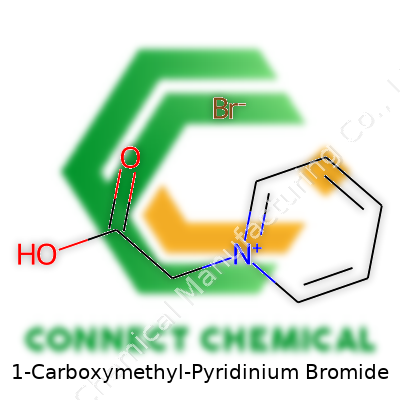

1-Carboxymethyl-Pyridinium Bromide: A Detailed Commentary

Historical Development

Chemistry circles in the early 20th century saw a surge in interest for pyridinium compounds, tracing roots back to research in basic heterocyclic chemistry and quaternization reactions. Scientists found that tweaking the pyridinium ring with carboxymethyl groups led to a lineup of salts featuring new, exciting properties. Bromide emerged as a popular counterion, mainly because it doesn't complicate most organic syntheses with annoying side reactions. The birth of 1-Carboxymethyl-Pyridinium Bromide stemmed from the need for soluble quaternary ammonium salts that enhanced reactivity in various organic settings, particularly within pharmaceutical development and catalysis. Over time, this compound became more than a curiosity as it showed advantages in synthetic and analytical laboratories searching for stability and straightforward handling.

Product Overview

This salt marries a pyridine ring, known for its aromatic stability, with a carboxymethyl group attached at the nitrogen through a methyl linkage, balanced by a bromide anion. Chemists lean on its fine crystalline nature and ease of dissolution in water and polar solvents, opening up a toolbox filled with possibilities for catalysis, phase-transfer reactions, and biological surface functionalization. Laboratories value its purity and consistent behavior in reaction conditions, making it a staple for projects ranging from molecular modification to complexation studies. Developers pay close attention to sourcing protocols and storage, since moisture sensitivity can sometimes impact salt form and performance.

Physical & Chemical Properties

Pure 1-Carboxymethyl-Pyridinium Bromide usually appears as an off-white to light tan powder or fine crystals, with a melting point typically in the 180 - 200°C range, depending on batch purity. The material draws moisture from the air, so those humidity-resistant containers matter. This compound dissolves quickly in water, methanol, and ethanol, showcasing a strong ionic character. Stability persists across a wide pH range, though acidic and highly basic environments can prompt decomposition over extended periods. The bromide counterion stays inert under most standard lab procedures, while the pyridinium ring and carboxymethyl side chain bring moderate reactivity at specific positions, lending themselves to downstream chemical tailoring.

Technical Specifications & Labeling

Suppliers calibrate quality through metrics like ≥98% pure content, limited bromide content below 2%, and heavy metals below established thresholds. Batches come labeled according to IUPAC naming conventions—rarely do reputable sources cut corners here. Packaging matches safety guidelines, featuring tamper-evident seals, batch numbers, and clear hazard warnings related to inhalation or accidental ingestion. Storage instructions call for a tightly sealed, dry, and ideally cool spot. Proper lot traceability helps research teams align any unexpected results with known product nuances. Labels printed with solubility data, CAS registration, and critical safety information keep everyone in the lab on the same page during ordering and handling.

Preparation Method

The classic method involves reacting pyridine with bromoacetic acid (or bromoacetate) under controlled temperature in a polar solvent. Stirring ensures even distribution while temperature control limits unwanted side reactions. Once the reaction reaches completion, precipitated product gets filtered, followed by recrystallization to remove unreacted raw materials and side products. Some producers switch to solvent-free microwave-assisted methods to slash reaction times and cut waste, which fits with green chemistry trends. Final drying under vacuum strips residual moisture, giving a product ready for analysis or direct use. Each setup relies on proper handling, given the potential for irritating intermediates and the generation of noxious fumes if mishandled.

Chemical Reactions & Modifications

The pyridinium core in this compound plays well with electrophiles and some nucleophiles, opening paths to new quaternary salts or substituted derivatives. Carboxymethyl groups support further esterification and amidation, so custom-tailored molecules branch from the original structure for advanced functions in sensors, drug delivery, or coordination complexes. Bromide, often considered by chemists as a leaving group, sometimes finds itself displaced under phase-transfer conditions during synthesis of ionic liquids or as a partner in halide-exchange reactions. Most modifications maintain the ring integrity and quaternary structure, critical to preserving the desired ionic, solubility, and surface-active behaviors.

