1-Butyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide: Exploring an Ionic Liquid’s Impact

Historical Development

Long before labs buzzed with interest in ionic liquids, conventional solvents dominated industrial and academic work. In the late twentieth century, chemists discovered families of imidazolium-based salts that stayed liquid at room temperature. This pivoted green chemistry into public debate. 1-Butyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide, often called [BMIM][NTf2], emerged from this context, shaped by researchers racing to replace volatile organics and messy halogenated solvents. Early patents described electrolytes for batteries, extraction agents for rare metals, and solvents that could dissolve cellulose or enable new catalytic pathways. Significant papers in the 1990s and early 2000s—especially from groups in Europe and Asia—marked [BMIM][NTf2] as a key player in ionic liquid chemistry’s mainstream acceptance.

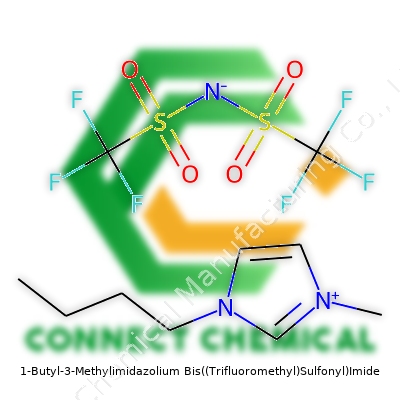

Product Overview

Commercial labs and suppliers recognize [BMIM][NTf2] by its clear-to-yellowish liquid form with faint odor and negligible vapor pressure. The salt blends a bulky cation—1-butyl-3-methylimidazolium—with a hydrophobic, charge-delocalized NTf2 anion. Chemists lean toward this product for its stability with both organic and inorganic compounds. Reliable suppliers, like Merck and Sigma-Aldrich, list it in technical and high-purity grades to suit work ranging from industrial extraction to fine organic synthesis. You will often notice product bottles tightly sealed, labeled with moisture-sensitivity warnings, and packed with meticulous handling instructions.

Physical & Chemical Properties

At room temperature, [BMIM][NTf2] presents a viscosity measured in centipoise, higher than water and common solvents—creating pump challenges in scaled processes. Its density hovers around 1.43 g/cm³. The melting point falls way below 0°C, so it remains fluid across most working environments. Ionic conductivity suits use in modern and next-generation batteries. Thermal stability exceeds that of many organic solvents, tolerating upwards of 350°C before decomposing. Water solubility is limited, though it absorbs some moisture over time, making careful storage a priority. Its chemical resilience resists nucleophilic and electrophilic attack, an attribute that finds value in labs seeking robust media for tough reactions.

Technical Specifications & Labeling

Reputable shipments of 1-butyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide include a suite of specs: purity (usually above 99%), water content (measured by Karl Fischer titration, target under 0.1%), residual halides, and batch traceability. Labels display the chemical formula (C10H15F6N3O4S2), molecular weight (419.36 g/mol), and safety symbols per GHS conventions—corrosive, irritant, and environmentally hazardous. Manufacturers provide Certificate of Analysis with each lot, allowing users to match precise requirements for research or production runs. Technicians familiar with custom labeling know the importance of expiration dates, batch numbers, and storage temperature ranges (store cool and dry, protected from light).

Preparation Method

Laboratories and manufacturers synthesize [BMIM][NTf2] through metathesis. They first produce the cationic precursor, typically 1-butyl-3-methylimidazolium chloride or bromide, by alkylating imidazole derivatives. Next, they react the salt with lithium or sodium bis((trifluoromethyl)sulfonyl)imide in water or acetonitrile, prompting the desired ionic liquid to separate into its own phase. Washing removes halide byproducts, leaving a viscous layer that undergoes vacuum drying. Some labs distill under reduced pressure to achieve even higher purity. This route, although efficient and scalable, reveals a key challenge for sustainability: reducing salt waste and improving recycling in batch or continuous systems.

