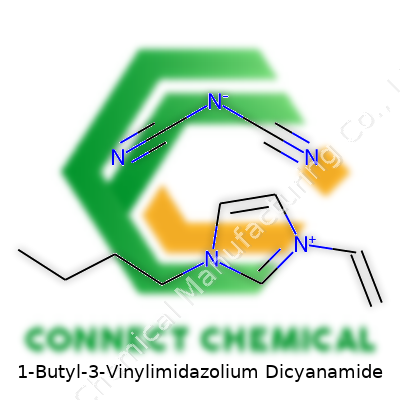

1-Butyl-3-Vinylimidazolium Dicyanamide: An In-Depth Look

Historical Development

Industrial chemists began exploring ionic liquids like 1-Butyl-3-vinylimidazolium dicyanamide as the search for new, environmentally-friendlier solvents reached a fever pitch in the final decades of the twentieth century. Imidazolium salts, once seen mostly as academic curiosities, began attracting more interest for their unlikely combination of low volatility and surprising stability. As green chemistry principles spread through research labs, this type of ionic liquid fit a growing need for alternatives to harsh, volatile organic compounds that often left heavy environmental footprints. Scientists around the world started to focus on tuning both cation and anion structures to create materials with custom performance in everything from synthesis to electrochemistry. The marriage of a butyl-vinylimidazolium cation with a dicyanamide anion grew popular for its blend of thermal stability, solvent power, and synthetic flexibility, helping shift ionic liquids away from experimental shelves into commercial and industrial trial runs.

Product Overview

No solvent can claim a single purpose, but 1-Butyl-3-vinylimidazolium dicyanamide stands out for its ability to bridge organic, polymer, and electrochemical spheres. In the lab, researchers use it for its unusual polarity: unlike water or common organic compounds, it balances both ionic strength and manageable viscosity, letting it act as a reaction medium or an electrolyte. Product specifications often focus on purity and water content since contaminants can throw off sensitive reactions or electrochemical measurements. Storage and handling protocols help keep the compound stable, with tightly closed bottles and low-humidity conditions avoiding hydrolysis or contamination.

Physical & Chemical Properties

One of the most helpful qualities, from a practical viewpoint, is the compound’s liquid state at room temperature. This trait eliminates the need for special heating or cooling equipment and opens the door for continuous-flow synthetic processes. Viscosity lands in a workable middle range; too thick, and handling equipment clogs, too thin, and containment grows wasteful. Thermal stability stretches beyond what most organic solvents provide, resisting decomposition up to 200°C in inert conditions. The dicyanamide anion gives the liquid moderate basicity and supports a range of redox and coordination chemistry. A mild odor and limited volatility mean safer handling, especially in comparison to common chlorinated solvents.

Technical Specifications & Labeling

Reputable suppliers provide comprehensive labels, including molecular formula (C10H13N5), CAS number (usually 799265-83-9), and purity grades. Quality assurance teams rely on chromatographic and spectroscopic methods for batch testing, often using NMR and FTIR to verify structure and screen for unintended byproducts. Product safety data sheets (SDS) include safe-handling tips, chemical compatibility checks, and emergency response instructions—a key aspect as regulations around ionic liquids tighten and safety inspectors place more weight on traceability and storage.

Preparation Method

Synthesis begins with an alkylation route. A butyl group attaches to an imidazole ring, which then undergoes vinylation. Later, a salt metathesis—typically using sodium dicyanamide with the imidazolium halide precursor—creates the final dicyanamide salt. Purification methods, like rotary evaporation to remove excess solvent, follow. Final drying steps under vacuum yield a product fit for both research and industrial use. Each step requires dialed-in conditions since impurities can carry over, blocking desired catalytic activity or impacting electrochemical panels.

