1-Butyl-3-Methylimidazolium Dicyanamide: A Closer Look

Historical Development

As modern chemistry kept pushing deeper into the structure and behavior of ionic liquids, 1-Butyl-3-methylimidazolium dicyanamide, often called BMIM DCA, came out of focused studies during the late nineties. Imidazolium-based ionic liquids appealed to researchers searching for alternatives to volatile organic compounds in the lab and in industry. Those early days saw an explosion in ionic liquid recipes, and dicyanamide anions brought key advantages: cost-effectiveness and a knack for dissolving tough solutes. Chemists all over the world started tuning cation–anion combinations, but BMIM DCA quickly earned its spot on the shortlist for flexible, low-toxic ionic liquids. Having spent time in research environments, I've watched the shift away from harmful solvents toward substances less likely to pollute waterways or challenge health and safety.

Product Overview

BMIM DCA presents itself as a clear liquid at room temperature, with a faint amine-like odor noticeable only nearby. Labs appreciate its low volatility and lack of flammability, which sharply contrasts the headaches that come from classic organic solvents. The compound belongs to the broader class of room-temperature ionic liquids (RTILs), which means it stays liquid in a broad thermal window. It’s not a household name, but regular chemical suppliers list it under several catalog numbers, and it's often found in industrial- and research-scale drums or bottles. Synonyms floating around include 1-butyl-3-methylimidazolium dicyanamide and BMIM DCA. Researchers and technicians appreciate its stability, as it doesn't decompose easily during storage under standard lab conditions.

Physical & Chemical Properties

BMIM DCA doesn’t boil over at low temperatures. Its melting point sits far below water’s, usually coming in under minus ten Celsius, which means even in colder environments it stays liquid. The density sits higher than water at about 1.06–1.08 g/cm³, and it has a notable viscosity—nothing syrupy, but more resistance than water or ethanol—making it useful for jobs where you need a stable and slow-moving solvent. This liquid shows low conductivity compared to saltwater but impresses for a pure organic solvent. The dicyanamide anion brings chemical resistance, as the two cyano groups keep it stable across a wide pH range. BMIM DCA dissolves a broad span of both polar and nonpolar substances, helping extract and isolate tricky chemicals.

Technical Specifications & Labeling

Standard BMIM DCA bottles come stamped with a purity number, usually at or above 98%, sometimes refined past 99% for more specialized research or pharmaceutical use. Labels include hazard statements, an emergency contact, and key chemical identifiers like the CAS number 50269-66-0. Most suppliers will spell out water content, halide contamination, and residual solvent percentage in detailed certificates of analysis. Color and clarity matter during inspection. Even the closure and bottle material get listed—HDPE, glass, or Teflon—since improper storage might let outside moisture creep in, changing the ionic liquid’s behavior.

Preparation Method

Making BMIM DCA involves several steps, starting with the quaternization of 1-methylimidazole and 1-chlorobutane, yielding BMIM chloride. Neutralization or metathesis follows—often with sodium dicyanamide in water or methanol—swapping the halide for dicyanamide. The final liquid sinks below a sharp phase boundary during washing, making for an easy separation without elaborate purification. Careful removal of water, usually by rotary evaporation and gentle heating under reduced pressure, leaves behind near-pure BMIM DCA. My own time with ionic liquid synthesis taught me how crucial each wash and drying stage becomes for consistent properties, as even a small sodium ion left over from raw sodium dicyanamide throws off conductivity and reactivity.

Chemical Reactions & Modifications

Ionic liquids like BMIM DCA rarely join in on the reaction, but they do nudge chemical transformations toward higher yields and cleaner products. For selective alkylations, cross-couplings, or even enzymatic reactions, BMIM DCA serves both as medium and stabilizer; its imidazolium core resists many forms of chemical abuse. Still, the liquid helps shuttle electrons or ions in electrochemical setups. Modifying the dicyanamide anion or swapping in functionalized imidazolium rings customizes solubility or polarity: changing the butyl group to octyl drags up hydrophobicity. Chemists continually hunt for tweaks that push performance beyond classic solvent game plans.

Synonyms & Product Names

BMIM DCA comes up under a laundry list of names: N-butyl-N-methylimidazolium dicyanamide, 1-butyl-3-methylimidazolium dicyanamide, or just “BMIM DCA” for those in the know. Chemical catalogs carry its CAS number—50269-66-0—for clarity. Brands like Sigma-Aldrich, TCI, Alfa Aesar, and Iolitec publish it in varying grades and bottle sizes, but the basic product remains consistent if the certificate of analysis checks out.

