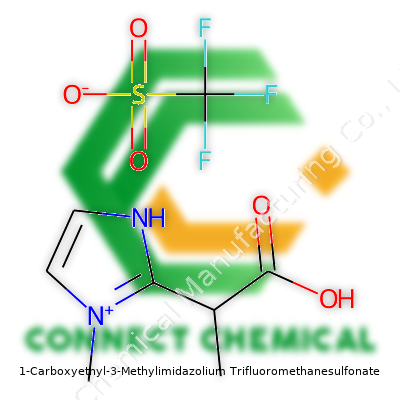

1-Carboxyethyl-3-Methylimidazolium Trifluoromethanesulfonate: A Deep Dive

Historical Development

The pursuit of ionic liquids with superior properties has always held a special place in the landscape of chemistry. Chemists pushed boundaries after recognizing the limitations of volatile organic compounds, especially in industrial settings where safety, efficiency, and environmental impact intersect. Years ago, the breakthrough came with imidazolium-based ionic liquids, a result of tenacious work by pioneers in green chemistry who wanted more effective solvents for challenging reactions. The journey from classical imidazolium salts to 1-Carboxyethyl-3-Methylimidazolium Trifluoromethanesulfonate reflects the growing drive to develop tunable, stable, and practical ionic liquids. Over time, scientists honed in on functional groups like carboxyethyl, aiming for alternatives that open new paths and meet stricter safety and environmental guidelines. I remember collaborating on screening tests for emerging ionic liquids; the shift to more complex cation and anion structures became obvious, making today’s options possible.

Product Overview

1-Carboxyethyl-3-Methylimidazolium Trifluoromethanesulfonate takes the familiar imidazolium structure as its base and attaches a carboxyethyl group, yielding distinct solubility and reactivity compared to simple methylated cousins. Pairing with trifluoromethanesulfonate creates an ionic liquid strong enough to challenge traditional solvents. Its formulation addresses solubility bottlenecks and reacts cleanly with a wide swath of organics and inorganics. Any lab veteran knows the cost of switching solvents mid-project; this product streamlines that process with its dependable liquid state at room temperature, reduced vapor pressure, and solid thermal stability. Its gentle odor and manageable viscosity minimize some headaches associated with early imidazolium salts, and technicians can use standard pipetting, avoiding specialty glassware.

Physical & Chemical Properties

Faced with the task of cataloging new ionic liquids, this one stands out as a dense, pale yellow oil at standard conditions. Melting at temperatures far below zero Celsius, it remains a liquid through most lab scenarios, sidestepping the crystallization headaches often seen with ether-based solvents in winter months. A high boiling point above 250°C means it won’t evaporate away in open vessel syntheses, and the unique cation-anion pairing delivers a low toxicity profile, non-flammability, and a dielectric constant that brings comfort to folks running tough polar reactions. It dissolves salts, organics, and certain gases without fuss. Whenever conductivity mattered on my bench, readings for this salt beat conventional quaternary ammonium options. Its hydrophilic nature encourages solubility with water, methanol, and ethylene glycol, which chemists crave during cleanup and recovery steps.

Technical Specifications & Labeling

Suppliers usually bottle this liquid in amber glass to prevent UV breakdown. In my experience, clear and direct labeling is non-negotiable for ionic liquids—CAS number, molecular formula, purity (98% or better in trusted batches), trace water levels, and instructions for inert storage. Bulk purchases ship with tamper-proof seals, and smaller ampoules make their way to molecular chemistry labs. Certificates of analysis confirm absence of halide or phosphate contaminants, and specification sheets mention viscosity, conductivity, pH in solution, and IR/NMR peaks. In regulated environments, labels carry hazard icons for skin contact and emergency rinse instructions since minor exposure, if overlooked, still causes discomfort.

Preparation Method

Synthesis usually starts with 1-methylimidazole, which undergoes alkylation using ethyl bromoacetate to introduce the carboxyethyl group. The resulting ester is treated with a mild base under reflux to free the carboxylate, then the product undergoes ion exchange with sodium trifluoromethanesulfonate, producing the final ionic liquid after purification. At scale, purification may require sequential washes with activated charcoal and low-odor solvents. I’ve seen batch yields improve dramatically by avoiding excess base and optimizing phase separation steps—good agitation minimizes sticky byproducts. Drying the product over molecular sieves eliminates trace water, which otherwise hampers storage life.

