1-Butyl-3-Methylimidazolium Dibutyl Phosphate: Modern Applications and Development

Historical Development

Back in the late 1990s, chemists started taking a closer look at ionic liquids as green alternatives to volatile organic solvents. 1-Butyl-3-Methylimidazolium Dibutyl Phosphate (often called BMIM DBP) cropped up as labs worked through the imidazolium family for applications beyond basic solvent work. The push to get away from flammable, toxic organic solvents encouraged researchers to develop new salts that would stay liquid at room temperature. By bringing together different cations and anions, they discovered that the phosphate side chain in BMIM DBP really helped with thermal stability and low volatility. Over the years, industry interest grew as process engineers discovered ionic liquids could sometimes outperform old-school solvents, especially for selective extraction, catalysis, or electrochemical work. BMIM DBP's story comes down to decades of trial and error, pushed forward by frustration with old technologies—showing how much determination can change what's possible in chemical engineering.

Product Overview

BMIM DBP, a member of the room-temperature ionic liquid family, shows up as a clear or pale amber liquid, usually kept in tightly sealed bottles away from moisture and open air. In practical lab work, people turn to this compound because its ionic nature means barely any vapor pressure, even when heating. That practically eliminates issues from fumes or sudden pressure spikes, especially when heating or mixing with reactive chemicals. The butyl and methyl modifications on the imidazolium ring make this molecule stable for processes that need long contact times or mild heat. Its solubility makes it easy to incorporate into reaction mixtures or separate phases, which streamlines purification. That dependable performance, and a shelf life counted in years if sealed well, means BMIM DBP gained trust beyond just academic benches and made its way into pilot-scale units.

Physical & Chemical Properties

BMIM DBP stands out mainly for its combination of low melting point (often around room temperature) and negligible volatility. The compound feels slightly viscous—if you pour it between beakers, it moves slower than water, but still flows smoothly. Thermal stability reaches into the 200–300°C range before significant decomposition, so it takes on demanding extraction jobs or long catalyst cycles. Unlike ethereal or halogenated solvents, the phosphate anion wards off easy hydrolysis or breakdown, even if some water sneaks in. The imidazolium head group gives the compound a slightly basic but mostly neutral reaction profile, and the molecule interacts weakly with many inorganic salts but forms strong complexes with a handful of transition metals, which makes it a favorite for extractions or specialized syntheses.

Technical Specifications & Labeling

Producers label BMIM DBP by giving purity in percentage (often at least 98% for lab use) and include water content as a crucial metric, since even a fraction of a percent makes a big difference in sensitive syntheses. Labels carry lot numbers for traceability, hazard identification using GHS pictograms, and recommendations for sealed, dry storage. Most manufacturers use amber glass bottles with induction seals to keep ambient moisture out. Buyers expect a full spec sheet, listing melting point, boiling point (though it usually decomposes before boiling), viscosity, and any residual impurities—often imidazole or DBP traces. Regulatory compliance requires listing handling precautions such as avoiding prolonged skin contact, and emergency measures for spills or exposure, which helps keep both first-time users and veterans working safely.

Preparation Method

It starts on the bench by mixing 1-butyl-3-methylimidazolium bromide (BMIM Br) with dibutyl phosphate under controlled temperatures in a reaction vessel designed for moisture exclusion. The process typically hinges on a metathesis reaction—one where the bromide ions get swapped out by phosphate, driven by mixing the two reactants in a common organic solvent like dichloromethane and then separating the resulting salt. The synthesis demands careful washing and drying to get rid of any leftover bromide and solvent because even tiny bits can gum up sensitive equipment or throw off later experiments. Most labs finish by using vacuum drying to knock water levels as low as possible, sometimes passing nitrogen or argon to chase off stubborn vapor. In scaling up, the process can transition to continuous flow with inline monitoring, which streamlines production for use in factories or pilot plants.

