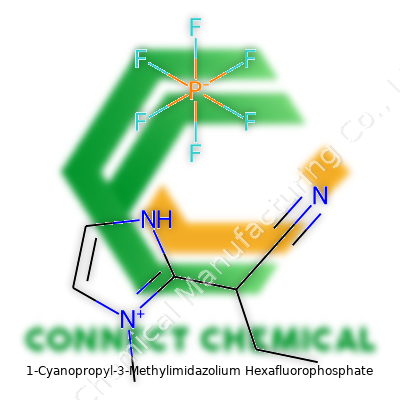

1-Cyanopropyl-3-Methylimidazolium Hexafluorophosphate: Chemistry, Uses, and Where It’s Headed

Historical Development

Back in the late 1990s, chemists around the world started to experiment with ionic liquids, exploring them as safer alternatives to traditional organic solvents. One such compound—1-cyanopropyl-3-methylimidazolium hexafluorophosphate—caught researchers’ attention as the hunt for less volatile, more eco-friendly solvents heated up. The discovery grew out of the push for “green chemistry.” Research teams in Germany and Japan often showed up with early syntheses in published journals, and the stories coming out of those labs highlight the pace of change. Twenty years ago, only a handful of people outside of specialized academic circles knew about this cation-anion pairing, but now, as ionic liquids move from lab bench to industry, this molecule is entering new conversations in chemical engineering and materials science.

Product Overview

1-Cyanopropyl-3-methylimidazolium hexafluorophosphate belongs to the imidazolium ionic liquids class, where the cation forms from a substituted imidazole ring and the anion comes from hexafluorophosphate. Chemists value its stability, unique solvation characteristics, and ability to support a wide variety of reactions. The cyano group on the propyl side chain marks it as distinct from simpler analogs, expanding its chemical possibilities. Shelves in research universities and several industrial labs now carry this salt as a viscous liquid, sometimes tinted faintly yellow, drawing focus from teams working on advanced battery materials to those interested in extraction solvents or catalysis. The compound bridges the lab and industry, showing up as a tool for those searching for better efficiencies and alternatives to hard-to-handle solvents.

Physical & Chemical Properties

By room temperature, this ionic liquid stays liquid well below freezing, thanks to its low melting point. You can’t miss the high viscosity either—pouring a sample looks more like topping off honey than a water-thin solution. Its chemical stability under both acidic and basic conditions builds confidence among chemists looking for a durable platform. Insoluble in many nonpolar solvents, but freely mixing with polar ones, this material handles polar solutes with ease, often bringing out reactions that stay stubborn in other media. Of special interest is the wide electrochemical window—the difference between the potential where the cation and anion decompose—which opens doors in battery and capacitor research.

Technical Specifications & Labeling

On packaging, a bottle typically carries labels marking the molecular formula C8H13N3PF6, often alongside batch-specific purity data—usually no less than 98%. Material safety data sheets list the melting point, sometimes as low as -10°C, with the decomposition temperature over 250°C as long as exposure to moisture stays minimal. Viscosity stands out, often measured near 120 centipoise at twenty degrees Celsius, and density stamps in at 1.35 to 1.40 g/cm³. The cyano group’s presence plays a role in these stats, and shelf-life warnings remind users about the risk of gradual hydrolysis if the cap stays off too long.

Preparation Method

Lab notebooks show step-by-step notes starting with 1-methylimidazole and 1-bromopropionitrile in a polar solvent, with potassium carbonate thrown in to soak up generated acids, forming the basic imidazolium bromide salt. Chemists then swap bromide out for hexafluorophosphate by mixing with potassium hexafluorophosphate in water or acetonitrile. After a few washes and extractions, they dry the product under vacuum, collecting a pure viscous fluid. This isn’t a process for the faint-hearted—handling hexafluorophosphate salts means diligent fume hood technique, and glassware must stay scrupulously clean to keep impurities low. The end result, reliably consistent for researchers, rests behind controlled-access storage in most labs due to its specialized nature.

