1-Cyanopropyl-3-Methylimidazolium Chloride: A Practical Perspective

Historical Development

Back in the early 2000s, the scientific community started digging into ionic liquids, searching for compounds that could offer strong chemical stability and lower environmental impact for a range of industrial processes. Researchers working on green chemistry projects, especially in solvent systems, fixed their sights on imidazolium-based salts. Out of that wave, 1-Cyanopropyl-3-Methylimidazolium Chloride emerged, prized for the way it bridges chemical robustness and versatility. My time in research labs taught me that breakthroughs like this one rarely land out of nowhere; they grow out of decades of experimenting with different cation-anion combos, each round seeking a better trade-off between reactivity and stability. This compound, in particular, grew out of that tradition—researchers figured out that adding a cyanopropyl side chain to the imidazolium core, then pairing with a chloride anion, created a compound with unique properties. Lab technicians and industrial chemists jumped on board, bringing this salt into broader circulation fast.

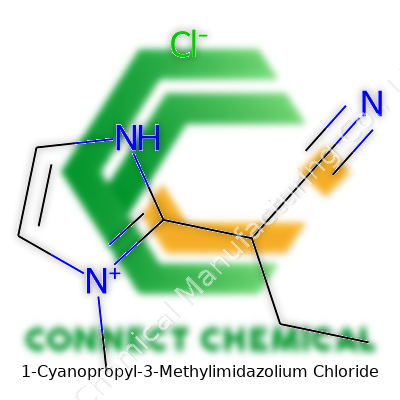

Product Overview

1-Cyanopropyl-3-Methylimidazolium Chloride stands out in the world of ionic liquids with its distinctive combination of a long cyanopropyl side chain and a methyl group on the imidazolium ring. In my experience, this combination gives it a sharp edge for tasks that demand a fine balance between hydrophilicity and solvating ability. It ships as a solid, often off-white or pale yellow, easily absorbing moisture from the air—so storage becomes a real concern. In chemical supply catalogs, I often spotted it listed as a highly pure, crystalline powder. Suppliers tend to stress high purity—often greater than 98%—because even small contaminants interrupt sensitive research.

Physical & Chemical Properties

This salt draws plenty of attention for its melting point, usually sitting between 80 to 120°C, and its (relative) low volatility, a boon in both research and industrial processing. Its hygroscopicity—meaning it tends to soak up moisture—means folks need to handle it in dry, airtight settings. It dissolves well in polar solvents like water and acetonitrile, holding up against common acids and bases. The chloride anion makes it a solid platform for anion exchange or functionalization, while the cyanopropyl group tilts the balance even further toward unique interaction with substrates. In my lab work, it often proved more stable under heat and electrochemical stress than comparable salts lacking the cyanopropyl tweak.

Technical Specifications & Labeling

Manufacturers lay out certifications and minimum purity on every label, and I’ve come to trust suppliers who back up claims with well-documented analysis—HPLC or NMR results posted right on the bottle or datasheet. The labeling often includes clear hazard pictograms and handling instructions, both to satisfy regulatory agencies and to protect end users. Any time we ordered this salt, we double-checked for batch numbers, production dates, and storage recommendations. The safety data sheets always stressed the need for gloves, goggles, and well-ventilated spaces. Packaging typically arrives vacuum-sealed or in screw-top bottles to keep humidity out.

Preparation Method

The synthesis most often starts by alkylating 1-methylimidazole with 3-chloropropionitrile, a reaction that uses anhydrous conditions to control byproduct formation. From my own efforts in the lab, maintaining a carefully controlled reaction temperature is crucial to drive the substitution without side reactions taking over. After the quaternization pushes through, the product usually gets purified through recrystallization and several washes to strip away residual starting materials and free anions. Each batch needs rigorous quality testing to hit demanding standards. I’ve seen shortcuts or sloppy purification lead to colored or impure crystallines—dead giveaways something went wrong. In scaling up, chemists often switch to continuous flow systems, which deliver tighter process control and let you keep an eye on yield in real time.

Chemical Reactions & Modifications

1-Cyanopropyl-3-Methylimidazolium Chloride acts as a workhorse for further chemical tweaking. That chloride anion means you can swap it out to make dozens of other ionic liquids tailored for very specific uses. The cyanopropyl side chain opens doors for nucleophilic addition or other functionalization routines. I’ve watched teams harness this platform for surface modification, tweaking material properties to build specialized membranes or catalysts. Sometimes, we introduced new functional groups to the side chain for targeted chelation or improved solubility. In organic synthesis, this salt serves as both solvent and reactant, handling everything from alkylation reactions to biotransformations that demand stable, inert environments.

