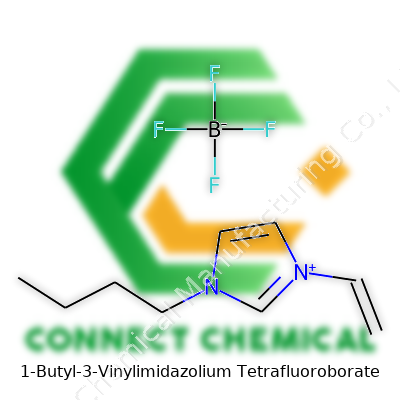

1-Butyl-3-Vinylimidazolium Tetrafluoroborate: A Comprehensive Commentary

Historical Development

Back in the late 1990s, talk about green chemistry had just begun to gather steam, spurring scientists to look for alternatives to volatile organic solvents. Ionic liquids, especially those based on imidazolium, started to stand out, and their tailorable structures made them a promising challenge for research labs working on cleaner industrial processes. 1-Butyl-3-vinylimidazolium tetrafluoroborate grew out of a need for ionic liquids with both thermal stability and functional vinyl groups. Early work harnessed its potential as a monomer in polymerizations and a solvent in catalysis, showing significant improvements in reducing environmental footprints compared to traditional solvents. My own experience dealing with green solvents has shown that these ionic liquids not only cut down on hazardous waste but also push the boundaries of chemical versatility in ways that old-school solvents never reached.

Product Overview

1-Butyl-3-vinylimidazolium tetrafluoroborate stands out as a room-temperature ionic liquid with a cationic imidazole core bearing both butyl and vinyl groups, paired with a tetrafluoroborate anion. Chemists value it for its unique combination of low volatility, high ionic conductivity, chemical and thermal resiliency, and the reactive vinyl functionality. Labs use it as a solvent, an additive in electrochemical applications, and sometimes as a building block for new materials. In production plants, its Mediterranean-like fluidity under ambient conditions is a big plus since handling does not require high temperatures or pressure swings, keeping engineering and energy costs down.

Physical & Chemical Properties

This compound pours as a colorless to pale yellow liquid and carries a gentle, sweet odor. It doesn’t evaporate under normal circumstances, which makes accidental releases much less concerning than traditional solvents. Its density sits slightly above that of water, and it does not combust easily. In terms of solubility, it mixes well with many polar solvents, including water. Chemically, the vinyl group offers a handle for polymerization, grafting, and surface modification, creating new materials that perform in areas like ion transport, separation, or catalysis. I find its electrochemical window especially wide—useful for devices requiring robust electrolytes. Researchers also appreciate its strong hydrolytic stability, so it doesn’t break down easily even under demanding lab conditions.

Technical Specifications & Labeling

In commercial containers, you’ll see purity ranges usually topping 97%. The specification sheets include details like residue on ignition, water content, color, and sometimes the proportion of free imidazole. The liquid is always labeled with clear GHS pictograms and hazard statements due to the moderate toxicity profile of imidazolium salts and the reactivity of tetrafluoroborate under strong acidic or basic conditions. Tamper-proof seals and UN-rated drums are standard in international trade, reflecting increasing regulatory vigilance for specialty chemicals. Anyone ordering lab or industrial quantities gets SDS documentation packed with transport, storage, and first-aid recommendations.

Preparation Method

Lab prep tends to start with 1-vinylimidazole, which reacts in a neat or toluene solution with butyl bromide under a nitrogen blanket. This quaternization gives the intermediate 1-butyl-3-vinylimidazolium bromide. Washing, extraction, and vacuum drying remove most organic and ionic contaminants. Next, metathesis comes into play, swapping the bromide for tetrafluoroborate with sodium or potassium tetrafluoroborate. A final wash with water strips away sodium or potassium bromide side products, and vacuum drying finishes the job. From experience, impurities in the starting imidazole or slack control of water during purification lead to problems such as poor electrochemical performance or polymerization issues down the line. Scaling up this preparation introduces a challenge: maintaining high purity while keeping moisture out, since the tetrafluoroborate anion reacts unfavorably with water during warehousing.

