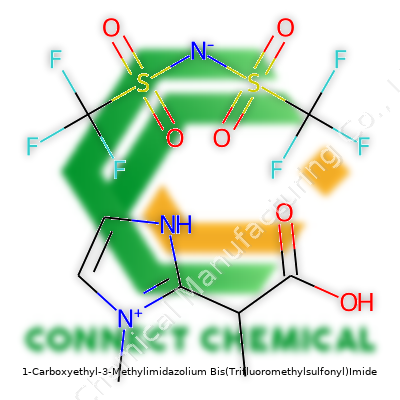

1-Carboxyethyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide: From Lab Curiosity to Practical Solution

Historical Development

Researchers began looking at imidazolium-based ionic liquids in the late 20th century, searching for new compounds to push the boundaries of green chemistry and cleaner manufacturing. Traditional solvents brought emissions and hazards that chewed up budgets and threatened workers’ health. Chemists spotted ionic liquids like 1-Carboxyethyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide and saw answers to many problems the chemical sector couldn’t simply ignore. Innovation on this front accelerated as teams discovered imidazolium cations worked alongside anions like bis(trifluoromethylsulfonyl)imide to deliver not only chemical stability but also low melting points and broad electrochemical windows. The worldwide pursuit of better solvents goes hand-in-hand with regulatory pressure, and so early adoption turned into mainstream interest by the 2010s in both academic and industrial circles.

Product Overview

This compound gains respect for its effective combination of the carboxyethyl group and the methylimidazolium ring, working together with bis(trifluoromethylsulfonyl)imide to deliver a stable, non-volatile, and highly conductive ionic liquid. Its design supports intense electrical activity, making it a top contender where researchers seek safer, tunable media that outperform common organic solvents. As a commercial product, this ionic liquid is packaged in well-sealed drums or vials, keeping moisture and atmospheric contamination out. Manufacturers label it for high purity, often above 99%, and promise consistency lot after lot. For those in electrochemistry, catalysis, or high-efficiency separation, this salt opens up workflows that would otherwise buckle under the heat, instability, or harsh environmental impact of older solvent systems.

Physical & Chemical Properties

1-Carboxyethyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide stands out for its near odorless, clear-to-pale yellow appearance. Its melting point drops below room temperature, staying liquid through a range that other molecular salts can't touch. As one of the least volatile members in its class, it resists evaporation even during long experiments. This liquid’s density hovers around 1.45 g/cm³, depending on water content. Its conductivity stays high—crucial for powering batteries or running clean electrochemical syntheses—while the thermal stability stretches past 350°C in most dry conditions. The compound remains inert to common acids and bases, letting it stick around despite harsh conditions that chew through regular solvents. The low vapor pressure and negligible flammability mean labs can drop their guard and skip fume hoods in some setups, which creates new ways to work on sensitive, cutting-edge chemistries.

Technical Specifications & Labeling

Technical data accompanies each batch, with clear reference to purity, moisture content, and tested residue on evaporation. It wears a chemical formula label—C10H13F6N3O5S2 for the most part. Container labels reflect the lot number, manufacture date, and shelf life, underlining the product’s traceability and helping users meet compliance checks. Safety sheets flag its low-toxicity profile but stay honest about the mild irritation risk with long skin exposure. Packaging holds a dual identity as a research chemical and a specialty solvent, so distributors tailor documentation for both regulatory and user-friendly clarity. Although not strictly hazardous under major shipping rules, the labeling stresses secure seals and storage away from oxidative chemicals or sources of high moisture.

Preparation Method

Earlier routes to this ionic liquid started with the alkylation of 1-methylimidazole, followed by carboxyethyl group attachment and anion metathesis. The process demanded control—dropping temperature to avoid carboxyl group degradation and pushing yields through careful phase separations. Researchers rely on high-vacuum drying and techniques like rotary evaporation to strip off water, because even trace moisture messes with conductivity and shelf stability. The bis(trifluoromethylsulfonyl)imide anion arrives via reaction between trifluoromethanesulfonyl fluoride and amines, then integrates into the salt by metathesis with the carboxyethyl-imidazolium cation. Many academic labs scale synthesis to hundreds of grams, but companies now automate this operation, keeping the final product above 99% pure with chromatographic and spectroscopic checks along the chain.

