1-Butyl-3-Propylimidazolium Acetate: A Deep Dive Into Its Development and Impact

Historical Development

The story of 1-butyl-3-propylimidazolium acetate traces back to the broader rise of ionic liquids—a class of compounds whose roots reach into the last century. Research ramped up during the 1990s, as scientists began looking for non-volatile, thermally stable substances to replace traditional organic solvents. Driving these efforts were stricter regulations on volatile organic compounds, worker safety standards, and the rising cost of disposal. Scientists noted that imidazolium-based ionic liquids responded to these challenges by offering low vapor pressure and strong chemical stability. By the early 2000s, custom ionic liquids, including 1-butyl-3-propylimidazolium acetate, emerged from university labs and began to show up in patents for cellulose processing and clean energy storage. These advances mirrored a similar trend in process chemistry, where researchers started to study not only the solvent capabilities, but also the role these liquids could play in catalysis, separation, and electrochemistry.

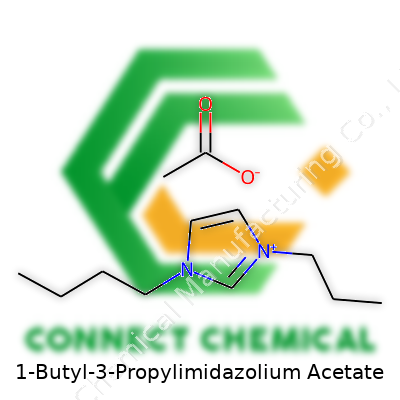

Product Overview

1-Butyl-3-propylimidazolium acetate belongs to a family of imidazolium-based ionic liquids marked by customizable cation and anion combinations. The butyl and propyl chains attached to the imidazolium ring give the molecule a unique blend of hydrophobic and hydrophilic features, while the acetate anion supplies moderate basicity and solvation power. This product comes as a viscous, clear-to-yellowish fluid, resistant to evaporation and conventional combustion. Compared to traditional solvents, this liquid stands out for its thermal robustness, ionic conductivity, and broad chemical versatility, finding a place in academic research, industry, and pilot-scale operations.

Physical & Chemical Properties

Anyone working in a lab with this compound notices its high viscosity, even at elevated temperatures. Its melting point often falls well below zero degrees Celsius. It resists boiling under normal atmosphere, thanks to its negligible vapor pressure. Density measurements run close to 1.05-1.10 g/cm³ depending on purity and handling. Because of the combination of imidazolium cation and acetate anion, it dissolves a wide array of organic molecules, metal salts, and certain polymers. Its electrical conductivity, while lower than aqueous salt solutions, still supports electrochemical applications. The acetate's moderate basicity means it can buffer solutions or participate in nucleophilic reactions—handy for anyone working in green synthesis or biomass pretreatment.

Technical Specifications & Labeling

Labels for 1-butyl-3-propylimidazolium acetate highlight its purity (often at least 98%), residual water content, and specific conductance. Manufacturers detail common impurities, such as imidazole or related halides. Storage instructions typically call for airtight containers, protected from moisture and sunlight. Batch data sheets display NMR fingerprints, elemental analysis, and reference the CAS registry number for traceability. I routinely check these technical documents before mixing any new batch since slight changes in water content or trace impurities can swing the results for a whole experimental run. Good traceability protects not just research, but also downstream application in chemical processing.

Preparation Method

The standard route involves alkylation of 1H-imidazole, first by introducing a butyl group and then propyl, or vice versa, to form the desired imidazolium precursor. The cation then meets sodium acetate in a metathesis reaction, swapping out halide anion for acetate under controlled temperature and atmosphere. Purification steps eliminate residual halides and solvents, sometimes through recrystallization, more often with activated charcoal or ion-exchange resins. Scale-up from bench chemistry to kilo-lab runs calls for careful monitoring of exotherms, yield losses, and safety protocols since even minor contamination affects both physical properties and downstream chemistry.

Chemical Reactions & Modifications

Imidazolium-based ionic liquids like this one enable a slew of synthetic transformations. They dissolve polar, non-polar, and amphiphilic compounds, opening new doors in catalysis. The basicity of the acetate anion allows subtle control over reaction pathways. I’ve seen firsthand how swapping the anion can tilt reaction selectivity toward one product or another, especially in transition metal catalysis. Some teams working on biorefinery projects harness the solvating power of this compound to deconstruct plant cellulose, making new bioplastics or fuels possible. Its own chemical skeleton—particularly the imidazolium ring—can also undergo alkylation, methylation, or functionalization to tailor solubility, stability, or catalytic behavior.