Chemical Reactions & Modifications

Chemists explore BMIM DBP's chemical flexibility, often leveraging its ability to stabilize reactive metal ions or serve as a non-volatile support for acids or bases. In catalysis, the phosphate group partners with copper, palladium, or nickel complexes, allowing researchers to push some reactions at lower temperature or higher selectivity than with conventional solvents. The imidazolium core stands up to functionalization, making the base molecule a platform for further chemical tuning: people modify the alkyl groups or swap in longer or shorter chains, aiming for different solubility or viscosity profiles. In mixtures, BMIM DBP often teams up with other ionic liquids to create “designer solvents” tuned for niche applications, like extracting rare earth metals or stabilizing unstable reactive intermediates. Because the phosphate end attracts some cationic polymers, blending it with certain membranes creates separation materials that outperform traditional organics in toughness and reliability.

Synonyms & Product Names

Across literature and catalogs, BMIM DBP appears under a few different aliases—some chemists write out its full IUPAC name, others use abbreviations like [BMIM][DBP] or just call it butyl methyl imidazolium dibutyl phosphate. Some commercial suppliers give it a product-specific code, so checking CAS numbers helps avoid mix-ups. Regardless of branding, competent suppliers clarify any differences in production process or final purity, noting whether they ship the salt pre-dried or need the end user to finish that step. Awareness of these naming quirks keeps confusion down in a field already crowded with closely related salts.

Safety & Operational Standards

Practical experience reminds everyone that, despite labeling it “green” compared to classic solvents, BMIM DBP deserves respect during handling. Direct contact causes mild skin or eye irritation if not washed off, especially during long bench work—so lab coats, gloves, and goggles cut down on accidents. Spills get slippery fast and, because the liquid resists easy soap-and-water cleaning, it’s important to have absorbents on hand and to keep spill kits stocked. Longer exposures to vapors, while rare due to the compound's low volatility, sometimes irritate the upper airways. Proper ventilation is just as critical here as when working with more volatile substances. For storage, containers live in dedicated cabinets that keep ambient humidity out, since some decomposition can release odors or, in rare cases, slightly corrosive byproducts. Waste disposal goes in special drums for incineration or chemical neutralization; flushing down the drain risks environmental harm as ionic liquids linger in ecosystems longer than common alcohols or hydrocarbons.

Application Area

BMIM DBP’s reputation grew in high-value niches—especially as a solvent for metal extraction, support for homogeneous catalysts, electrochemical media, and separation sciences. Hydrometallurgists use it to pluck out cobalt, rare earths, and actinides from tough feeds where organic solvents can't cope. Its resilience under voltage means it powers electroplating cells or high-precision batteries where even tiny volatility matters. Pharmaceutical process developers discovered it handles some peptide syntheses without racemization or hydrolysis, delivering better yields with fewer byproducts. Green chemistry advocates turned to BMIM DBP for carrying out reactions under milder conditions or reclaiming valuable metals from scrap, helping companies redirect waste into salable products. In renewable energy research, the liquid’s stability under cycling helps push forward supercapacitors and fuel cells. These specialties drove investment in continuous process design, as engineers saw potential for less hazardous working environments and lower emissions.

Research & Development

Researchers worldwide focus R&D on improving the recyclability and cost-effectiveness of BMIM DBP, hoping to make its benefits accessible beyond specialized manufacturing. Ongoing projects test blends with biodegradable solvents to ease downstream treatment burdens. Instrumentation scientists investigate how the compound’s unique electrochemical stability can sharpen sensor response or fuel new battery chemistries. Environmental scientists publish work on minimizing persistence in waterways—developing filters and adsorbents that catch ionic liquids before they escape waste streams. Teams in Japan, Europe, and the U.S. have active grants for using BMIM DBP in carbon capture, motivated by its superior solvation of CO₂ compared to traditional methods. These collaborations often cross boundaries between academia and industry, building on each other’s successes or lessons from failed attempts. Many breakthroughs happen outside of planned projects, when someone with a tough separation challenge stumbles on BMIM DBP’s properties and finds a new use, pushing the field forward for everyone.

Toxicity Research

Animal and in vitro models show BMIM DBP’s acute toxicity sits much lower than classic organic solvents like toluene or acetonitrile, but chronic effects stir debate among toxicologists. Some cell studies hint at slow membrane disruption or enzyme inhibition if concentrations creep too high. Aquatic toxicology studies report that, unlike quick-evaporating solvents, ionic liquids can build up in water, affecting sensitive life stages in fish or invertebrates even at sub-ppm levels. On land, soil microbes break down the compound at a slow pace, sometimes stalling plant growth if residues build up. Regulatory boards recommend careful disposal and avoidance of regular large-scale releases. Academic collaborations with industry keep expanding databases of ecological effects, so environmental releases steadily drop as cleanup and monitoring strategies improve. Real progress happens as chemical manufacturers fund long-term observation studies and publish both positive and negative findings, building a clearer picture over time.

