1-Butyl-3-Methylimidazolium Acetate: A Close Look at a Modern Chemical Workhorse

Historical Development

1-Butyl-3-methylimidazolium acetate didn’t just appear overnight in labs and factories. Traditional solvents were the norm for centuries, but the hunt for safer, more sustainable chemical processes pushed researchers to look for alternatives in the late 1990s. Imidazolium-based ionic liquids, including this acetate, answered that call because of their low volatility and ability to dissolve all sorts of substances. As demand rose for greener chemistry, scientists focused on modifying the imidazolium ring, attaching butyl and methyl groups to improve stability and handling, and settled on acetate ions for the right mix of chemical compatibility and biodegradability. By the early 2000s, these liquids started showing up everywhere research on biomass conversion, metal processing, and organic synthesis needed safer solvents.

Product Overview

1-Butyl-3-methylimidazolium acetate, often abbreviated as [BMIM][OAc], stands out among ionic liquids thanks to its excellent solvating ability, low vapor pressure, and straightforward synthesis. Its clear appearance hides a dense, viscous liquid that can replace traditional volatile organic compounds, helping companies cut hazardous emissions. From a consumer perspective, it’s more about what this chemical allows: dissolving stubborn materials like cellulose, extracting bioactive compounds, or serving as a safer electrolyte in energy storage systems. Instead of sticking with fossil-derived, flammable solvents, chemists and engineers pick up [BMIM][OAc] because it makes tough chemistry happen without as many health or environmental headaches.

Physical & Chemical Properties

Pour out a sample, and you’ll notice the viscosity. It flows a bit like honey at room temperature, with a very mild odor (sometimes slightly sweet due to the acetate). Its melting point usually sits just below room temperature, so it’s a liquid in most lab and shop settings. Water mixes with it in all proportions, making cleanup and dilution a simple affair. The chemical's negligible vapor pressure means no real risk of inhalation from evaporation under typical handling conditions. Chemically, the imidazolium cation stabilizes a wide range of ionic species, while the acetate part offers basicity useful in biomass deconstruction and catalysis. Stability under both acidic and mildly basic conditions makes it valuable in processes where pH jumps around.

Technical Specifications & Labeling

Look at any typical product spec sheet, you’ll find purity levels keyed to the intended purpose—often upwards of 98% for research or high-grade industrial applications. Moisture content stays below 0.5% thanks to careful packaging and storage under dry nitrogen. The label also demands attention for its chemical stability and advice on storage temperature, usually advising a dry, cool place and airtight containers. Containers themselves need chemical resistance—high-density polyethylene works well. Material Safety Data Sheets provide handling instructions, eye and skin protection guidance, and spill protocols, reflecting a cautious approach found across responsible chemical manufacturing.

Preparation Method

To produce 1-butyl-3-methylimidazolium acetate, start with 1-methylimidazole and react it with 1-chlorobutane through a straightforward alkylation. The product, 1-butyl-3-methylimidazolium chloride, then undergoes anion exchange—typically with sodium acetate—yielding the acetate version as a viscous ionic liquid. Layer separation or solvent extraction purifies the liquid, and rotary evaporation removes traces of unwanted side products. Each step demands control over moisture and temperature: water can hydrolyze or contaminate the ionic liquid, so the process runs under dry conditions. Final purification may include activated charcoal treatment and filtration to produce a clear, high-purity product ready for storage or further synthesis.

Chemical Reactions & Modifications

[BMIM][OAc] does more than sit around as a passive solvent. The acetate ion acts as a mild base, making it especially handy for breaking down biomass and enabling transformations that struggle in regular water or alcohol. In the world of cellulose, the acetate serves to attack hydrogen bonds between polymer chains, making recalcitrant plant matter dissolve and break apart for biofuel production or chemical feedstocks. The imidazolium ring resists degradation but can participate in ionic exchanges or even functionalization to tailor the liquid’s reactivity for special purposes—like organic catalysis or extracting target molecules from complex mixtures. Heating under inert conditions brings out its full potential without fear of runaway decomposition or noxious fumes.