Chemical Reactions & Modifications

Applying 1-Butyl-3-vinylimidazolium dicyanamide in the lab spurs innovation in reaction design. The vinyl functionality lets it participate in radical and polymerization chemistry, linking with other monomers to create advanced polymeric materials. Both cation and anion portions open the door for ion exchange, complexation, and mediation in electron-transfer reactions. Chemists in battery research rely on its ability to form stable interfaces, enhance ion transport, and increase cycle life for next-gen energy storage. Stimulation by light or heat can change its reactivity, giving it a role in tailor-made catalysts or functional materials.

Synonyms & Product Names

Suppliers and catalogues list this compound under several names: 1-butyl-3-vinylimidazolium dicyanamide, BVImDCA, and its systematic variant, 3-vinyl-1-butyl-1H-imidazol-3-ium dicyanamide. These aliases matter for research reproducibility and for procurement departments aiming to avoid costly ordering errors or regulatory mix-ups. International markets stick to IUPAC naming conventions to maintain clarity, especially in customs paperwork and regulatory filings.

Safety & Operational Standards

Safe labs develop habits that keep both staff and the environment protected, and this ionic liquid fits right in. It escapes the risks usually tied to volatile organic solvents—no real inhalation hazard, low flammability—but that does not mean protocols slip. Direct skin contact remains a problem, sometimes causing irritation, so full nitrile-glove protection and chemical goggles remain a daily practice. Spills can make for an unwelcome surprise if allowed to reach drains or mix with incompatible chemicals, so sealed containers, secondary containment, and closed-system handling get enforced. Waste follows controlled disposal routes; ignoring local environmental regulations puts research licenses and company reputations on the line.

Application Area

The versatility built into 1-Butyl-3-vinylimidazolium dicyanamide makes it a recurring player in fields as diverse as organic synthesis, electrochemistry, and coatings. Industrial facilities exploring cleaner synthesis routes lean on its solvating power to speed up otherwise sluggish reactions. Polymer scientists mix it into new blends to test out conductivity, flexibility, and thermal windows. Battery designers experiment with it as a safer electrolyte, hunting longer cell life and fewer toxic byproducts. In research circles, this compound acts as a reliable testbed for pushing the envelope on “greener” chemistry, challenging traditional beliefs about what a solvent or ionic medium should accomplish.

Research & Development

Recently, research groups worldwide have been designing new processes rooted in ionic liquids, seeking both better yields and cleaner outputs. Projects funded by government green initiatives or private sector investment almost always favor compounds like this one, which limit the dangerous vapors or persistent pollution of old-school, carbon-based solvents. Strong collaboration between academia and industry drives progress, as start-ups and big-name chemical companies alike try to patent new processes that can reduce costs without dropping performance. Lab results point toward improved control over polymerization, catalytic selectivity, and electrode optimization—a testament to the flexibility that comes from decades of careful structure tuning.

Toxicity Research

Early high hopes for ionic liquids sometimes brought complacency about toxicity, but current studies take nothing for granted. In-vitro and in-vivo trials now examine acute and chronic effects, testing exposure on skin, lung, and cell cultures. For 1-Butyl-3-vinylimidazolium dicyanamide, data show a moderate level of toxicity if ingested or if it sits in extended contact with skin, but almost no evidence of significant vapor hazard during standard lab procedures. Environmental scientists keep an eye on breakdown products in wastewater, addressing any risk of toxicity to aquatic life. Laboratory users adjust their protocols as data emerge, swapping in newer ionic liquids if persistent effects show up in soil or aquatic tests.

Future Prospects

Practical hurdles, such as price per kilogram or recycling logistics, have kept ionic liquids like this one from conquering every industrial sector, but new partnerships and process innovations are changing the landscape. Advances in recovery from reaction streams, purification of spent batches, and upscaling from bench-top to ton-scale production all hint at a future where this class of compounds grows central to everything from batteries to pharmaceuticals. Researchers keep pressing for higher-yield syntheses and lower environmental footprints, making every generation more resource-friendly. Cross-disciplinary projects—blending synthetic chemistry, materials science, and engineering—should keep 1-Butyl-3-vinylimidazolium dicyanamide a focus of experiment and debate for years to come.