Chemical Reactions & Modifications

The vinyl group sets this molecule apart, making it an eager participant in radical or cationic polymerization reactions. You can graft it onto solid supports or let it copolymerize with acrylates or styrenes. In real applications, these reactions let you tune properties like ion selectivity or softness of polymeric materials for membrane technology or sensor surfaces. The imidazolium core undergoes stable ion exchange, and swapping anions allows further property adjustments without redesigning the whole molecule from scratch. Teams working in organic electrosynthesis see simplified coupling or oxidation reactions thanks to the ionic liquid medium. Notably, those same reactions call for scrupulous handling because the vinyl group reacts easily with radicals—including oxygen—so storage under an inert atmosphere works best.

Synonyms & Product Names

Other names in the literature include 1-Butyl-3-vinylimidazolium tetrafluoroborate, [BVIm][BF4], and sometimes n-butyl-3-vinylimidazolium tetrafluoroborate. You also see it listed simply as a functionalized imidazolium ionic liquid in catalogs from niche specialty suppliers. Naming conventions rarely stray from the IUPAC or common monomer designation, keeping confusion to a minimum in catalog orders or scientific publications.

Safety & Operational Standards

Users always need to address hazards linked to imidazolium-based salts and tetrafluoroborate anions. Prolonged skin exposure leads to irritation, and inhalation in fine aerosolized droplets brings a moderate risk of respiratory discomfort. Since the tetrafluoroborate anion decomposes under acidic or strongly basic conditions, releasing boron-containing gases, good ventilation is crucial. Most labs rely on nitrile or neoprene gloves and splash-proof goggles during transfer and mixing. From personal experience, attention to detail during waste collection is not just a formality: improper mixing with strong acids or bases causes gas release that tripped lab sensors on several occasions. Regulatory focus on chemical stewardship pushes manufacturers and universities to follow Globally Harmonized System (GHS) standards, reinforced with local training on chemical hygiene.

Application Area

Polymer chemists prize this ionic liquid for its vinyl functionality and ability to impart ionic character to otherwise inert polymer networks. In electrochemistry, it works as both an electrolyte and a stabilizing additive for energy-storage devices or sensors, especially where high thermal and oxidative stability are required. Several papers from the last decade highlight its positive influence on battery cycling, supercapacitor efficiency, and electrode wetting. Its low volatility lets it replace flammable organic solvents in green catalysis, reducing fire hazard and environmental impact in syntheses of fine or specialty chemicals. In my own projects, switching to this solvent simplified product isolation steps and shaved hours off batch times. Membrane tech benefits as well, with researchers grafting this molecule to enhance selective ion transport for fuel cells or water purification.

Research & Development

Chemists continue to expand the possibilities for this ionic liquid, diving into hybrid material creation, new polymer matrices, and even enzyme stabilization systems. Research teams report new findings on how modifying the butyl or vinyl groups can improve the compatibility with inorganic fillers or boost ionic conductivity. Interest in anion-exchange membranes, especially for alternative energy, drives funding and patent filings for specialty applications built around this ionic liquid. Academic groups push the boundaries further in sustainable chemistry, crafting closed-loop processes that recycle ionic liquids back into new batches, addressing long-standing concerns about cost and large-scale sustainability. My encounters with interdisciplinary teams have shown that bringing together synthetic chemists, process engineers, and toxicologists creates better product iterations and safer workplace protocols.

Toxicity Research

Assessing toxicity sits at the front of safe handling policies. Animal studies highlight low acute toxicity in most imidazolium-based ionic liquids, yet long-term or high-dose exposures can disrupt cellular membranes and linger in aquatic environments. This particular compound’s reactivity demands a closer look at chronic exposure and environmental persistence, something still under active investigation. Some jurisdictions request environmental impact assessments before factory-scale production, and regulatory compliance often involves real investment in analytical tools for trace detection. In the lab, the move toward greener solvents pairs up with a sober view of end-of-life disposal, and ongoing research looks for biodegradable variants or treatments that break the molecule down safely before entering waste streams.