Safety & Operational Standards

BMIM DCA looks gentle on paper, but careful handling reduces risk. Skin or eye contact burns if left unwashed, and inhaling vapor from large-scale spills irritates the throat. Working in ventilated spaces while wearing gloves and splash protection lines up with good lab habits. Waste ionic liquids don’t go down the drain; labs collect them for specialized disposal, as dicyanamide anions resist breakdown in municipal treatment plants. Agencies like OSHA or REACH set the expectation for documentation and emergency procedures, imposing clear labels and safety sheets. During my early work in R&D, vigilance paid off—not just for personal safety, but to respect colleagues sharing the workspace.

Application Area

BMIM DCA carved out a spot in pharmaceuticals, metal extraction, battery electrolytes, and analytical chemistry. Companies use it to pull rare earth elements from recycled electronics, to dissolve cellulose for advanced fibers, and to act as an additive in supercapacitor research. In academic settings, research teams test it for enzyme stabilization—a leap beyond traditional water-based protocols—and for efficient organic synthesis, sidestepping some of the harsher reagents. BMIM DCA’s negligible vapor pressure makes it popular for green chemistry projects seeking to cut air emissions and hazardous waste.

Research & Development

The research effort to unlock ionic liquids’ potential never lets up. Whole teams measure how BMIM DCA affects reaction rate or product selectivity for synthetic chemistry. In material science, researchers blend it with polymers for solid-state electrolytes or with nanoparticles to test dispersion and stabilization. Physical chemists map phase diagrams, conductivity, and viscosity as a function of temperature and water content—and try to predict performance in new device architectures. My own experience tells me R&D doesn’t happen in isolation. It works as a feedback loop: end-users send complaints or suggestions upstream, while technical staff experiment to match requirement lists, feeding new knowledge right back into production protocols.

Toxicity Research

BMIM DCA gained a “relatively low toxicity” label during early studies, but the story grows as more gets known. Lab mice and aquatic species tolerate it at low doses, but higher concentrations or prolonged contact reveal chronic impacts. Environmental scientists track its persistence after accidental spills and challenge the “green solvent” label, especially with concerns over dicyanamide’s breakdown products. Direct ingestion or injection is clearly unsafe, but skin exposure in small amounts, if washed quickly, rarely leaves lasting harm. Having worked with risk assessments, I see these findings as signals: don’t treat any new compound as innocuous. Repeated low-dose interactions still carry unknowns, so thorough long-term studies are still underway.

Future Prospects

Looking ahead, BMIM DCA stands to benefit from better regulations and more detailed toxicity profiles. Green chemistry’s rise signals a shift toward replacing hazardous solvents, and new generations of battery and supercapacitor developers need liquids that strike a balance between performance and safety. Expanding the role of ionic liquids in recycling rare earths, cellulose processing, and specialty organic synthesis means investments in supply chain reliability and product stewardship. My hope is that industry and academic researchers commit to transparency and data-sharing, building collective trust in BMIM DCA’s place in chemical innovation, all without repeating the mistakes of earlier “safe” compounds that turned problematic once scaled. There’s plenty of space for improvement on synthesis cost, end-of-life degradation, and full environmental impact mapping. Stakeholders from labs, regulatory bodies, and manufacturing plants will need steady collaboration and real-world testing to drive the next breakthroughs.

Meeting the Challenge of Solvents

Most labs I’ve visited still stock old-school solvents, but chemists everywhere talk about how flammable and toxic some options get. This is why 1-Butyl-3-Methylimidazolium Dicyanamide—let’s call it BMIM DCA—keeps popping up in conversations. BMIM DCA isn’t just another lab curiosity. It brings down volatility and handles temperature stress much smoother than traditional solvents. When researchers run reactions needing steady, moisture-free conditions, BMIM DCA usually outperforms the usual suspects. These traits sound technical, but in practice, they make a big difference on a lab bench, where spilled organic solvents still set off fire alarms every year.

Catalysis Gets a Boost

My colleagues in the catalysis field always look for ways to push reaction rates faster and get cleaner products. BMIM DCA enters the scene because it keeps metal catalysts stable and promotes the recycling of these expensive agents. Less waste and the ability to run multiple cycles with the same catalyst—not just possible, but routine. Some team leads refuse to run certain hydrogenation or carbon–carbon bond-forming reactions without it. Not just because it works, but because running safer and cleaner experiments keeps teams healthy and costs down.