Synonyms & Product Names

Across catalogs and technical literature, 1-Cyanopropyl-3-Methylimidazolium Chloride pops up under a long string of names: 1-(3-Cyanopropyl)-3-methylimidazolium chloride, [CnPrMIm][Cl], and sometimes abbreviated as C3CN-MIMCl. I’ve seen product listings lean on company-specific codes as well, and custom blends take on their own internal names in industry. Having worked through supply chain confusion a few times, checking the CAS number turned out to be the most reliable way to avoid mix-ups. The flood of similar-sounding imidazolium salts out there makes careful double-checking critical.

Safety & Operational Standards

Working with 1-Cyanopropyl-3-Methylimidazolium Chloride, I always felt the need to pay close attention to personal protective equipment because the compound’s low volatility deceives some into thinking it poses little risk. The chloride anion, combined with the imidazolium ring, creates occupational hazards if inhaled or accidentally ingested, so fume hoods and gloves form the basic line of defense. Safety protocols call for storing it in cool, dry places and keeping it away from strong oxidizers, since side reactions can yield nasty byproducts. Disposal demands special care—regulations push for collection as hazardous chemical waste to keep these salts from contaminating water systems. Over the years, the industry has leaned into training programs for proper handling, as even minor spills or contact events can trigger skin or respiratory reactions.

Application Area

This ionic liquid keeps popping up in places where a traditional organic solvent won’t do—like electrochemistry, catalysis, and advanced material synthesis. Last year, I saw a team use it as an electrolyte in lithium battery prototypes. It holds steady under electrical charge, barely decomposing, and supports better ion mobility. In other projects, it became a driver for tough organic reactions under conditions too harsh for typical solvents. Material scientists lean on its thermal stability to process polymers or create nanomaterials with custom surface functions. Pharmaceutical researchers explore the way its unique chemical structure supports selectivity in drug delivery mediums. In short, its use spans bench-chemistry to pilot-scale manufacturing, with environmental chemists testing it as part of greener cleaning solutions or CO2 capture methods.

Research & Development

I’ve watched R&D labs gravitate toward 1-Cyanopropyl-3-Methylimidazolium Chloride when aiming for innovation in electrochemical devices and sustainable catalysis. A few years ago, a graduate project I mentored set out to challenge the compound’s utility in biomass breakdown, comparing it with room temperature ionic liquids for dissolving lignocellulose. Their results showed strong solvation and lower toxicity, opening fresh research questions. Other laboratories keep pushing it toward greener processes—swapping volatile, hazardous solvents for this chloride-based ionic liquid makes life easier around the bench. Diverse consortia now test it in large-scale pilot projects, logging its shelf life, reactivity, and integration with emerging technologies. Strong funding from government sustainability initiatives keeps this line of inquiry lively.

Toxicity Research

Toxicity stands as a stubborn question for most ionic liquids. Researchers launched studies on 1-Cyanopropyl-3-Methylimidazolium Chloride, seeking data on environmental fate, persistence, and metabolic breakdown. Early cell-based toxicity assays flagged some risks if exposure levels spike, mostly irritation or cell viability drops in aquatic species. Chronic bioaccumulation and impact on soil microbiota stay under review. Still, compared with older ionic liquids common in the 1990s, this compound appears less aggressive, likely due to the stabilizing features of the cyanopropyl side group. From what I’ve seen, transparency in toxicity testing gives downstream users—especially in pilot plants or regulatory roles—confidence in handling and disposal standards.

Future Prospects

1-Cyanopropyl-3-Methylimidazolium Chloride looks ready to shape big changes in how chemists approach clean, efficient, and adaptive process design. Renewable energy sectors crave high-performing electrolytes, and this compound sits near the top of shortlist candidates for next-gen batteries and supercapacitors. Pharmaceutical and polymer industries seek out new solvents to overcome regulatory pressure on legacy chemicals; this ionic liquid represents a viable alternative. I keep seeing grant calls that push for deeper analysis of long-term durability, cost, and performance in the real world, not just in a petri dish. Deeper work on reusability, recyclability, and scaled-up green synthesis will cement its place in the toolbox for sustainable science.

This Unusual-Sounding Molecule Packs a Punch in Research Labs

Not every chemical compound draws much attention outside of science circles. For example, 1-Cyanopropyl-3-methylimidazolium chloride might not ring a bell for most people. I remember working with similar ionic liquids during my early days in research and discovering just how much versatility they bring to tough lab problems. Scientists aren't drawn to it for simple table salt style chemistry. Instead, this compound finds its place on the shelf for much bigger roles—especially when handling reactions most solvents would botch.