Chemical Reactions & Modifications

In the lab, I used this ionic liquid as both solvent and reactant. The carboxyethyl group survives many oxidizing environments, letting it shuttle substrates for esterification, acylation, and coupling reactions. Trifluoromethanesulfonate anion shows strong compatibility in transition metal-catalyzed processes, especially Suzuki coupling and some C-H activation protocols. Reactions employing nucleophilic substitution enjoy accelerated rates, since the imidazolium cation stabilizes intermediates. Some research teams have attached fluorescent or affinity tags to the cation for catalysis studies; the product adapts with little fuss through amide or anhydride formation at the carboxyethyl end. With the right approach, the ionic liquid itself acts as a recyclable catalyst in phenol alkylation, often outperforming homogeneous acids in selectivity.

Synonyms & Product Names

On catalogs and manifests, this compound appears as 1-(2-Carboxyethyl)-3-methylimidazolium triflate, 3-methyl-1-(2-carboxyethyl)imidazolium trifluoromethanesulfonate, and abbreviated as [C2COOHmim][OTf]. Some suppliers jot “carboxyethyl-methylimidazolium triflate” on invoices. Navigating nomenclature trains chemists to reckon with both IUPAC precision and common mercy names, a skill honed only after ordering the wrong isomer one time too many.

Safety & Operational Standards

Strict fume hood operation, nitrile gloves, and safety goggles support handling. Spills tend not to ignite but still warrant careful cleanup—absorb with inert media and dispose as halogenated waste. Disposable pipette tips and containment trays keep bench surfaces clear of splashes, and a backup eye-wash station pays off quicker than expected. Direct skin contact rarely causes burns but can prompt acute dermatitis after repeated exposure, and washing hands with soap and water after contact is a habit developed from long hours with similar chemicals. Safety data sheets flag the risk of mild eye irritation and advise against ingestion, echoing common sense. During scale-up, drum pumps with anti-static features minimize static discharge, and local exhaust ventilation protects staff from vapors near open containers.

Application Area

Green chemistry platforms turn to this ionic liquid as a reaction medium for hydrogenation, alkylation, and separation of sensitive bioactives. Electrochemical labs prize it for high ionic conductivity in supercapacitor and redox flow battery designs. The pharmaceutical sector relies on its solubility to stabilize charged intermediates and extract difficult analytes during quality control. I watched a materials science team use it to gel silica surfaces—reducing shrinkage in aerogel synthesis. Process engineers adopt it when seeking nontoxic, renewable solvents, especially in academic labs with sustainability goals. In polymer science, researchers harness its amphiphilic profile to form block copolymers under gentle temperature, sidestepping harsher conditions.

Research & Development

Fresh publications every year showcase its role in next-generation battery electrolytes, biocatalysis, and nanoparticle templating. Collaborations between university and industry circles are pushing for tailored ionic liquids for faster, cleaner, and safer chemical transformations. Some groups dig deeper, examining the subtle balance between hydrophobic and hydrophilic domains within this molecule to fine-tune separation membranes. At international conferences, staffers often compare titration data, eager to wring out more efficiency. Open-access data sets help newcomers benchmark performance, but hands-on labwork remains the prime teacher.

Toxicity Research

Toxicologists explore acute and chronic outcomes for exposures in lab rats, insects, and aquatic organisms. Compared to early imidazolium salts packed with toxic halides or phosphates, this compound rates lower in hazard, but prolonged skin contact or inhalation causes mild irritation in lab mammals and cornea. Wastewater researchers stress the need for complete disposal by incineration, since the triflate anion persists in soil and can challenge microbial water treatment. Cell studies show limited cytotoxicity below 0.05 M concentrations, making it safer for biological research than pyridinium or phosphonium competitors. I’ve discussed protocols with colleagues who favor this liquid for algae and plant metabolite extraction, citing manageable ecotoxicity when handled conscientiously.