Future Prospects

Innovation drives chemists to keep exploring uncharted territory for this molecule, especially in membrane and electrochemical device design. Efforts steered toward integrating this ionic liquid into block copolymers, creating bespoke electrolytes, and supporting greener manufacturing practices promise new applications with each passing year. Enhanced recycling processes, paired with predictive tools for toxicity and biodegradability, look set to address the most persistent criticisms related to cost and environmental safety. As more sectors chase carbon-neutral or climate-resilient technologies, demand for molecules that combine performance and environmental sense grows, making 1-butyl-3-vinylimidazolium tetrafluoroborate a practical choice in the new era of specialty chemicals.

Life in the Lab: Why Chemists Reach for This Compound

Walk into a modern chemistry lab and you’ll bump into a lot of ionic liquids, with 1-Butyl-3-Vinylimidazolium Tetrafluoroborate earning its spot because it doesn’t act like water or oil. Its chemical structure, tough to pronounce as it is, lets it replace some harsher solvents, and you find it involved in projects ranging from advanced batteries to pharmaceuticals. The buzz mainly traces back to how it dissolves and stabilizes things that would fall apart in typical solvents.

Researchers favor this liquid for reactions that regular solvents can’t handle cleanly. From my own time in graduate school, I remember teams using this compound to coax reactions that would normally demand high pressures or temperatures, helping avoid complicated safety risks. A big plus: low volatility, so fewer fumes to breathe in or clean up.

Helping Energy Storage and Clean Technology Move Forward

With electric cars and renewable energy in the news each week, battery research keeps heating up. The role of 1-Butyl-3-Vinylimidazolium Tetrafluoroborate centers mostly on electrolytes for lithium-ion and other batteries. Researchers lean on it because it resists breaking down during charge cycles—a persistent pain point with traditional electrolytes. Bench tests show this ionic liquid keeps moisture away and even blocks the growth of the tiny needles (dendrites) that can wreck batteries.

Supercapacitors, another area where quick charging and discharging matter, also benefit. Here, the ionic liquid supports higher operating voltages, which means more storage without runaway heat problems. Across both types of devices, its chemical stability keeps the gadgets running longer, meaning fewer batteries ending up in landfills—a small but important win for the environment.

Greener Manufacturing and Catalysis

Factories often rely on solvents that release nasty byproducts or pack a hefty environmental footprint. 1-Butyl-3-Vinylimidazolium Tetrafluoroborate steps in as an alternative, especially in organic synthesis. In practical terms, it acts like a supportive environment for chemical reactions, helping manufacturers reduce hazardous waste. Take pharmaceutical synthesis—one synthetic route that once required volatile organics can shift to this ionic liquid for cleaner separations and easier recycling.

Catalysis feels the boost, too. This compound helps stabilize catalyst particles, letting chemists reuse expensive metals more times before needing to replace them. In pilot projects, it’s shown that gold or platinum catalysts last longer and don’t leach as much, which cuts costs and metal contamination in the final product.

Environmental and Practical Considerations

Companies aiming for greener credentials always look for tools that trim down risk. The toxicity profile of 1-Butyl-3-Vinylimidazolium Tetrafluoroborate stays under regular review. Some early lab data point toward relatively low toxicity compared to many common industrial solvents, but as industrial demand grows, long-term monitoring becomes essential.

It also won’t solve every problem. Cost stands out—while laboratory-scale syntheses don’t always break the bank, scaling up remains expensive. For small-batch specialty chemicals, research tools, and prototype devices, the investment makes sense. Moving into mass-market production will depend on new synthesis methods or recycling strategies, both areas where chemists still have work to do.

If we want cleaner factories and better batteries, exploring these greener chemical building blocks offers one practical path forward. Putting more options into the toolbox doesn’t just help the environment—sometimes it makes economic sense, too, as more companies turn these lab discoveries into real-world products.

The Role of Structure in Stability

Anyone who’s worked with ionic liquids in a research lab knows they gather attention for many reasons: low volatility, thermal stability, and their interesting solvation powers. 1-Butyl-3-vinylimidazolium tetrafluoroborate steps into this crowd as a salt with unusual attributes. The backbone, featuring a vinyl group hanging off the imidazole ring, makes it different from its more common methyl or ethyl versions. The tetrafluoroborate anion helps in bringing both hydrophobic and electrochemical stability to the mix.

