Exploring 1-Butyl-3-Vinylimidazolium Hexafluorophosphate: Insights and Perspectives

Historical Development

The story of 1-Butyl-3-Vinylimidazolium Hexafluorophosphate goes back to the early surge in interest surrounding ionic liquids during the late 20th century. At that time, researchers across the world looked for ways to replace hazardous volatile organic solvents in the lab and industry. Modern organo-ionic chemistry began to pivot, chasing better thermal stability, lower toxicity, and the kind of easy tuning that organic synthesis often demands. The imidazolium cation, with its tunable alkyl and functional substituents, shined as a candidate. People working in small university labs would hand-mix these salts and marvel at their physical peculiarities—liquids that didn’t even smell. The addition of a vinyl group and pairing with a robust hexafluorophosphate anion pointed this salt down the road toward more chemical utility, particularly in electrochemical systems and green chemistry efforts.

Product Overview

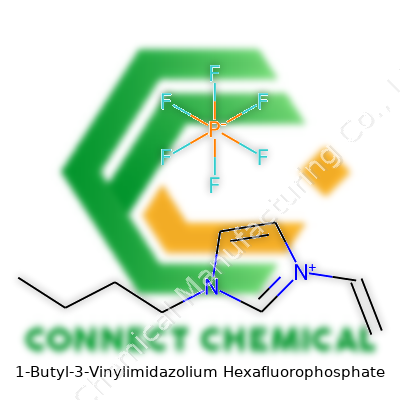

1-Butyl-3-vinylimidazolium hexafluorophosphate pairs a flexible organic cation with a stable, anion known for its weak coordination properties. Its chemical formula charts as C11H17F6N2P. This ionic liquid became popular for both its stability and functionality, acting in applications as simple as a specialty solvent and as advanced as a monomer for polymerization and synthetic transformations. Academic labs, especially those focusing on sustainable chemistry, turn to this compound for its capabilities in catalysis and electrochemistry experiments. Pharmaceutical fields, sensor technology, and polymer synthesis each find reasons to stretch this product in new directions. Over time, the compound has moved from a handful of specialty catalogs into more standard inventory for chemical suppliers worldwide, painting a picture of growing demand for this quite modern class of chemicals.

Physical & Chemical Properties

Visually, 1-butyl-3-vinylimidazolium hexafluorophosphate comes as a colorless or pale yellow, viscous liquid. This viscosity stands out, giving a sense of its unique molecular structure even to the naked eye. Temperature and moisture have a significant impact: the salt absorbs water from the atmosphere, which often calls for handling inside a glovebox or under an inert gas stream. The liquid’s density and refractive index sit at values consistent with those of other imidazolium-based ionic liquids, with density close to 1.2 g/cm³. It exhibits low volatility, which allows open-bench handling in ways impossible for classic volatile organic solvents. The presence of the vinyl group opens the door for many chemical reactions, distinguishing it from its saturated cousins, and the hexafluorophosphate anion resists nucleophilic attack and hydrolysis much better than simple halides or nitrates.

Technical Specifications & Labeling

This compound’s technical label centers on purity—typically supplied at >98% purity with careful attention to halide and moisture content. Industrial and research-grade material comes in tightly sealed bottles, usually amber glass or specialized plastic, with clear labels showing hazard symbols for irritant or environmental warning (due to the fluorinated anion). Shipping documentation has to flag this substance for possible PF6-associated hazards. Handling instructions describe the need for chemical gloves, goggles, and good ventilation, as material safety data sheets point out the risk of hazardous decomposition under strong heating or exposure to acids. As this salt straddles the fine line between specialty commodity and research chemical, distributors keep tight track of lot numbers, quality control measures, and sources of starting materials—a reflection of its growing use in regulated industries.

Preparation Method

Crafting 1-butyl-3-vinylimidazolium hexafluorophosphate in the lab feels like a small piece of alchemy. The typical route begins with the alkylation of 1-vinylimidazole using butyl halide, usually bromide or chloride, under controlled temperatures and solvent conditions. This yields the bromide or chloride salt, which chemists purify through crystallization or vacuum drying. The next stage swaps the halide for hexafluorophosphate with a metathesis reaction—mixing with potassium hexafluorophosphate in water or acetonitrile, prompting a brisk exchange and the formation of the desired ionic liquid. Extraction and drying remove residual water and solids, after which the product is filtered, washed, and dried in vacuo, ending with a high-purity, ready-to-use liquid. Attention to detail in solvent drying and controlled reaction atmospheres makes all the difference in getting a reproducible, clean product.