Synonyms & Product Names

Over years of catalog listings, research publications, and supplier brochures, I’ve noticed a handful of alternate names show up alongside 1-Carboxymethyl-Pyridinium Bromide. N-(Carboxymethyl)pyridinium bromide, Pyridinium-1-ylacetic acid bromide, and CM-PyBr pop up often. Some labs mark custom batches with shorthand like Py(CM)Br, especially during reaction planning. These synonyms matter for procurement and literature review, especially when researchers dig into international patents or cross-reference older articles that used slight variations in naming conventions.

Safety & Operational Standards

Handling safety starts with gloves, goggles, and an eye toward ventilation. Pyridinium salts tend to be mild irritants, particularly if inhaled or spilled, so the bottle stays capped until the moment of use. Training in proper spill cleanup and waste disposal keeps risks low, and safety data sheets walk labs through first-aid steps or fire hazards. Storage out of sunlight and away from strong oxidizers or acids ensures longevity and limits hazards. Disposal procedures run through hazardous waste streams to limit environmental release, matching both regulatory compliance and ethical lab protocols. Emergency procedures get regular updates as part of workplace safety audits, especially with larger-scale users or universities, who need reliable response plans.

Application Area

In my experience, the reach of 1-Carboxymethyl-Pyridinium Bromide extends well beyond basic analytical chemistry. Synthetic organic chemists use it for phase transfer and as a catalyst bedrock in alkylation or acylation protocols. The ionic nature shines in electrochemical sensor development, where its charge maintains conductivity and supports functionalization of surfaces. Pharmaceutical projects tap into its structure to craft intermediates or explore new salt forms for active pharmaceutical ingredients. Environmental chemists study its mobility and interaction with soil and water systems. Material scientists incorporate this compound for ionic liquid precursor synthesis and as a building block in advanced polymers, where targeted solubility and reactivity matter most.

Research & Development

R&D teams look for salts that balance reactivity, stability, and environmental profile. Current studies continue to push the envelope—in drug delivery systems, researchers add carboxymethyl-pyridinium motifs to target specific receptors or promote solubility under physiological conditions. Material science groups want more sustainable ionic liquids and turn to this compound for alternative synthetic strategies. Analytical chemists re-engineer the salt as a derivatization reagent, making trace analysis smoother and more selective. Electrochemistry experiments exploit changes in conductivity and redox behavior, opening discussions on next-generation batteries or supercapacitors. The ever-expanding array of potential tweaks and applications means university and industrial groups keep their eyes peeled for new synthesis routes or cleaner modification methods.

Toxicity Research

Toxicological profiles for 1-Carboxymethyl-Pyridinium Bromide remain underreported compared to blockbuster industrial chemicals, but trends hint at moderate acute toxicity, similar to many small cationic salts. Cell culture studies sometimes point to membrane disruption at high concentration, though most lab users work with small amounts far below these levels. Environmental fate receives close attention—ionic mobility and the presence of bromide ion raise flags for waterway contamination in the rare event of a spill. Regular monitoring and responsible disposal prevent buildup in labs or treatment plants. Universities run student safety courses that stress respect for all quaternary salts, and ongoing research works toward definitive animal and environmental impact data so that guidelines keep pace with new uses.

Future Prospects

Advances in green chemistry, digital synthesis, and battery development all circle back to the need for versatile, aptly designed ionic salts like 1-Carboxymethyl-Pyridinium Bromide. As companies and academic labs chase more sustainable catalytic cycles and turn toward bio-based materials, the spotlight will keep moving to salts that balance easy preparation, safety, and functionality in aqueous or mixed-solvent systems. Expect increasing demand for purer forms and data-driven synthesis optimization. Automation could speed up production, offering more cost-effective paths for specialty chemical makers. As the world’s dependence on electrochemical technology grows, the compound’s role as both a research tool and a scalable component will likely expand, fueled by a generation of chemists eager to blend tradition with discovery.

What Does 1-Carboxymethyl-Pyridinium Bromide Do?

Most people probably haven’t come across 1-Carboxymethyl-Pyridinium Bromide at the grocery store or in casual conversation. The name doesn’t roll off the tongue, but its chemistry makes it pretty useful in the lab. Scientists lean on this compound mainly for its part in organic synthesis and as a phase-transfer catalyst.

Phase-transfer catalysis matters in chemistry because sometimes two substances just don’t like to mix. Picture oil and water refusing to do each other any favors; that’s a challenge for chemists trying to get molecules to react across these gaps. Here’s where 1-Carboxymethyl-Pyridinium Bromide steps up. It helps ferry the right ions across the boundary, speeding up reactions that wouldn’t happen easily otherwise. In drug research, this opens up more room for creativity and efficiency.