Real-World Experiences: Stability Inside and Outside the Bottle

I once cracked open a container of this compound and picked up a distinct, often barely-there aroma. It tells a lot. Odor sometimes signals purity or hints at degradation. Unlike regular organic solvents, this ionic liquid cleans up after itself when you get a spill—no aggressive fumes, no fast evaporation. That ties directly to its chemical stability under ambient conditions. It keeps structure at room temperature, doesn't decompose just because the lid’s off for a few hours, and shrugs off moisture better than many other salts. The tetrafluoroborate counter-ion’s role interests me most: it guards against hydrolysis far better than hexafluorophosphate analogs, which can crank out toxic byproducts with stray water and heat.

What Happens Under Fire

True diagnostics take shape at higher temperatures. I’ve heated samples or run them through a rigorous electrochemical cycle, and they show their mettle. The compound stands up to moderate heat, with published thermal stability data steadily clearing the 200°C mark before breakdown starts. That means you don't run into subtle decomposition in most catalytic or separation applications. Still, anyone who’s seen a synthesis fail from trace acids understands the real problem: tetrafluoroborate begins to let go of corrosive species, especially at the edges of its thermal window or when strong acids sneak in. Hydrolysis products like hydrogen fluoride can form if pushed too far, making appropriate storage and handling more than just a formality.

Potential for Laboratory and Industry Use

From my time exploring green solvents for organic synthesis, I’ve found this ionic liquid tackles a lot of pain points. Its chemical backbone resists polymerization even with that reactive vinyl group, as long as other initiators stay out of the flask. That balance of stability and reactivity explains why polymer chemists and electrochemical engineers keep experimenting with it. The electrochemical window—important for batteries and plating—keeps wide and stable under good conditions. Plus, the ingredient doesn’t munch at steel or glassware, which sweetens the deal for maintenance and safety.

Staying Safe and Improving Stability

Curiosity aside, responsible handling never goes out of style. Hydrophobicity guards against accidental water pick-up, but desiccators remain a wise choice for storage. I’ve seen people use amber bottles and avoid direct sun to keep degradation to a minimum. Simple steps, straightforward chemistry, and good habits keep this ionic liquid not just stable in theory but flexible and trustworthy in practice. Researchers keeping up with best practices and routine purity checks get long life and real performance out of each batch—or at least, that’s been my experience in the lab.

An Ionic Liquid That Demands Respect

Everyone working in a chemistry lab knows a few substances that look easy enough on paper but reveal a stubborn streak once brought onto the shelves. 1-Butyl-3-vinylimidazolium tetrafluoroborate sits in that category. Chemically speaking, it’s a room-temperature ionic liquid. Brokers in the chemical industry like to play up the ionic part, but most of us just see it as a curious, barely-evaporates liquid—clear, a little viscous, and much heavier than water. It’s the go-to for catalysis, electrochemistry, and even as a solvent if the project calls for a truly nontraditional setting. But let’s be real: those perks matter little if storage turns the whole bottle into a mess after a few weeks.

Water: The Unseen Spoiler

On my first project involving ionic liquids, the temptation to let the bottle sit in a normal solvent cabinet cost me a productive afternoon. Tetrafluoroborate salts love to take up moisture out of the air. That easygoing glass bottle capped tight loses its friendly nature if the substance pulls in water, turning yellow or even developing a gritty sediment at the bottom. More seriously, contact with water doesn’t just ruin your yield or introduce impurities; it can slowly eat away at your ability to repeat results and trust your reagents.

Storing 1-butyl-3-vinylimidazolium tetrafluoroborate in a dry place, ideally in a desiccator with silica or molecular sieves, keeps those problems at bay. Some labs move quickly, transferring what’s needed to small vials, each sealed and only opened right before use. I’ve seen teams store these bottles either under an argon or nitrogen blanket, especially in humid climates, because trading a few extra minutes of setup beats losing an expensive reagent to hydrolysis.

Compatible Containers: Glass First, Plastics with Caution

Most lab supply houses pack this material in glass bottles, and for good reason. Tetrafluoroborate ions stay inert toward glass under normal circumstances, while certain plastics might not hold up long-term. Thin plastics may allow slow diffusion of moisture. Pushing past two months, I’d rather trust glass, and if someone hands me a plastic bottle I repackage it.