Reshaping Chemical Processing

1-Butyl-3-vinylimidazolium dicyanamide finds its home in the world of ionic liquids. Chemists often talk about how stressed they feel working with toxic and volatile organic solvents. Here’s where this compound enters the room with real benefits. In my time working at a research lab focused on cleaner chemistry, I’ve seen the eagerness for smarter solvents. This compound supports reactions that need stable, low-vapor pressure environments. Synthesis of pharmaceuticals and high-value chemicals benefit most. Production facilities get safety and yield in a package that doesn’t stink up the room or demand strict hazard storage protocols. Numbers from peer-reviewed journals underscore this: using ionic liquids instead of traditional solvents often drops both workplace incidents and waste by significant margins.

Plastic Revolution

The plastics industry constantly seeks additives that bring new life to old formulas. 1-Butyl-3-vinylimidazolium dicyanamide acts as more than a background player—it actively provides antistatic and conductive properties to polymer blends. If you’ve ever shocked yourself on a plastic device, you can thank the lack of smart additives. Tech companies behind things like handheld gadgets and 3D printing materials turn to this compound for enhanced performance. The vinyl group doesn’t just sit there; it allows the molecule to co-polymerize, actually becoming part of the polymer backbone. That offers stability that other ionic liquids can’t deliver. Articles in respected materials science journals show measurable improvements in conductivity and durability, confirmed by repeatable lab and industrial trials.

Sparking a Greener Electrochemical Field

Development in batteries and capacitors depends on more than just lithium or rare metals. Electrolytes have a huge role in efficiency, lifespan, and environmental safety. A friend in the battery prototyping area shared how frustrating it feels watching equipment degrade because the electrolyte can’t cope with repeated cycles. This ionic liquid brings about better charge transport without setting off environmental red flags. In supercapacitors and next-gen batteries, it reduces flammability risk and expands the voltage window. Electrochemical Society studies have shown the compound’s use reduces cell failure and extends storage capacities. It addresses safety, a factor too often skipped when companies chase performance.

Sustainable Extraction and Separation

Mining and refining industries look for greener ways to pull out metals from complex ores. Conventional solvents often pollute rivers and soil. In pilot runs, 1-butyl-3-vinylimidazolium dicyanamide makes metal extraction more selective and less reliant on acids and toxic organics. I’ve seen process engineers, after long shifts, breathe easier (literally and figuratively) knowing fewer regulations clamp down on their processes. Reports from environmental chemistry departments show that this liquid sharply reduces heavy-metal leaching and solvent loss compared to the old-school methods.

Future Steps and Room for Growth

No chemical is perfect, and scaling up this compound does present cost and handling questions. There’s real potential in localizing production and recycling—I’ve met teams tackling these issues, using both green chemistry principles and business sense. Collaboration between manufacturers, regulatory bodies, and academic labs fuels improvement. Safer workspaces and a lighter environmental footprint can turn from vision to reality through persistent research, solid pilot projects, and open data on environmental impact.

Across chemical processing, product manufacturing, batteries, and resource extraction, the main value of 1-butyl-3-vinylimidazolium dicyanamide stands in its combination of safety, performance, and adaptability. Whether working at the bench or on the shop floor, better solutions like this compound move the entire field toward a cleaner, more resilient tomorrow.

Getting Down to the Reality of Chemical Safety

People who spend time in labs come across a long list of chemicals, some friendlier than others. 1-Butyl-3-Vinylimidazolium Dicyanamide comes with its own set of rules, and ignoring them means risking your health and the safety of those nearby. This isn’t just about respecting the paperwork—experience always teaches faster than any safety data sheet.