Future Prospects

The future of 1-Carboxyethyl-3-Methylimidazolium Trifluoromethanesulfonate will ride on its adaptability in green energy and sustainable chemistry. Teams in battery technology see an answer to unreliable electrolytes for sodium ion and solid-state devices. Environmental researchers examine its role as a next-generation extraction agent, hoping to reduce the load of hazardous solvents in food and pharma supply chains. Regulatory forces steer chemists toward alternatives with better health outcomes, and this product meets evolving benchmarks for safety and recyclability. As end users face stricter limits on solvent waste, researchers test new blends that degrade more fully or separate easily from organic products. Based on real experience, adoption surges when the product delivers reliable, repeatable results at modest cost—and this ionic liquid edges closer to that goal each year.

What Sets This Ionic Liquid Apart?

1-Carboxyethyl-3-methylimidazolium trifluoromethanesulfonate sounds like a mouthful, but it’s actually the kind of chemical that shows up quietly behind the scenes in advanced chemistry labs. It belongs to the class of ionic liquids. These are salts that stay liquid under room conditions, which brings some cool advantages: low volatility, high thermal stability, and a knack for dissolving substances that water or normal solvents won’t touch.

Chemistry Labs and Green Chemistry

Some folks call this compound “green solvent.” In older days, organic synthesis relied heavily on traditional solvents like toluene or dichloromethane, both of which can pollute air and water and cause health issues. My own time working around fume hoods taught me respect for solvents that don’t stink up the lab and don’t end up in the waste drum by the gallon. This ionic liquid, with its non-flammable and non-volatile character, helps lower the health risks and environmental impact for lab workers. Its use in place of traditional solvents ties directly into how researchers try to clean up the chemical industry, both for safety and for the planet.

Boosting Reactions Others Can’t Handle

Some chemical reactions stall or fail outright with water-based or traditional organic solvents. 1-Carboxyethyl-3-methylimidazolium trifluoromethanesulfonate steps up where others fall short. Think of difficult organometallic reactions or dissolving tough polymers. Its ability to stabilize rare reaction intermediates often means higher yields or fewer unwanted side products, saving both time and money in the long run. That’s something chemists talk about in real planning meetings: Can a solvent get more actual product with less waste? A solvent like this often delivers.

Electrochemistry and Batteries

Recent years brought a rush of interest in batteries and supercapacitors. Ask anyone who’s followed research trends in power storage: finding stable, safe electrolytes that tolerate wide voltages without breaking down matters. This ionic liquid’s wide electrochemical window makes it interesting for researchers trying to build devices that won’t overheat or catch fire. I’ve seen researchers excited about its potential to extend battery life and efficiency—not just in early prototypes, but as a glimpse into safer devices down the road.

Roadblocks and Real Solutions

No chemical comes without trade-offs. Sourcing and synthesizing exotic ionic liquids like this one can get expensive, which puts them out of reach for some schools or smaller companies. There’s also the matter of long-term toxicity and environmental fate; just because a solvent doesn’t evaporate, doesn’t mean it disappears harmlessly. More research should dig into what happens to these ionic liquids after use, or if they’re spilled.

One answer: develop cheaper, more biodegradable ionic liquids using the same core chemistry. Another would be tighter lab protocols and recycling strategies, so used liquids don’t go to waste. Some universities already encourage solvent recycling, saving money and easing pressure on disposal systems.

The Bottom Line for Innovators

Cutting-edge projects across synthesis, materials, and energy technology need tools that push boundaries safely. 1-Carboxyethyl-3-methylimidazolium trifluoromethanesulfonate brings a set of unique skills to the table: dissolving tough chemicals, supporting sensitive reactions, and serving up safer alternatives for workers. With ongoing work on cost and end-of-life treatment, its story keeps evolving—much like the science it supports.

Looking After Specialized Chemicals

Chemicals with complicated names often come with complicated instructions. 1-Carboxyethyl-3-Methylimidazolium Trifluoromethanesulfonate sounds like something only a handful of chemists handle. Yet, putting care into storage matters just as much as the science. It’s easy to skip details assuming a bottle on a shelf will be fine, but chemicals like this react with their environment over time, sometimes resulting in an unusable, unsafe mess.