Synonyms & Product Names

Lab catalogs list this material under names including 1-butyl-3-propylimidazolium acetate, [C4C3Im][OAc], BpimOAc, and methyltriazolium acetate (though this last one crops up less often). CAS registry codes, EC numbers, and other identifiers depend on jurisdiction and cataloging system. Vendors may supply it as part of a wider set of ionic liquids, sometimes bundled for cellulose dissolution, catalyst screening, or electrochemical studies. Consistent naming improves safety and regulatory compliance during shipping and handling, an underrated detail in multinational collaboration.

Safety & Operational Standards

No one should underestimate the importance of safety data. 1-butyl-3-propylimidazolium acetate, while not explosive or especially flammable, still creates risks typical for ionic liquids: strong dermal and eye irritation, mild aquatic toxicity, and the potential for cumulative exposure over repeated handling. Personal experience taught me to always wear gloves and goggles, and to work in a well-ventilated fume hood. Safety data sheets describe first aid steps, waste handling, and spill control. Disposal requires careful separation from other waste streams, since some breakdown products can linger in aquatic environments for years. Emergency response teams expect chemical training, not just basic personal protective equipment.

Application Area

This material moved rapidly from chemical novelty to real-world use. The pulp and paper industries value its role dissolving biomass, which replaces toxic, high-pressure systems that dominated for decades. Electrochemists leverage its ionic nature for batteries, supercapacitors, and new forms of sensors. Pharmaceutical labs explore its potential as both reaction medium and recyclable extraction solvent. In materials science, it finds a place in forming nanostructured surfaces or photonic devices. The most promising uses tie back to its green chemistry profile—low vapor pressure, reusability, and the ability to streamline processes that once needed energy- or solvent-intensive steps.

Research & Development

Most innovation in this space comes from combining practical needs with disciplined science. Researchers try new combinations of alkyl chains or anions to boost performance in biomass conversion, plastic upcycling, or CO2 capture. Published papers and patents document progress, but discoveries don’t stop in journals—they ask for real proof at the bench and pilot scale. Teams working across fields treat this compound as a starting point, adapting it through in situ synthesis or partnering with local startups to tweak technical details. The push for greener solvents in industrial chemistry puts this substance in a leading role.

Toxicity Research

From my own work and review of the literature, toxicity remains a growing concern even as interest in ionic liquids surges. Initial optimism gave way to careful studies on cytotoxicity, biodegradability, and long-term ecological impact. 1-butyl-3-propylimidazolium acetate shows moderate toxicity toward aquatic microorganisms and potential chronic effects in mammals at high doses. Regulators demand comprehensive risk assessments, especially for new applications near food or environmental interfaces. Some teams approach this by searching for “benign by design” alternatives, swapping out specific functional groups to maintain performance with less downstream risk.

Future Prospects

Looking ahead, developers aim to integrate this liquid into more sustainable supply chains. Circular manufacturing calls for solvents like this to get recycled in closed loops, not simply discarded or burned. Ongoing work focuses on ways to lower production costs, cut impurities, and expand applications beyond current niches. The prospect of using ionic liquids in carbon capture or next-gen batteries drives further research dollars and industry partnerships. The challenge involves not just chemistry, but infrastructure, training, and policy support—a dynamic I’ve seen across both academic and industrial projects. Broadening the use case to fields like agriculture or water treatment will hinge on clear demonstrations of cost, safety, and real-world performance.

Pushing Back Against Harsh Solvents

Stepping into any lab or industrial facility reveals the strong smells of old-school solvents. They work, but the price comes in the form of environmental damage and health risks. I’ve watched teams suit up in thick gloves and masks, all to avoid breathing in toxic vapors. In my own chemistry days, I always wondered if something less punishing could get the job done without the mess.

1-Butyl-3-Propylimidazolium Acetate, an ionic liquid, gives a fresh take. It stays liquid at room temperature, doesn’t evaporate easily, and skips a lot of the hazards tied to compounds like benzene or chloroform. Its secret? A combination of imidazolium, butyl, and propyl groups linked to an acetate anion, pulling together strong dissolving skills for both polar and non-polar substances. This stuff breaks down cellulose—one of the world’s toughest natural polymers—without sending nasty gases into the air.

Opening the Door for Better Biomass Processing

Back in university projects on converting plant matter to biofuel, breaking up raw materials felt like tugging at ropes woven tighter than steel. Traditional acids and bases damaged the sugars we wanted to preserve. Using 1-Butyl-3-Propylimidazolium Acetate, researchers discovered cellulose dissolves gently, letting enzymatic breakdown happen more easily. This one change powers new ways to make ethanol, bioplastics, and specialty chemicals—right from corn stalks or sawdust.