Chemical Reactions & Modifications

1-Cyanopropyl-3-methylimidazolium hexafluorophosphate rarely sits idle in the flask. Chemists reach for it to activate cross-coupling reactions involving transition metals, as its polarity favors certain intermediates. The cyano-fitted cation sometimes gives rise to nucleophilic attack, yielding derivatives used in advanced material synthesis. Arduous catalytic cycles for difficult bond formations respond well to this ionic medium, where other solvents dry out or break down. It pairs well with solid acid catalysts in alkylation and acts as an effective charge carrier for redox-active systems. In the right hands, the imidazolium ring can be further modified, attaching other side chains to create tailor-made solvents—helping university researchers probe the frontiers of custom ionic liquid design.

Synonyms & Product Names

Lab supply catalogs occasionally list this compound under alternate names. Common alternatives include 1-Cyanopropyl-3-methylimidazolium hexafluorophosphate, C3CN-MIM PF6, or even the more systematic 3-methyl-1-(3-cyanopropyl)imidazolium hexafluorophosphate. Some suppliers abbreviate as [C3CNmim][PF6]. Each label refers to the same viscous liquid, but savvy chemists scan for these names to track down trusted sources or cross-check batch data. Mismatches in nomenclature have led to well-known ordering mistakes, which slows down experiment timelines and burns through grant money, so product catalogs benefit from keeping synonyms handy in their search functions.

Safety & Operational Standards

Direct contact with skin or inhalation of vapors raises health concerns, and lab rules demand splash goggles, gloves, and proper ventilation anytime this salt leaves its bottle. Its toxicity risk remains moderate compared to many legacy solvents but carelessness can trigger respiratory irritation or contact dermatitis. Spills must be wiped up promptly since moisture intrusion degrades the salt and can generate corrosive decomposition products. Waste disposal guidelines strictly limit this compound’s entry into wastewater, directing hazardous waste containers for collection and incineration. Chemical hygiene plans developed with industrial input now train lab members in pragmatic, experience-based protective measures.

Application Area

This unique salt has found a home in several frontier research fields. Electrochemists use it for supporting electrolytes in supercapacitors and next-generation lithium-ion batteries, attracted by that broad electrochemical window and thermal stability. The solvent power and environmental profile have prompted exploration into biocatalysis and selective extraction for rare earth metals. Universities utilize it as a “designer solvent” when traditional options fall short, and a few forward-thinking companies are testing it in green synthetic processes. Among quantum materials specialists, it enables high-yield crystal growth by suspending otherwise unstable intermediates. The cyano group’s specific chemistry also lends itself to organic synthesis as a mild activating group or a scaffold for building more complex molecules.

Research & Development

Teams worldwide continue unraveling the molecular-level behavior of this ionic liquid, especially its interactions with charged surfaces and metals. At recent ACS meetings, speakers routinely highlight renewed attempts to engineer recyclable ionic liquids based on the imidazolium ring, aiming to minimize environmental footprints. Sophisticated analytical tools—NMR, IR, mass spectrometry—unpack subtle degradation byproducts, helping to tweak both synthesis and storage methods. Collaborations between universities and manufacturing plants foster real-world pilot programs, where bench-scale results scale up into kilo-lab runs, testing the salt’s endurance outside textbook conditions. These R&D partnerships have already spawned a handful of high-value patents, with more applied technology on the horizon.

Toxicity Research

Studies over the last ten years give a clearer picture of this compound’s impact on both health and environment. Acute toxicity seems lower than many halogenated solvents, but long-term effects on aquatic life need ongoing monitoring. Ecotoxicology teams have published data showing slow biodegradation rates, raising reasonable caution about persistent residues in soil or water. In controlled animal models, evidence points toward low bioaccumulation, but regulatory bodies seek large-scale studies before giving an unqualified green light. Safer substitutes for heavily used industrial solvents spark interest, but safety data must march lockstep with application. The demand for more robust longitudinal health and disposal studies reflects an industry trend toward greater transparency and public trust.