Future Prospects

The road ahead for BMIM DBP leads directly through the toughest process engineering challenges—extracting value from waste, improving renewables, and lowering chemical footprints at every turn. Chemists and engineers know scaling up from beaker to plant brings headaches, but the lessons of the past few decades—better drying, tighter process control, smarter waste separation—suggest that barriers can fall with enough curiosity and persistence. Breakthroughs in synthesis offer cheaper, more sustainable routes, sometimes using renewable biomass as feedstock for either the imidazolium base or the phosphate acid. Scientists pursuing energy storage, pollution control, or precision manufacturing find themselves returning to BMIM DBP’s properties again and again, tweaking its structure or mixing it with other new liquids to fill novel roles. Education will play a big part, too, as more chemists and technicians train to handle ionic liquids safely and design closed-loop systems that prevent escape into the environment. The promise of BMIM DBP rests not just in its neat chemical profile but in how researchers value its strengths, find honest solutions for its risks, and stay open to uses that haven’t even been imagined yet.

What Sets This Chemical Apart

Most of us don’t see 1-butyl-3-methylimidazolium dibutyl phosphate in our daily lives, but it’s a workhorse for chemists. It comes from the broad family of ionic liquids. At room temperature, this chemical stays liquid, which is far from what you'd expect looking at traditional salts. Because it doesn’t vaporize like water or ethanol and doesn’t burn easily, it’s become popular for carrying out tough reactions in labs and some industrial plants.

Solvent for Tough Tasks

A main draw comes from the way it dissolves materials that normally resist mixing. Think of those tough organic molecules, lignin from wood, or even cellulose in raw plant matter. Traditional solvents choke on these — ionic liquids clear the way. Chemists use this specific phosphate version to break down plant material, making it easier to extract valuable chemicals or create biofuels. In bio-refining labs, converting straw or sawdust into sugars relies on its ability to bust apart plant cell walls that regular chemicals bounce off.

Extracting Metals and Cleaning Up Waste

Rare-earth metals keep our smartphones, wind turbines, and electric cars running. Digging them out of ores or recovering them from used electronics calls for precise chemistry. 1-butyl-3-methylimidazolium dibutyl phosphate helps grab onto these metals through extraction processes. Its reputation for selective binding means it can pull useful elements out of a mess of useless dirt or electronic scrap, sometimes with higher yield than older solvents. In my own work, I’ve seen teams use it for stripping unwanted metal ions from contaminated groundwater, giving sites a shot at recovery instead of quarantine.

Safe and Green by Design?

A lot of the push behind ionic liquids comes from regulators and factory managers fed up with hazardous solvents. The risk from fumes, fires, and spills with traditional chemicals drives up insurance and equipment costs. The dibutyl phosphate version gives a much safer profile; it doesn’t emit much, and it can often be recycled back through several cycles before losing effectiveness. Safety isn’t just a lab brag. In places with minimal emergency services, the reduced risk means more options for processing waste locally and less need to ship hazardous materials over long distances.

Room for Criticism and Solutions

There’s a catch. Ionic liquids like this one don’t always break down easily in the environment. Large-scale spills or leaks could mean long-term presence in soil and waterways. Some reports suggest they stick around where you least want them. One fix might involve adjusting the chemical recipe — sometimes chemists swap out one part of the molecule to help microbes eat it faster after use. Strict rules around collection and recycling also go a long way. Green chemistry focuses on what happens after a process, not just cutting risk up front.

What the Future Holds

Demand for niche chemicals and high-value metals keeps growing. 1-butyl-3-methylimidazolium dibutyl phosphate sits at the edge of this demand, offering chemists another tool for the tough jobs. Continued research might tweak its environmental footprint or unlock new ways to recycle it at the end of each run. For now, it shows how far chemistry can stretch to tackle industrial challenges without some of the old downsides.