What Makes This Compound Stand Out?

The real magic of 1-cyanopropyl-3-methylimidazolium chloride shows up once you need a solvent tough enough for stubborn systems. Ionic liquids like this one refuse to evaporate at regular temperatures, so they work in setups where most fluids would fizzle out or introduce unwanted complications. Though researchers explored several classes of ionic liquids, this particular type—thanks to the imidazolium backbone and the cyanopropyl modification—offers a blend of chemical stability and solubility for both organic and inorganic reactants.

The past few years brought more talk about green chemistry and ways to avoid toxic solvents. Traditional organic solvents leak volatile compounds straight into the atmosphere. Labs and chemical manufacturers have looked for replacements. Here’s where 1-cyanopropyl-3-methylimidazolium chloride shines: it carries a low vapor pressure, so less risk for workplace exposure and fewer problems when disposing of waste. Many of my peers opt for this class of solvent in reaction tables when reactions call for careful cleanup or especially hazardous reactants.

Helping Complex Reactions Go Further

I’ve seen researchers use this ionic liquid to speed up or simplify difficult organic reactions. Chemists call these “solvent effects”—the right liquid can make certain molecules fit together better, react faster, or take on new shapes. One example includes nucleophilic substitutions and alkylation chemistry, where ionic liquids unlock higher yields and offer easier product recovery. This can save hours of troubleshooting and mountains of raw materials. In industrial settings, every uptick in efficiency translates into less chemical waste and lower manufacturing costs.

Protein folding, catalysis, and even battery research tap into ionic liquids too. Since 1-cyanopropyl-3-methylimidazolium chloride doesn’t mix with water easily, it’s possible to run experiments that need strict moisture control. I’ve run extractions and separations in graduate school that would fall apart using other solvents. This ability to “negotiate” with water makes processes involving biomolecules or tricky metals far more practical.

Room for Growth and Responsible Use

No chemical tool comes without its trade-offs. Cost, purity, environmental persistence—these questions still linger for every new solvent on the market. The good news is, institutions keep studying the long-term impacts, and manufacturers now focus more on recycling methods. Whenever labs choose ionic liquids like this one, safe handling and responsible disposal should stay at the center. It's always worth reviewing the latest safety sheets and peer-reviewed literature before diving into production or scale-up.

1-Cyanopropyl-3-methylimidazolium chloride stands out because it gives researchers extra leverage for tough chemical reactions and greener processes. Using tools like this, science keeps moving closer to less hazardous, more efficient chemistry—something every lab can support.

Challenges in Chemical Storage

Every year, news surfaces about mishaps in labs and warehouses due to poor storage or sloppy handling of chemicals. Years back, I saw a warehouse manager open an improperly labeled drum. The compound inside reacted with moisture, releasing harmful fumes. It left him coughing for hours, feeling lucky things didn’t turn worse. Stories like that remind us how quickly a lapse in storage protocols can turn disastrous.

Compounds vary: some thrive in the dark, dry corners of a storeroom, others demand ventilated spaces or even specialized fireproof cabinets. A lot comes down to not just keeping the stuff on a shelf, but understanding what you’re dealing with.

Temperature and Light Considerations

Not all compounds hold up at room temperature. Many require refrigeration or even storage below zero. I’ve seen colleagues lose thousands of dollars’ worth of material just because a cooler malfunctioned overnight. Most laboratory compounds break down faster if left in sunlight. A lot of people don’t realize a simple piece of foil can stand between a stable material and a dangerous or useless one. With photoreactive chemicals, direct exposure leads not just to wasted stock, but serious risks if dangerous byproducts form.

Humidity and Air Exposure

Where there’s moisture, some compounds break down or clump together, turning into rocks or releasing dangerous gases. Desiccators, those simple airtight jars with drying agents, work as lifesavers for moisture-sensitive materials. I’ve seen powders turn to sludge in a single week of humid summer if stored open. Oxygen in the air causes slow oxidation, especially in metals or organics, so sealing and filling containers with inert gas isn’t just a technicality—it prevents fires and financial losses.

Safety and Labelling

Good labeling, even on the smallest vial, prevents confusion that can lead to accidents. Once, a student in my lab grabbed the wrong bottle during a routine synthesis, mixing up two colorless liquids. That mix-up caused a dangerous reaction, forced an evacuation, and taught him a lesson as clear as day: put the right name, date, and hazard information every time. Regulatory bodies like OSHA and the EPA require hazard communication, which isn’t some pointless paperwork. It protects everyone in the building.