Future Prospects

New battery chemistries, sustainable extraction processes, and more resilient plastics all look to ionic liquids for next phase development, and 1-cyanopropyl-3-methylimidazolium hexafluorophosphate features prominently in that set. Regulatory hurdles, material cost, and concerns about environmental persistence shape R&D agendas in both academia and the private sector. Funding increasingly depends on strong evidence that these smart solvents can lower hazardous emissions and support circular manufacturing methods. To break into mass-market applications such as grid-scale batteries or pharmaceutical synthesis, this salt must clear both price and toxicity barriers. Advances in synthetic routes and recycling schemes promise to bring down costs and boost acceptance, but chemical innovators need to keep a close eye on ecosystem impacts. Policy makers and industry leaders have a responsibility to fund honest research, encourage open data sharing, and shape rules that balance progress with caution, creating safer chemistry for the future.

What Makes This Ionic Liquid Stand Out?

A lot of people have not heard of 1-cyanopropyl-3-methylimidazolium hexafluorophosphate. In research labs and industrial settings, chemists and engineers keep turning to these ionic liquids for their stability and versatility. As someone who has worked in a materials science lab, I have seen researchers reach for ionic liquids with imidazolium groups when they need a solvent that won’t evaporate easily and can support demanding conditions. The unique properties stem from their molecular structure: they show low volatility, high thermal stability, and outstanding ionic conductivity.

Solvent for Challenging Reactions

Traditional organic solvents often fall short for today’s green chemistry standards—many are toxic, flammable, and difficult to recycle. On the other hand, ionic liquids like this one step forward as safer alternatives. Synthesis of pharmaceuticals and advanced polymers calls for stable environments where ordinary solvents break down or promote unwanted reactions. I remember a project synthesizing heterocyclic compounds where switching to an imidazolium-based liquid cut reaction times and simplified purification.

Electrochemical Applications

Many of my colleagues working in battery research have praised this family of ionic liquids for boosting performance of electrochemical devices. Their chemical resilience allows them to handle the stress found in supercapacitors and advanced batteries. When it comes to making electrolytes for energy storage, every chemist pays attention to conductivity and electrochemical window. This ionic liquid doesn’t catch fire easily and keeps electrolytes working under heat and pressure, so it expands the choices for durable rechargeable battery technologies.

Catalyst and Reaction Medium

Ionic liquids often act as both solvent and co-catalyst. During my time collaborating on research into greener synthesis routes, we explored using this type of ionic liquid for transition metal-catalyzed reactions. The liquid not only stabilized the transition state but also shielded reactive intermediates from moisture and air. In industries focused on efficient synthetic routes for agrochemicals and dyes, these properties lead to higher yields, fewer byproducts, and less energy use.

Separation and Extraction

Trying to separate valuable compounds from mixtures can get complicated and wasteful. I have seen how ionic liquids outperform traditional solvents in liquid-liquid extraction setups—particularly for rare earth elements and organic molecules. This chemical cuts down on the need for volatile organic solvents in the separation of pharmaceuticals and specialty chemicals, making the process safer for workers and the environment.

Solution to Environmental Issues

The world grows more sensitive to the impact of hazardous chemicals. By swapping out flammable, toxic solvents for 1-cyanopropyl-3-methylimidazolium hexafluorophosphate, companies cut down emissions of volatile organics and curb workplace risks. Research from the American Chemical Society records a noticeable drop in chemical waste when using ionic liquids in synthesis and separation. Though disposal methods still need care, the day-to-day risk goes down for lab staff and plant workers alike.

Pushing Research Forward

From direct experience, once these liquids entered the lab, older bottlenecks disappeared; new experiments became possible. The blend of chemical stability, conductivity, and low volatility keeps pushing chemical manufacturing, energy storage, and green technology research forward. As demand grows for high-performance, sustainable processes, this class of ionic liquids keeps making a mark.