Electrochemistry and Green Power

The rise of battery research and supercapacitors makes everyone in materials science curious about new electrolyte options. BMIM DCA excels because it doesn’t catch fire or evaporate, even under harsh electrical currents. That matters for anyone building lithium-ion batteries or trying to stretch how long phone batteries last. A few years ago, a student in my group spilled his old electrolyte and had to deal with the stink for weeks. Using BMIM DCA, those headaches dropped off. Plus, the lower toxicity and recyclability help push the tech toward wider acceptance in energy storage.

Biotechnology and Life Sciences

Anyone handling biological samples needs gentle solvents that won’t denature proteins. BMIM DCA offers a kinder approach. Many labs now use it for enzyme reactions or to help extract delicate natural products. Old approaches involving harsh, stinky organic solvents often ruined the quality of sensitive natural samples. Swapping in BMIM DCA keeps the structure intact and boosts yields, especially with pharmaceuticals or nutraceuticals made from plant extracts. Some biotech startups prefer using BMIM DCA over older options thanks to fewer environmental red flags.

Troubles and Tuning for Real-World Use

Of course, not everything is smooth sailing. BMIM DCA costs more than legacy solvents and often takes special disposal steps. The world of green chemistry pushes for non-toxic, sustainable chemicals, which means the industry still debates BMIM DCA’s long-term environmental impact. Some teams succeed by recycling it, others by finding ways to break it down safely after use. From my experience, open discussion among researchers and manufacturers drives real progress. Teams coming together to share results and safety information—not just what worked, but what went wrong. That's what helps end-users and policymakers figure out where BMIM DCA adds the most value and where it could use a fresh look.

A Deep Dive into a Modern Ionic Liquid

Working in the lab pushes you to notice which chemicals quietly change the way we do science, and 1-butyl-3-methylimidazolium dicyanamide (BMIM DCA, for short) stands out. Its name reveals a lot, but real understanding comes from breaking down its chemical bones.

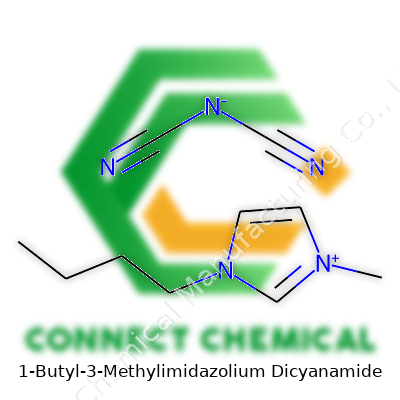

The Building Blocks: Formula and Skeleton

On paper, BMIM DCA looks like this: C8H15N5 for the whole thing, with the cation going by C8H15N2+ and the anion as N(CN)2- (dicyanamide). The structure matters because every piece affects how this ionic liquid behaves. Take the cation: a five-membered imidazolium ring at the center, flanked by a methyl group on one nitrogen and a butyl chain on the other. Chemists often sketch it as a planar, aromatic ring, giving BMIM DCA a stable backbone for all sorts of applications.

The anion, dicyanamide, features two cyanide groups (–C≡N) attached to a central nitrogen. That arrangement makes the anion both compact and highly delocalized, which affects how it interacts with the cation and other molecules. Handling a substance like this in the lab, one learns quickly it rarely acts like simple salts. It stays liquid over a wide range of temperatures, resists evaporating, and dissolves both polar and nonpolar compounds.

Why the Structure Matters in Real Life

In my own experience running electrochemical tests, BMIM DCA behaves differently from standard solvents. The imidazolium ring doesn’t just look pretty—it’s responsible for strong ionic bonding and stability, so the liquid doesn’t break down easily. That keeps reactions running smoothly without unwanted by-products, a feature researchers prize in green chemistry projects. Dicyanamide’s linear shape and electronic structure mean it doesn’t clog up molecular workings or form stubborn side products. A lot of ionic liquids end up becoming sticky messes on glassware, but BMIM DCA washes out under mild conditions.

Safety and Environmental Impact

People ask why anyone should care about the formula or structure—it’s more than academic trivia. 1-butyl-3-methylimidazolium dicyanamide has a low toxicity compared to many organic solvents. Its stability helps reduce emissions and waste in industrial settings. Of course, every chemical comes with risk, and proper handling is essential. As seen in recent research, dicyanamide-based ionic liquids don’t bioaccumulate, so their footprint shrinks relative to older solvents.

Looking for Less Hazard in the Lab

Incorporating ionic liquids like BMIM DCA into synthesis or separations lets chemists ditch volatile organics, lowering exposure to fumes and fire hazards. Academics and industry both target alternatives to flammable, toxic solvents, and the chemical blueprint behind BMIM DCA plays a role in making checks at the safety box. Efforts still push toward even greener options, but knowing the character of each atom and bond in BMIM DCA provides the foundation. Cutting-edge research today uses this knowledge to design custom ionic liquids for cleaner, more efficient chemical reactions, and the chemical structure is what makes the difference.