Chemical Reactions & Modifications

Chemists don’t just stop at synthesis. They treat 1-butyl-3-vinylimidazolium hexafluorophosphate as both a solvent and a reagent. The vinyl group’s unsaturation makes it ripe for addition reactions, free radical polymerization, and even functional group transformations under the right conditions. In polymer science, this salt becomes the backbone for ionic polymers featuring enhanced conductivity and unique mechanical properties. That vinyl handle supports cross-linking, facilitating the design of gel electrolytes or solvent-free ionic polymer networks used in advanced batteries and fuel cells. The hexafluorophosphate anion, inert and hydrophobic, protects the system against hydrolysis and nucleophilic attack—a boon for long-term stability in devices and during catalysis. Researchers tinker by swapping the butyl side-chain or tweaking the anion, tuning solubility, viscosity, and electrochemical window for specific demands in new material design or process optimization.

Synonyms & Product Names

Chemical nomenclature often turns messy, giving this compound several aliases across journals and catalogs. It appears as 1-butyl-3-vinylimidazolium hexafluorophosphate, BVI-PF6, or BVIM PF6. In some supplier sheets, it falls under trade names referencing either the core ionic liquid class or blends containing similar cations. These synonyms, while seemingly trivial, can mean the difference between stumbling through a dataset and finding a compound’s full track record in research. Over the years, naming conventions have drifted closer to IUPAC standards, though specialty suppliers sometimes lean into shorthand or brand styles. To avoid confusion, laboratory stockrooms and ordering systems keep an internal index of abbreviations and synonyms alongside the standardized CAS number.

Safety & Operational Standards

Working with fluorinated salts often proves safe but requires respect for toxic decomposition products. 1-butyl-3-vinylimidazolium hexafluorophosphate ranks lower in volatility and acute toxicity than traditional organic solvents but introduces risks around PF6^- decomposition to toxic gases such as HF, especially at high temperatures or in acidic conditions. Chemists avoid excessive heating or contact with strong acid, relying on sturdy fume hoods and PPE. Environmental health teams in academic settings remind staff that PF6^- persists in water and soils, raising disposal and spill-control issues. Waste management involves segregating ionic liquid waste for incineration or specialized chemical processing, never mixing with halide-rich or acidic streams. SOPs highlight prompt clean-up of spills, restricted use in open containers, and regular monitoring of lab environments for persistent contamination.

Application Area

Industry and research fields mine the value of this ionic liquid across several domains. In green chemistry, its use as a solvent with low volatility and high stability helps cut down emissions in synthesis and processing. Polymer scientists polymerize the vinyl group to create robust electrolyte membranes geared for batteries or fuel cells. Electrochemistry labs pursue it for its wide electrochemical window, enabling studies of redox-active species without interference from solvent degradation. Sensing technology employs this salt in designing chemically selective layers on sensors, drawing benefits from its ionic nature and resistance to fouling. Catalysis research, particularly for transition metal-catalyzed systems, values the unique coordination environment provided by both the imidazolium ring and the PF6^- anion. Academic review literature shows steady growth in its application footprint, linking back to broader efforts in renewable energy, sustainable materials, and molecular electronics.

Research & Development

Development circles focus hard on tuning this compound for performance. Labs worldwide publish data on how the butyl group length, vinyl group position, and choice of counteranion nudge properties including conductivity, viscosity, and electrochemical stability. Funding bodies chase ideas like greener production methods, replacing wasteful solvents used in ionic liquid synthesis with directly recyclable or solvent-free processes. As battery technology surges ahead and societies look for new ways to store intermittent renewable energy, the demand for ionic polymers, gel electrolytes, and solid-state conduction paths all drive applied research. Cross-institutional collaborations explore blending this ionic liquid with biodegradable polymers, using its intrinsic stability to toughen up water-based materials. Patent filings now blend process innovation with formulation science, keeping the intellectual property landscape lively.