Why Storage and Shelf Life Matter for Researchers and Industry

Ionic liquids sound fancy, but plenty of labs and industries treat them as everyday workhorses. Chemists gravitate toward them because these liquids don’t evaporate like regular solvents, and their ability to dissolve a range of substances feels almost magical. Unfortunately, the story doesn’t end at impressive properties on paper. Real-world use always brings up a recurring question: how long will that ionic liquid in a container work as promised?

My earliest research project threw me right into this issue. I arrived at the lab, pulled down a bottle labeled “fresh” from the shelf, and watched my experiment turn brown in minutes. The disappointment was real. Since then, checking stability became less an afterthought and more a step I relied on before every synthesis run.

Moisture and Air: Persistent Enemies

Even with the best packaging, ionic liquids hate water. Their open salt structures latch onto stray water molecules from the air. As water creeps in, the melting point shifts and the solvent power drops—sometimes subtly, sometimes like flipping a switch. Different types of ionic liquids, such as imidazolium-based or pyrrolidinium-based, show their hydrophilic or hydrophobic tendencies in the wildest ways.

Oxygen poses similar risk, especially for ionic liquids carrying a reactive center or an unsaturated nitrogen ring. Some, like those with hexafluorophosphate anions, break down over a few months if exposed. You’ll see byproducts like hydrofluoric acid crop up, which is not only dangerous but wrecks the original solvent quality. In high-throughput settings, those slow byproduct build-ups mean ruined reactions and unexpected hazards.

Heat, Light, and the Unforgiving Passage of Time

Storing ionic liquids on the same shelf you use for alcohols or standard lab chemicals does not cut it. Heat above 40°C speeds up unwanted reactions. Direct sunlight messes with compounds, especially those that carry aromatic rings or metal ions. I learned the hard way that exposing a bottle to UV from a regular window means never trusting its label again. Color changes, or odd layer separation at the bottom, always spell trouble.

Under ideal conditions—airtight bottles, low humidity, out of direct light, cool rooms—many ionic liquids maintain their structure for years. Some researchers report samples that run five years strong. But relax on those conditions, and shelf life drops to months or even weeks. I once saw a batch last barely a summer on a poorly ventilated shelf.

What Chemists Can Do

Analytical techniques like NMR, FTIR, and mass spectrometry easily track breakdown, shifting peaks for new contaminants long before the liquid looks funny. Frequent testing never feels like wasted effort, especially for costly or rare samples. Strictly using desiccators, nitrogen gloveboxes, and dark glass bottles increases the odds that a liquid will stay pure. Writing a clear date of opening—something my mentor insisted on—saves endless debate later.

A Few Facts Worth Remembering:- Imidazolium ionic liquids absorb water in minutes of open air exposure, leading to altered physical and chemical properties.

- Hexafluorophosphate-based liquids can break down to hydrofluoric acid in just weeks if mishandled.

- Shelf lives stretch from months to years depending on storage, purity, and protective measures.

Good sample discipline protects results, keeps experiments cleaner, and avoids surprise hazards. Ionic liquids can work wonders, but their stability can’t be taken for granted. Those who treat them with the same suspicion as fresh produce—always checking for spoilage—get better results, fewer ruined runs, and a safer lab to work in.

Why Attention Matters in the Lab

Few lab chemicals bring both promise and risk into such close quarters as ionic liquids. Among them, 1-Cyanopropyl-3-Methylimidazolium Hexafluorophosphate calls for a keen eye on safety. After seeing fume hood mishaps and skin irritation up close, safety guidelines jump from theoretical advice to hard-learned habits. It’s never just about the chemical; it’s about keeping people whole and experiments on track.

Understanding the Hazards

Even substances that look friendly, like colorless liquids, can mess with health. This one can sting your skin or eyes, spark allergic reactions, and if you breathe too much, your lungs suffer. Mixing with water sometimes gives off corrosive acids – the sort that damage equipment and inflame lungs. Stories from seasoned chemists in my circles stick with me: a simple splash often means a costly doctor’s visit and ruined experiments.