The Story Behind an Unfamiliar Chemical

Most folks outside chemistry circles would never run into 1-butyl-3-methylimidazolium dicyanamide at home or the grocery store. This ionic liquid gained popularity among scientists searching for alternatives to traditional solvents in labs and industry. Companies tout its low volatility and unique properties, but the real questions revolve around safety. The full story shouldn’t get buried under technical jargon. When new solvents come to market, people expect honest answers about what they do to health and the planet.

Putting Toxicity into Perspective

I remember the first time I learned about ionic liquids during a university lab. The promise seemed huge — solvents that skip most of the health and fire risks of classic chemicals like acetone or chloroform. After some digging, concerns started cropping up around what these new liquids actually do in contact with skin, water, and air. 1-butyl-3-methylimidazolium dicyanamide (BIMIM-DCA) isn't just a splash—its dicyanamide ion poses risks. Animal tests revealed toxicity at certain doses, especially for aquatic animals. I’m always startled when papers show a compound classified as "toxic to aquatic life with long lasting effects," based on European Chemical Agency data. No backyard chemist would want that leaking near rivers or even down the sink.

Breathing in vapors isn't something most of us would face with BIMIM-DCA, since it barely evaporates. Touching or accidentally swallowing it can lead to headaches, nausea, and much worse in higher doses—think nerve trouble or even organ stress. Lab work sometimes hides behind gloves and goggles, but these do not erase the need to recognize what a spill or exposure means for health.

Why Care About Long-Term Risks?

Some chemicals hit hard right away. Others don’t show damage until years pass. Ionic liquids, including BIMIM-DCA, sometimes linger in water and soil. Research points out the breakdown products, including cyanamide derivatives, which carry their own set of worries. Their fate in nature still sparks debate. My own comfort with any new solvent always comes down to: how does it leave the building, and who or what gets caught downstream? Left unchecked, routine lab or plant waste can add up. Pollution rarely comes with flashing lights.

Scientists still wrestle with how persistent these compounds stick around. Regulatory agencies started tightening oversight, gradually adding new data and risk thresholds. Sometimes chemists love shiny new tools, but history has plenty of examples—take PCBs or even asbestos—where excitement outpaced precaution.

Working Toward Safer Solutions

Facing toxic risks, people need steps that don’t stop at paperwork. For BIMIM-DCA, the answer sits partly in reducing accidental releases and keeping it far from unprotected hands or open drains. Labs must store and dispose of it with the same care as any hazardous chemical. Substitution gets pushed whenever possible—greener solvents now arrive regularly, and young chemists keep pushing for molecules that are tough on stains, yet gentle on people.Companies must share detailed hazard data, not just highlight the upsides. Clear, easy-to-find safety sheets, employee training, and everyday vigilance all make a real difference. Community watchdogs, university EH&S crews, and even curious students help hold folks accountable.I’ve seen first-hand how one quick check with a safety officer, or an updated label, can prevent emergencies. Real safety isn’t only about laws; it comes down to how much people truly respect what’s inside the bottle.

Respecting Chemical Safety

Over the years, working with specialty chemicals like 1-Butyl-3-Methylimidazolium Dicyanamide has taught me that routine makes the best shield against avoidable accidents. Labs and factories run on the daily ritual of good habits. This particular ionic liquid pops up in research and industrial settings for its versatility, but convenience never means overlooking safety.

Keep It Cool and Dry

Nearly every workspace has encountered the trouble of atmospheric moisture sneaking into storage rooms. Letting containers stand in direct sun or humid air invites unpredictable reactions and quickens product breakdown. Stashing this compound in a spot with steady temperature, away from any heat, pays off. Humidity can mess with the dicyanamide anion, sometimes making the liquid start to decompose. That means no crowded shelving near sinks or external doors. If you can keep it under 25°C, you’re doing the material a favor.

Closure and Containment Matter

I’ve seen too many accidents caused by half-tightened lids. This liquid likes to pull in moisture, which can spoil both the bottle and whatever’s planned for the next experiment. It’s good practice to check all caps, using only compatible sealing types. A simple glass or high-density polyethylene bottle with a solid, chemical-resistant cap sidesteps many headaches. Desk clutter and sharing storage with other reactive chemicals can start a chain of leaks. Keep this bottle standing alone, on a tray that catches anything that might spill.

