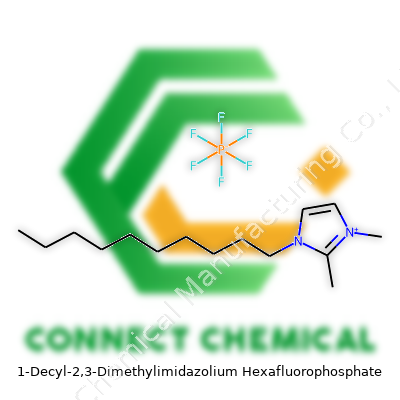

1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate: A Deep Dive

Historical Development

Curiosity in ionic liquids picked up steam in the late 20th century. Researchers pressed for alternatives to volatile organic solvents, especially those that address the mounting environmental and health challenges from industrial chemicals. The imidazolium family, which includes 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate, came out of decades of synthetic tweaks, driven by the urge to unlock safer, less reactive, and often non-flammable materials. For context, chemists tinkered with alkyl chains and substituents on the imidazolium core, hoping each variant would chip away at the problems regularly faced in industry and academia. The hexafluorophosphate anion, once viewed with some skepticism due to fluoride-release anxieties, quickly made itself indispensable because it tempers water solubility and ramps up the chemical’s thermal stability. It’s always surprising how quickly a niche lab curiosity becomes every synthetic chemist’s tool of the trade.

Product Overview

Mention 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate in the corridors of a high-tech lab and you’ll sense a mixture of respect and practicality. Known for its role as an ionic liquid, this compound finds use in batteries, catalysis, and extraction technologies. Many labs choose it because it avoids the flammability hurdles that come with conventional solvents. This chemical’s unique structure—where a long decyl group distinguishes it from those with shorter chains—offers a balance between viscosity and hydrophobic behavior, which broadens its scope. Anyone who has handled bench-scale extractions or tried to coat electrodes in electrochemical devices immediately sees the difference a compound like this brings to the table.

Physical & Chemical Properties

Look at the clear, almost oily liquid—viscosity speaks volumes about molecular packing, and 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate clearly takes its time flowing out of a bottle. Its melting point usually falls below ambient temperature. Hydrophobicity matters, and here, the longer decyl chain dulls any water affinity, so it resists mixing. Superior thermal stability means it won’t degrade at the moderate heat seen in most lab reactors, and its weakly coordinating hexafluorophosphate counterion steps aside during many catalytic and electrochemical processes. There’s an almost pleasant inertia to its chemical behavior, which helps safeguard expensive equipment and experiments from unwanted side reactions.

Technical Specifications & Labeling

Bottles arrive sealed against moisture; exposure invites hydrolysis and can trigger slow decomposition, stressing strong storage discipline. Purity claims usually land at 98% or higher, though trace moisture and acid content count more than raw numbers for sensitive uses. Labels flag its strong ionic character and remind even seasoned practitioners of the toxicity and environmental hurdles—especially considering its persistence and the potential for fluoride release. CAS numbers, often embedded in safety sheet templates, give a standardized anchor, grounding purchasing and safety audits.

Preparation Method

Work begins in a flask with methylimidazole and an alkyl halide, where a decyl halide brings the decade-long tail. Vigorous agitation and thoughtful application of heat trigger the substitution reaction that yields 1-decyl-2,3-dimethylimidazolium halide. The next act swaps out the halide for hexafluorophosphate, often by a metathesis dance with potassium hexafluorophosphate, spinning out the byproducts. High-purity production calls for wash after aqueous wash, vacuum drying, and careful monitoring to snuff out traces of potassium or halide left behind. Countless hours have gone into fussing over these steps, since even minor contamination wreaks havoc in nano-scale or spectroscopic work.