Synonyms & Product Names

In the chemical trade, [BMIM][OAc] pops up under a few aliases. You’ll see “1-butyl-3-methylimidazolium acetate” most often, but catalogs call it “BMIM acetate,” “BmimAc,” or “ionic liquid, imidazolium, C6H11N2O2.” Some European suppliers list it as “Butylmethylimidazolium acetic acid salt.” CAS number 284049-75-8 links all these names. Buyers need to keep an eye out, since quality and labeling practices shift between companies; always check the fine print for water and halide content if you need reliable, repeatable results.

Safety & Operational Standards

Even with its safety edge over volatile organic solvents, [BMIM][OAc] calls for respect in the lab and factory. Prolonged skin or eye contact leads to irritation, especially at higher concentrations or with prolonged exposure. Standard operating procedure involves gloves (nitrile lasts longest against its solvent powers), goggles, and well-ventilated workspaces—just in case accidents happen during the weighing or transfer. Spills wipe up with absorbent material, but waste needs its own label for safe disposal according to local and national codes. Companies train their teams on toxicity and handling because, while not as acutely dangerous as benzene or similar solvents, accidents or fire can produce irritating or corrosive decomposition products.

Application Area

Among ionic liquids, [BMIM][OAc] earned its stripes in cellulose processing first. Factories use it on pretreated wood chips to crack open cellulose fibers for paper and bioethanol production, slashing energy costs over steam or acid hydrolysis. Scientists use it in the lab to extract DNA, break down starches, or synthesize complex organic molecules in one vessel where traditional solvents fail. Battery designers spot its stability under electrical load, so it winds up as an electrolyte or electrolyte additive for prototype rechargeable batteries. In analytical chemistry, extraction of tricky pesticides or pharmaceuticals from soil and food samples gets a boost from [BMIM][OAc] thanks to its high affinity for polar and nonpolar compounds alike. Its compatibility with enzymes also lets it play a role in green catalysis and bioprocessing, opening new doors for sustainable manufacturing.

Research & Development

Labs and startups across the world work to improve every part of [BMIM][OAc] production and use. Some teams synthesize it with recyclable catalysts to cut residual waste, while others tweak the alkyl side chains or the anion to find more active, recyclable versions. Researchers keep an eye on environmental impact, developing breakdown pathways and recovery loops to prevent accidental release. Competitions for green chemistry prizes usually have a project or two based on ionic liquids that, like [BMIM][OAc], target efficient, high-yield chemical transformations without the emissions tied to benzene or toluene. Efforts from big names in energy and specialty chemicals show up in patents and pilot-plant data, where productivity and product purity dominate the discussion. Even the food industry is experimenting with its use in extracting natural flavors or nutraceuticals from plants, chasing ways to slash cost and waste at the same time.

Toxicity Research

You won’t find this ionic liquid on the list of everyday consumer products, and for a reason. Despite a generally favorable profile compared to old-school solvents, toxicity matters. Lab tests show that [BMIM][OAc] exhibits moderate acute toxicity in aquatic life—zebrafish embryos and algae, in particular, display sensitivity at higher concentrations. Human cell studies describe moderate cytotoxicity, typically in the 1–10 millimole range, well above typical exposure levels but still worth monitoring on the shop floor and in waste streams. Teams track how it breaks down; evidence points to slow degradation in the environment, urging producers and users to recapture and recycle spent liquid. Regular testing at discharge points, safety training, and closed-loop systems all play a part, since one leak or spill unchecked could undo years of sustainability gains.

Future Prospects

[BMIM][OAc] faces a bright future, but it’s not without obstacles. As new regulations limit emissions from chemical manufacturing, interest in non-volatile, recyclable solvents only grows. Research shows promising cost savings in pulp and biofuel industries, hinting at broader adoption if scale-up challenges get managed. Patents suggest tweaks to its structure or pairing with other green solvents to enhance performance or cut purchasing costs. As energy storage technology advances, the need for safer, stable electrolytes creates another market ready to embrace ionic liquids. Training new generations of chemists to handle these specialized materials safely, and creating robust recycling programs, will determine whether [BMIM][OAc] becomes a staple in manufacturing or remains a specialty tool for only the toughest jobs. Open collaboration between regulators, industry, and the academic community will shape just how far this versatile liquid goes—carving out uses in everything from medicine to materials science and keeping environmental costs in check as it does so.