Setting Up Safe Storage

So, what gives peace of mind? Controlled storage keeps both the chemical and colleagues protected. Choose tightly sealed glass or high-grade plastic bottles. Metal degrades from acids this stuff can form. Place containers in designated corrosive storage cabinets, far from direct sunlight or heat, since temperature swings affect stability. Desiccants guard against moisture sneaking in. Never let it rest next to strong bases, acids, or compounds that break down into anything aggressive, limiting the risk of unwanted surprises.

Handling: Simplicity Wins

In our lab, routine wins every time. Don gloves—nitrile gloves hold up better if things spill. Long sleeves, lab coats, and snug goggles matter for every transfer, dilution, or pipetting. Pour or mix in a fume hood, not on the open bench. Our team sticks warning labels on containers, preventing mix-ups in the rush of real experiments. Good records track the age and stability of each lot. If you spill, have spill kits and neutralizers within arm’s reach, and practice their use before trouble lands.

Getting Disposal Right

Flushing ionic liquids down the drain causes headaches for wastewater systems and the environment. Instead, collect waste in a separate, labeled bottle. Coordinate with hazardous waste crews at the institution or city facility. This route cuts down on pollution in rivers and accidental exposure through water recycling.

Training: The Overlooked Lifeline

Numbers on paper can’t replace hands-on training. I’ve walked rookies through cleanup drills, and nothing prepares like a close call or a mock spill. Online, the American Chemical Society and local universities explain risks and showcase proper techniques. Seasoned staff can’t overlook the basics either. Regular refreshers drill these lessons in, even for those who’ve handled thousands of chemicals.

Moving Forward Safely

Anyone working with 1-Cyanopropyl-3-Methylimidazolium Hexafluorophosphate owes it to themselves and colleagues to work with intention. Investing in reliable storage, careful disposal, and rigorous training creates a safer lab and stronger results. Modern technology drives forward with new materials, but tried-and-true habits keep people safe every step of the way. Taking shortcuts with chemical handling lets danger in through the back door. Real safety grows from the everyday routines that never make headlines, but keep teams together for the next experiment.

Everyday Impact of Melting Point

If you’ve ever tried to make homemade chocolate, you’ve dealt with the drama of melting point. Chocolate starts turning gooey at body temperature, which is why it melts in your mouth and not in your hand – at least that’s the theory. The same logic applies across industries. When makers pick a material for machinery, packaging, or food, they lean on the melting point because it tells them how much heat the product can handle before turning into a mess.

A product with a low melting point can’t hang around hot kitchens, steamy warehouses, or long-haul trucks in the summer. I remember a summer job stocking shelves in a grocery store — the chocolate bars kept arriving as a sticky disaster, no thanks to trucks that didn’t stay cool. That one detail, the melting point, shaped how stores ordered stock and how manufacturers engineered better products over the next few years.

Viscosity: More Than Just a Number

Viscosity gets all the attention in the world of oils, sauces, lubricants, and paints. If a motor oil is too thin, it can’t cushion engine parts. If it’s too thick, the engine will struggle and burn extra fuel. This balance isn’t just a technicality— it affects fuel economy, equipment wear, and even the smell of burnt oil in your garage.

I’ve worked on cars since high school, and the wrong oil viscosity used to leave engines ticking and rattling. Some of us learned the hard way that simply grabbing any bottle off the shelf can do more harm than good. A product’s viscosity decides if it pours like syrup or water, and that simple property shapes how it works in the real world.

Why These Numbers Deserve Respect

Melting point and viscosity help us predict behavior. They also offer clues about purity, consistency, and even safety. If a substance melts in your pocket or hardens in cold weather, expectations crash and reliability flies out the window. Companies test these numbers over and over, not because they enjoy paperwork, but because lost batches and failed products drain profits.

In food production, medical devices, manufacturing, and cleaning supplies, ignoring these two physical markers drives up costs, complaints, and environmental waste. The FDA and other regulators keep an eye on melting point and viscosity for consumer protection. Reliable measurements reduce recalls, protect workers, and build brand trust.