Chemical Reactions & Modifications

[BMIM][NTf2] survives an array of reaction conditions that traditional solvents cannot handle. In my own work synthesizing organometallic complexes, this ionic liquid helped stabilize intermediates others simply destroyed. The imidazolium ring, though usually inert, participates in carbene chemistry at high temperatures—sparking interest for catalysis research. Modification of the butyl or methyl side chains leads to new ionic liquids with distinct properties. Chemists sometimes use [BMIM][NTf2] to mediate organic, polymer, and electrochemical reactions where solvent breakdown would otherwise derail sensitive projects. The NTf2 anion occasionally swaps with others in situ, expanding the toolbox for designers of custom fluids.

Synonyms & Product Names

Across chemical catalogs, 1-butyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide shows up under several guises. CAS registry number 174899-83-3 reliably points to it. Common abbreviations include BMIM-NTf2, [BMIM][TFSI], BMIM-bistriflimide, or just imidazolium NTf2. Labs sometimes refer to the salt as bistriflimide ionic liquid. Different suppliers attach their own brands, but the key lies in recognizing the cation-anion pair to avoid mix-ups with close relatives like BMIM-PF6 or EMIM-NTf2.

Safety & Operational Standards

Careful handling defines responsible work with [BMIM][NTf2]. Skin exposure can cause irritation, and spills feel greasy but, unlike many organics, rarely evaporate away. Contact with water increases corrosivity, and fire-fighting must use suitable foam or CO2, not water jets. Safety data sheets list appropriate PPE: gloves, goggles, lab coats, and fume hoods. Technicians transport the liquid in airtight containers, avoiding accidental release. Working under established protocols reduces risk—especially during large-scale syntheses where exposure or improper waste management pose real hazards. Disposal follows regional regulations, calling for classified hazardous waste collection to keep both workforce and environment safer.

Application Area

This ionic liquid turned heads in multiple industries. Battery makers value it for high-voltage stability in lithium-ion electrolytes, outpacing legacy carbonate blends. Metal extraction benefits from [BMIM][NTf2]’s selectivity for rare earths, while pharmaceutical labs explore its potential to crystallize and purify tricky compounds. In biomass processing, its ability to solubilize cellulose and catalyze conversions to value-added chemicals impressed green chemists working to advance circular economies. High-temperature reactions, such as alkylations or polymerizations, thrive in this medium, as thermal breakdown rarely stalls the process before the chemistry’s work is done. Electrochemical research and analytical labs both lean on it for steady state, low volatility, and tolerance of reactive environments.

Research & Development

Universities and corporate R&D centers chase improvements around [BMIM][NTf2]. Materials scientists test new electrolyte blends with custom additives. Green chemists push the limit on low-impact synthesis, aiming to reuse and recycle the ionic liquid in looped processes. In my experience, R&D hinges on both collaboration and competition. Funding streams from energy storage programs or sustainable manufacturing drive rapid innovation, pressuring chemists to report both successes and setbacks in public forums. The open literature now tracks research, from bench-scale recipes to data-driven property prediction. Digital labs and robotics platforms handle the labor-intensive optimization, expanding the impact well beyond individual labs to global trends.

Toxicity Research

Environmental impact stirs debate wherever large volumes of specialty chemicals flow. Toxicity studies for [BMIM][NTf2] show low acute toxicity to mammals at typical exposure levels, but concerns arise with chronic contact and environmental persistence. Ecotoxicity data point to harm for aquatic life even at low concentrations, tied to the stability of the NTf2 anion and poor biodegradability. My own teaching experience underscored the gap between academic curiosity and industrial responsibility: pilot plants and factories need rigorous risk assessments, full life-cycle analysis, and clear disposal protocols. Researchers continue mapping breakdown pathways and seeking green alternatives with similar performance but safer profiles.