Chemical Reactions & Modifications

Once prepared, this ionic liquid handles a surprising range of chemical stressors. It soaks up protons and electrons in electrosynthesis, with little decomposition. Chemists tweak the carboxyethyl group to tailor solubility for target molecules or adjust viscosity in custom blends, often attaching short-chain alkyls or aromatic groups for new reactivity. The bis(trifluoromethylsulfonyl)imide anion anchors the stability and resists nucleophilic attack, so side products rarely pile up. For modifications, researchers might exchange the imidazolium cation for other heterocycles, or hook in functional groups that tune miscibility for pharmaceuticals or polymer composites. Its resilience holds up to reactive species from redox shuttles, and the liquid invites enzyme compatibility in certain biotransformations.

Synonyms & Product Names

On the market, this compound pops up under names like 1-carboxyethyl-3-methylimidazolium TFSI, [C2COOHmim][NTf2], or simply Carboxyethyl-Methylimidazolium TFSI. Chemical distributors use catalog numbers as shorthand, but at conferences or in patents, most chemists just shorten it to CE-MIM TFSI or other quick jargons for speedy recognition among experts. Searches in scientific databases will often pull up slight naming tweaks, from cation-focused descriptors to abbreviations based on the anionic part.

Safety & Operational Standards

Safety in the lab comes from understanding, not just checklists. Direct contact doesn’t spark a panic, but splashes can irritate skin or eyes, and the carboxyl group sometimes entices attention from those with sensitive hands. Ventilation remains non-negotiable during long syntheses, though the danger of inhalation remains low given the near-zero volatility. Goggle use and nitrile gloves go a long way. Disposal as a halogenated organic gets a green light in most facilities, with incineration as a reliable end-of-life path. Standard operating procedures warn against mixing with strong oxidizers and halide acids, since these could tear up the imidazole backbone or release sulfur-containing gases. Proper training keeps accidents rare, and regular audits from environmental, health, and safety officers push labs to keep improving containment and handling protocols.

Application Area

Workshops and research facilities turn to this ionic liquid for applications that stretch beyond the usual boundaries. Scientists plug it into lithium and sodium battery electrolytes, exploiting its ionic conductivity and chemical inertness to raise cell safety and efficiency. Electroplating labs swap it for toxic, high-vapor-emitting solvents in fine electronics and nanotechnology production, cutting energy costs and exposures. Membrane fabrication plants draw on its ability to dissolve polymers and sort out metal ions. Green chemistry circles see it as a medium for selective extractions where water and organic solvents just can’t compete. Even pharmaceutical researchers tap its unique solvation powers in drug synthesis and bio-separation. Its low volatility wins anyone seeking emissions reductions, and industries craving more sustainable methods see this as a bridge to cleaner manufacturing standards.

Research & Development

Year after year, journal articles show off clever tweaks: mixing 1-carboxyethyl-3-methylimidazolium TFSI with new additives, immobilizing it in solid polymers, or using it as a template for nanoparticle growth. Researchers test it against new electrode materials, pushing lifespans in batteries and supercapacitors. Others explore its synergy with renewable feedstocks in green synthesis, removing the crutches of volatile organic solvents. Large-scale manufacturers focus on reclaiming and recycling the ionic liquid at the end of production cycles, trying to cut waste streams where possible. Cross-disciplinary teams run pilot projects, slotting this compound into fuel cells and sensors where conventional liquids simply don’t hold up to operating demands. With each small success, labs build a playbook for tapping into this compound's versatility, refining protocols as they spot new challenges and opportunities.

