1-Butyl-3-Methylimidazolium Thiocyanate: A Comprehensive Commentary

Historical Development

Long before most people ever heard about ionic liquids, laboratories and universities were toying with compounds that pushed chemistry in new directions. 1-Butyl-3-methylimidazolium thiocyanate belongs to a family of ionic liquids, and its story begins with the broader search for safer, more versatile solvents. Chemists in the late twentieth century grew frustrated with traditional solvents that often harmed the environment, and research started digging into imidazolium-based alternatives. The discovery that 1-butyl-3-methylimidazolium paired with thiocyanate ions created a liquid at room temperature offered a practical jump in the options available for green chemistry and catalysis. This drive for alternatives, not just in academic labs but also in industry, has steadily carved out a space for this ionic liquid in both research and commercial fields.

Product Overview

1-Butyl-3-methylimidazolium thiocyanate, commonly abbreviated as [BMIM][SCN], brings together a large organic cation and a thiocyanate anion. The combination creates a salt that stays liquid around room temperature. For scientists and engineers, this product means fewer flammable vapors and the chance to use an ionic liquid in everything from extractions to battery electrolytes. The chemical’s naturally low vapor pressure keeps workplace air cleaner—something you appreciate in a crowded lab.

Physical & Chemical Properties

[BMIM][SCN] tends to flow easily, with viscosity that rivals common glycol-based liquids. Its melting point usually falls well below 25°C, and it can even go much lower depending on purity and storage. The liquid nature across a range of environments means no crystallization headaches in daily use. The thiocyanate anion supports strong hydrogen-bonding capabilities. In practice, this gives [BMIM][SCN] an edge in dissolving a range of organic and even some inorganic compounds, surpassing many conventional solvents. The density and refractive index track closely with other imidazolium salts, but the thiocyanate makes this one stand out in terms of polarity and solubility range.

Technical Specifications & Labeling

Key details matter for anyone ordering or handling this material. Purity usually lands above 99%. Color is typically clear to faintly yellow, and manufacturers publish water content numbers, as ionic liquids tend to absorb moisture from air. You’ll find CAS numbers, batch numbers, and sometimes conductivity data on most labels. Physical state, shelf life, and storage recommendations—often suggesting a tightly sealed vessel away from humid air—also appear on documentation. Industry expects clear hazard symbols, which often highlight risks for skin contact or eye exposure, given the thiocyanate component.

Preparation Method

The synthesis of 1-butyl-3-methylimidazolium thiocyanate generally relies on a metathesis reaction. Manufacturers first prepare 1-butyl-3-methylimidazolium chloride or bromide, usually from the respective halide and 1-methylimidazole. After the base salt is in hand, it’s reacted with a suitable thiocyanate donor such as potassium thiocyanate in water or an organic solvent. The ionic liquid forms in the organic phase, and workers wash it repeatedly to remove any halide or residual potassium ions. Proper drying removes any final traces of moisture before bottling the product. This stepwise process gives a high-purity product, though labs keep a close eye on contamination and batch consistency.

Chemical Reactions & Modifications

1-Butyl-3-methylimidazolium thiocyanate doesn’t just serve as an inert medium; it can act as a reagent in some situations. The thiocyanate ion can participate in nucleophilic substitution or complexation reactions. Over years of working with imidazolium salts, it’s clear that pairing with different nucleophiles or metal centers yields a range of functional materials. Chemists often modify the butyl or methyl side chains, or replace the anion with others, to tune miscibility, viscosity, and thermal stability. During catalytic processes, [BMIM][SCN] sometimes stabilizes active species or uniquely influences selectivity.

Synonyms & Product Names

Over the years, 1-butyl-3-methylimidazolium thiocyanate has picked up several aliases. Common listings include BMIM-SCN, [BMIM][SCN], and 1-butyl-3-methylimidazolium isothiocyanate, depending on regional labeling and the supplier. Some catalogs refer to it by just the cation name followed by ‘thiocyanate’, while academic literature usually sticks to the full chemical title or abbreviation.

Safety & Operational Standards

Safety takes precedence, as always. With [BMIM][SCN], risks focus on contact with eyes and skin, as the imidazolium can irritate and the thiocyanate brings certain toxicological concerns. Proper lab coats, gloves, and eye shields are non-negotiable. Facilities mandate ventilation, since small amounts of thiocyanate vapor may arise during storage or reactions. Every bottle carries safety datasheets, and responsible users make sure secondary containment is in place. Disposal follows regulations for both imidazolium salts and thiocyanates, since improper dumping can harm aquatic environments or groundwater. Training staff to recognize symptoms of mild exposure, like skin irritation or headaches, helps keep a safe workspace.