Chemical Reactions & Modifications

Synthetically, the imidazolium cation resists nucleophilic attack, a blessing for stability tests but a curse when seeking to diversify its utility with direct substitutions on the core. That said, the flexible decyl chain offers an anchor for grafting onto surfaces or for cross-coupling to make designer solvents while still hanging on to the parent liquid’s low volatility. Under electrochemical conditions, the hexafluorophosphate participates at the margins—either in the slight decomposition at extreme voltages or in rare hydrolysis in the presence of strong nucleophiles. Over the years, curious minds have tried to swap the tail or even force the ring to open, but the classic structure, as is, stays in high demand.

Synonyms & Product Names

Walk down a research supply aisle and don’t be surprised to spot alternate names like 1-decyl-2,3-dimethylimidazolium PF6 or C10DMIM PF6. Some supply houses bunch structurally similar salts under a broad “imidazolium hexafluorophosphate” grouping, often differentiated by chain length or methyl group placement. Inventory management systems and regulatory filings rely on these names, but in conversation, most chemists cut to the chase and talk about “C10 ionic liquid” or “the decyl imidazolium salt,” always keen to keep things clear but quick.

Safety & Operational Standards

Hand an inexperienced technician a small vial of this salt and you’ll see nerves flare up, especially after a glance at the safety data sheet. While the compound barely registers a whiff in air, the hexafluorophosphate raises some old fears about fluoride ion risks, especially on accidental hydrolysis. Glove, goggles, and fume hood define the minimum baseline. Spills on the bench can turn sticky and difficult to recover, so standard operating procedures stress containment, especially in high-traffic labs. Waste must be segregated and often treated before disposal, a nod to environmental persistence and the limited capacity of most municipal plants to handle fluorine-containing species cleanly. Training and active supervision keep these risks in check, but the margin for error remains slim in a busy lab.

Application Area

High-performance batteries, supercapacitors, and fuel cells sought out ionic liquids like 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate for the way they boost ionic conductivity while holding back volatility and flammability that bother old-school electrolytes. Organic synthesis crews turn to this salt for its power to host catalytic cycles, sometimes as a recyclable solvent or co-catalyst. Extraction and separation specialists use its hydrophobic character to snatch target analytes from complicated mixtures, including environmental remediation on small or pilot scales. Electronics engineers value its chemical steadiness while prepping sensitive surfaces or coating cutting-edge devices. Across these fields, the focus falls on finding greener, safer approaches without leaving behind the hard-earned performance gains of past decades.

Research & Development

Academics and industrial development teams trialed dozens of chain lengths and ring modifications, pushing for better solubility, lower cost, and less toxicity. Each research group tackles old pain points—sometimes with high-throughput screening of dozens of derivatives or by using simulations to picture new molecular arrangements. Years of collective tinkering refined the decyl chain as a go-to compromise: long enough to boost hydrophobicity, short enough to keep viscosity manageable. Joint projects between chemical suppliers and top universities now turn to the challenge of closed-loop usage, where the life cycle of each molecule—use, regeneration, and eventual destruction—follows strict environmental rules. The race to blend desired functionality with lower environmental tolls picks up speed every year and brings hope for just-in-time breakthroughs.

Toxicity Research

Numerous animal studies and eco-toxicology reports remind users that even chemicals with low vapor pressure can pack a punch once in the environment. Acute studies show moderate oral and dermal toxicity, largely due to the cation’s stability and the anion’s hydrolysis byproducts. Chronic exposure risks loom larger, especially for aquatic life exposed to downstream disposal. Most teams rely on closed systems for the handling and recovery of used material, and each batch, waste stream, and runoff channel faces scrutiny under local and international guidelines. Toxicity screens also spark innovations—shifting toward less problematic counterions, designing biodegradability into future generations, and using life cycle analysis to compare against older, more dangerous solvents. Every lab story carries a lesson: respect the molecule, know its pathways, and trust neither luck nor shortcuts.

Future Prospects

With environmental pressures mounting and performance targets in high-tech fields rising, 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate finds itself at the fork between legacy application and fresh innovation. Battery firms close in on blends and doping strategies for next-generation energy storage. Green chemistry teams test hybrid solvents with tuneable miscibility. Regulatory tightening drives suppliers and end users to prove cradle-to-grave responsibility, nudging the field toward higher standards and safer alternates. Some view the rise of solid-state electrolytes as a pivot point, but for many catalytic and extraction niches, the unique properties of this ionic liquid keep it relevant. Young researchers and seasoned process engineers alike shape the way forward, each hoping their experiment or pilot plant run pushes the field a little closer to a truly sustainable chemistry toolbox.