Seals and lids also deserve a careful look. Metal lids lined with PTFE-backed liners resist chemical attack and prevent slow leaks of volatile components. If that sounds overly cautious, remember how one small leak can spoil shelves and compromise neighboring chemicals. Always label both date and moisture status on each bottle; better safe than scrambling during a critical experiment.

Temperatures: Cool, Not Freezing

High heat and direct sunlight degrade the chemical, especially if vinyl groups get excited by UV exposure. A cool, dark cupboard in the lab, or a standard chemical fridge, works best. Avoid extreme cold, since ionic liquids sometimes separate out weird impurities once thawed. I’ve watched as carelessly frozen samples came back with cloudiness, demanding a time-consuming purification before the next step could proceed.

Solutions for Busy Labs

Busy academic or industrial spaces sometimes assign a technician to check high-value shelf reagents monthly. That kind of hands-on stewardship pays off. Monitoring the color and viscosity gives early warnings. If you see yellowing or crystals, best to discard the bottle before any more hours get wasted. Regular audits not only prevent wasted material but reinforce safe chemical management—crucial given that mishandling fluoroborates can, in rare cases, produce toxic decomposition products.

For those just beginning with ionic liquids, training matters as much as equipment. Staff quickly learn the extra steps are a small price for consistent results and safe, sustainable operations.

Safe Handling Pays Dividends

Storing 1-butyl-3-vinylimidazolium tetrafluoroborate properly means you get every last drop to perform at its best. Good practice in the lab—dry storage, reliable glass containers, clear labeling, and routine checks—ensures your experiments rely on chemistry, not chance.

A Closer Look at Safety

Few people outside of labs ever hear about chemicals like 1-Butyl-3-Vinylimidazolium Tetrafluoroborate, but for those working in materials science or electrochemical research, these substances regularly turn up on the bench. This particular compound, often grouped under the banner of ionic liquids, promises improved battery designs, chemical processing, and even greener extractions thanks to its interesting set of properties.

Talking about hazards with a chemical like this takes some lived perspective. In research, you pay close attention to a data sheet before popping open any new bottle. With 1-Butyl-3-Vinylimidazolium Tetrafluoroborate, it’s obvious from early safety data sheet entries that it isn’t harmless. Touching the chemical causes skin irritation. Breathing in its vapors or dust stings the lungs and eyes. I’ve watched a graduate student new to glovebox work wince and stumble for the eyewash after a tiny splash, learning the hard way that lab goggles matter even for colourless liquids.

Is it toxic? It wouldn’t act as a deadly poison at trace levels, but repeated exposure builds up trouble. The European Chemicals Agency lists this substance as acutely harmful if swallowed or inhaled. Chronic exposure isn’t well studied, but closely related tetrafluoroborate salts can trigger negative effects in animals’ nervous systems and, for some, the kidneys. In practice, researchers handle this liquid with gloves, lab coats, eye protection, and often inside a fume hood. Nobody stands around breathing its fumes for fun.

Tetrafluoroborate Risks and Environmental Concerns

The “tetrafluoroborate” anion deserves some special attention. In most scenarios, it stays tightly bound and causes little harm. Break it down—by burning the material or letting it weather in a landfill—and boron trifluoride and hydrogen fluoride gas can form. Both are nasty: boron trifluoride burns the lungs, and hydrogen fluoride is infamous in chemical safety talks. Luckily, normal use in a properly managed lab keeps these dangers away from most people.

Thinking about waste, nobody chucks these ionic liquids down the drain in a responsible lab. Disposal calls for sealed containers, hazardous waste tagging, and professional pickup. Even outside the lab, a spill reaching soil or water creates a risk since many ionic liquids resist breaking down in nature. Long-term accumulation can mess with aquatic environments—tiny organisms take in the chemicals, and negative effects can stack up as you move up the food chain. There’s a lot we don’t know about how these substances behave outside their containers because regulators still race to keep up with new chemistries.