Toxicity Research

Toxicological studies provide a foundation for safe handling and expanded applications. Chronic exposure studies, while still emerging, suggest lower risk than many halogenated organics or metallic salts, but environmental chemists worry about the fate of the hexafluorophosphate ion. Laboratory exposure monitoring, modeled on the best practices of organofluorine safety, keeps labs alert for airborne or waterborne byproducts. Acute toxicity tests in model organisms show mild irritation effects, yet the potential for long-term bioaccumulation persists, especially if disposal practices slip. Environmental impact research stretches into aquatic systems, asking whether the resistance to hydrolysis seen in PF6^- creates unexpected environmental persistence. Regulatory bodies keep a close eye on these findings, updating recommendations for storage, transport, and waste management in step with fresh research.

Future Prospects

This compound sits on the border of specialty chemical and mainstay industrial material, with its promise shining brightest in next-generation materials and devices. Researchers look toward the development of even more stable ionic networks, recyclable solvents, and less hazardous anion systems. Battery research will likely expand its scope, chasing safer, longer-lived electrolytes for everything from wearables to electric vehicles. Green chemistry advocates push for lifecycle assessments, calling for more direct synthesis from bio-derived feedstocks or coupling reactions with lower environmental impact. Regulation and transparency move to the forefront, as larger-scale use demands tighter control and more comprehensive toxicity data. The widening field of polymer science encourages new cross-linking strategies, blending ionic liquids with biodegradable and renewable backbones. As more companies invest in sustainable technology platforms, the genius of tuning both cation and anion components will keep driving innovation, shaping the way this salt finds its place in the story of modern chemistry.

Why This Compound Matters

Science likes its long names, and 1-Butyl-3-Vinylimidazolium Hexafluorophosphate certainly stands out. Ask anyone who’s spent time in a modern lab, and they’ll tell you: ionic liquids like this one are the unsung workhorses. You won't find it in grocery stores or behind the pharmacy counter, but it shapes everything from sustainable manufacturing to advanced electronics.

Role in Green Chemistry

Most folks think solvents are just the fluids that carry other chemicals. Conventional options—like acetone and toluene—leave trouble behind, either polluting the air or creating tough disposal problems. 1-Butyl-3-Vinylimidazolium Hexafluorophosphate swaps out those hazards with lower toxicity and almost no vapor pressure. In straightforward language, it won’t easily evaporate or set off air pollution alarms. This makes it easier for chemists to stick to tight environmental rules—something companies can’t ignore as greener standards become the law, not just a marketing trick.

Electrochemical Devices and Batteries

Run-of-the-mill batteries can’t handle heat or high-energy conditions well. Here’s where this compound steps up. It keeps its form at higher temperatures and does not break down as quickly, even in punishing settings. Scientists have used it in fuel cells, lithium-ion batteries, and even in next-generation supercapacitors. The payoff shows up in longer battery life and greater safety, something everyone appreciates if you’ve ever felt a phone getting dangerously warm.

Polymerization and Material Engineering

Material nerds (I count myself one) get excited by how this ionic liquid acts as a solvent and a building block, thanks to its vinyl group. Imagine making plastics without messy catalysts or risky additives. That’s possible here. The vinyl group hooks easily onto growing polymer chains, letting researchers control the process more tightly. This matters for industries looking to tailor plastics for specific jobs, whether that’s filtering water or creating medical devices that don’t leach unwanted chemicals.

Biotechnology and Extraction

Anyone who’s worked on bio-based extractions—pulling valuable molecules out of plants, for instance—knows the headaches caused by conventional organic solvents. 1-Butyl-3-Vinylimidazolium Hexafluorophosphate can dissolve stubborn biomolecules that water alone can’t touch, all without risking chemical contamination or residue. It opens new ways to extract pure compounds for medicine, food, or biofuels, offering both high yields and fewer environmental risks.

Challenges and Responsible Use

No honest look at specialty chemicals would skip their downsides. Cost looms large; synthesis remains expensive, which blocks wider adoption for now. And while the compound scores points for being less polluting, full life-cycle studies don’t always make headlines. My own research circles talk through the need for recycling quests—ways to recover and reuse these ionic liquids after their first job wraps up. Better process engineering and stricter lab practices could stretch their impact further.