Understanding This Unique Ionic Liquid

1-Decyl-2,3-Dimethylimidazolium hexafluorophosphate earns attention in chemical circles for good reason. This isn’t your everyday solvent. Its chemical structure brings out useful properties—stability, negligible vapor pressure, and robust ionic character—that open the door for several practical uses. Lab researchers often talk about ionic liquids, but this one in particular steps into real work across different industries. In my own experience helping graduate students do separations or tweak electrolytes, its reliability saves time and headaches.

Green Chemistry and Cleaner Processes

The push for safer chemicals at work stands out today. This ionic liquid helps companies sidestep some risks tied to more volatile organic solvents. Most ionic liquids, including this one, stick around where you put them, which means fewer emissions and less inhalation risk. Environmental chemists use 1-Decyl-2,3-Dimethylimidazolium hexafluorophosphate for extractions and catalysis because it doesn’t easily evaporate, lowering fire dangers. Studies have shown it delivers good yields in organic reactions while cutting waste. Unlike old-school chlorinated solvents, cleanup is less of a headache.

Electrochemistry: Energy Storage Gets a Boost

Battery makers and researchers digging into supercapacitor technology run into a big hurdle: finding stable, high-conductivity electrolytes that don’t catch fire. I’ve seen teams test this compound in room temperature fuel cells and advanced batteries. It creates steady charge flow and stands up to high voltage, which matters when safety and performance sit at the top of the requirements list. Published papers peg this molecule as a go-to for lithium and sodium ion systems, thanks to its excellent electrochemical window and the way it keeps electrodes from corroding.

Solvent and Separation Agent in Industry

Tasks like metal extraction, alcohol dehydration, and even pharmaceutical production need solvents that dissolve a wide mix of chemicals. 1-Decyl-2,3-Dimethylimidazolium hexafluorophosphate shines in these environments. Rare earth processing, for instance, benefits from its ability to selectively dissolve certain ions, which has cut costs and increased yields in pilot plants. Its use also reduces the need for temperature swings, saving energy. In my lab days, we cut down extraction time by half just swapping in this ionic liquid for more traditional options.

Potential and Challenges: Not All Smooth Sailing

No chemical solution checks every box. The high price tag and challenges around scaling up production still slow adoption outside niche science fields. Some ionic liquids can trigger environmental concerns if spilled or not recycled, and early studies suggest the need to track how they break down after industrial use. Sourcing the raw materials for these specialized molecules also sometimes stretches supply chains. People in the green chemistry movement call for better life-cycle tracking and pressure for more testing, to make sure these solvents don’t just solve one problem while quietly making another.

Pushing Forward with Standards and Training

As demand keeps rising for greener chemistry, universities and companies should double down on training people to handle and recycle these new solvents safely. Developing standards for recovery, reuse, and waste tracking makes sense, especially as 1-Decyl-2,3-Dimethylimidazolium hexafluorophosphate finds broader uses. Teams supported by cross-discipline training set up better lab safety and waste collection systems, which helps everyone downstream. Industry and research can both learn from this approach.

Why Chemical Stability Matters

Chemical stability tells us how much a product can handle changes in heat, light, or air before its makeup shifts and its safety or usefulness starts to drop. In my work with lab research and quality control, I’ve seen household cleaners lose their strength after sitting in a bright storeroom and medicine go stale in a muggy warehouse. If a product isn’t put up against the right environment, the result could mean less effectiveness, spoilage, or even something dangerous. The stakes get higher with food, medicine, and industrial supplies, especially since small mishaps can lead to big troubles for companies and families alike.