Separation and Segregation

Compounds that don’t play well together should live on separate shelves. Acid next to a base spells trouble; organics stored with oxidizers is even worse. Major fires have started from ignoring this rule. Remember the warehouse explosions in China and India? Improper separation played a big role.

Solutions Rooted in Experience

A little know-how goes a long way. Temperature monitors, humidity cards, and regular audits keep problems from sneaking up. Training new staff, sharing experiences, and staying current with SDS (Safety Data Sheets) protect assets and lives alike. Taking time to inspect containers, replace aging seals, and never skipping over that “last one for the day” storage step has saved me, and many others, from expensive lessons.

With chemical compounds, the right storage and handling isn’t busy-work—it’s about keeping people safe, protecting investments, and making sure the science stands up tomorrow as well as it did today.

A Close Look at Chemical Safety

Reading a long chemical name like 1-cyanopropyl-3-methylimidazolium chloride can turn most heads away. Yet, these “ionic liquids” keep cropping up in labs, factories, and even environmental research. These chemicals offer benefits over old-school solvents, such as less chance of starting fires or polluting the air. No chemical gets a free ride, though—every advantage comes with questions about hazards, both for us and the planet.

Personal Glimpses from the Lab

Years of working with chemicals from paints to pharmaceuticals have made me cautious. Ionic liquids like this one promise a lot: they don’t evaporate easily, so they’re less likely to foul up workplace air. That means your nose doesn’t sting and your lungs are less irritated. Plenty of times, colleagues have switched to ionic liquids only to realize they still need gloves and goggles—skin contact can still cause redness, or worse, burns. A study from 2021 flagged this group of chemicals as sometimes harsh on skin, with some showing toxic effects on liver or kidney cells, especially after repeat exposure.

Understanding the Risks

Seeing “imidazolium” in the name should raise an eyebrow. The structure can seep through skin and sometimes acts like detergent, pulling apart cell walls. Some ionic liquids become trouble when swallowed or when dusts get airborne. Research in journals like “Chemosphere” supports the idea that even “green” chemicals pose real hazards, especially if they escape the lab.

Researchers tend to focus on a few key risks: harmful effects on aquatic life if spilled, slow breakdown in natural environments, and possible buildup in soil or water. One team at the University of York showed that similar compounds, dumped in streams, built up in fish and tiny plants, slowing their growth and raising stress markers. Microbes had trouble breaking down these new chemicals, meaning they hung around a long time—sometimes longer than solvents we’ve already banned.

Spotlight on Solutions

Chemical makers can’t just toss new compounds onto the market and hope for the best. Experience tells me that any chemical with low volatility still needs careful handling: closed-system transfers, spill containment, and routine skin checks matter. Extra ventilation might not be needed, but gloves and quick-wash stations are a must. Storage should be dry and out of the sun, far from food prep or places where water might wash spills away.

For disposal, treatment plants lag behind in removing the latest ionic liquids, so they slip downstream. To fix this, upgrading filtration—using activated carbon or advanced oxidation—shows promise. Labs, universities, and industries should combine efforts to track these chemicals from their first synthesis to their final disposal or destruction. Some researchers now work on designing “biodegradable” versions that break apart safely, but these take years to move from concept to shelf.

Ultimately, trusting a chemical because it’s “new” or “green” hurts real progress. Honest hazard assays, strict storage rules, and clear disposal plans protect both people and the places we live. Having better information in plain language also lets both workers and neighbors speak up if something seems off. Sharing details and demanding answers builds the habit that keeps us all safer.

Getting the Basics Right

The chemical formula tells us what makes up a substance. Whether in a lab, on a farm, or in a factory, the formula matters. It gives a clear snapshot of the elements and their proportions in a product. For example, sodium chloride has the formula NaCl. Simple enough. But hidden in those two letters and two atoms is a universe of possibilities and caution.

Straight Talk About Molecular Weight

The molecular weight, or molar mass, comes from adding up atomic weights of all the atoms in a molecule. This number isn’t just academic. It drives real-world choices, from measuring for reactions to figuring out how much of a substance ends up in a dose or a mix. Skip the math or overlook this number, and you risk a ruined batch or, in medicine, putting someone at risk.

Why I Trust the Numbers

Back in school, making a solution was more than mixing salt and water. The professor would check our calculations twice before letting us proceed. I remember one grad student using an incorrect formula for a reagent. The result? Hours lost, and worse, all the data had to be thrown out. In the workplace, big companies use these same fundamentals. Every chemical shipment comes with certificates spelling out the formula and molecular weight, and teams run spot checks to verify. This avoids costly mistakes.