Application Area

The real draw comes from the versatility. Electrochemistry labs put [BMIM][SCN] in as a supporting electrolyte for batteries, capacitors, and sensors. Material scientists value the solvent power when working with biopolymers or nanoparticles, since few liquids dissolve as broad a range of targets. Environmental engineers use ionic liquids for selective extraction—pulling out metals or organics from industrial waste. In organic synthesis, the unique polarity and non-volatility support green processes, replacing volatile organic compounds in derivatizations or separations. Research teams have even tested this compound in the pretreatment of lignocellulosic biomass, aiming to break down tough plant material for renewable fuels.

Research & Development

Universities and start-ups continue to pour effort into making ionic liquids more affordable, and [BMIM][SCN] features heavily in these ongoing projects. Recent studies explore the effect of modifying the alkyl chain or swapping the thiocyanate for similar anions, pushing for better thermal or chemical stability. Power storage remains a bustling application, with R&D efforts probing how these salts function under high charge-discharge cycles. My own experience, collaborating with organic chemists, showed just how much [BMIM][SCN] can enhance phase-transfer catalysis, often leading to higher yields and less solvent waste. Publications track new catalytic conversions, each hinting at fresh opportunities for sustainable chemistry.

Toxicity Research

Toxicologists haven’t ignored the risks. While imidazolium-based ionic liquids once earned a reputation as ‘green’, further study revealed environmental persistence and bioaccumulation risks, especially for aquatic organisms. The thiocyanate ion in [BMIM][SCN] may disrupt certain metabolic pathways in fish and invertebrates. Lab tests aim to fine-tune disposal practices and monitor for long-term effects following accidental releases. Workplace exposure guidelines reflect recent studies, prompting companies to install real-time monitoring for spills or leaks. This research keeps pushing companies to reformulate or offer safer alternatives where possible.

Future Prospects

Researchers keep asking what comes next for [BMIM][SCN]. The rise in battery development and sustainable chemical manufacturing promises continued demand for reliable, non-volatile solvents and electrolytes. Advances in purification and recycling processes aim to cut costs and environmental impact. Some startups are piloting closed-loop systems that reuse spent ionic liquids, which will likely shape how widely [BMIM][SCN] gets adopted in industry. The march toward a low-emission economy relies on more affordable green solvents, making this compound a cornerstone in modern applied chemistry. As the field grows, tighter regulatory frameworks may arise, ensuring safe use without sacrificing the benefits gained from this unique ionic liquid.

What Sets 1-Butyl-3-Methylimidazolium Thiocyanate Apart

Chemists often look to new solvents that handle modern demands for sustainability and performance. 1-Butyl-3-methylimidazolium thiocyanate stands out in labs and industry thanks to its unique combination of being an ionic liquid—a salt that’s liquid at room temperature—and its ability to dissolve a wide range of substances. I’ve seen researchers gravitate toward this material because it opens doors that weren’t available just a decade ago.

Replacing Old-School Solvents in Synthesis

Current research shows that 1-butyl-3-methylimidazolium thiocyanate helps replace volatile organic solvents. A lot of those old solvents give off fumes that contribute to air pollution, and they’re not kind to workers’ health. This ionic liquid stays put, doesn’t evaporate, and reduces those risks. In some of the green chemistry journals, scientists point out that efficiency can jump when reactions run in these ionic liquids. Yields climb higher, and it’s easier to pick out the product at the end. That can save researchers both time and money.

Extraction and Purification in the Real World

Outside fancy research labs, the material finds a job in extracting valuable elements out of natural ores and waste streams. One of my colleagues in the environmental field mentioned how these ionic liquids help extract rare earth elements without the mess traditional acids leave behind. They’re also cropping up in pharmaceutical production, smoothing out purification steps that once needed multiple washes or hazardous chemicals.

Biomass and Energy

Turning plant stuff into energy and chemicals means breaking down tough fibers. Regular water and alcohol can’t do much by themselves. 1-butyl-3-methylimidazolium thiocyanate opens up cellulose fibers, making it easier to turn plant waste into fuels or base chemicals. Scientists at several universities are experimenting with these ionic liquids to create cleaner fuels and cut down reliance on petroleum-based products.