Why It Matters

Stepping into a lab or plant where ionic liquids like 1-Butyl-3-Methylimidazolium Dibutyl Phosphate get moved around, there’s always a feeling of responsibility. This compound stands out for its stability and engineering uses, but safety habits need to stay sharp. Some folks underplay these colorless chemicals, thinking “It doesn’t smell strong. No fumes. How dangerous can it be?” The answer: plenty, if the basics get skipped.

Handling Means Gloves – Always

Getting some on your skin might not lead to instant pain, but the risks add up. Studies have found that chemical burns and long-term irritation often come from repeated contact with even mild-looking solvents. So, I reach for nitrile gloves every time. Latex works less well—these liquids find weak points and get through. Goggles matter as much as gloves. One splash near the eyes brings a whole new kind of emergency.

Ventilation - Don’t Forget the Air

People figure “low vapor pressure” means they can cut corners with fume hoods, but accidents catch everybody off guard. There’s a reason careful labs stick to local exhaust or chemical hoods for each transfer. Even small amounts released in a closed room settle on surfaces or float around for hours. The industry learned years ago from solvent exposures—eliminate the vapor, you cut the risk.

Know the Spills – Plan Before, Not After

The time to learn spill cleanup is not right after a bottle falls. I keep spill kits right next to work areas, not hiding in some storeroom. Neutral absorbents, scrap rags, and a clear plan save nerves and time. My advice: Train everyone on small and large spill steps. Call for backup on big spills. Don’t walk barefoot in a lab. It sounds obvious—until it isn’t.

Label Everything, Keep the MSDS Handy

One lesson stands out in my years working with chemicals: label everything as soon as it leaves the main container. Sloppy labels lead to mistaken identities. The safety data sheet, usually printed and taped up somewhere close, isn’t just paperwork. You need fast answers in emergencies—symptoms, antidotes, what to do after a spill. Copying down the hazard statements helps everyone remember the risks.

Storage—Watch for Heat and Light

These phosphate ionic liquids can break down with too much heat. I learned from a near miss that even a temporary storage near a sunny window changed the way the liquid looked and felt. Store in tight-sealing containers, away from sunlight, and never above chest height. Use secondary containment trays to keep drips from becoming big problems.

Don’t Work Alone—Build a Culture

Most of the close calls I’ve seen happened when someone skipped communication. One chemist returned from lunch and found a bench slick with unreported residues. If you use this compound, tell others right away. Sensors and alarms do their part, but direct talks keep people safe. Schedule regular drills for eye washes and showers—don’t just hope people remember where they are.

Final Thoughts on Care

Safe handling starts with respect for what can go wrong. The stories stick with me: gloves that leaked, fume hoods left unused, spill kits unopened when needed. Companies and universities do better when workers see safety as daily practice, not a box to tick. Read up, talk openly, and keep eyes sharp for the next step in safely handling 1-Butyl-3-Methylimidazolium Dibutyl Phosphate.

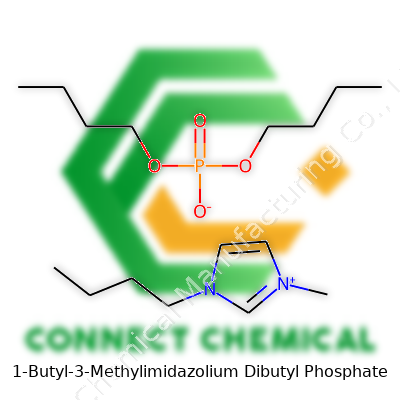

Breaking Down the Formula

1-Butyl-3-methylimidazolium dibutyl phosphate might sound like a bit of a tongue-twister, but its chemical structure plays a real role in the world of modern solvents. The chemical formula for the cation is C8H15N2+, while the anion dibutyl phosphate brings in C8H19O4P−. Bring both of those together, and you get the ionic liquid: C8H15N2+ C8H19O4P−.

Imidazolium-based ionic liquids, especially ones paired with anions like dibutyl phosphate, have carved out their own space in chemical processing, battery technology, and even green chemistry. They stand out because of their low volatility and high thermal stability. The molecular structure gives them a liquid state at room temperature and brings together both polar and non-polar components—something that traditional solvents rarely manage so well.