Why This Compound Shows Up in Industry

Pharmaceutical companies and researchers take advantage of this compound’s knack for shuttling ions during syntheses. Making a new medicine, designing a target molecule, or scaling up a laboratory discovery often runs into roadblocks with reactivity. Using a phase-transfer catalyst like this one trims down wasted time and helps boost product yields.

Beyond medicine, industries concerned with making specialty chemicals, polymers, or even agricultural products benefit from improved reaction control thanks to compounds like this. Being able to tweak the chemistry at the interface between different liquids lets engineers and scientists fine-tune their processes. I remember as a student seeing a phase-transfer reaction bring two otherwise stubborn substances together, and it always impressed me how something so small could have such a big impact on the outcome.

What About Safety and Research?

Safety always plays a big role in the lab. 1-Carboxymethyl-Pyridinium Bromide doesn’t tend to cause the same alarm bells as some older phase-transfer catalysts, which could sometimes come with serious health or environmental risks. Still, any compound making its way into an industrial process demands careful review for toxicity and biodegradability. Regulatory bodies like the EPA and the European Chemicals Agency offer guidance so companies don’t put workers or downstream users at risk.

Spotting the Challenges and Possible Solutions

One problem worth talking about has to do with waste. After a reaction, leftover catalyst often faces disposal challenges. Lab teams must work out safe ways to neutralize or recover 1-Carboxymethyl-Pyridinium Bromide. Some researchers look for ways to re-use these compounds or switch to environmentally friendlier options. The trend toward “green chemistry” focuses on reducing waste and making recycling a standard step. New research has pointed at possible biodegradable alternatives or tweaks that could help this compound break down more easily after use.

Looking Forward

Chemical innovation thrives on small breakthroughs: safer catalysis, better yields, and smarter waste handling. If labs keep focusing on both effectiveness and environmental impact, compounds like 1-Carboxymethyl-Pyridinium Bromide may keep finding new roles in research and industry. Science pushes forward, and so do expectations for responsible chemistry.

The Chemistry Under Review

1-Carboxymethyl-Pyridinium Bromide, a mouthful of a name, carries a lot of weight in research circles. The molecular formula: C7H8BrNO2. Calculating this, you get a molecular weight of about 234.05 g/mol. This single number guides dozens of decisions in the lab. Students, seasoned chemists, and even regulatory experts keep a close eye on these values. Why? Because a misstep here causes trouble, all the way from inconsistent results to safety mix-ups.

Getting It Right: Not Just Lab Detail

Looking at the formula isn’t about reciting facts. My first experience with molecular weight calculations happened during a late-night university lab. I remember copying the wrong value from an old database, which led to a whole batch of failed synthesis. Half a week lost, supplies wasted, and a stern talk from the professor burned the lesson in: numbers have consequences. The smallest shift in elements—add a hydrogen, swap out a group—throws the whole profile off. With this compound, losing sight of that nitrogen or the placement of the bromide opens the door to error.

Why the Details Shape Outcomes

In pharmaceuticals, the difference between safe and risky can sit inside a single milligram. Drug developers count on the exactness of C7H8BrNO2. Bioactivity changes if someone makes a substitution or uses an impure sample. In advanced materials, swapping a methyl for an ethyl group can make or break conductivity, solubility, or stability. Knowing that 1-Carboxymethyl-Pyridinium Bromide clocks in at 234.05 g/mol sets the baseline for correct concentrations, dosing, and expected reactivity.

Traceability Backs Safety and Trust

Scrutiny follows specialty chemicals. They enter consumer products like cleaners, medical diagnostics, and even food-testing labs. Traceability ties every vial on a shelf back to a reliable synthesis and an unbroken paper trail. It's easy to cut corners—I've seen companies tempted to skip cross-checks because "nobody will notice." Until regulators call, or a batch goes bad. Public trust, hard-won and easily lost, rests on following protocols every step of the way. Databases like PubChem or ChemSpider have made it easier to double-check identities and weights. You still want a thick skin and a questioning mind: cross-verify with supplier paperwork and chromatography data whenever something feels off.

Smoothing the Path Forward

Mistakes often sneak in when teams face time crunches, loose communication, or scattered information. Building a habit of slowing down at critical moments pays long-term dividends. Double entry—writing and checking out loud with a colleague—saves future headaches. Tying every new batch to a signed-off procedure, and keeping records up to date, keeps the science honest. Training helps, but so does building a culture where it’s fine to stop and ask, “Are we sure about this number?” Honest questions lay the groundwork for safe, innovative research. In chemistry and any technical field, small details aren’t just academic—they carve the path toward better, safer, more productive work.