The Role in Modern Chemistry

1-Butyl-3-methylimidazolium acetate sounds like something out of a hard-to-pronounce textbook. Behind the clunky name, it’s changing how chemistry gets done in labs and manufacturing floors. Most people walk past grocery shelves or drive past paper mills without realizing ionic liquids like this one are shaping the background. It’s not a household chemical, but it’s picking up fans among scientists and engineers because it solves a stubborn problem: dissolving stuff water and common solvents just can’t touch.

Breaking Down Biomass Barriers

Breathe in next to a field of corn or poplar trees, and you’ll see plants packed with cellulose, hemicellulose, and lignin. These are tough molecules—great for making plants stand up to weather but a headache when trying to make renewable fuels or bioplastics. Most solvents struggle with these plant bits, so companies searching for eco-friendly materials face a big roadblock. Here’s where 1-butyl-3-methylimidazolium acetate impresses. It sinks right into those tangled plant fibers, breaking them down much faster and more completely than old-school methods. A team at the Joint BioEnergy Institute proved this by using the liquid to dissolve up to 50% of raw biomass, which helps convert waste into sugars for fuels. Instead of tossing corn stover or sawdust, projects can tap into these leftovers and turn them into value.

A Promise for Greener Manufacturing

Besides busting apart biomass, this ionic liquid is turning heads in the paper and textile world. Wood pulping uses massive amounts of water, strong acids, and a trail of chemicals needing cleanup. 1-butyl-3-methylimidazolium acetate steps in and trims the step count. It pulls cellulose from wood or cotton using relatively mild conditions, cuts waste, and slashes the need for harsh toxins. Several Scandinavian mills invested in technology carrying this liquid, aiming to meet green targets and cut costs. While setting up these processes isn’t cheap up front, the lower waste bill and rising demand for clean-label products make it worth the trouble for forward-thinking factories.

Helping Chemists Work Smarter

On the research side, chemists ran into headaches with classic solvents—many were flammable, toxic, or just didn’t play well with sensitive ingredients. The acetate-based ionic liquid skips the flames thanks to a low vapor pressure, hardly smells, and holds up under heat. Researchers in pharmaceuticals, paints, and coatings run delicate reactions in it, often getting purer results or using fewer steps. Instead of dealing with barrels full of waste, labs can recover and reuse the liquid, fitting the push for cleaner, circular chemistry. This cuts costs and lowers risks for workers. With Europe’s REACH rules clamping down on hazardous solvents, tools like this liquid give companies a lifeline to keep producing safely.

Challenges and Where to Go Next

No story ends at easy wins. Producing 1-butyl-3-methylimidazolium acetate takes real energy, and nobody likes chemicals drifting out into the world unchecked. Over the past decade, industry watchdogs flagged the need for strict handling and proper recycling. Green chemistry experts agree: it’s better than burning through barrels of solvents, but not a free pass. I’ve watched several university labs set up robust re-purification stations to tackle this—less landfill waste means less public worry and smoother compliance down the road.

Final Thoughts

From farm waste to high-value products, this chemical unlocks doors that used to stay closed. It doesn’t solve every problem, but for companies and researchers pushing for greener, faster, cleaner results, it’s a step in the right direction. With the right attention to recycling and safety, it could anchor the next wave of sustainable industry.

Learning From Real-Life Lab Work

I grew up in a family that ran a chemical cleaning company. Things like gloves and careful storage were burned into my memory before I was tall enough to grab a lab bottle off the shelf. Years later, working with chemists in academic settings, I learned that not all chemicals get the respect they deserve. 1-Butyl-3-Methylimidazolium Acetate is a mouthful. It lives in the crowded world of “ionic liquids,” those fancy chemicals that don’t act like water or oil. They dissolve cellulose, power up green chemistry work, and make modern synthetic chemistry faster and cleaner on paper.