Where We Go From Here

This chemical won’t show up on supermarket shelves, but its value echoes through green tech, safer batteries, medical breakthroughs, and cleaner manufacturing lines. The next step means making these liquids cheaper, easier to recover, and scaling up production that keeps both people and the planet in mind. Until then, 1-Butyl-3-Vinylimidazolium Hexafluorophosphate earns its respect as a quiet backbone in progress.

Paying Attention to Stability

Chemical stability forms the backbone of safe and effective storage. People sometimes forget that storage habits can make all the difference, not just for keeping potency, but also for safety. Over years working with different chemicals in both the lab and production settings, I saw drama unfold over what seemed like minor mistakes in storage. Spilled solvents and angry reactions serve as reminders that chemical products don’t forgive carelessness.

Stability depends on more than just a product’s formula. Heat, moisture, air, and light push against its shelf life. Organic compounds, for instance, can start breaking down under standard room conditions. Oxidation steps in if oxygen gets into a bottle meant to stay tightly sealed. Anyone who uncaps a bottle of hydrogen peroxide and leaves it sitting out can see bubbles forming, signaling fast degradation. That same reaction, happening in a stockroom, makes old bottles unreliable and dosage unpredictable in medical or industrial settings.

Recommendations from Real-Life Trials

I learned early not to trust every label’s promise about “shelf-stable.” In one case, we stored a sensitive ingredient just a few degrees warmer than suggested, and by month’s end, crystallized clumps signified lost value. Each manufacturer tests and suggests optimal conditions for their product. Listen to them, but don’t just follow them blindly—check up on stock. Rotate supplies, label containers with open dates, and buy in quantities that match your usage so excess doesn’t go bad on the shelf.

Humidity often acts as a silent enemy. Powders clump or dissolve, metal containers corrode, and even plastic seals shrink from years of exposure. Silica gel packs, desiccators, and tight, moisture-proof packaging go a long way. Pharmacies, food storage facilities, and industrial sites usually grab dry storage cabinets to combat these issues. I’ve seen the difference firsthand. A poorly-sealed storeroom with a broken dehumidifier once ruined two seasons of raw materials at a partner site—even though the temperature stayed stable. Moisture likes to sneak in, so keeping things dry matters as much as keeping them cool or dark.

Safe Spaces for Dangerous Goods

Storing hazardous products—especially flammable, caustic, or reactive types—asks for a separate set of rules. Always choose areas with airflow, away from sunlight or ignition sources. Simple care like keeping acids below eye level, not above, saves lives. Industry guidance from OSHA and NFPA gives easy steps: chemical-resistant shelving, separate incompatible groups (like acids and bases), and fireproof storage for flammable goods. Label every container, use correct secondary containment, and keep Material Safety Data Sheets (MSDS) within reach. Over the years, real emergencies taught me this is not just bureaucratic red tape, but life-protecting sense.

Looking Ahead

Stability never stays guaranteed forever. Even best practices can’t stop the clock, but they stretch out a product’s usefulness and safety. Anyone handling chemicals—from hobbyist to industrial manager—should make storage a habit, not an afterthought. Check labels, seal containers, keep things cool, and re-evaluate setups from time to time. As simple as these steps sound, diligence and common sense keep materials reliable and people safe.

The Real Risks Behind the Chemistry

Chemical safety often gets swept under the rug until something goes wrong on the shop floor or in the lab. 1-Butyl-3-vinylimidazolium hexafluorophosphate looks like a tongue-twister, but what matters is what happens when it gets onto skin, into lungs, or out into water. With so many ionic liquids cropping up in advanced manufacturing, it’s worth asking: are we putting people or the environment on the line by bringing these new compounds into regular use?

What We Know From Research

Clear answers can be hard to find, but let’s dig into the basics. Research shows that this compound’s hexafluorophosphate part can break down and release hydrofluoric acid under heat or in humid environments—even spillages can start that reaction. Hydrofluoric acid is no joke. It can chew through skin and bone far faster than most realize and sometimes tricks people because it doesn’t sting right away. Anyone who’s accidentally opened a tank or flask with the wrong gloves learns respect for this risk in a hurry.