Thinking Beyond the Label: Storing Chemical Reagents Safely

Plenty of chemicals spend their days tucked away on lab shelves, rarely grabbing attention until someone needs them. 1-Carboxymethyl-Pyridinium Bromide is one of those niche compounds, but that doesn’t mean it can be left to fate in a corner. I spent years in university research spaces where keeping a tight ship with your reagents wasn’t just about avoiding spills; it was about avoiding weeks of repeating work or losing valuable data. Ignore proper storage and you might as well pour money down the drain.

The Dangers of Not Paying Attention

Back in my grad days, we had a classic case: a well-meaning colleague left a specialty pyridinium salt exposed to air “just for a day.” A week later, the material clumped, lost potency, and we had no way to recover what was left. Not every risk in the lab announces itself with a loud bang—most sneak up when containers aren’t closed properly or get left in humid spots. 1-Carboxymethyl-Pyridinium Bromide isn’t flammable or shock-sensitive but absorbs moisture fast. In a humid city, that property transforms storage from an afterthought into a challenge.

Simple Steps to Keep It Safe

Sealing is the first line of defense. Always use tightly capped bottles, preferably with screw tops lined for chemical resistance, to keep air out. Even a short exposure to damp air makes the salt sticky and messy. That spells trouble for those trying to weigh it out for reactions or storage. I’ve dodged more than one ruined experiment this way.

Next, location counts. This isn’t a household cleaner; it should go on a shelf with similar, stable compounds, in a cool and dry spot away from windows and direct light. Direct sunlight can turn a reagent into a useless mess, and a sunny windowsill is the quickest road to disaster. In university labs, we had desiccators—vacuum-sealed chambers with drying agents—that kept chemicals bone-dry for months. Even a low-cost silica gel pack inside storage containers can make a difference at home or in resource-limited labs.

Temperature and Security

Temperature swings mess with almost any chemical. Keep 1-Carboxymethyl-Pyridinium Bromide away from heating vents, radiators, or anywhere that feels toastier than a standard room. A stable 20 to 25°C works well. I always made sure to check on the thermometer in our stockroom once a week—better safe than out of pocket for lost materials.

Don’t forget about security and labeling. The best containers won’t help if you can’t find your reagent or mistake it for another white powder. Clear labeling with date of receipt, name, and concentration helps everyone in the lab. During reviews, I’ve seen labs fined for ambiguous container labels—nobody needs that hassle.

Long-Term Habits and Training

Training new staff or students to store chemicals with care pays off. In my teaching experience, the best approach involved setting clear routines—seal it up, label it, return it to the same place every time. Good storage helps protect health, investments, and results. It’s less about fear and more about respect for the craft and your own time.

Understanding What You're Working With

Walking into a lab or production area, each chemical brings its own set of risks. 1-Carboxymethyl-Pyridinium Bromide, while interesting for its applications in synthesis and research, doesn’t take kindly to careless handling. It holds an ionic structure and often comes as a fine powder. If you’ve handled similar pyridinium compounds, you know they can be irritating to the skin, eyes, and respiratory tract. I’ve witnessed cases where even brief contact caused redness and itching. Neglecting gloves or eye protection has sent more than one person fumbling for the eyewash station.

Gloves, Goggles, and Common Sense

Some folks shrug at PPE, but direct exposure to powders like this one brings real problems. It dissolves in water, and contact with skin may lead to rashes or dryness. Inhaling dust could spark coughs or trouble breathing, especially for those with underlying sensitivities. I make a habit of wearing nitrile gloves, a buttoned-up lab coat, and snug-fitting goggles. Accidents seem rare—until they happen. An unexpected sneeze in the middle of weighing powders can turn any desk into a contamination site.

Air Matters More Than You’d Think

Ventilation often gets overlooked in labs. This compound shouldn’t be handled in stuffy spaces or at cluttered desks piled high with solvents and paperwork. Fume hoods weren’t invented for show. Working in a hood limits inhalable dust and keeps vapors at bay, especially if you’re combining it with other reagents. Even a moment’s inattention could mean weeks of nagging coughs or worse. I’ve seen busy spaces turn into coughing fits as soon as powders drift outside their intended zones. Good airflow changes the game.