Room for Growth and the Push for Safety

Regulatory agencies and health experts keep an eye on all new chemicals, even those touted as “green.” Studies so far point to low flammability and slow evaporation rates—big plusses for workplace safety. Yet, every chemist needs to pay attention to possible toxicity for humans and aquatic life. Companies and labs working with 1-butyl-3-methylimidazolium thiocyanate focus on closed systems and recovery processes, aiming to recycle and reuse these materials after each job.

What Still Needs Work

Plenty of potential exists, though nobody’s claiming this ionic liquid solves every problem. Researchers press for more data on long-term stability and environmental impact. Investment in cleanup and recovery technology grows, encouraging a future where industries make use of this chemical without leaving trails of waste. By building on real testing and keeping safety in the front seat, 1-butyl-3-methylimidazolium thiocyanate looks set to anchor greener labs and factories for years to come.

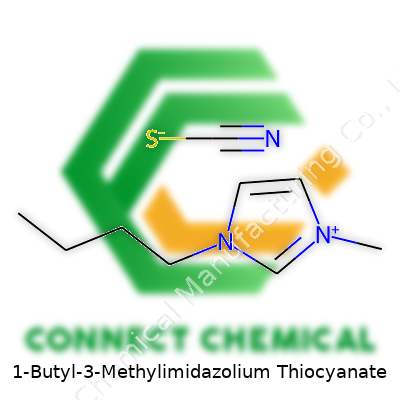

Digging Into the Formula

Anyone who’s worked in a chem lab knows names like 1-butyl-3-methylimidazolium thiocyanate often sound intimidating at first. Strip away the jargon, and you’re left with clear structure and purpose. The chemical formula for this compound is C9H15N3S+ SCN−. For people not living in the world of chemistry, that’s a cation-anion pair—the “ionic liquid” crowd loves this sort of thing.

What Goes Into This Compound

Walk through the pieces: the 1-butyl-3-methylimidazolium part comes from the imidazole ring with a methyl group and a butyl chain attached. This forms the cation. On the other side sits thiocyanate, a classic anion where sulfur, carbon, and nitrogen link up in a straight line. Throw them together and you get one of the more popular room-temperature ionic liquids out there, appreciated for properties that fall outside the norm of common solvents.

Why It Matters: Real Use Cases

These ionic liquids don’t just please chemists on paper. Back in grad school, I fiddled with similar compounds for green chemistry projects. Compared with regular solvents, ionic liquids like 1-butyl-3-methylimidazolium thiocyanate resist evaporation, go easy on the ozone layer, and open new doors to more sustainable industrial processes. Imagine running a reaction that releases almost no vapors and can be recycled again and again—quite a relief when you’ve spent a day with headaches from volatile organics.

In labs across the globe, scientists turn to these substances for work in catalysis, electrochemistry, and materials development. For example, I’ve seen them boost the separation of metal ions, cut waste, and push boundaries for battery technology. Stories of success often come from researchers outside the major funding spotlight, who reuse these liquids to wring maximum value out of every dollar and keep toxic waste out of their local water supplies.

The Safety Angle

No responsible chemistry chat skips the health part: this compound, like many ionic liquids, avoids fire hazards and vapor inhalation issues tied to classic solvents. That said, nothing in chemistry is risk-free. Quick rinsing and proper glove use beats the alternative—skin exposure or accidental splashes. The big question comes down to environmental fate. Many new solvents get the “green” label a bit early; careful, long-term studies help us judge which ones stay benign beyond the lab. From my own work, disposal always demands attention, and no bottle goes down the drain unless approved.

What Could Change in The Future

Chemical research always hunts for the right balance between innovation and responsibility. Scientists I’ve met are working to tweak this cation and other parts, searching for even lower toxicity, higher recyclability, and more tailored characteristics for specific uses—be it purifying pharmaceuticals or powering safer electronics. One smart approach lies in lifecycle analysis, following a chemical from synthesis to disposal. That way, the next generation of solvents earns its stripes through both performance and genuine safety, not just clever branding.

What’s In the Bottle?

Chemists and engineers bump into new substances all the time, especially as industry leans on ionic liquids for greener projects. 1-Butyl-3-methylimidazolium thiocyanate cropped up as a promising candidate in labs worldwide. Some folks see “ionic liquid” and expect an easy ride, no flammability, low vapor pressure — sounds like a nice change from nasty solvents. Yet dangers rarely vanish just because a liquid looks unthreatening.