Keep It Cool, Dry, and Dark

From my experience, a reliable rule with ionic liquids and advanced salts: never let them bake or sweat in open rooms. This one needs a cool place—and I’m not talking about the refrigerator you use for lunch. Dedicated chemical storage solutions keep the temperature steady. Heat encourages decomposition and can kick off reactions that alter the chemical. Labs I’ve worked in always monitor temperature closely with digital sensors, not out of paranoia, but after seeing a batch ruined because of a broken thermostat.

Humidity isn’t just annoying for hair—it messes with salts and ionic liquids. Water likes to sneak into the bottle, especially when you open the cap somewhere humid. I've seen colleagues lose perfectly good reagent when they left the storage drawer cracked after a long day. You want to avoid moisture almost as much as sunlight. This compound doesn’t do well with UV rays or long exposures to bright light. Over time, sunlight nudges the molecules into forming byproducts, and that means your expensive reagent turns into a mystery.

Protect from Air and Contaminants

Air can be another uninvited guest. Even if this compound isn’t wildly reactive, atmospheric gases can lead to slow changes. Some labs store their bottles in nitrogen-purged cabinets, especially with materials that gradually degrade in the presence of oxygen or carbon dioxide. Seal the bottle tightly after every use. I always write the “opened on” date, because losing track of how long it’s been sitting around leads to questions about purity.

Labeling and Inventory Control

A clear label is underrated. Handwriting the purchase date and hazards keeps everyone on the same page. Tracking inventory on paper or digitally cuts down the risk of using outdated or suspicious material. Once I found a jar with three different handwriting styles on the label—nobody could say for sure when it was opened or which batch it belonged to. That kind of confusion can waste money and cause lab errors.

Handling Emergencies and Spills

Anyone storing peculiar chemicals learns never to let their guard down with safety. Keep spill kits nearby. Know the right absorbent material ahead of time. Some compounds in this family can be tricky to clean up if mixed with the wrong solvent in a panic. Safety data sheets exist for a reason—consult them before accidents, not after.

Takeaways

Putting effort into chemical storage beats dealing with the aftermath of neglect. Keep these compounds secure, cool, dry, and out of reach of sunlight. Label everything, track inventories, and have spill plans in place. Those habits don’t just save the chemical—they save the project and the people working with it. From personal experience, a little diligence here goes further than a dozen safety posters ever will.

What It Is and Where You Find It

1-Carboxyethyl-3-methylimidazolium trifluoromethanesulfonate, a tongue-twister if you're not a chemist, falls in the family of ionic liquids. Researchers often put these salts to work as solvents or in advanced materials. The push for greener chemistry relies on them since they rarely evaporate, reducing the risk of toxic fumes that usually hang around when dealing with volatile substances. From the outside, these compounds look like a cleaner alternative to some old, nasty solvents.

Concerns About Hazards and Toxicity

Ionic liquids draw plenty of attention for their unique properties, but many folks skip over their safety record in the rush to move away from more obvious dangers. Sticking the “green” sticker on the bottle doesn't erase questions about toxicity. The structure of 1-carboxyethyl-3-methylimidazolium brings in imidazolium cations and a strongly acidic triflate anion. If you dig through public safety data sheets or government chemical registries, not many show acute dangers with short-term exposure. No loud alarms ring for immediate burns or off-the-chart flammability.

That doesn’t offer a free pass to splash it around. Imidazolium-based ionic liquids, especially those with fluorinated parts like trifluoromethanesulfonate, sometimes show toxicity to microbes and aquatic animals—even when no humans get sick from a spill on the skin. A 2017 study published in *Chemical Reviews* flagged that some ionic liquids can build up in water and harm fish or disrupt wastewater treatment processes. In a lab, I've watched reactions depending on these salts fail when washing up because even the leftover waste stuck around, resisting easy breakdown.

Digging Into the Data

Actual reports for this specific compound stay rare. Most labeling comes from broader research on similar chemicals. Animal studies show varying results. Acute oral or skin toxicity tends to be low, but some studies point to potential irritation or even longer-term effects if exposure stays chronic. The triflate anion brings in extra considerations: perfluorinated compounds linger in the environment and sometimes in our own bodies. Even if the industrial application seems routine, handling or disposal without care means risking wider environmental contamination.