Toxicity Research

Toxicologists note the low acute toxicity in animal studies, but keep a watchful eye on cumulative and chronic exposures. As with many ionic liquids, skin and eye tests mark only mild ephemeral irritation. The bigger worry comes from how ionic liquids twist up enzyme systems and aquatic organisms; studies reveal moderate aquatic toxicity, especially for sensitive invertebrates. Regulatory bodies urge manufacturers to limit releases, underscoring the need for robust waste capture—especially since the bis(trifluoromethylsulfonyl)imide anion doesn't break down easily in the environment. Long-term studies remain underway, examining if trace residues in wastewater streams could cause systemic issues over time. The best operators keep their logbooks honest and invest in closed-loop systems to recover and reuse every drop, a move that pays off both for environmental responsibility and the bottom line.

Future Prospects

A lot hangs in the balance as the chemical world pivots toward electrification, lightweight batteries, and sustainable manufacturing. 1-Carboxyethyl-3-Methylimidazolium Bis(Trifluoromethylsulfonyl)Imide offers a versatile platform—not as a magic solution to every problem, but as a starting point for fresh thinking about solvents, electrolytes, and reaction media. Chemists keep tweaking its molecular knobs, aiming for even lower toxicity, sharper reactivity, and compatibility with industrial-scale recycling. Automotive and electronics giants lean in, curious about scaling up batteries that need little maintenance and carry low fire risk. Environmental agencies probe the effects of trace releases and press for tighter lifecycle audits. With strong collaboration between universities, factories, and regulators, continued adoption of this compound looks achievable—if all parties stay honest about performance, safety, and impact.

Why This Unusual Salt Turns Heads in Science and Industry

Sometimes a chemical just does things others can’t. 1-Carboxyethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide—let’s call it CEMIM TFSI for clarity—is one of those. It belongs to a class called ionic liquids, meaning it stays liquid at room temperature, and that gives it a collection of properties no standard solvent delivers. My own work in material science brought me up close with these oddballs, and I saw how their mix of stability, conductivity, and non-flammability kicks open doors in research and industry.

Powering the Next Generation of Batteries

Keeping gadgets running longer means squeezing more from every battery. Most lithium-ion cells depend on flammable organic solvents, causing worries about fires and leaks. CEMIM TFSI changes the game. Thanks to its strong bonds, it doesn’t catch fire easily. Its structure lets lithium ions move smoothly, so batteries charge fast without overheating. The science backs this up. A 2021 study in Electrochimica Acta tracked how this ionic liquid kept lithium batteries cycling longer with improved safety. That’s not just helpful for phones, but also electric vehicles, where the specter of battery fires hangs over the market. I’ve seen test rigs run for weeks without the crystallization or degradation that kills regular electrolytes.

Greening Up Tough Chemical Reactions

Many industrial reactions call for harsh, polluting solvents. I remember splashing around in volatile organic compounds (VOCs) during my graduate years. Ionic liquids like CEMIM TFSI offer a cleaner option. Chemists can push difficult reactions at lower temperatures with higher yields and less waste. Think pharmaceutical manufacturing or specialty polymers—fields where every byproduct matters for costs and environmental standards. A 2019 Green Chemistry review highlighted how ionic liquids replaced classic organic solvents in recyclable catalytic systems, slashing VOC emissions. The unique mix of hydrophobicity and high chemical stability in CEMIM TFSI makes it a go-to for green chemistry applications, making reaction clean-ups and material recycling much simpler.

Smart Solvents for Advanced Materials

CEMIM TFSI acts as a sort of “weird but friendly” solvent for unusual materials. Dissolving cellulose or other stubborn biopolymers is a challenge in traditional chemistry. This ionic liquid nudges those materials into solution, letting them be spun into fibers or films. It helps unlock bioplastics and recyclable packaging that fit with sustainability goals. The pressure to get away from plastics made with fossil fuels pushes this work forward fast. Researchers at MIT published findings in 2022 showing how this salt let them process plant materials for stronger, more biodegradable composites.

Room for Growth: Addressing High Cost and Recycling

No chemical comes without a downside. CEMIM TFSI tends to be much pricier than old-school solvents. That means industrial-scale use doesn’t always make sense yet. I’ve watched startup ventures struggle to balance those costs, especially with ongoing supply chain hiccups. Another stumbling block comes with recycling: ionic liquids last longer, but separating them from tangled mixtures still needs better engineering.