Don’t Eat, Drink, or Touch Your Face

After years in research, I can say food and chemicals don’t mix—not on glassware, not on work surfaces. Any residue coming in contact with your lunch or coffee mug has a clear path to your stomach. I always wash my hands thoroughly and keep personal items off the bench. You can’t undo exposure after a mistake—especially if you touch your mouth or eyes without thinking. Even short-term exposure runs risks because these compounds aren’t designed for the human body.

Spill Response Isn’t an Afterthought

Spills bring chaos, but preparedness takes the edge off. Having absorbent pads nearby and knowing the spill protocol saves minutes that matter. Sweeping up with a dry brush only stirs up dust. I use a damp disposable towel and a sealable bag for cleanup. Afterward, extra ventilation clears lingering residue. Watching coworkers ignore a minor spill, hoping no one noticed, is how small lapses become health problems.

Storing it Right

Strong light, heat, and moisture don’t mix with 1-Carboxymethyl-Pyridinium Bromide. I pack it tightly, mark the container with all the hazard information, and keep it away from acids and oxidizers. Memory slips easily; clear labeling closes that gap. Even the cleanest lab faces contamination risks if bottles stay uncapped or drift into the wrong cabinet. In my experience, organized shelves make accidents less likely.

Building Good Habits

Handling any chemical safely draws on more than rules. It asks you to pay attention, use your head, and care for your colleagues. Each moment of carelessness builds toward an accident. I rely on checklists, open communication, and a willingness to speak up if something looks off. Real safety doesn’t show up on display; it shows up in the routines that protect everyone in the room.

The Truth behind Purity Grades

Lab work often depends on details others skip over. Purity counts as one of those details. Plenty of folks hear the name 1-Carboxymethyl-Pyridinium Bromide and immediately want to know: is it available in multiple grades? The answer’s straightforward—yes, it is. But there’s a big difference worth talking about.

Some researchers reach for the highest purity grade without thinking twice. It sounds safer, and big projects sometimes demand it. Experience teaches that pushing for upper-tier purity isn’t always necessary. Purity grades are set up for real-world applications—high-purity chemicals (think 98% and above) land in pharmaceutical labs and demanding analytical setups. Lower grades, maybe 95% or less, see use in chemical synthesis or teaching labs. Some folks find what they need for routine work without splurging on extra purity or blowing through lab budgets.

Quality and Contamination Aren’t the Same Thing

Anyone who’s handled chemicals learns soon enough that low grade doesn’t mean contaminant soup. The actual difference falls in the parts per million or the presence of byproducts and solvents from the manufacturing process. When I ran a project trying to synthesize a series of pyridinium compounds, I chose the “standard” grade. The assays showed a trace amount of a bromide salt byproduct, but for our work, it made zero impact.

Pharma and biotech researchers don’t play games with trace contaminants—they know any impurity can derail a batch. A little research goes a long way; labs look at the certificate of analysis (CoA) and demand a breakdown of residual solvents, moisture, and even metallic ions. In industrial chemistry, the expectation for ultra-high purity drops off, especially if the chemical will get purified again downstream.

How’s It Sold and Why Should You Care?

Suppliers don’t list random numbers. Those purity grades spell out what’s packed in each bottle. Reputable suppliers, such as Sigma-Aldrich or TCI Chemicals, usually offer at least two grades. Their catalogs write things out, not just “pure” or “technical,” but with a percentage—sometimes 98%, sometimes 95%.

People sometimes skip checking the small print. There was a time one of my colleagues ordered the cheapest available grade for a sensitive NMR study. The surprises came only after running expensive tests. One unexpected impurity meant rerunning the whole set and weeks lost on a rushed order. Purity has cost-and-performance trade-offs.

What’s the Fix? Ask, Compare, and Trust the Data

If your work can’t handle tiny unknowns, don’t guess—get the CoA before ordering. Comparing providers helps, too. Not every lot meets the spec printed on a website, and trusted brands often publish more data for review. In education settings or early-stage research, spending for pharmaceutical grade doesn’t always make sense. For published work or clinical development, higher grades transition from “nice-to-have” to “non-negotiable.”

The chemical industry has been challenged to be more transparent—some labs even perform their own in-house analytical runs before blending or scaling up. Over the last few years, regulations like REACH have made impurity thresholds more than a backroom detail. High-impact research or manufacturing can’t afford shortcuts.

The Bottom Line

Purity choices for 1-Carboxymethyl-Pyridinium Bromide reflect both the intended use and the reality of lab logistics. Judging suppliers by their willingness to share purity data and work with customer requests builds trust. A little diligence up front prevents headaches later. Facts, not hype, drive smart chemical sourcing.