Ventilation and Personal Gear

A lot of smart people skip gloves because they trust their steady hands. This habit doesn’t hold up. Even a small droplet of 1-Butyl-3-Methylimidazolium Dicyanamide can make skin irritated or trigger allergies for somebody in the lab. The proper gloves, goggles, and a well-fitted coat stand as daily musts. Good ventilation counts as much as personal protection. Fume hoods or extraction fans pull away vapors before they cause long-term headaches for you or your coworkers. Don’t wait for a strong smell before turning on the system; subtle exposures matter over time.

Fire and Waste Thinking

This compound won’t burst into flames by itself, but it does break down if heated or mixed with incompatible chemicals. Open flames, sparks, or smoking anywhere near storage or handling zones just ask for trouble. Metal containers or foil wrappers lure static electricity; skip those where you can. Disposal calls for seriousness, too. Dumping remnants down the drain pollutes groundwater and backs up treatment systems. Specialized waste barrels with labels and dated logs help shift used liquid to licensed chemical handlers, cutting down on environmental damage.

Training and Routine Inspections

No one wins by assuming everyone else knows what they’re doing. Staff and trainees handle all sorts of chemicals each day, and it’s easy for details to blur between materials. Regular refresher sessions, easy-to-find safety data sheets, and monthly storage inspections spark a culture of awareness. Walk through storage areas with fresh eyes every now and then. Look for crusted caps, bulging bottles, or forgotten labels—those small steps often head off bigger trouble.

Wrapping It Together

In my experience, these habits don’t slow anyone down; they just mean fewer panicked phone calls, less lost time, and safer, more productive workspaces. Stocking and using 1-Butyl-3-Methylimidazolium Dicyanamide safely boils down to respect: respect for the chemical, your colleagues, and the environment we share.

Understanding the Basics: Appearance, Texture, and State

1-Butyl-3-methylimidazolium dicyanamide—usually shortened to BMIM dicyanamide—shows up as a colorless or pale yellow liquid at room temperature. It doesn’t give off much of an odor, and when you touch it, you’ll notice it’s got that slick, almost oily feel that’s typical of many ionic liquids. Familiarity with these traits helps anyone working in a lab quickly recognize if something’s amiss with a sample, especially when handling unfamiliar chemicals feels daunting.

Melting Point: The Importance of Being Low

BMIM dicyanamide’s melting point usually sits well below standard room temperature, roughly -22°C to -24°C. That puts it firmly into the category of a “room-temperature ionic liquid.” For folks interested in green chemistry or battery electrolytes, this melting behavior tells you it’s a liquid in most typical indoor conditions. It won’t crystallize out unless things get exceptionally cold, which is more practical than a compound you’d need to keep heated just to maintain a working solution.

I’ve seen labs spend way too much time with compounds that turn solid if you so much as crack a window in winter. Having a genuinely room-temperature liquid removes plenty of hassle from storage and handling. It’s also less risky—you won’t deal with sudden, sharp chunks or leaks due to crystallization.

Solubility: How It Mixes with Other Materials

BMIM dicyanamide dissolves easily in water and a lot of common organic solvents. Water, methanol, acetone—nearly all swallow it up with little trouble. That’s different from many ionic liquids, which sometimes shrug off attempts to mix them with water.

In the real world, this opens doors for researchers. You can clean up reactor setups more easily and swap between solvents in the middle of an experiment without worrying about residue or incomplete mixing. During one project, switching from a regular organic solvent to an ionic liquid like BMIM dicyanamide sped up our process. No need to wrangle stubborn solids out of glassware at the end of a long day.

This property also gets attention from chemical engineers. Better solubility makes recycling and waste treatment simpler, as you avoid forming emulsions that clog pipes or create disposal nightmares. Solvents that quickly break down, combine with water, or separate out can save days of headache.

Density and Viscosity: Fluidity in Practice

A liter of BMIM dicyanamide often weighs in at about 1.05 to 1.1 grams per cubic centimeter. This means you feel a bit of heft if you’re used to lighter organic liquids like ethanol or acetone. Its viscosity beats out water, usually landing between 50 and 80 centipoise at room temperature. You’ll notice it pours slower, closer to syrup than water.

High viscosity often annoys anyone mixing or pipetting, but it’s a feature in energy storage and separation applications. In my own work with electrochemistry, the higher viscosity hinted at better ion mobility and provided thermal stability for battery electrolytes—traits prized by anyone designing safer, longer-lasting devices.

Real-World Solutions

BMIM dicyanamide’s combination of low melting point, impressive solubility, and manageable density lets it fill roles that traditional solvents or electrolytes can’t handle as safely or efficiently. For researchers and engineers facing challenges around safe handling, environmental cleanup, or advanced materials design, switching to ionic liquids with these kinds of physical properties offers a practical solution—not just hype.