People often call it “bmim acetate.” Despite its reputation as a safer, less-volatile alternative to traditional solvents, that bottle still deserves a cautious approach. Every chemical has risks, and experience shows that even those labeled “green” have their trade-offs.

Facts That Matter, Not Marketing Hype

Let’s clear away the buzzwords. Most safety data sheets for bmim acetate flag it as an irritant. The eyes, the skin, the lungs can all get hit if you’re not careful. It won’t catch fire easily like ether, but skin exposure sometimes leads to rashes or a burning feeling. If you get a big enough splash, expect a trip to the eyewash station or an urgent shower, hoping the sleepless night ahead is just paranoia and not the start of an allergic reaction or worse.

There aren’t decades of poison control data for this chemical. Regulatory bodies like the European Chemicals Agency highlight “may cause skin and serious eye irritation.” Short-term exposure usually won’t kill you, but chronic risks rarely show up until workers have been around years. Some researchers worry about inhaled vapors in warm labs, especially in tight spaces without good air flow.

Hard Lessons in “Safe Enough”

Companies push bmim acetate for reducing hazardous waste. That’s a good goal, but it sometimes tricks teams into lowering their defenses. I’ve watched people wipe up spills with bare hands or work without fume hoods, just because they read the label wrong or trusted marketing copy. Most ionic liquids don’t have enough study history to fully trust. Even if a product isn’t listed as a carcinogen or mutagen yet, nobody should assume it’s harmless.

Much like some early solvents once hailed as miracles, enough use can turn up surprises. Environmental scientists worry about ionic liquids breaking down outside the lab. Few can answer what these chemicals do in rivers or with microbes. Once disposal leaves your site, you lose control. In one story I remember, a poorly trained intern wiped down a bench after a spill and went home with red, itchy hands that needed a doctor’s visit. That cost the lab time, money, and a fresh look at protocols.

Smart Steps: Real Protection, Not False Comfort

In practice, nitrile gloves and safety glasses belong on every workbench with bmim acetate, no excuses. Stick with good ventilation or fume hoods. Store it tightly closed in labeled containers, far away from food, skin lotions, or drink bottles. Everyone in the lab should know the exact first aid steps, because a single day’s careless rush can haunt you.

Nothing beats teaching new team members to read labels, respect even the “greener” chemicals, and slow down. The science says bmim acetate isn’t as volatile or flammable as old-school solvents, but it isn’t water, either. Every fieldwork veteran has their own close call story. Most would say: use it, but don’t treat it like soap and water. Listen to experience, not just labels.

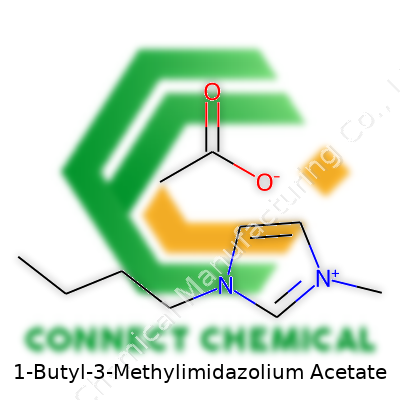

Getting to Know the Formula

1-Butyl-3-methylimidazolium acetate carries the formula C10H18N2O2. It’s an ionic liquid, one of those modern chemicals that show up across a growing range of research and industrial settings. The cation part, 1-butyl-3-methylimidazolium ([BMIM]+), is joined with the acetate anion ([OAc]-). These two pieces work together to form a salt that’s liquid at room temperature.