Future Prospects

The push for sustainable chemical processes ratchets up the importance of robust, reusable solvents. More institutions favor ionic liquids like [BMIM][NTf2] for demanding catalytic systems, energy storage devices, and renewable material extraction. Forward-looking work targets new synthetic methods, smarter recycling strategies, and green degradation routes for the NTf2 anion. Startups scout for applications in separation science, carbon capture, and electroplating, betting that versatility in both lab and plant scales keeps demand steady. I see a growing role for hybrid technologies that combine ionic liquids with biobased solvents, advanced membranes, or digital process control—driving productivity and lowering footprints without sacrificing performance.

What This Chemical Brings to the Table

Stepping into a chemistry lab with a bottle labeled “1-butyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide” or BMIM-TFSI can raise eyebrows, especially for someone who rarely sees such a name. Yet, this colorless to pale yellow liquid silently makes breakthroughs possible across clean energy, manufacturing, and environmental science.

BMIM-TFSI comes from a class chemists call “ionic liquids.” Unlike table salt, which forms crystals, these stay liquid at room temperature. I watched researchers get downright excited by the possibilities. They pour it into a beaker without the plume of toxic fumes that follows most solvents. It does not catch fire easily, and it shrugs off moisture from the air.

Electrolytes Powering a Green Future

The push to ditch fossil fuels brought attention to batteries and supercapacitors. BMIM-TFSI moves up the list for labs hunting safer, more stable electrolytes. Its ions slide between electrodes with little resistance. Lithium-ion batteries and next-generation alternatives need stable electrolytes. Here, BMIM-TFSI offers an edge—resisting heat, helping devices last longer, tolerating tough charging cycles. Peer-reviewed data points to higher voltage windows and longer battery life. The fluorous sulfonyl group in this chemical helps block water, keeping performance steady even in less-than-ideal conditions.

This chemical also steps into supercapacitor tech, where fast charging and long lifespans matter. Traditional electrolytes wind up breaking down or causing fires. BMIM-TFSI sticks around, handling rapid charge-discharge routines without breaking a sweat. I’ve seen engineers mix it with different carbon-based electrodes, searching for combinations that yield breakthroughs for renewable energy storage.

Turning Tough Chemistry Into Child’s Play

BMIM-TFSI lands on the bench in research labs chasing green chemistry. Many organic reactions once relied on nasty, stinky solvents. This ionic liquid often swaps in for those, cutting down on hazardous waste. It dissolves a wide range of materials, letting chemists skip harsh acids or volatile organics for synthesis, purification, or extraction. Scientists in pharmaceutical and materials science have published studies measuring yields and product purity, showing that using BMIM-TFSI can simplify cleanup and reduce environmental strain.

Taming Industrial Giants

Some tasks look simple on paper—separating a metal from ore or cleaning up pollutants from wastewater. In practice, these eat up chemicals and make dangerous byproducts. BMIM-TFSI breaks new ground in extracting metals like lithium, cobalt, and rare earths, especially from recycled batteries and e-waste. Its stable ionic structure helps capture metals without forming stubborn solids or complex mixtures that chew up time and money. In the lab, soaking old catalysts or metal scraps in a solution of BMIM-TFSI makes recovery more efficient and safe.

Staying Alert to Health and Cost Concerns

No chemical stands above scrutiny. BMIM-TFSI looks safe compared to old-school solvents, but researchers keep a close watch on its fate in ecosystems. Mishandling this ionic liquid means environmental release or buildup over years. More data is streaming in, tracking its toxicity to aquatic life and soil microbes. Labs and companies turn to closed-loop systems to catch spills and recycle spent chemicals. Costs still squeeze small manufacturers. Synthesizing BMIM-TFSI isn’t cheap, so expanding its use outside the lab depends on cheaper production routes and effective recycling.

The Road Ahead

A mouthful of a chemical name hides a powerhouse for greener technology. Decision-makers, scientists, and engineers would do well to remember that practical chemistry keeps progress moving—not hype or wishful thinking. Whether charging an electric car faster or cleaning up waste without poisoning rivers, the molecules chosen today can shape our future.