Known Hazards in the Real World

This compound falls under the category of ionic liquids, which often sound less threatening because they don't boil off easily in the air. Even so, that doesn't mean they’re easy on lungs, skin, or the environment. Dicyanamide, a key part of this molecule, can be toxic. Direct, unprotected contact with skin opens the door to irritation or even chemical burns. Breathing in dust—or accidentally letting it touch an open cut—increases the risk of toxic effects. Not every lab is equipped with perfect ventilation or instant-eye-wash fountains, leaving those who cut corners more exposed to problems.

Precaution as Routine, Not Afterthought

No piece of research or factory production line should overlook personal safety. Gloves resist chemical soaking, and not all gloves are created equal—nitrile often gives strong protection, but checking compatibility with dicyanamide really matters. Chemical splash goggles shield eyes from splashes, which always seem to happen at the worst time. Disposable lab coats block small spills from soaking through to skin or clothing, which isn’t just about comfort—old hoodies covered in chemical residue wind up in the laundry, spreading risk.

Ventilation goes beyond running a noisy fan. A working fume hood pulls away airborne particles and vapors, trapping them before they turn into a hazard. Labs without good airflow develop exposure problems over time, and those handling this chemical without a working hood invite trouble. Monitoring for spills with absorbent pads keeps contamination from spreading to bench surfaces, and regular disposal prevents buildup.

Storage: Small Habits, Big Impact

This compound should stay in tightly sealed containers, away from heat and direct sunlight. Airtight bottles marked clearly with hazard labels help everyone avoid accidental mix-ups. Never store it with strong acids or bases—bad reactions can creep up and make a simple mistake much worse. Anyone in labs with faulty shelves or crowded chemical spaces understands the headache of tracking down leaks or contamination. Keeping chemicals where they belong shortens clean-up and improves safety for everyone passing through.

Training and Communication: Culture Over Compliance

Knowing which chemicals cause harm doesn’t matter unless people actually talk about it. Training isn’t just a boring checkpoint; it’s what keeps people healthy years down the line. Sharing stories about slip-ups and close calls keeps awareness alive in a way that no poster or handout captures. Encouraging honest questions and reminding colleagues to wear their gear—especially on busy days—sets a standard. Safety grows from these habits more than from rules printed on walls.

Looking Ahead: Solutions from Day-to-Day Practice

Many organizations improve safety by offering regular drills and open talks about near-misses. Digital sensors and chemical inventory apps reduce forgotten containers and help track expiration dates. Simple ideas, like more obvious labels and shelves designed to prevent tipping, matter just as much. Feedback from those handling this chemical every day leads to the changes that actually work. In busy labs and production floors, no substitute exists for practical, hands-on experience shared across the team.

Understanding What Chemical Purity Means on the Ground

Ask someone who’s worked in a lab or run a food processing line, and they’ll tell you—chemical purity makes or breaks the whole deal. At the most basic level, purity speaks to how much of your product is actually the chemical you paid for, as revealed by precise lab analysis. Purity runs on a scale, usually in percent— you see figures like “99.9% pure sodium chloride,” for example. Even that small decimal makes a big difference in something like pharmaceuticals, electronics, or specialty foods.

A product with proper certification will nail down not just the main ingredient, but a whole host of impurities—stuff like heavy metals, moisture, and other trace leftovers from the production process. High-end suppliers hand over a certificate of analysis for each batch, spelling out these specs in detail. If you’re in a QC lab, you rely on this info every day. Most assume “pure” means “perfect,” but absolute chemical purity only exists in theoretical chemistry. The real world always brings a few parts per million of something unwanted.

Why Product Specifications Matter

Chemical purity is only one slice of the pie. Actual product specs cover physical qualities, packaging, how the material reacts to air or light, and even its grain or solution form. For example, if your organization uses sodium hydroxide, you probably specify grades like “ACS,” “technical,” or “reagent.” Each one tells you what contaminants might ride along. Pharmaceutical grade, on the other hand, applies much tighter controls—meeting requirements set out by pharmacopoeias such as USP or EP, with requirements for not only purity but also specific identity and limits on arsenic, lead, and microbes.