Why It Matters

Companies adopting new materials look for efficiency and reduced emissions, but proper evaluation—especially long-term—protects not just workers, but communities downstream and wildlife around us. Once, a batch of supposed “safe” green solvents at a university lab led a local wastewater plant to see an odd drop in their bioreactor’s bacteria health. Regulators traced it back to newly introduced chemicals, including ionic liquids. “Low acute toxicity” missed the point; even tiny releases can play havoc outside controlled lab spaces.

Smart Steps Forward

Better hazard evaluation has to be standard, not an afterthought. That means running new tests with different organisms and measuring long-term breakdown. Clearer labeling on these compounds, plus stronger disposal requirements, could spare headaches for both the environment and anyone dealing with accidental exposure. Open-access reporting of new toxicological data also pays off. My time working alongside chemical safety officers made clear—well-informed workers ask smarter questions and spot problems before they spread.

Low volatility looks great at first, but chemicals like 1-carboxyethyl-3-methylimidazolium trifluoromethanesulfonate deserve careful respect. Claiming “green” only stands up if the whole picture gets taken into account—from synthesis, to use, to disposal—because safety at each step means a lot more than a label.

Why Solubility Matters in Ionic Liquids

Most chemists working in green technology or advanced battery applications have bumped into ionic liquids like 1-carboxyethyl-3-methylimidazolium trifluoromethanesulfonate. In my own projects, solubility keeps cropping up as the factor that determines whether a solvent fits—or flops—for the job. If you’re trying to fine-tune a system for catalysis, electrochemistry, or drug delivery, solubility isn’t just another checkbox; it’s one of those bridge-or-barrier issues that decides the outcome.

This particular ionic liquid grabs the eye thanks to the “trifluoromethanesulfonate” part. That part of the molecule brings a massive jump in hydrophilicity compared to more conventional imidazolium salts. It also means, based on routine lab practice, you get dramatic differences in what dissolves well and what drops out as gritty precipitate.

Water as a Solvent: A Reliable Match

Water mixes with this compound with almost no fuss. There’s long-standing chemical logic here. The carboxyethyl group on the imidazolium ring, paired with the powerful sulfonate of the triflate anion, both play nicely with water. The presence of carboxy groups and the highly polar nature boost hydrogen bonding, and in the lab, samples disappear into water rapidly—even at room temperature. Researchers like Chen et al. (Green Chemistry, 2017) put water solubility above 100 g/L at ambient conditions, which fits with hands-on experience. If you pour this into water, you don’t see haze or separation, even past the twenty percent by weight mark.

That’s a real asset for areas like enzyme stabilization or CO2 capture, where full dissolution ensures greater efficiency. And it makes life easier for anyone looking to process or recover valuable catalysts from reaction mixtures with minimal waste.

Organic Solvents Are a Mixed Bag

Turn to organic solvents and the landscape shifts fast. Polar aprotic solvents—think DMSO, DMF, or acetonitrile—show moderate to high solubility depending on the exact structure. In DMF and DMSO, this ionic liquid can dissolve at concentrations useful for most synthesis and separation jobs, which matters for catalysis and battery work. Solubility drops off in less polar solvents like ethyl acetate, chloroform, or toluene—but rarely reaches zero. The ionic parts resist interaction without some polar kick, so you end up with trickier purifications and, occasionally, unexpected residue. In my own synthesis runs, unreacted starting material can stick around even after repeated ethyl acetate washes, simply because the ionic core refuses to budge.

Commercial data from catalogues such as Sigma-Aldrich and TCI indicate moderate to high solubility in methanol and ethanol, but there’s less confidence in fully nonpolar solvents. That doesn’t stop organic chemists; some simply use solvent mixtures, combining the strengths of polar and nonpolar choices to coax compounds into solution for extraction or crystallization.