Looking Closer at Ionic Liquids

More labs and manufacturers have started focusing on ionic liquids because these substances step away from the standard features of salts. Rather than forming rigid crystals, ionic liquids stay liquid around room temperature. This distinctive quality opens a lot of opportunities in research and industry. Over the years, I’ve noticed that researchers keep circling back to the same questions: what makes these liquids so special, and how can they push technology forward?

Physical Properties That Set Ionic Liquids Apart

It’s impossible to miss the way ionic liquids pour almost like syrup. Compared to water or even organic solvents, they show much higher viscosity. I remember working with one of these liquids in the lab: it took me twice as long to fill a test tube due to the thick, almost molasses-like texture. This matters, especially for industries that depend on rapid mixing or fast flow rates in equipment.

Density also stands out. Most ionic liquids weigh more per cubic centimeter than typical solvents. Drop-for-drop, they sink right to the bottom in a layered system. For separation techniques, this makes the job easier, especially when isolating products from reactions.

One of my favorite features is their thermal stability. Most common organic solvents begin to evaporate or break down if you heat them a bit. Ionic liquids resist this for much longer. This stability cuts down the risks in high-temperature chemical reactions, making them a safer choice for stubborn or heat-sensitive materials.

Ionic liquids also carry next to no vapor pressure. I’ve spilled a few drops on the lab bench, and they stick around until wiped up – never filling the room with fumes. This simple property goes far in reducing emissions of volatile organic compounds, a big step forward for workplace safety and regulatory compliance.

Chemical Properties That Matter in Real Applications

The makeup of ionic liquids throws together bulky organic cations with various anions. What always impresses me: you can change one or the other and get totally different properties. If your reaction needs more acidity, swap the anion. Need something more hydrophobic? Change the cation’s side chains. This versatility lets companies design solvents tailored to the trickiest tasks, like dissolving biomass for renewable chemistry or capturing gases in environmental technology.

Ionic liquids rarely spark unwanted chemical reactions with their surroundings; they’re stable against both acids and bases. During one project, I saw unexpected durability, even after heavy use with strong acids—something you never get with traditional solvents. This means equipment lasts longer, and fewer safety incidents slow down production.

Many ionic liquids dissolve salts, organic molecules, and even some metals, which opens doors for recycling rare elements or processing pharmaceuticals. And unlike water-based solvents, they won’t rust your equipment. This single advantage saves money for companies by stretching the lifespan of everything from pumps to vessels.

Challenges and Practical Steps Forward

Despite all their upsides, ionic liquids come with tradeoffs. Their higher viscosity slows some chemical processes. Price remains a hurdle, since making them on a large scale takes more effort than standard solvents. Disposal presents questions too, since long-term effects on the environment still need examination. A practical path forward means ramping up pilot projects, collecting health and environmental data, and investing in greener synthesis routes. By focusing on these gaps, researchers and companies move closer to unlocking the full promise of these fascinating substances for the next generation of technology.

Understanding the Chemical and Its Role

1-Butyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, or BMIM-TFSI, often shows up in research labs and advanced manufacturing facilities. You’ll spot it in batteries and some solar cells. The chemical world likes these ionic liquids because they don’t evaporate much, they’re good at dissolving complex materials, and they stay stable under pressure and heat. At the same time, not every scientist handling BMIM-TFSI has the same depth of information about its hazards as they might with better-known solvents.

Hazards from Personal Perspective

My background includes time spent in academic labs where ionic liquids like BMIM-TFSI got daily use. It’s not acutely noxious like old-school solvents such as benzene or chloroform. Nobody faints after smelling an open bottle. Still, the colorless liquid can creep onto skin or splash onto surfaces because it hardly gives off fumes, making carelessness easy. A few years ago, I learned just how unforgiving these liquids can be. Someone in the lab skipped gloves thinking a quick transfer wouldn’t matter. Within the hour, their hands itched and skin turned red. BMIM-TFSI passed right through, proving that just because it lacks a strong smell doesn’t mean it’s harmless.