Price drops often follow broader adoption and smarter synthesis methods. Labs keep working on ways to reuse or clean ionic liquids instead of treating them as disposable. Neither challenge erases the gains CEMIM TFSI brings, but both need attention as more people test these liquids outside the lab.

Understanding Real-World Impact

People often overlook chemical stability, picturing it as a matter for chemists and lab techs. In reality, stability shapes how a product behaves in warehouses, on long-haul trucks, or midway through a production process. Products lacking stability break down, lose effectiveness, or even become dangerous quicker than expected. That’s not just scientific trivia. Businesses face recalls. Workers get exposed to risks. End-users may not see the performance promised on the label.

Take fertilizers with ammonium nitrate or consumer-grade hydrogen peroxide solutions. If those aren’t stable, shelf-life plummets. Heat during shipping can kick-start decomposition. In cities with hotter climates, trucks turn into unintended ovens. A stable formulation means the difference between a reliable solution and a safety hazard. For me, having spent years working in warehouse logistics, the difference between a safe delivery and a hazardous spill usually traced back to how predictable a product stayed under stress. Real-life experience proves manufacturers can't afford to treat thermal decomposition temperature as a technicality.

What the Numbers Say — and What They Don't

Scientists use metrics like decomposition temperature to provide a baseline. If a material starts breaking down at 120°C, plant managers must keep those storage rooms cool, not just for comfort. Decomposition usually means release of gases, color changes, or occasionally, energy in the form of heat — sometimes sparking a fire or even an explosion. After seeing factory incidents traced back to underestimating these thresholds, I’m convinced temperature limits aren't just soft recommendations.

Manufacturers report stability by running accelerated aging studies and stress tests. Good labs publish detailed reports: “Stable up to 110°C over 30 days,” for instance. But these tests can’t always account for mishaps during transport, or batches pushed past their shelf life. Anyone who’s worked on a shop floor knows small lapses add up. I remember one July shipment of resin, supposed to stay below 40°C. The truck driver got stuck in traffic, and thermometers in the cargo area hit 55°C. The delivered material clumped, dried, and the client nearly lost week’s worth of production as a result. Numbers printed on paper need back-up in the form of responsible handling and training.

Solutions and Smarter Practices

No product achieves perfect stability. Teams should plan for the weak links. Labels must do more than list an expiration date or basic temperature warning. QR codes can link to regularly updated online guidelines or real-time safety alerts. Warehouses invest in climate-controlled zones, and transport companies use data-loggers to flag shipments that dip into risk zones. Insurance carriers ask for these records today before they approve policies on bulk chemical storage. That’s a recent shift influenced by claims data showing how unexpected decomposition incidents lead to massive payouts.

Clear communication between purchasing, shipping, and receiving departments also drives better practice. If chemical specs change, word travels fast. Policies must expect new products or reformulations to arrive with different requirements. I’ve seen facilities lose valuable stock simply by assuming “it’s the same as last year’s batch.”

Taking Stability Seriously

Ignoring chemical stability and thermal decomposition risks often spells trouble, especially in real-world handling. Those with hands-on experience know stability simply isn’t a single lab number but a running relationship between the product, its environment, and the people who move it. That’s how to keep products safe—and those who use them safer.

Small Steps, Big Impact

Ignoring storage guidance on a label often seems harmless. Tossing pasta into the pantry or stashing medication in a bathroom drawer usually feels like enough. I learned the hard way that these small shortcuts eat into quality, sometimes in ways you can't see right away. Years ago, a simple bottle of aspirin turned to powder long before its expiration date. It turns out humidity from the shower broke down the coating. If someone takes expired or degraded medicine, the results can be worse than wasted money—safety risks aren't always obvious until it’s too late.

The Science Behind the Dates on the Box

Manufacturers test products under different temperatures, light, and humidity to set those storage guidelines. For example, pharmaceuticals often require a range between 15°C and 25°C, out of direct sunlight, because even a short stint in the wrong spot—like a hot glove box—breaks down the active compounds. Dairy, meat, and fresh produce follow similar rules: the colder, the slower bacteria grow. According to the USDA, most perishable foods shouldn't sit unrefrigerated for over two hours. Temperature neglect often causes spoilage long before you see mold.