Digging Into Toxicity

Most research on this compound tucks into the larger discussion of imidazolium ionic liquids. What I’ve seen in published studies, exposure to these compounds often spells trouble for cells and aquatic organisms. Several peer-reviewed sources, such as Chemosphere and Ecotoxicology and Environmental Safety, outline how similar ionic liquids damage fish gills, slow plant growth, and disrupt bacteria in wastewater plants. No laboratory animal wants to bathe in this stuff.

The thiocyanate part of the molecule doesn’t do safety any favors. Thiocyanate ions can release irritant gases under heat or strong acid. Some early reports connect thiocyanate exposures with thyroid problems in humans, especially after chronic exposure. This isn’t the same as swallowing table salt.

Real Life Hazards

Most accidents don’t come from big explosions. Leaky vials, messy disposal, and splashy lab technique do almost as much harm. Eyes get a sting fast. Plenty of my colleagues keep chemical resistance charts stuck to their gloveboxes; imidazolium salts force us to double check nitrile and latex won't slough off. My own experience: a whiff of these liquids, even in a filtered fume hood, leaves an acrid taste and sometimes a headache right after.

Go beyond the lab. Spill response specialists warn that ionic liquids stick to surfaces, seep into drains, and make cleanup long and unpredictable. For anyone running experiments or pilot-scale work, ignoring goggles and fume hoods could mean direct skin or inhalation exposure. Several studies (“Ecotoxicological risk assessment of ionic liquids,” 2020) show stubborn persistence in the environment — bugs and fish can’t break this compound down easily. Even lab-scale spills can run downstream.

Regulation — Playing Catch Up

Regulators move slower than innovation. The US EPA, ECHA, and OSHA list some imidazolium compounds as emerging contaminants, but only a handful face strict limits. Chemical safety officers in my experience usually import guidelines from similar substances and raise red flags for waste disposal. Green chemistry claims fall apart fast when end-of-life gets ignored, or waste drums collect forgotten residues.

Common-Sense Solutions

Simple steps shave risk: test spill kits for ionic liquids, don’t let undergraduates lab-shop without reading risk assessments, and label waste streams clearly. I’ve seen good manufacturers design closed-system bottles to cut down accidents. Waste incineration works better than pouring into water or landfill. Within research groups, one person trained in the details of ionic liquid handling can stop a dozen small mishaps a semester.

No chemical belongs on a pedestal. 1-Butyl-3-methylimidazolium thiocyanate brings plenty of promise, but that comes framed by toxicity risks. Lab safety programs and research plans have to look past the buzz and set rules that fit the full story — not the best-case scenario.

Why Proper Storage Matters

1-Butyl-3-methylimidazolium thiocyanate shows up in labs for its use as an ionic liquid. Anyone who’s handled it will understand the frustration of a substance wrecked by poor storage—moisture, decomposition, strange smells, and extra lab cleanup. When a chemical breaks down early or gets contaminated, the results waste time, damage budgets, and throw off experiment results.

Direct Experience in Handling and Storage

With ionic liquids like this, I keep a checklist of must-do’s. Knowing that moisture is the enemy here makes a big difference. Even a small dose of water in the bottle kicks off hydrolysis, changing the chemical itself and any results using it. I’ve lost a whole sample before from a leaky seal, only to discover a crust and a weird color at the bottom weeks later.

Direct exposure to air doesn’t just invite moisture. It can also introduce dust or organic vapors, so closing the container right after each use matters. Toss out the habit of leaving caps or lids off, even for a few minutes. Once, in a crowded storage room, a loosely closed bottle picked up enough humidity that entire reactions later failed. Getting into the habit of securely sealing bottles after every use pays off.

Key Storage Recommendations

Keep It Dry: Store this compound in a moisture-free environment. That means using desiccators packed with silica gel or molecular sieves. Not all lab storerooms keep humidity low, so using a dedicated dry storage container adds protection.

Avoid High Temperatures: Room temperature works for short-term storage, but I keep my ionic liquids in a cool area, away from direct sunlight or heat sources. At higher temperatures, many organic compounds break down faster or react with things in the air. A consistently cool, shaded cabinet will stretch the shelf life.

Use Suitable Containers: Original containers work best, provided they’re air-tight and chemical-resistant. Screw tops with PTFE liners stop vapor exchange and reduce risk of leaching. Glass is preferred for long-term stability; avoid plastics that might react or allow slow leaks.

Label Clearly: Every time a container is opened or transferred, mark it with the date. Freshness counts, and an illegible or missing label makes it impossible to track age or condition. Not once have I regretted overlabeling; lost or outdated chemicals cost a lot more.