The Structure: Why It Matters

Looking at the cation, the imidazolium ring brings nitrogen atoms into play, adding to the chemical diversity. The butyl group attaches at the first position (N-1), a methyl at the third, giving the liquid its name. The anion comes from dibutyl phosphate, a phosphorus atom bonded to four oxygen atoms and two butyl side chains. This combination shapes the solvent properties, supporting everything from industrial catalysis to extracting rare metals from waste streams.

Ionic liquids don’t just replace old-fashioned toxic solvents; they give process engineers and lab chemists a real toolkit for pushing research into greener, cleaner territory. 1-Butyl-3-methylimidazolium dibutyl phosphate becomes more than just a shelf chemical. In my own experience, working in a lab where safer materials matter, switching to an imidazolium-based solvent reduced concerns about worker exposure and vapor toxicity.

Importance of Safe and Green Chemistry

Regulatory agencies, alongside university researchers, have tracked the hazards associated with common volatile organic compounds. Imidazolium-based ionic liquids provide an alternative—one without the same risks for atmospheric pollution. Studies published in journals like Green Chemistry and Journal of Hazardous Materials have shown measurable reductions in emissions and workplace exposure levels when teams shift toward these phosphate-based combinations.

That said, not every ionic liquid ends up being completely benign. Phosphates can pose risks if they escape into waterways, leading to potential algal blooms and ecosystem impacts. Practical steps, like proper storage and well-managed waste procedures, remain the cornerstone of responsible lab and plant management.

Solutions and Future Directions

Continued testing and stricter evaluation standards help in flagging compounds with unexpected persistence or toxicity. Educators, lab managers, and industry professionals push for training on handling and disposal—something I see as just as important as technical innovation itself. Supporting more research into the life cycles of ionic liquids and encouraging collaborations between chemists and environmental scientists will shape the future use and disposal strategies.

With the whole industry turning toward sustainability and safety, learning about both the formula and structure of chemicals like 1-butyl-3-methylimidazolium dibutyl phosphate drives real progress. By taking informed steps, asking the right questions, and sharing results across labs, the path forward gets clearer and cleaner.

Real Risks You Can't Ignore

Plenty of folks underestimate the risks with specialty chemicals. 1-Butyl-3-methylimidazolium dibutyl phosphate stands out as one of those compounds people often treat casually. After working for years in research labs, I learned to respect every label and keep potential hazards top of mind. A lapse in storage protocols doesn't just endanger the product; it can threaten people’s health and careers.

Let’s Talk Environment and Containment

Cool, dry, and steady—that’s the sweet spot for storing chemicals like this one. You don’t toss ionic liquids on a crowded shelf with sodium hydroxide or something acidic. Mixing strong bases, acids, or oxidizers and sharing close quarters could invite disaster. So, keep it in its original, labeled container with a tight seal. The reason: air can bring moisture that messes with the material, sometimes even introducing slow degradation if humidity lingers.

During an internship, I watched a co-worker once spill a whole batch of a similar ionic liquid just by misjudging the condition of a container. That factory lost days of productivity, and a fume hood needed a costly decontamination job. Mistakes like that start with sloppy storage habits.

Temperature Swings Spell Trouble

Extreme temperatures don’t serve anybody well in chemical storage. I’ve seen temperature spikes from a broken HVAC system make sensitive reagents degrade before ever reaching the experiment stage. So, steady room temperature—ideally between 20°C-25°C—works best. Heat might cause slow breakdown; cold storage in a fridge often avoids these spikes. Forgetting to check temperatures leads to ruined supplies and wasted research funding.

Too many ignore chemical compatibility. If you use metal shelving without checking for corrosion, even accidental contact with moisture can spark corrosion and leaks. I always place chemicals like this on chemical-resistant trays, just in case. Neat, contained spills mean easier cleanup—not knee-deep in an emergency.

Ventilation Makes a Difference

Even chemicals with low volatility need good ventilation. Tiny leaks can build up fumes over weeks, which a nose tuned to laboratory smells rarely catches early. Chemical storage rooms should vent outside, far away from any intake fans. During a stint at a university lab, a barely-noticeable buildup of low-odor vapors tripped air quality alarms, teaching the whole team a lesson on silent hazards.