Evidence Around Toxicity

Animal studies tell us BMIM-TFSI can cause irritation. European Chemical Agency records show eye and skin contact can spark inflammation and pain, though not severe tissue damage at low doses. Repeated exposure raises bigger red flags. The imidazolium part, when tested in labs, sometimes disrupts enzyme function or leaves damage in animal organs after prolonged exposure. BMIM-TFSI isn’t friendly to aquatic systems: even small leaks cause trouble for fish and water bugs. Looking at the whole picture, it doesn’t rise to the level of the deadliest industrial chemicals. Still, it doesn’t belong in the kitchen, or anywhere children roam.

Long-Term Concerns and Environmental Impact

Unlike something like ethanol, BMIM-TFSI hangs around. It doesn’t break down fast in soil or water, which puts stress on local plants and animals. Labs using it usually collect all waste for hazardous disposal by a registered waste contractor. Just pouring leftovers in a sink fouls up wastewater and eventually rivers. Photos of dead zones around chemical plants show the chain reaction that follows ignoring this. There are not many real-world accidents on record, thanks to its use staying mostly inside research sites, but the potential is there if rules slip.

Practical Protection and Safer Alternatives

Lab managers shouldn’t treat BMIM-TFSI differently from other hazardous solvents. Gloves, goggles, a working vent hood, and smart cleanup—those rules work. Product makers switching to more “green” chemicals often avoid this compound in consumer gadgets, keeping the risks further out of the average home. As research moves forward, safer ionic liquids with a lower biohazard footprint keep popping up.

Responsible Handling Supports the Future

What motivates me to follow good practice isn’t just personal safety. Protecting coworkers, the next person to use my cleaned-up space, and the world outside the lab walls stays on my mind. BMIM-TFSI, like any powerful chemical, deserves a steady hand and clear rules. For those pushing the frontiers of science, respecting these hazards means the breakthrough stays safe long after the first test tube gets washed.

Understanding Real Risks

Walking into a warehouse or even a regular garage, you can usually pick out a few things right away. That stack of fertilizer, those cans of paint, some cleaning chemicals pushed to the back. It’s easy to forget how quickly these ordinary products can turn dangerous if they go unchecked. Years loading trucks in summer heat taught me that even a half-empty bottle of bleach can mess up your day if it leaks. Unsealed lids, boxes shoved onto shaky shelves, or products in direct sunlight all make trouble grow fast.

Temperature and Climate Make a Difference

Most chemical and food products don’t handle heat or freezing well. That includes everything from garden weed killer to vitamins. Extreme temperatures eat away at packaging, spoil the actual contents, or build pressure that sends containers bursting open. Storing stuff off the ground on pallets, away from heaters and windows, gives products a fighting chance. Good air flow keeps humidity from turning powders into sludge or making cardboard soggy and weak.

Clear Labelling Saves Time and Trouble

Trained eyes always find the label before touching anything. Simple instructions like “Keep Dry” or “Store Below 25°C” can mean the difference between a usable product and a costly mess. I remember a pallet of adhesives shipped in with plain brown boxes—no labels, no warnings. Half the batch clumped together because it sat too close to the bay door under summer sun. Proper labelling stops people from guessing and keeps everyone safe.

Avoiding Cross-Contamination and Spills

Working with both food and industrial chemicals made it clear to me just how fast accidents spread. Keeping incompatible materials apart in sealed, clearly separated sections gives everyone peace of mind. Oil and acid products tucked together take only one slip to react dangerously. Drip trays and sturdy shelves cut down on leaks hitting the floor or soaking into packaging. Cleanups with the right gear—gloves, masks, and the actual absorbents called for by the product—lock down risks before they spread.

Training Hands, Not Just Eyes

Policies mean nothing without workers who know what they’re doing. Hands-on practice makes the limits of a product clear—what to touch, what to avoid, how to spot trouble early. A half-hour safety talk beats thousand-dollar repairs on ruined merchandise. If something comes with a safety data sheet, review it and walk through a real scenario: moving drums from storage, cleaning up a broken jar, checking worn-out labels. Peer-to-peer explanations stick better than posting rules on a corkboard.

