen academic labs shift suppliers just because one outfit let water seep into the bottle. Small flaws add up, especially when you deal with compounds like BEIM-Cl that end up in specialty batteries, extraction systems, or green catalysis.

Better Sourcing for Better Outcomes

Getting the right BEIM-Cl starts with direct questions to your supplier. Ask for specs, certificates, and storage methods. Seek documentation that proves minimal water and organic contaminants. For long-term storage, keep containers sealed tightly and, if possible, work under inert gas to keep moisture at bay. Engage with suppliers willing to discuss custom packaging, especially for odd-scale projects or sites with storage quirks.

Purity and packaging aren’t just technical specs—they shape every step from the first mix to the last cleanup. A good supplier answers tough questions without flinching, and that peace of mind goes a long way when your research or production line demands consistency.