Limit Access: Only trained, authorized staff should handle and store these liquids. Accidents happen more often when storage routines break down or inexperienced hands grab unfamiliar bottles.

Risks of Poor Storage—and Solutions

Compromised storage shows up as funky smells, residue, or unexpected changes in performance. I noticed this most during a project that demanded reproducibility: inconsistencies pointed right back to poorly stored base compounds. Labs should perform monthly checks, replacing or discarding any degraded chemicals.

Chemical hygiene links directly to safety and reliable results. Well-stocked desiccators, clear labeling, and consistent climate control all drive better science. For less-experienced handlers, supervision and clear written protocols help close the gap. Even an extra five minutes on storage routines can mean the difference between a solid experiment and wasted effort.

What I’ve seen first-hand—careful, informed storage protects budgets, data quality, and peace of mind in the lab. With more research labs under pressure to cut waste and improve reproducibility, handling chemicals like 1-butyl-3-methylimidazolium thiocyanate with care becomes a shared responsibility across teams.

Why Mixing Matters in Real-World Chemistry

As someone who has spent time in both the research lab and real industry settings, I often hear questions about which solvents an ionic liquid can handle. 1-Butyl-3-methylimidazolium thiocyanate (BMIM SCN) catches attention because it's not one of those old-fashioned, single-task chemicals. It’s an ionic liquid, meaning it stays liquid around room temperature and brings a chunky ion pair to the table. What interests most folks is whether it mingles well with water, given that so many chemical reactions and extractions either start with or end up mixed with water.

BMIM SCN and Water: A Closer Look

One thing jumps out from published work and chemical catalogs: BMIM SCN is quite hygroscopic. The stuff is eager to pull water from air and blend with it without fuss. Those who have handled it know that, if left out, it gets sticky as moisture sneaks in. Its parent group, the imidazolium ionic liquids, often celebrates how they break free from the constraint of single-purpose solvents. Ionic liquids like BMIM SCN dissolve a wide range of polar and even some nonpolar compounds, including dyes, some polymers, and even cellulose—which proves helpful for labs looking for greener chemistry.

When BMIM SCN meets water, it usually forms a single phase, so you don’t see messy separation. There’s measured proof: researchers have noted its full miscibility with water at room temperature. This makes it helpful for things like extraction processes or electrochemical applications that call for water-based solutions. Anyone cleaning up a reaction or moving from bench to industrial scale recognizes the headache of dealing with immiscible solvents. With BMIM SCN, that’s not a sticking point.

Mixing with Other Organic Solvents

What about those times you want to pair BMIM SCN with organic solvents? Here the story becomes more layered. With polar solvents like methanol, ethanol, or acetone, BMIM SCN dissolves pretty well. Observing the vial after a gentle shake, one sees a clear solution—not some murky mess. This comes in handy for methods that demand a smooth solvent exchange or downstream purification.

On the other hand, bring in low-polarity solvents—think hexane or toluene—and BMIM SCN doesn’t blend. Chemists run into this wall when trying to wash out their ionic liquid with nonpolar solvents. The disparity in polarity stops them from making a uniform mixture. Experiences in the lab confirm this: the ionic layer stays put, refusing to mix with lighter hydrocarbons.

Risks and Smart Steps Forward

From the safety side, letting BMIM SCN pick up too much water from the air can change its properties fast. Its viscosity drops, and sometimes its ability to solvate things changes. Proper storage in airtight bottles fights off this sneaky water uptake. For larger operations, drying the ionic liquid before use becomes routine; a few hours in a vacuum oven sorts things out.

For anyone aiming to cut hazardous, volatile organic solvents out of a process, BMIM SCN’s wide compatibility with water and several alcohols opens doors. Greener chemistry isn’t just a trendy label—it’s a necessity, given today’s regulatory push. Dumping less harmful waste and ditching flammable solvents goes a long way toward safer, more sustainable procedures.

Real-World Uses and Avenues to Explore

Those in the extraction or analytical fields already use ionic liquids like BMIM SCN to pull out stubborn organic compounds, precious metals, or residues. When the process starts or ends in water, having a miscible partner solves more problems than it causes. For material scientists experimenting with polymer processing, BMIM SCN’s broad solvent compatibility offers new options for dissolving tough materials and blending composites.

Folks in both university and industry labs stand to gain by learning which solvents pair seamlessly with BMIM SCN before scaling up any reaction or extraction. The right solvent choice keeps costs under control, cuts down on clean-up, and lets teams focus on better yields, not solvent headaches.