Why It Matters to Real People

The effort put into safe storage and careful handling goes far beyond company rules or government checklists. It keeps people from breathing in fumes, suffering burns, or sending dangerous waste into sewers. Anyone working with products, hazardous or harmless-seeming, owes it to themselves and everyone around them to ask questions, report problems, and never cut corners. Protection gear, clean equipment, and secure shelving become habits that pay back every day, on every shift.

Practical Solutions That Work

Set up storage at the right height and away from sun or drafts. Use bins and secondary containers to catch leaks before they spread. Stay organized with updated inventory records so forgotten products don’t sit and degrade. Strong relationships between coworkers, supervisors, and safety teams keep communication open and turn every worker into a safety leader. It isn’t always about new technology or strict locks—basic respect for the task and those you work with matters most.

Pursuing Quality in Every Gram

In the world of chemicals, purity isn’t just a technical detail. A slight dip in percentage can send a lab project into chaos, turn a manufacturing batch into expensive waste, or throw off a researcher’s entire thesis. Anyone who’s handled analytical work knows what it feels like to pore over a certificate of analysis, sweating the decimals. Whether you’re setting up a synthesis for drug development or preparing a simple buffer, precise purity data gives you the ability to plan, adjust, and trust your results.

Most chemical compounds ship in purities reaching 98% or higher. Lab-grade options offer more reliability, but there’s always a tradeoff between cost and necessity. Sometimes 95% is enough for quick screening, but you’ll want 99% and above for pharmaceutical testing or critical electronics work. I remember days in a university lab chasing absolute purity. Impurities complicated every step, from separation processes to biological assays. One mistake with an off-purity lot meant starting over, with a lecture from a supervisor thrown in for good measure.

The Reality of Sourcing and Supply Chains

Many suppliers mark packaging as a selling point, but practical needs drive those choices. Tiny glass vials with a gram or less see use in academic circles and small startups. Five, ten, or twenty-five gram bottles hit the sweet spot for R&D. Larger operations—think pilot plants or established chemical manufacturers—prefer 100-gram or full-kilogram drums. Shipping and storage risk comes into play at scale. Strong packaging with chemical compatibility matters just as much as purity. I’ve received fragile ampoules wrapped in so much insulation it took a scalpel and steady nerves to access the compound.

Hazardous materials create even more restrictions. Some compounds degrade if they see daylight or moisture. Commercial suppliers step up packaging with amber bottles, vacuum-sealed bags, and nitrogen flushing. Years ago, we ordered a batch of highly sensitive organometallics. The bottles arrived double-sealed, encased in barriers to block oxygen. Any slip in packaging meant ruined product and safety headaches.

Putting Transparency First

Documentation can make or break a sourcing decision. I check for batch-specific purity data, clear identification of solvents or stabilizers, and full disclosure about additional ingredients. Without these, there’s no way to confidently set up protocols or troubleshoot issues. If I spot “trace impurities” on a datasheet, I’ll often reach out to the technical service team for specifics. They might provide a breakdown—sodium, chloride, unreacted starting material—which is better than going in blind.

Some vendors offer flexible sizing if the catalog options don’t fit. If an order for one kilogram exceeds safety requirements, I’ll ask for four bottles of 250 grams. This approach lessens the risk of losing all contents to spoilage and helps with inventory control. It’s rare to see such accommodations outside specialized suppliers, but the choice allows better planning.

Pushing for Improvement

Many labs and companies want more than the usual technical sheet. They look for certifications, traceability, and even sustainability claims, especially in regulated environments. Supply chain disruptions and quality scares have underscored the need for open communication from suppliers. For compounds used at scale, tighter regulations and clearer labeling need to become normal practice. End users deserve confidence in every bottle—large or small, high or standard grade.