Moving Toward Safer Practices

Keeping chemical exposures in check depends on habits, training, and investment in good infrastructure. Labs providing enough hoods, up-to-date data sheets, and time for regular safety meetings keep their users the safest. People get lax and cut corners when they’re in a rush or skip reading the details. I’ve had days where a mislabelled bottle or forgotten mask led to avoidable near-misses—direct reminders that even substances without household-name risks deserve respect. Researchers should always investigate new compounds’ health and environmental data before use.

For a chemical like 1-Butyl-3-Vinylimidazolium Tetrafluoroborate, safety isn’t a mystery—it’s a commitment. Proper handling, disposal, and awareness make all the difference. While research efforts explore “greener” ionic liquids, no shortcut replaces common sense and preventative steps in the workplace. Research pushes forward, but everyone’s best work happens when risks get managed up front, not fixed after harm shows up.

An Ionic Liquid With a Twist

Staring at the long name 1-butyl-3-vinylimidazolium tetrafluoroborate, any chemist recognizes the formula as more than just another ionic liquid. The addition of a vinyl group, right on the imidazole ring, changes the game. That tweak gives the molecule the ability to join in polymerization—meaning it can become part of the growing chain instead of sitting on the sidelines like many solvent-style ionic liquids.

The whole point with vinyl groups comes down to reactivity. Chemists have spent decades adding vinyls to all sorts of structures for the sole reason of getting them to react with classic radical initiators or work wonders in living polymerization setups. Adding it to an ionic liquid wasn’t always obvious, but as soon as you try it, the potential opens wide.

What Changes in the Lab?

Back in grad school, we would always chase the “green chemistry” angle: solvents that do more than just dissolve. Ionic liquids already aim for this. They stand out because they hardly evaporate, and their ionic nature can coax tricky reactants into behaving. When bringing in 1-butyl-3-vinylimidazolium tetrafluoroborate, you don’t just get the clean-up benefits; you let the solvent become an actual part of the plastic you want to create.

Researchers have spotted how this dual-purpose liquid works best in free-radical polymerizations—especially with acrylates and styrenics. Instead of typical solvents that get burned off during processing, the vinylimidazolium acts as a co-monomer. It doesn’t just vanish at the end; it stays locked into the plastic backbone. That boosts ionic conductivity, which is huge if you’re after things like ion-gels or flexible electronics. Plus, its tetrafluoroborate side brings stability. Folks working in battery membranes—especially lithium-ion—have started paying attention because they need materials that handle both electricity and mechanical stress, day in and day out.

Sustainable Chemistry and Real-World Challenges

Anyone who’s slogged through the purification of standard polymerization products knows that removing solvent traces is brutal. Ionic liquids like this give a cleaner alternative, since there’s no nasty fugitive organics left to strip away. On an industrial scale, that simplifies at least one step of production. Now, if you’ve tried using these as co-monomers, you’ll also notice polymerization rates can slow down. The ionic environment changes things. Sometimes that delay is helpful—especially for controlling molecular weights—but for fast-paced continuous processes, it can become frustrating.

Cost factors still matter, too. Ionic liquids aren’t cheap by any standard. A bottle of 1-butyl-3-vinylimidazolium tetrafluoroborate can push budgets, especially compared to bulk commodity monomers. That price point limits widespread adoption to specialty plastics and research settings for now. Still, with demand from energy storage and wearable tech, demand has climbed. We saw researchers and companies invest in scaling up synthesis. Prices have ticked down, but they haven’t reached the lowball rates of the big vinyl monomers yet.

Room for Innovation

Academic labs keep experimenting with combinations: tweaking the tail (switching out butyl for longer or shorter chains), exploring alternative anions, and running polymerizations under greener conditions. Some use lower temps or mix with bio-based vinyls—for less waste and lower energy bills. None of these tweaks has changed the underlying fact: this ionic liquid shapes the way the resulting polymer behaves. That means you can plan for conductivity, mechanical toughness, or even optical clarity, just by changing your setup on the bench.

Better education on how to formulate these systems could help more teams use them. Sharing standard methods, like the best initiator systems or cleanup steps, would speed up adoption. Controlled radical setups (RAFT, ATRP) look promising with this co-monomer, and those who spend time tweaking feed ratios and stirring speeds can fine-tune the final product for tough market demands.