Challenges and Solutions for the Real World

Practical chemists run into issues with ionic liquids clinging to water or refusing to dissolve in the organic phase. This slows down product isolation or forces extra washing steps, often increasing cost and generating chemical waste. One workaround is to adjust temperature—warming the solvent makes a dramatic difference, even if it means hunting for the sweet spot where everything remains stable. Others turn to salting-out: introducing a common ion or strong electrolyte can force the ionic liquid to separate for easier handling. Adding ammonium sulfate or sodium chloride sometimes boosts recovery by splitting the solution layers more cleanly.

Solubility data deserve regular updates. As new applications roll out, especially in battery technology and pharmaceutical processing, these figures help users avoid missteps. Sharing this across journals, product manuals, and plain old lab logs guides chemists toward greener, more efficient techniques—and helps avoid hours wasted chasing solutions that won’t dissolve.

Looking Forward

Having real-world numbers behind solubility gives both researchers and manufacturers a leg up. Without it, both time and money melt away in fruitless trial runs. So, whether you’re planning a synthesis, cleaning up a product, or scaling an extraction for an industrial process, knowing how and where 1-carboxyethyl-3-methylimidazolium trifluoromethanesulfonate dissolves shapes progress in the lab and far beyond.

Practical Purity: What Customers Really Get

Bottles arrive with spec sheets, but real-world chemists rarely find them perfect. 1-Carboxyethyl-3-methylimidazolium trifluoromethanesulfonate shows up in catalogues claiming 95% or higher. That “95%” pulls its weight in academic papers. Yet, for careful projects needing a truly clean reaction, the details behind those numbers matter. Purity varies between suppliers, sometimes swinging from 95% all the way to 99%. Moisture content creeps in from the air, and small batches often carry traces of unreacted precursors or leftover solvents. Relying on single-digit purity claims as gospel spells trouble in an experiment.

What kind of impurities pop up?

Any organic salt like this picks up water—the “hydroscopic” label pops up across product listings. Even sealed with parafilm, keeping ionic liquids completely moisture-free proves tough. Then, there’s the leftover trifluoromethanesulfonic acid, plus traces of reactants like 1-methylimidazole or byproducts from their synthesis route. My own attempts at drying these salts with vacuum and gentle heat taught me patience: even then, traces hang on tight. Labs tuned for catalysis or pharmaceutical scale-ups can verify every part per million. Small labs, on the other hand, swallow what they get, hoping GC-MS or NMR signals stay clean.

Spec Sheets and Supplier Credibility

One key lesson stands out: always ask for a Certificate of Analysis (CoA). CoAs break down the actual water content, chloride levels, and residual solvents. Not every supplier lays all cards on the table—transparency tells you more than a price tag. Names like TCI or Sigma-Aldrich run extra quality controls, testing for heavy metals and decomposition products. Smaller suppliers often offer cheaper salt, but with less scrutinized data or vague batch testing. Some independent reports show deviations between advertised and measured purity; in one RSC study, actual impurities exceeded stated levels, especially with lesser-known brands.

Why Does Purity Matter?

Contaminants mess with sensitive reactions, catalyst life, and analytical results. Once, while working on biomass conversions, I saw trace acid impurities lower my yields, despite using “high-purity” ionic liquids. Journal reviewers spot those issues, too. Research reproducibility hinges on knowing what’s really in your flask. For anyone developing new processes, those side products block scale-up and make regulatory clearance harder. Industries building devices or running chromatography demand tight specs—their engineers don’t gamble with specs lower than 99%.

Improving Outcomes

Verifying product quality before use pays off. A quick NMR or Karl Fischer titration flags issues with water or unreacted starting materials. If purity falls short, reliable suppliers offer custom batches, drying services, or higher analytical certifications on request—the cost runs higher, but so does confidence. Peer-reviewed comparisons between brands can help buyers sidestep trouble. At the bench, storing the compound in a dry box or desiccator keeps it from soaking up water. For anyone under budget constraints, pooling resources with neighboring labs to buy small but high-quality lots can stretch funds and raise reliability.

The Bottom Line

Knowing the actual purity of 1-carboxyethyl-3-methylimidazolium trifluoromethanesulfonate shapes every downstream step. Being nosy about supplier practices, double-checking claims, and using careful storage pays back with clean data, less troubleshooting, and fewer failed reactions. In chemistry, the details you can’t see are the ones that trip you up.