Read the Expiry—But Don't Stop There

An expiration or “best by” date is only a helpful guide if storage fits the recommendations. Flour keeps for a year in a cool, dry cupboard, yet develops off tastes within months if exposed to humidity. Vitamin C loses potency when stored near heat. Food and Drug Administration inspections commonly spot degraded foods and supplements where storage rooms run hot or damp. It doesn’t matter how careful the packing process is—once a carton or jar ends up in the wrong part of a kitchen or warehouse, its shelf life drops fast.

Why Storage Conditions Shape Health and Value

No matter if it's food, supplements, or cosmetics, proper storage keeps products safe and effective. Nutrient levels, flavor, and even color fade if exposed to air, sunlight, and warmth. Unsafe storage fuels food poisoning outbreaks and contributes to household waste. In the United States, consumers toss billions of pounds of food each year, much of it because it "went bad" in a cupboard or refrigerator that ran too warm. The World Health Organization points out that unsafe medications, spoiled milk, or even expired sunscreen all put people at risk, especially kids and seniors.

Simple Choices Make the Difference

Clear storage advice isn’t hard to follow. Keep dry goods away from dishwashers and stoves, since temperature spikes chip away at quality. Store cleaning products and pills well out of reach of kids, but not in a steamy bathroom. Check dates before grocery runs to avoid duplicating what's already at home. A thermometer in the refrigerator lets you keep perishable goods safely below 40°F (4°C). Dry edible products like grains or beans last much longer in airtight containers, away from light and moisture. Storing correctly often means fewer trips to the store and less cash wasted on spoilage.

It Adds Up Quickly

Paying attention to storage pays off not just in health, but in savings and convenience. A bit of knowledge and a few small upgrades—like a cooler pantry shelf or sealed jars—can stretch the life of everything from snacks to skin cream. With household spending so squeezed, every little decision on where to stash your groceries or medicine really counts.

Real Impact of Compatibility in Daily Settings

On shop floors and in research labs, compound compatibility can spell the difference between a reliable product and a costly mistake. I recall the time a routine production batch ballooned into a multi-week headache—an unstable compound reacted with a supposedly “safe” cleaning solvent. The result: corroded equipment, lost materials, frantic schedule changes, and a red face at the next safety meeting. Exploring which solvents and materials play well with your compound carries more than academic curiosity—it informs safety, equipment cost, and, most of all, peace of mind during daily operations.

How Solvents and Materials Shape Outcomes

Some compounds mix easily with alcohols or ketones, turning into practical formulations for disinfectants, inks, or adhesives. The trouble starts with stubborn reactions. Acids might eat through stainless steel, releasing byproducts that taint the whole batch or even threaten worker health. Even solid plastics, often chosen for their resistance, can crack or warp if overlooked interactions slip by. These headaches pile up if manufacturers rely on old compatibility assumptions. Regulations like OSHA and the EPA heavily fine or even shut down operations where inattention leads to chemical mishaps or worker injuries.

Specific Cases from Industry Experience

During my years working in quality control for specialty chemicals, I watched colleagues put glassware through solvents without double-checking resistance tables. Ether attacked rubber stoppers, which then contaminated medicinal syrups that should have been free from trace impurities. It taught our team that cross-checking solvent compatibility charts wasn’t a luxury—it kept batches within spec and stopped a recall in its tracks. Facts from the American Chemical Society back this up: cross-reactions or leaching often sit behind the bulk of pharmaceutical process failures caught during audits.

Data and Science Over Assumption

Rushed decisions can create flammable vapor hazards or hidden microcracks in containers. Cautious labs use sources like the CRC Handbook or solvent resistance data from material suppliers. For example, polyvinyl chloride (PVC) stands strong against aqueous acids, but swells in the presence of most organic solvents. Stainless steel tanks handle alkaline solutions but can suffer with concentrated chlorides. It only takes one overlooked misfit for a storage tank to spring a leak. It pays to review both chemical structure and storage conditions—temperature, time, concentration—all of which amp up reaction risk.