Specs grow tougher depending on the risk involved. If you produce semiconductors, your silicon needs to be so pure that impurities are measured in parts per billion. A tech like that—on the level used by the chip industry—demands absolute control from raw material right through to finished wafer. One minor contaminant and you've thrown away weeks of effort. In agriculture, by contrast, bulk chemicals like potash or urea focus less on purity and more on matching typical application needs—though even there, markets push for tighter specs as global standards rise.

Where Real-World Problems Crop Up—and How to Solve Them

In the real world, chemical purity turns into a trust issue—sourcing from a reliable partner is more than just paperwork. Shortcuts happen. I’ve seen cases where a cheaper batch slips through, purity comes in lower than promised, and after a few weeks you’re chasing down odd results in your process. These moments always shed a harsh light on why purchasing teams and lab folks need to speak the same language. Good suppliers step up, investing in their own testing, following GMP or ISO 9001, and keeping a tight audit trail.

The answer starts with buying from companies with traceable sources, demonstrated certification, and a willingness to stand behind their analysis. Don’t just grab the cheapest quote—ask for the last batch’s certificate, compare real numbers, and watch for any pattern of drifting impurity levels or missed specs. That kind of attention doesn’t just protect the end product; it keeps your reputation and, sometimes, people’s safety intact. Just one impure shipment can grind production to a halt, or worse, endanger those who trust your work.

So, chemical purity is never just a lab number. Trust, transparency, and regular vigilance go hand-in-hand with technical figures. Dig deeper and demand better. That’s what keeps any operation moving forward without nasty surprises.

Understanding the Risks Upfront

1-Butyl-3-Vinylimidazolium Dicyanamide slips into all sorts of lab routines. It brings value in catalysis and as a solvent, but this chemical isn’t just another bottle to toss on the shelf. I’ve worked in labs that downplay safety around chemicals like this, and it’s a shortcut that eventually brings real problems. Sometimes, you only realize the stakes when an accident ruins good work or threatens health. It only takes one spill or an unexpected reaction to find out what ignoring proper storage means.

Environment Matters More Than You Think

Keep 1-Butyl-3-Vinylimidazolium Dicyanamide away from moisture and sunlight. The dicyanamide ion can react with water, giving off hydrogen cyanide under the wrong conditions. You can’t see it or smell it as soon as it starts, which makes humidity a much bigger problem than it looks. Store it in airtight containers. Glass or high-quality plastic with a tight seal beats bags and makeshift lids. I’ve seen old glass jars with missing rubber gaskets or scratched lids let in air and ruin chemicals faster than you’d think.

Temperature: The Forgotten Factor

Cool, dry space—those three words always pop up for a reason. Heat encourages decomposition, and this is never harmless with chemicals carrying nitrile groups. My own small fridge for volatile reagents changed everything in my work area. Keep this compound at room temperature or cooler, as long as the area stays dry. Don’t pile other reactives close by. Proximity increases risks, especially if something leaks. I’ve had solvents stored right next to incompatible compounds—moving them made the difference between a dangerous mix-up and a safe cleanup.

Respect Chemical Compatibility

Never place this chemical near acids, strong bases, or any reactive metals. All too often, I’ve seen general chemical shelves turn into a jumble. Even one misplaced bottle can turn a shelf into a risk zone. Invest a little time in organization upfront. Separate storage cabinets with clear labels and secondary containment trays can prevent contamination. I remember a nightshift tech who didn’t realize the hazard of storing imidazolium salts next to acidic waste. Catching it early meant nothing dangerous happened, but this kind of vigilance takes effort from everyone using the space.

Personal Touch: Keeping People Safe

Personal accountability ripples through an entire lab. Lock corrosive and toxic chemicals away from shared or public spaces. If you work with students or anyone new to the lab, train them with live demonstrations. Only seeing a chemical’s label without hands-on instruction invites guesswork, not good judgment. Check your chemical’s SDS or technical sheets, but also learn from people who’ve handled it before. They might mention quirks that don’t show up in paperwork.