The imidazolium-based ionic liquids bring their own set of concerns. Some early data shows these can mimic biological processes, cause irritation, and damage cell membranes. Animal studies show liver and kidney effects at moderate doses, although it usually takes sustained high exposure to see the worst outcomes. Workplaces with good airflow, strong cleaning routines, and well-trained staff avoid most acute problems, but not everyone operates under perfect conditions.

Human Experience Trumps Theory

Rules and data don’t mean much unless people follow the right safety steps. I remember working in a pilot plant where these kinds of chemicals spilled into a drain. The site manager assumed nothing would happen—until a technician developed burns and had to visit urgent care. The lesson was clear: even small mistakes with ionic liquids like this one can create real harm before anyone grasps the mistake.

Long-term toxicity often shows up too late. Chronic exposure tends to slip through routine health checks. Take hexafluorophosphate’s breakdown into fluorine compounds—they often end up as persistent organic pollutants, spreading through soil and water, strange smells in an exhaust vent, or odd results from fish in nearby streams. Cleanup isn’t easy and can stretch budgets to the breaking point.

Solutions Worth Considering

Controlling risk is possible, but not by cutting corners. Wear the thick nitrile or specialty gloves, not the ones that come with cheap supply kits. Ventilate work areas and monitor air regularly, especially where heat or moisture might accelerate breakdown. Routine medical exams for workers catch problems early. Local governments and researchers need to stay honest about unknowns in toxicity reports and push for more transparency on test results.

Waste treatment deserves just as much attention. Chemical companies can’t dodge responsibility by dumping rinse water. Retention ponds, specialist incineration, or chemical neutralization should be standard—these don’t come cheap, but they shield communities and workers alike, long after profit has moved on.

What’s at Stake

Trying to cut through the jargon leaves one truth: 1-butyl-3-vinylimidazolium hexafluorophosphate isn’t harmless. Teams that respect its risks and invest in real solutions outrun trouble. Companies, DIY chemists, and regulators owe it to everyone to treat this chemical with the caution and care it deserves—because getting it wrong doesn’t just mean a failed experiment, but real consequences for health and the world around us.

Why Purity Shapes Trust and Results

People often judge a product’s value by its outward looks and by what’s written on the label about purity. But under the surface, purity calls for much more than just a number with a percent sign. In my line of work in laboratory settings, the promise of 99.9% purity often sounds impressive. Not all purity claims mean a product performs the same way. Contaminants, even in tiny amounts, can wreak havoc in pharmaceuticals, food additives, or during chemical reactions. One batch of raw material with an off-color hint or trace metallic smell once stalled an entire project for weeks. Once the investigation began, the problem traced back to a supplier using inconsistent filtration. That small slip led to ruined reactions, wasted resources, and hours of troubleshooting.

In pharmaceuticals, purity claims stand as a matter of safety, not just a certification. Impurities can spark harmful side effects or weaken the intended effect. The American Pharmacopoeia sets strict rules, but it’s impossible to spot some impurities just by glancing at the product. Rigorous analysis like HPLC or GC-MS gives the full story. Patients and consumers need assurance their medication or supplement contains exactly what it should—nothing more, nothing less. That reassurance builds trust in every industry, from food science to superalloy manufacturing.

What Does Physical Appearance Tell Us?

Physical appearance acts as the first checkpoint. If a white powder turns up with a suspicious yellow tint or clumps, alarm bells ring. These telltale signs suggest moisture, incomplete drying, or exposure during transit. I’ve unboxed shipments where the container looked pristine, but the powder inside packed hard and formed lumps. In cases like this, quality drops, and results turn unpredictable.

Crystals, powders, liquids—each form demands different handling. Fine powders disperse evenly but can attract moisture, so humidity in storage rooms changes everything. Crystals offer stability, but improper handling creates dust and loss. A clear, colorless liquid often points to high purity, but a faint odor or light haze hints at breakdown or solvent residue.

Methods like visual inspection, touch, and simple solubility tests pick up on faults before expensive equipment even comes into play. Long ago, a shipment of sodium chloride arrived with a dull, gray sheen instead of its usual sparkle. Routine tests found traces of iron, proving that visual checks flag mistakes early.