More than that, it reduces the need to burn through huge amounts of water or produce toxic waste. That matters for global projects trying to lower their carbon footprint. A 2018 study published in Green Chemistry showed ionic liquids like this one outperform conventional solvents for plant biomass refinery work, cutting both pollution and dangerous conditions for workers.

Speeding Up New Materials and Reactions

My time in materials science taught me patience. Dissolving tough fibers, recycling plastics, or shaping new membranes sometimes eats up whole days. 1-Butyl-3-Propylimidazolium Acetate works like a shortcut. Whether researchers use it to craft porous films for batteries or help with nanoparticle synthesis, it brings a flexibility few other liquids manage. Direct results include better-performing filters and greener electronics manufacturing.

Organic chemists have started relying on this ionic liquid to swap out classic catalysts and solvents. The ionic liquid environment encourages selectivity in certain reactions, meaning fewer unwanted byproducts and cleaner product separations. Nature Communications ran a feature on how these conditions allow milder reaction temperatures, saving energy even in large-scale production.

Challenges and Honest Solutions

No magic bullet exists here. Ionic liquids often carry a price tag higher than basic chemicals. Worry hangs around their long-term toxicity and recyclability, since many solvents end up dumped after a single use. Companies working with them need tough protocols to capture, clean, and recycle these liquids safely.

I’ve seen better answers coming from closed-loop systems, where the liquid gets filtered and reused. Research teams in Japan and Germany are tweaking the recipe for these ionic liquids, making them break down faster in the environment and cutting production costs by switching to renewable starting materials. Grants given to scale up these green fluids go a long way toward replacing harsher, older options. This matters as more regulations squeeze out petroleum-derived solvents from chemical production lines.

A Close Look at the Building Blocks

Curiosity about molecules often stems from their names. Take 1-butyl-3-propylimidazolium acetate as an example. The structure hides in plain sight within the name. The core of this compound, imidazolium, acts as a familiar anchor for chemists exploring ionic liquids. This five-membered ring, with two nitrogen atoms at opposite edges, shapes the backbone. At one of those nitrogen spots, the butyl group connects—a straight carbon chain four atoms long. Across the ring, a propyl group—just three carbons—links to the other nitrogen.

Ionic Nature Gives Character

The full picture includes the acetate anion—two carbons, three hydrogens, and two oxygens. This pairing creates an ionic liquid, a class of substances turning heads in chemical engineering labs for the past twenty years. Their melting points drop far below what anyone expects from ordinary salts. At room temperature, these salts flow like oil, bringing a mix of stability and low volatility.

What Sets This Structure Apart?

With both butyl and propyl chains stretching from the imidazolium ring, you get a larger, more flexible cation. The arrangement influences everything from how it dissolves plant fibers to its knack for pulling metal ions out of waste streams.

The acetate anion stands out, too. Simple in shape, the acetate binds with cations easily, yet doesn’t bring high toxicity. It joins the list of “green” choices for chemists looking for less hazardous solvents.

Experiences Using 1-Butyl-3-Propylimidazolium Acetate

Work in the lab shows patterns quickly. Structures like this one dissolve cellulose—think wood pulp or cotton—better than most conventional liquids. In projects working with biofuels, the acetate version paces ahead of chloride-based cousins. Less corrosion, lower risk, higher yield. The long alkyl chains spread apart, letting larger biomolecules squeeze in and break down. Lignin, notorious for clogging bio-refineries, gives way.

On the industrial front, such ionic liquids open doors for new recycling methods. Instead of harsh acids, these salts help reclaim valuable metals from old electronics using mild heat and clever mixing. The butyl and propyl groups keep things liquid at room temperature, which means less energy spent on heating tanks or processing plants.

Safety and Research Priorities

No substance comes without risks. Handling imidazolium salts calls for respect and training. Eye and skin contact happens easily if you move too fast. Most researchers wear double gloves and work under strong fume hoods. Acetate-based liquids tend to produce fewer toxic byproducts, yet spills need quick cleanup. Waste management follows a tight loop—recycling and regeneration remain cheaper than dumping.

Toxicity studies haven’t covered every angle, especially at the scale required for widespread industry use. Scientists continue to test how these salts break down, both in water and soil. Supporting innovation relies on hard data from toxicity studies and real-world trials.