Solutions: Training and Testing in Practice

No single chart shows every reaction. Field testing with small-scale mockups often outsmarts textbook wisdom. My team once introduced a new cleaning agent, expecting flawless compatibility, only to see microbubbles and surface degradation after a week of exposure. Tiny pre-launch trials, measured with GC-MS or FTIR, highlighted small byproducts that didn't appear on paper. Larger companies now require these routine checks and enforce clear, ongoing staff training. Regulatory agencies recommend ongoing surveillance and regular review of established compatibility, not just a one-time test before launch.

The Stakes Get Higher Each Year

With newer “green” solvents and polymer blends hitting markets, the old methods for checking compatibility matter more. One overlooked reaction in an eco-friendly process can backfire, undermining years of sustainable design. Out in the field and on the line, compound compatibility isn’t just a technical hurdle—it’s a cornerstone of safety, compliance, and product quality. Anyone working with chemicals and materials owes it to their team, their community, and their customers to take this step seriously and keep asking tough compatibility questions.

The Real Risks in the Workplace

Anyone who’s worked with industrial chemicals knows certain compounds demand respect. Whether it’s solvents, acids, or bases, these substances don’t care if it’s your first day on the job or your last. Over the years, I’ve seen what can happen when short-cuts replace basic safety habits. The fallout isn’t just paperwork or a ruined batch—sometimes it’s someone taking weeks off to recover from skin burns or fume inhalation.

Direct Contact: More Than Just a Nuisance

Take skin exposure, for example. Acids like hydrochloric or bases like sodium hydroxide will burn deep before you even feel pain. Gloves aren’t optional; they’re your first line of defense. The right pair makes all the difference—nitrile or butyl rubber gloves stand up much better than the thin latex type you find in cheap first aid kits. Aprons and chemical splash goggles stop liquid from sneaking through cuffs or splashing into eyes. One coworker lost peripheral vision after ignoring goggles during a minor transfer. That memory sticks.

Breathing Hazards: Nothing to Take Lightly

Then there’s inhalation. Even chemicals you can barely smell, like some ethers or alcohols, can knock you out or do long-term damage. Large plants invest in local exhaust or fume hoods for good reason. I still remember standing in a poorly ventilated garage, suddenly dizzy and nauseated after just a ten-minute exposure. Small shifts lead to big trouble fast. Respirators bridge the gap—filters specific to vapors or particulates, properly fitted, can mean the difference between a normal day and an ER visit.

Handling and Storage: The Basics Matter

Spills and vapor buildup don’t announce themselves. I learned to check drum labels every time—mixed-up storage turns minor leaks into major emergencies. Flammables need grounding; I saw a static spark in a dry warehouse light up a drum of solvent because the rules weren’t followed. Chemical-specific storage guidelines are public for a reason. Even a simple cabinet with the right venting and segregation by incompatibility reduces risk. Never once regretted double-checking before pouring anything from one container to another.

Long-Term Health: Don’t Ignore the Data

We hear about acute accidents more than chronic illness, but some chemicals put up a slow fight. Repeated inhalation or skin absorption sometimes leads to more than rashes—think asthma, nerve damage, or worse. Benzene, a common ingredient in labs and workshops, has a direct link to leukemia. That’s not a scare tactic; it’s a cold fact. Regular blood tests for high-risk workers give early warning, but only if people actually follow the schedule. Company safety programs only work when folks take them seriously.

Simple Steps to Stay Safe

Sticking to written protocols sometimes feels like a chore, but I’ve seen fewer folks get hurt where people call out up unsafe steps or take time to label freshly mixed solutions. Training can get old, but it pays off during close calls. Even the best safety plans fail if no one respects the risks. Whether moving a drum or just pouring a sample, it comes down to habit—safety glasses on, gloves checked, work area tidy, and a clear mind focused on the task. That’s the plain way most problems get solved before anyone lands in the hospital.