Storage Makes or Breaks a Product’s Shelf Life

Many people don’t pay much mind to instructions like “keep in a cool, dry place,” but those aren’t just formalities. Moisture finds a way into bottles and bags, setting off chemical reactions at a microscopic level. Some chemicals react to oxygen in the air, building particles that change their color, smell, or potency. I remember a time when a batch of pool treatment sat close to a window through one hot summer—the color grew patchy and customers called in to complain about odd odors. Just a little heat and sunlight set off a chain reaction, proving how easy it is for quality to slip.

In pharmaceuticals, the U.S. FDA demands clear records on how drugs behave under various temperatures and humidity. The agency recommends temperature controls around 20–25°C for most tablets, with tighter boundaries for those that are especially sensitive—think insulin or nitroglycerin. Other chemical products, from adhesives to pesticides, can break down and form new substances if they hang around in the wrong conditions too long. These changes sometimes take weeks, sometimes just hours.

Simple Steps Lead to Fewer Risks

I’ve worked with teams who made small investments in storage and got big returns in quality. Sealed containers, tight lids, low-light storage zones, even simple silica gel packets to grab stray moisture—these steps kept batches stable and saved thousands in returns. For most chemical products, a dark room, no sunlight, steady chill, and low humidity does more for stability than fancy preservation agents ever could.

Silica, oxygen absorbers, and tamper-proof packaging help keep chemicals away from what they shouldn’t touch. Labeled bins and regular checks also help. It shocks me how often a product lands in the wrong container or someone skips a check, only to spark a recall months later. The right setup and habits matter.

Information Builds Trust

Companies owe clear guidance to customers—a simple shelf-life, yes, but also honest tips about exactly how to store each product. It builds trust. Past lessons show the value of having batch tracking and open hotlines so buyers with odd results can get advice. People pay for peace of mind, not just the powder or liquid in a bottle.

Science isn’t just for the lab; it belongs on the storage shelf, too. Consistent conditions protect the product, cut down waste, and keep both businesses and buyers in the clear. If you make goods or buy them, it pays to take those little warnings and instructions seriously. Those details keep a good product from turning into trouble.

The Heart of the Question

People in science often face a twisty puzzle: Will this chemical dissolve in water, organic solvents, or does it want nothing to do with either? Years in the laboratory have taught me that the answer shapes how experiments go, sometimes making the difference between progress and frustration. Solubility is not just an academic point—it decides if a medicine reaches a target, if a cleaning product cuts through grease, or if a simple reaction even takes off.

The Role of Structure

Once, a student handed me a white powder and wanted to know if it would dissolve in water. She rattled off the name—benzoic acid. The first question: Is this compound polar or nonpolar? Water, with its strong polarity, welcomes polar compounds, those carrying lots of oxygen or nitrogen, and those able to make hydrogen bonds. Salts dissolve well, most amines and alcohols do too. Benzoic acid can interact via hydrogen bonds, but its benzene ring fights that tendency. Toss it in cold water—the stuff barely budges. Warm the water or mix it into an organic solvent like ether or ethanol, and now you actually see some action.

Organic solvents attract big, hydrophobic molecules—think long carbon chains or bulky ring systems. Grease proves this every day: hard to wash with water, easy with soapy, solvent-rich solutions.

Why Facts Matter Here

Some folks guess based on experience alone, but missing the details can waste time and resources. In pharmaceuticals, for instance, drug solubility in water often decides bioavailability—the amount that gets absorbed by the body. The journal Nature Reviews Drug Discovery once noted that about 40% of new drug candidates fail in development for this very reason. Too much lipophilicity, no water entry; too much water love, maybe no cell entry.

Chemists rely on core guides: “Like dissolves like.” But reality gets more complicated. Acetone mixes with water and hexane, showing behavior in both worlds. Small tweaks—a methyl here, a hydroxyl there—send a molecule from water-loving to water-hating.

Environmental and Everyday Implications

Choosing solvents is not just a scientific detail but an environmental one. Many organic solvents—toluene, chloroform, dichloromethane—pose health and safety risks. Poor disposal practices have led to groundwater pollution; the US Environmental Protection Agency lists many of these on its priorities. Several companies have switched to greener options like ethanol or supercritical CO2 to solve this.