Why Ionic Liquids Spell Opportunity

Traditional solvents like chloroform or toluene get a lot of flak for being volatile and sometimes hazardous. Time in the lab has shown me how quick spills and vapors can cause headaches—not just literally, but for health, safety, and waste disposal too. By contrast, ionic liquids such as 1-butyl-3-methylimidazolium acetate hardly evaporate, giving a chance to cut exposure and environmental impact. This specific ionic liquid dissolves cellulose, something standard solvents cannot handle without heavy-handed chemistry. For anyone who’s tried to break down plant waste or recycle paper, that’s a real breakthrough.

Real-World Applications Are Already Here

There’s been a lot of buzz about using this compound for making biofuels, especially by treating raw plant material so enzymes can break down tough fibers more easily. Industries trying to ditch petroleum-based solvents see 1-butyl-3-methylimidazolium acetate as a window to greener processing. Textile recycling, pharmaceutical synthesis, and some battery technologies are all actively testing this liquid for newer, cleaner pathways.

Challenges Don’t Get Swept Under the Rug

Green chemistry often comes down to more than just swapping one solvent for another. I’ve seen costs for ionic liquids stretch budgets, especially when large-scale purifications get factored in. The full story on toxicity isn’t written yet, either. Some ionic liquids linger in water or soil, and breaking them down completely can be tough. Without reliable recycling and disposal strategies, promising a green future feels empty.

What Works? Practical Solutions

Clear labeling and safety data for every new batch form the backbone for working safely with chemicals like this one. I always look for robust reporting from reputable sources, with transparency around purity, ecological risks, and recycling techniques. Investment in closed-loop systems—where solvents like 1-butyl-3-methylimidazolium acetate get captured and reused—keeps waste low and reduces fresh demand. Educational outreach, so every chemist and operator understands what these liquids can and cannot do, gives much better results than relying on marketing promises. Research into biodegradable analogs that mimic its performance but break down in nature deserves more funding.

Trust Earns Its Place

Deciding to swap out harmful solvents for something new isn’t about hype. It’s about looking at research and real outcomes. Using the right chemical formula—C10H18N2O2—as a standard proves critical for consistent, safe, and meaningful results. Ensuring high standards and honest data brings better science and a cleaner world within reach.

Recognize What You're Dealing With

Some chemicals have a reputation that sends people looking for their thickest gloves and a safety shower in every corner. 1-Butyl-3-Methylimidazolium Acetate isn’t out to get you, but that doesn’t mean you should drop your guard. This compound falls into the family of ionic liquids—generally stable, not eager to evaporate, and much less flammable than the volatile solvents that clutter up so much of chemistry. I've always felt more at ease around these than flammable organics, but it’s easy to forget that even if something isn’t highly toxic or explosive, neglect brings its own set of troubles.

Watch the Water

This liquid attracts water from the air like nobody’s business. Leave a bottle open longer than you meant, and you’ll find its weight creeping up. Too much water can change the way this ionic liquid behaves in a reaction, in a battery, or wherever someone plans to use it. In my experience, storing it with a tight seal keeps things simple. During busy weeks, I mark new bottles with the date and pull out what I need for the next few days. Stubborn humidity in a storage room can turn reliable chemicals into headache material, so humidity control isn’t just for climate nerds—it's basic good practice.

Skip Sunlight and Heat

If I could give one rule for most specialty chemicals, it’s this: keep them cool and out of direct light. Sunlight just doesn’t do weird molecules any favors, and it might nudge 1-Butyl-3-Methylimidazolium Acetate into slow decomposition over time. Getting careless with temperature shortens shelf life, and every wasted bottle cuts into budgets. That’s not just theory—I've seen degraded samples throw off experiments and waste weeks of work. Nobody wants to chase invisible problems that started in the storeroom, not the lab.

Keep the Container Clean—and Labeled

Contamination comes more from old habits than evil intentions. A sloppy scoop, a dirty spatula, or pouring leftovers back into the bottle—a few seconds saved at the bench can mean months lost troubleshooting. Old tape labels and mystery stains don’t inspire confidence, either, so swapping to a fresh vial and clear labeling always pays dividends. I’ve had to sort out the aftermath of a “mystery bottle” mix-up before, and writing up incident reports never gets any more fun.