Molecular Formulas Can Signal Danger or Safety

If you see C6H6, that means benzene. A chemist knows benzene is dangerous, even carcinogenic. If you spot C2H6O, that's ethanol, found in spirits as well as hand sanitizer. The formula can tell you what precautions to take. If the molecular weight is far heavier than water, this changes how the chemical spreads in the air or water, or how it’s handled in the body. Small details make a real-world difference.

Facts and Transparency: They Build Trust

Seeing the chemical formula and molecular weight lets users, regulators, and scientists ask tough questions. This is where transparency moves from buzzword to real practice. The Environmental Protection Agency and the Food and Drug Administration both demand clear disclosure of these facts for anything entering the market. Users must be able to confirm if a product contains what it claims. Recent recalls in food and pharmaceuticals often come down to incorrect ingredient labeling. Simple errors around formulas can trigger huge consequences.

Smart Solutions for a Clearer Path Forward

A better system for verifying chemical formulas and molecular weights starts with education. High schools and trade programs should run hands-on labs where checking and double-checking calculations becomes muscle memory. Digital tools can track and compare reported formulas against trusted chemical databases, cutting down on manual error. Batch testing before products ship catches mistakes before they become problems.

Public access to product profiles, including formulas and molecular weights, would let consumers and professionals make smart decisions. A bar code on chemical packaging that links to this data in a government-verified database pulls the industry forward into a new era of accountability.

Every Number Counts

Mistakes in chemical formulas or molecular weights have real costs. The numbers tell the truth. Science moves forward when everyone agrees on the basics and insists on accuracy at every step. Chemistry might seem abstract, but the discipline and care behind these numbers shape our world, keep us safe, and help us work smarter.

One Ingredient, Many Choices

Walking through a warehouse or scanning vendors online, it’s easy to think a chemical product is just a product. Scratch that surface and the choices multiply: purity grades, packaging sizes, sometimes even color. For anyone working in science, food production, or manufacturing, these factors can mean the difference between smooth sailing and a recall, between trustworthy output and extra cost.

Purity is Not Just Numbers

People in labs always keep a sharp eye on purity grades for good reason. Impurities mess with reactions, spoil analysis, or even change a whole product line's safety. If you’re running a pharmaceutical process, you can’t settle for less than the top-tier grade, which often comes with a certificate of analysis. Grades like “analytical,” “technical,” or “USP” exist because demands vary so much. Analytical chemists pay for purity down to the decimal, hoping to keep noise out of their measurements. Factories making glue or dyes aim for something they can buy by the drum with acceptable levels of non-critical stuff.

Scaling Up or Down: The Size Dilemma

Packaging size gets most folks only when a purchase goes wrong. A 500-gram bottle is handy for classrooms or R&D. A pallet of 25 kg bags suits a cement mixer, not a high school. Startups feel the squeeze: small packs can run up costs, but ordering industrial drums often overshoots their needs. Even seasoned buyers run into pains: storage troubles, shelf-life worries, waste disposal spirals. In food service years back, buying too much yeast always ended in waste since no restaurant wants to gamble with old stock, even when the price per unit seems sweet.

Traceability: Trust Built on Transparency

Too often, the trouble starts with a lack of clarity. Last year I heard from a bakery that ordered the same ingredient twice, same vendor, same label, but different results. Turns out, the supplier had switched to a new grade without telling anyone. Bad batch, ruined dough, long day. Trust in sourcing comes from details like lot numbers and clear grade markings. Strong track records help. Anyone serious about safety or performance will push for documentation—not just for peace of mind but to meet audits and regulations.

What’s the Fix?

Clear information shields everyone. Producers should offer purity grades front-and-center, with unambiguous explanations of what’s what: “Pharma/USP grade: for critical use,” “Technical: industrial, not edible.” Packaging should show every option from sample vials to 100 kg super sacks. Buyers, on their end, should dig into their real needs before ordering, not just what “seems about right.” Ask about shelf life, storage, and availability in other sizes before placing that big order. Request sample certificates for high-stakes uses. Some companies are moving toward digital traceability — QR codes that reveal every detail of the batch you’re holding in seconds. This boost to transparency shouldn’t just be a luxury.

Why It Matters Every Day

For anyone who’s ever seen a project stall out over missing specs, it’s not “just” chemistry—it’s dollars, time, and reputation. So next time someone shrugs off the question of purity grades or packaging, remember what really rides on those choices. After all, it’s the details that keep the doors open and the work reliable.