Solutions Aren’t Complicated—but They Work

A chemical storage log keeps inventory tight and ensures everyone knows what’s in the cabinet and what’s running low. Good ventilation matters—for you and for the rest of your team. If you find damaged containers or leaking lids, don’t put it off. Contain the spill, flag the area, and replace what’s damaged. Small actions like regular checks and shared reminders keep everyone accountable.

Taking care with 1-Butyl-3-Vinylimidazolium Dicyanamide isn’t overkill—it’s just good chemistry. I’ve seen careful storage build trust in shared workspaces and reduce accidents. It’s one of the lowest-effort, highest-reward habits in the lab, and it always pays off.

From Chemistry Textbook to Real-World Labs

As someone who spent long hours coaxing stubborn mixtures to behave in the lab, I lean into the nitty-gritty when looking at new ionic liquids like 1-butyl-3-vinylimidazolium dicyanamide (BVIM DCA). Research and industry circles have tossed this compound’s name around with a sense of promise. The vinyl group gives chemists a convenient handle for making functional materials. That single tweak in structure opens up a menu of polymerization options, some more straightforward than others.

Facing Up to Polymerization Challenges

Real progress in polymer science rarely comes from theory alone. BVIM DCA’s vinyl group sits ready for radical polymerization, creating polymers with ionic bumps all along the backbone. These types of polymers push the limits in energy storage and separation technologies. If you aim to make something like a polyelectrolyte membrane, you’ll notice how the DCA anion drops viscosity compared to more classic ionic liquids. The result: easier processing, whether you’re mixing by hand or scaling up to pilot runs.

A practical snag happens during the polymerization itself. Imidazolium-based monomers, including those with vinyl, can slow down the reaction because the ionic groups grab onto radicals, or sometimes act as a mild chain transfer agent. So, you can’t just transfer recipes from vanilla acrylates and expect a smooth ride. Running careful kinetic studies helps to squeeze the best results from BVIM DCA, especially if you plan to combine it with traditional monomers to dial in properties.

Digging into Ionic Liquid Applications

In the world of ionic liquids, dicyanamide stands out for low toxicity and mild coordination chemistry. BVIM DCA slides into roles as both a solvent and functional building block. Electrochemists look at this compound because it lets ions zip around quickly without high volatility or flammability. Safe, conductive fluids have value in batteries and capacitors, so BVIM DCA isn’t just a curiosity—it forms the backbone of serious device prototypes.

Many ionic liquids work just as designer solvents for hard-to-dissolve materials or for pulling off clean separations. BVIM DCA shows better performance than some traditional imidazolium salts because the dicyanamide anion is less likely to poison catalysts or drag down reactivity. The result is more reliable yields in delicate syntheses.

No Silver Bullet, but Tools Worth Knowing

There’s no magical solution for every problem in polymer or battery technology, but BVIM DCA is carving out its place. Its ionic nature can affect polymer microstructure—sometimes making films more brittle, sometimes increasing conductivity in finished products. You need to balance composition, process conditions, and downstream use if you want real-world success.

Constant feedback from real applications is crucial. In pilot lines, small tweaks to the monomer mix or processing temperature can swing results from sticky mess to robust, conductive film. Experienced hands make the difference between theoretical promise and practical adoption. That’s why keeping BVIM DCA on the short list for ionic liquid and polymerization R&D makes sense, especially as demands for safer, tunable, and high-performance materials keep rising.

Looking for Smarter Materials

Growing interest in sustainable chemistry and safer solvents drives the search for more options like BVIM DCA. Innovation in this sector means plenty of bumps, but also real potential for breakthrough products. Field reports and iterative experimentation, backed up by solid data, set apart those who just chase trends from those who set them. Anyone serious about cutting-edge polymerization or energy storage should consider what this compound brings to the table—quirks, benefits, and all.