Room for Progress

Manufacturers keep pushing for materials with more predictable melting and flow behaviors. They’re investing in better lab equipment so no batch gets shipped with the wrong specs. Still, there’s always the risk of shortcuts. Standards mean little if nobody checks the lot before it leaves the warehouse.

Some labs are moving toward automated, real-time monitoring. Sensors now track viscosity and detect temperature spikes before disaster hits. Transparency in reporting—laying out melting point and viscosity numbers on safety data sheets—helps customers avoid nasty surprises. It’s possible for everyone in the supply chain, from plant workers to engineers, to demand this accountability.

The lesson here is practical: knowing the melting point and viscosity of a product cuts through confusion. It turns science into something that matters during a summer blackout or when you’re sweating over a leaky engine. Details like these prove their worth far beyond the lab.

Practical Chemistry with Ionic Liquids

Talking about chemicals like 1-Cyanopropyl-3-Methylimidazolium hexafluorophosphate (sometimes called [C3CNmim][PF6]), you’ll often hear people discuss their “compatibility” with other solvents. My own years in chemical research have shown me that some labs jump into projects with novel ionic liquids, eager to see what magic might happen. These ionic liquids look tempting—stable, non-volatile, often less toxic than the next-best option—but they also bring some headaches.

What Makes Compatibility Tricky

Imidazolium-based ionic liquids don’t act like the standard solvents you might find on a shelf. Their properties depend a lot on the cation and the anion. In this case, the PF6- anion gifts the compound with a hydrophobic nature and modest stability, though it doesn’t always play well with water or moisture. Labs that ignore this run into problems pretty fast—PF6- can break down, creating toxic byproducts like hydrofluoric acid (HF), which chews through glass and skin alike. I’ve seen glassware etched and projects stopped cold by unintended HF formation just because someone chose the wrong cosolvent.

Lessons Learned About Solubility

Solubility remains the first hurdle. 1-Cyanopropyl-3-Methylimidazolium hexafluorophosphate pairs well with other nonpolar or slightly polar organics, like dichloromethane or toluene, though don’t expect totally free mixing. Introduce water or alcohols and things get sticky, both figuratively and literally. Ionic liquids with PF6- slowly leach PF6- into small amounts of water, which changes both the ionic liquid and the cosolvent properties in unpredictable ways.

Potential Reactions: Facts from the Lab

Mixing this ionic liquid with strong nucleophiles or basic substances rarely ends well. PF6- anions can hydrolyze or break apart in the presence of bases, leading to fluoride release—a big red flag, given fluoride toxicity. In one of my own group’s experiments, heating the ionic liquid with aprotic polar solvents set off odd color changes. Investigating, we found minor decomposition under mild basicity, something manufacturers rarely note on their labels. Research—especially from journals like Green Chemistry or ChemSusChem—documents that many ionic liquids degrade, especially above 130°C or in the constant presence of reactive co-solvents.

Choosing Safer Pairings and Better Results

Simple steps improve results. Stick with apolar or mildly polar cosolvents, and maintain low moisture. Working in a glovebox with humidity control prevents breakdown. Additives like molecular sieves help extend shelf-life. For those needing to dissolve more polar substances, look for other cations or replace PF6- with more stable anions like BF4- or NTf2-. Chemistry teams in Europe and the US report that using these swaps controls hydrolysis and extends the range of compatible solvents.

Smarter Chemical Choices Save Money and Time

Careful record-keeping matters. Anyone planning to use this ionic liquid in synthesis, extraction, or electrochemistry should track what happens with every combination. I keep a log of past blends—solvents, ratios, temperatures, surprises. A good notebook saves on wasted time and costly cleanup. And don’t skimp on PPE: gloves, goggles, fume hood—the basics protect you from the unknowns that come from misjudged mixtures.

Better Chemistry Through Respect for the Details

This chemical, like most ionic liquids, offers big opportunities once you learn to respect its quirks and limits. Pushing for perfect compatibility with water or strong bases rarely leads to success. Instead, selective use, thoughtful solvent choices, and a dash of caution unlocks reliable outcomes for everyone from grad students to industrial process engineers.