How to Aim for Better Quality

True quality control starts at sourcing. Reliable suppliers keep detailed records, batch test reports, and offer full traceability. Auditing suppliers in person uncovers practices missed on paper. Companies such as Merck and Sigma-Aldrich offer transparency, sharing certificates of analysis down to individual lots, including clearly labeled impurity profiles.

Regular training for staff sharpens their eyes for physical clues. In a real-world lab, our team made a habit of photographing every shipment and tracking changes. Sharing this visual documentation with suppliers, we pressed for improvements and tracked patterns. This approach found its way into our own in-house protocols to help catch slips before risks crept into experiments.

Anyone handling raw materials should own the process: use well-sealed storage, monitor climate, and rotate stock to keep everything fresh. Purity and appearance stand as partners. One without the other can cost time, money, and sometimes, safety. Quality checks—rooted in habit, not just paperwork—keep standards high and trust intact.

Respecting Chemical Power, Not Fearing It

Work in a lab long enough, you learn to respect chemicals, not fear them. 1-Butyl-3-vinylimidazolium hexafluorophosphate fits right into that mindset. This compound, often used as an ionic liquid, brings some unusual risks—chief among them, its strong potential for chemical burns, eye damage, and toxic fumes if mishandled. Gloves become more than a suggestion. Splash protection and well-fitted goggles matter. A friend in graduate school spilled a tiny amount on his arm during clean-up; the stinging reminded him for days that carelessness hangs a heavy price tag.

Personal Protective Equipment: No Cutting Corners

Goggles, lab coat, and right-sized nitrile gloves always deserve their spot in the lab. Improper ventilation, even during seemingly 'routine' transfers, rapidly changes the game. Fume hoods aren’t some extra backup—they’re essential, since these hexafluorophosphate salts often release hydrogen fluoride, a chemical that can do far more than threaten the respiratory system. Reports show persistent exposure—without aggressive ventilation and PPE—quickly eats away at respiratory health and skin integrity.

Storage Isn’t Just About Space

Store 1-butyl-3-vinylimidazolium hexafluorophosphate away from light, high heat, and anything that even hints at moisture. A tightly sealed, labeled bottle—preferably amber or opaque—helps slow down chemical breakdown. Moisture leads to hydrolysis, which brings volatile and toxic byproducts like hydrofluoric acid right into the workspace. That means routine inspections. Any bottle with a crusty cap or a suspicious color shift deserves professional disposal right away.

Safe Disposal: The Slow, Deliberate Way

Tossing any leftover solvent or contaminated material in the drain breaks lab and environmental safety rules. The Environmental Protection Agency closely tracks hexafluorophosphate salts under hazardous waste lists. Strict guidelines demand labeling all waste containers—no mismatches or handwritten notes crammed into margins. Log every disposal on a chain-of-custody form, so there’s no confusion on where the material finishes its journey.

Companies specializing in chemical waste handle this process best. Most municipal waste-processing centers can’t neutralize the toxicity of such ionic liquids. These disposal experts treat the salts with neutralizing agents in controlled settings, often involving steps to bind up the fluorine component and stop it from polluting the water table.

Clean-Up Runs on Speed—and Patience

Spill kits with neutralizing powders, pads, and sealable bags belong nearby. Immediate response keeps vapors from spreading. Never wipe down spills with damp rags. Any water can accelerate reaction and release gas. My own practice involved slowly trapping and sweeping up any solid using a dedicated broom, double-bagged for containment. Label it as contaminated and move it to a hazardous storage bin—never put it with regular trash.

Accountability at Every Step

Training isn’t something you do once and forget. Refreshers every six months—especially for newer staff—reduce risky shortcuts. People often overlook recordkeeping. If an incident happens, proper logs demonstrate where everyone stood and what actions unfolded at each phase. Cross-reference with the latest research and material safety data sheets, since disposal rules often change to reflect new environmental realities.

The Bottom Line—Respect and Diligence

Effective handling and disposal of 1-butyl-3-vinylimidazolium hexafluorophosphate rests on everyday habits. Careful protective gear, smart storage, and proper waste protocols make a world of difference. Those extra few minutes for double-checks save much more time than any emergency response ever could. The people who work in your lab, and those downstream in the ecosystem, depend on a job done right the first time.