Take Safety Seriously, Not Solemnly

Ionic liquids rarely catch fire and carry a lower risk to lungs compared with traditional solvents, but that’s no invitation to toss out goggles and gloves. Spills stay sticky. A slip on the floor or a little on your skin still means it’s time for soap and water. Safety data sheets spell out simple precautions—gloves, lab coat, goggles, a bit of respect. On days when distractions run high, it’s worth having a reminder printed up where everyone sees it.

Practical Solutions Make for Fewer Headaches

A storage routine that works in a school won’t always fit a full-scale lab, but a few standards go a long way. Sealed bottles, a cool room, minimal light, clear records of what comes in and goes out. For groups with heavy turnover, keeping an inventory log—digital or a battered notebook—keeps confusion down and accountability up. I’ve worked in labs that ran out of stock simply because no one checked; I’ve also seen thousands wasted on ruined chemicals stored the wrong way. It feels like a small thing until you count the cost of the alternative.

Bottom Line

1-Butyl-3-Methylimidazolium Acetate doesn’t want to be your enemy. Treat it with the respect good lab practice demands—clean, cool, dry, dark, labeled—and it’ll do its job without surprises. A little prevention always beats cleaning up a mess that started in storage.

What It Looks and Feels Like

1-Butyl-3-Methylimidazolium Acetate doesn’t turn heads in a lab based on color—it’s a clear liquid, a little thicker than water and not all that flashy. This transparency tells you a bit about its purity and why scientists like using it for delicate procedures. The density lands around 1.07 to 1.10 grams per cubic centimeter; that means it’s heavier drop for drop compared to water but doesn’t feel syrupy or sticky between the fingers.

Melting and Boiling Without the Drama

It stays liquid at most room conditions, only turning solid below about -20°C. In places where winters don't freeze pipes, chances are this ionic liquid won’t freeze either. Trying to boil it away isn’t like working with ethanol or acetone—it barely budges until you push it over 200°C. Instead of fizzing off into vapor, it tends to break down chemically before producing much steam, which tells you boiling isn’t the right play if you ever try to remove it from a mixture.

How It Mixes and Moves

Pouring this stuff into another solvent gives you clues about its loyalty. It mixes easily with water and even with some polar organic solvents, but it snubs many oils and straight-chain hydrocarbons. This comes from its roots: ionic liquids by nature prefer to keep company with things that have charges or partial charges. Working with it, you notice its viscosity—thicker than water, for sure, but not as sluggish as honey. At room temperature, moving a stirring rod through it offers gentler resistance, kind of like half-and-half cream.

Smell, Toxicity, and Safety

Open a bottle, and you won’t gag on harsh fumes. You might sense a faint vinegar note, owing to the acetate group. It’s surprisingly low on volatility, which means fewer worries about breathing in dangerous levels under normal lab work. Studies point to respectable stability at moderate temperatures. Still, skin contact or eye splashes call for caution because the same properties that help it dissolve tough residues can irritate tissue. Details from peer-reviewed sources, like the Journal of Hazardous Materials, remind researchers to glove up and shield eyes for safety.Many ionic liquids get the “green solvent” tag, and this one often gets mentioned for being easier on the environment than classic chlorinated solvents. Though generally safer than some toxic predecessors, I’ve always leaned on good ventilation and used lab coats when working with even “green” substances.

Why These Details Matter Outside the Lab

Getting a handle on these physical properties doesn’t just help chemists. The thick, yet flowing texture makes it popular for breaking down tough plant fibers or dissolving cellulose, turning what would have been waste into biofuels or new materials. The low vapor pressure holds big promise for workers—less evaporation means safer, cleaner air, and reduced chemical loss over time.

Solutions still matter in industrial handling. Keeping the material uncontaminated, properly labeling storage bottles, and managing waste with local environmental agencies could curb accidental release. As companies look for safer alternatives in chemical processing, keeping eyes on those melting points, vapor profiles, and mixing tendencies helps avoid hiccups and keep everyone safer.