Pushing for Greener Chemistry

The push to swap out traditional organic solvents for safer, more reusable materials gains ground every year. Molecules like 1-butyl-3-propylimidazolium acetate show real promise, especially in bioprocessing and recovery projects. To get there, more effort will go to life cycle analysis—tracking every atom from creation to disposal. Open access to this research speeds progress. Cooperation across universities, government, and private labs promises smart, sustainable advances.

The Reality Behind the Name

Massive names like 1-Butyl-3-Propylimidazolium Acetate show up in research labs, green chemistry, and even some specialty manufacturing projects. Many chemists see it as a kind of ionic liquid solution. The hype about its role in dissolving cellulose, recycling, or cleaner chemical reactions sounds great, but people often gloss over what it feels like to handle this stuff in real life.

Looking Past the Hype: Real Risks at the Bench

Every trained scientist or technician who’s spent time with unfamiliar chemicals sooner or later learns to avoid assumption. Seeing “ionic liquid” sometimes tricks people into thinking it’s gentle compared to volatile organic solvents such as acetone or dichloromethane. That’s not always the case. 1-Butyl-3-Propylimidazolium Acetate doesn’t boil away or release a choking odor right out of the bottle, so quick exposures don’t necessarily raise alarms.

Still, if you dig into the safety data, red flags emerge. Lots of these imidazolium compounds tend to irritate the skin and eyes. Some research points to the risk of respiratory issues if aerosols or vapors go unchecked, especially where heating or agitation is common. Spilling a drop or splashing it across bare skin might sneak by without the immediate sting you get from strong acids, but repeated contact dries out skin and leaves rashes or chemical burns. The acetate part creates extra concern for people with sensitive skin or allergies.

Personal Experience: The Cost of Overlooking Safety

A few years ago, I worked in a university materials lab trying to dissolve plant fibers with this exact substance. In summer, everyone got lazy about gloves for supposedly mild reagents. The mistake showed up in cracked palms and stinging knuckles after half a week of carelessness. Washing thoroughly helped, yet the warning showed up late. One graduate student developed a mild dermatitis that lasted for months. This happened in a well-ventilated academic lab, so I imagine crowded production sites could see worse.

The Hard Evidence: Regulatory Guidance and Known Data

Looking at the material’s safety profile, regulatory agencies don't list it as a major toxin or carcinogen. Still, the European Chemicals Agency pushes caution: irritation to skin and eyes ranks as the primary hazard in official dossiers. Waste disposal also poses a challenge. It doesn’t break down fast in the environment, and aquatic organisms face trouble even at parts-per-million.

Relying on the MSDS (material safety data sheet) seems boring, but it saves skin—sometimes literally. Recommended precautions include triple-layer gloves for scale work, safety goggles or shields for any splashing, and splash-resistant lab coats. A chemical fume hood isn’t just overkill for this liquid; the less you breathe in, the lower the risk your throat or lungs will react. Proper disposal prevents buildup in wastewater streams, and labeling the storage bottles helps stop accidental misuse.

Better Habits In and Out of the Lab

Nobody gets a rush from putting on extra protective gear or logging waste, but real safety culture grows from these annoying routines. Asking questions and checking for the newest hazard studies keeps people safer. Research on ionic liquids is still evolving. If another, less risky solvent becomes available, the switch often makes sense. Until then, keeping your guard up, treating new compounds with respect, and backing up habits with proven data go a long way.

Anyone working with ionic liquids like 1-Butyl-3-Propylimidazolium Acetate quickly learns that even small missteps in storage come with real costs. These chemicals offer unique properties—low volatility, non-flammability, and good solvating power. They only deliver those benefits when stored right. After years in the lab and helping colleagues troubleshoot issues, I’ve seen firsthand how little things snowball into big problems if you tuck this liquid away without much thought.

Temperature and Moisture: More Than Just Numbers

I’ve opened containers that looked perfectly fine on delivery, only to find a sticky mess thanks to trace moisture in the air. 1-Butyl-3-Propylimidazolium Acetate loves to soak up water from its surroundings. Keep it dry or risk degraded performance, altered viscosity, and headaches downstream. Room temperature works for short-term storage, but I keep bulk supplies cool—always below 30°C, far from sunlight or heat-generating equipment. This slows unwanted reactions and keeps the liquid stable for months.

Sealing and Material Choices

It pays not to skimp on bottles or seals. Glass or high-quality polyethylene containers do the job, provided the cap forms a tight seal. I once caught a batch in a plastic container that started to degrade, likely from minor chemical incompatibility or a leaky lid. That mistake forced a total replacement. Never assume an ordinary plastic cap will keep out air and moisture; a strong, chemically resistant seal is non-negotiable. For extra security, I've seen some colleagues switch to amber glass to block out stray light, which can spark degradation over time.