Label Everything Without Cutting Corners

Clear labeling isn’t just for new hires or auditors. It saves experienced researchers from mix-ups, especially on busy days. Dates, identities, and hazards: skipping those details ends up in waste at best and medical bills at worst.

I once saw an experienced colleague undo two weeks’ worth of work by misreading a barely-visible marker on a storage jar. All it takes is one overlooked label to unravel trust in a lab environment.

Personal Protection and Cleanup Plans

Even careful storage won’t prevent every accident. PPE—gloves, splash goggles, and long sleeves—should be just as routine as breathing when handling this class of chemicals. In one busy teaching lab, quick access to spill kits stopped a minor leak from turning into a shutdown.

Emergency showers and eyewash stations, regularly checked, turn near-misses into learning opportunities rather than disasters. No chemical storage plan stays truly safe unless people remember that accidents respect nobody’s schedule.

Responsible Chemical Management Starts Small

Safe storage of 1-butyl-3-methylimidazolium dibutyl phosphate isn’t just about ticking boxes—it’s about treating every bottle as a test of discipline. People with strong storage habits make safer labs, healthier colleagues, and more reliable results.

A Chemist’s Take: Why Water Solubility Matters

1-Butyl-3-Methylimidazolium Dibutyl Phosphate—just saying the name tells you it isn’t your everyday kitchen compound. This ionic liquid shows up in labs for some smart reasons, whether it’s solvents for tricky syntheses or as a tool in separation science. Understanding if and how this molecule mixes with water makes a big difference to anybody working with green chemistry or industrial processes that rely on environmentally responsible practices. Water solubility determines if it cleans up easily, if you need to scramble for custom waste management, or if it fits well into closed-loop water cycles.

Water and Ionic Liquids: Looking at the Science

Typical ionic liquids, like this one, often don’t follow neat rules. Some dissolve right into water; others float stubbornly on top or sink like a stone. Breaking it down, 1-Butyl-3-Methylimidazolium Dibutyl Phosphate brings together an organic cation and a bulky phosphate anion. The butyl chains add oily, water-fearing (hydrophobic) character, but that phosphate group clings to polar molecules, including water. Most research puts this compound into the “moderate to high” solubility range. You pour water over it, and it doesn’t hide—it mixes in, often forming a single phase unless you use very high concentrations. It beats out many traditional solvents for safety and doesn’t leave a sticky mess.

Why It Matters in the Real World

Let’s get practical. In hundreds of labs, I’ve seen how ionic liquids drive greener chemistry. Their ability to dissolve organic and inorganic molecules, including a good mix with water, means less reliance on traditional, volatile, and toxic solvents. If a sloppy spill happens—which it sometimes does—being water-soluble speeds up cleanup, can prevent hazardous exposure, and minimizes environmental worries. It also means industrial sites won’t likely need to invest in complicated, custom incineration equipment. Instead, simple water-based waste streams tend to handle these ionic liquids, and that changes how much energy and money plants burn during processing.

It’s not just safety. Many water-soluble ionic liquids show promise in a surprising range of jobs, like separating metals in old batteries, or capturing carbon dioxide emissions straight from the air. Their easy mixing in water means they can work at a bigger scale, often in existing tanks and pipelines. In my own experience piloting a metal recovery process, switching to a water-compatible ionic liquid meant my team could use standard equipment, bringing new tech out of the fume hood and into the real world.

Questions, Worries, and Workarounds

Solubility isn’t an automatic green light. Once an ionic liquid gets into water, where does it go? Studies raise concerns about persistence and toxicity if these liquids reach rivers or groundwater. Every industrial user needs to back up their choices with toxicity tests and think about end-of-life plans. We can’t just swap a flammable solvent for a water-miscible one and assume nature shrugs it off. It’s smart to look for technologies that not only use water-compatible solvents but can also filter, recover, or break them down. Membrane separation and advanced oxidation pop up as solutions worth investing in, especially for big users.

Final Thoughts

Solubility tests tell chemists if 1-Butyl-3-Methylimidazolium Dibutyl Phosphate plays well with water. From what I’ve seen in the lab and in industry, this compound fits into water-based systems, working with—not against—safety rules and process needs. Anyone using it should pay just as much attention to its fate after use as they do to its smooth mixing up front, marrying innovation with responsibility.