Labeling, Access, and Safety

Walking into a cluttered storage room filled with lookalike bottles creates risk, especially with colorless or faintly yellowish liquids. I always label each bottle with the full chemical name, date of receipt, and last opened date. It sounds obvious, but skipping these steps has burned plenty of researchers. If 1-Butyl-3-Propylimidazolium Acetate ends up contaminated or too old, project timelines stretch and data goes questionable. Store only the amount you need for immediate tasks on benchtops. Everything else should stay out of reach, in a ventilated chemical storage area, away from acids, oxidizers, or open flames.

Spoilage and Waste

Once water gets in, or if the liquid sits open for too long, it starts to change—sometimes you see sticky residue, sometimes a faint fishy odor appears. Disposal brings another set of rules. Never pour it down the drain or toss it with regular trash. Each lab or workplace has its own hazardous waste plan, usually involving specialist contractors and clear logging requirements. Cutting corners here invites fines and puts people at risk.

Planning and Protocols

The right storage approach doesn't start with a product purchase; it starts with a plan. I build my protocols with advice from Safety Data Sheets, manufacturer documentation, and conversations with people who've learned these lessons the hard way. It's not about ticking boxes but about protecting every investment in time, money, and health. Neglecting the basics can derail months of work or spark needless dangers in the lab. Paying attention to details upfront keeps everyone safer, equipment cleaner, and budgets intact.

The Realities of Buying This Chemical

Not every purchase fits a simple search-and-click model, especially with lab-grade compounds. Getting your hands on 1-Butyl-3-Propylimidazolium Acetate means stepping into the world of specialty chemicals. People sometimes expect Amazon or eBay to carry everything under the sun, but for a substance like this, you need to look towards chemical suppliers tuned into research and advanced manufacturing.

Over the years, I’ve helped colleagues navigate this world, and one thing stands out: cutting corners never pays off. Legitimate suppliers ask for evidence of a legitimate research or industrial need. If a site glosses over who they’re shipping to, the red flag can’t get much redder. Typically, the top suppliers include Merck/Sigma-Aldrich, TCI America, Alfa Aesar, and Thermo Fisher Scientific. Each one asks for end-use statements or institutional proof, and for good reason.

Quality Control and Safety: Key Factors

Anyone can sell something that looks like the right stuff in a bottle. True value for science and industry comes from purity, handling history, and proper storage. I’ve seen bright students frustrated by results, only to trace the problem back to sketchy sourcing. With 1-Butyl-3-Propylimidazolium Acetate, impurity levels can mean the difference between a breakthrough and a wasted grant. The consistent labs rely on vendors who document every step of their process.

Another issue is regulation. Some ionic liquids raise eyebrows for regulatory bodies. It’s not that this particular one sits on a hot list, but governments around the world expect buyers to explain their purposes, trace inventory, and apply safe handling. Back in 2020, new documentation requests swept through labs where I worked, all to head off illicit uses. Good vendors walk you through compliance, making your life easier in the long run.

How to Approach the Buying Process

Start with clear intent. Commercial suppliers want to know what you plan to do. My university set up accounts only after vetting projects, listing responsible persons, and training on hazardous material handling. Even a high school chemistry teacher goes through a similar process for lower-stakes chemicals. Send inquiry emails with details: intended use, quantity, and any purity benchmarks.

If you’re running research at home or hoping to tinker, it’s much harder than it used to be. Reputable sellers need a university affiliation, lab credentials, or verified business entity. A lot of small startups find themselves stalled here, but this isn’t just red tape—it’s a necessary bar to entry that keeps science safe and credible. Some distributors work with startups if you provide articles of incorporation and clear documentation of lab safety protocols.

Better Solutions: Collaboration and Shared Resources

For solo researchers and small teams locked out by supplier minimums, there’s another way. Universities sometimes offer chemical sharing programs or material transfer agreements. Professional societies connect researchers, sometimes even pooling resources on bulk purchases to cut costs. A few years ago, I joined a shared purchase effort through a networking group, which opened doors otherwise closed by high minimum order sizes.

Navigating specialty chemical sales isn’t for the faint of heart, but the safeguards serve a real purpose. If you commit to transparency and safe practice, the reputable companies work with you. Start with suppliers who put traceability, documentation, and quality upfront—and never trade certainty for convenience.