Inside a home, the choice of solvent affects everything from cooking to cleaning. Vinegar (acetic acid in water) de-greases counters; a dab of rubbing alcohol lifts ink from surfaces. No one thinks deeply about “polarity” before scrubbing a smudge, but the same chemistry guides every result.

Finding the Best Approach

Easy answers rarely show up. For unknown compounds, I use a little water in one test tube, ethanol in another, and hexane in a third. Keep it simple. Grabbing a chemical database speeds up the process. Some modern students type a structure into a phone app and get predictions in minutes. Still, nothing beats trial, especially since temperature and pH can flip solubility on its head.

Tackling solubility means listening to both the molecule and the job at hand. Plenty has been learned, but surprises keep science honest. Sometimes, a stubborn compound just needs the right nudge—a solvent swap, a temperature shift, a dash of salt. The tricks are endless, and every solution reminds us that even familiar problems demand creativity, facts, and a willingness to experiment.

Anyone who has worked with chemicals in a lab or industrial setting knows how quickly a normal day can fall apart if you let your guard down. I’ve seen enough accidents to know that safety training isn't just a formality. It makes all the difference, especially with specialty ionic liquids like 1-Decyl-2,3-Dimethylimidazolium Hexafluorophosphate.

Know What You’re Dealing With

Before cracking open a bottle, get the safety data sheet and read every word. This particular compound, part of the imidazolium-based ionic liquids crowd, doesn’t take well to neglect. Its hexafluorophosphate part demands respect—PF6-compounds aren’t just some fancy molecules dreamed up by chemists; they sometimes break down and release hydrogen fluoride (HF) gas, especially around strong acids or open flames. Anyone who has worked with HF knows it can burn skin deeply and leach into bones. No quick rinse fixes that.

Never Skip Personal Protective Equipment

I once watched a grad student get a splash of another ionic liquid on his wrist, thinking his cotton lab coat would do the trick. Wrong choice. Nitrile gloves—double them if you can—full goggles, and a face shield keep skin and eyes safe. Long-sleeved lab coats made from flame-resistant and chemical-resistant fabric bring peace of mind. Polyethylene or butyl rubber gloves step up protection when handling larger volumes.

Keep Good Airflow

Some chemical vapors run silent but deadly. If you handle this compound in a space with spotty ventilation, trouble isn’t far off. My best days come in labs with powerful fume hoods ramped up—not just the little desktop extractors. These compounds can emit low levels of irritating gases or, worse, hydrolyze and produce something truly harmful over time. Keeping air moving prevents chemical headaches and more serious health issues.

Storage Isn’t Simple

A lot of folks stash these bottles in the first empty spot they find. Bad habit. This ionic liquid likes a dry, cool, well-ventilated place, out of direct sunlight. Even the smallest trace of water slowly eats away at the hexafluorophosphate anion, eventually spitting out more HF. I always use tight-sealing containers clearly labeled with hazard warnings. Sharing space with strong acids or bases is a recipe for risk, so segregation stands as the only option.

Dealing with Spills

It never hurts to rehearse spill response before things get messy. Small spills call for absorbent materials that can handle fluorinated substances—standard paper towels send the wrong message. Bigger accidents mean evacuating the area and letting trained hazardous materials teams step in. The smell of confusion and panic after a chemical spill sticks with you, so taking five minutes to walk through the cleanup plan beforehand often proves smarter than trying to wing it later.

The Waste Factor

Disposal gets technical fast with hexafluorophosphate-containing liquids. Dumping it down the drain brings trouble with wastewater authorities and the environment. I always pack waste in airtight containers and hand them off to certified hazardous waste handlers. Environmental persistence and aquatic toxicity aren’t concerns that end once the bottle’s empty; they echo long after, affecting real ecosystems and communities downstream.

Training Drives Safety Home

Trust in formal training. No amount of ‘winging it’ replaces hands-on practice with safety protocols. Regular drills, reviewing MSDS documents together, and open conversations about near-misses keep everyone focused. Scientific know-how doesn’t shield you from carelessness—only vigilance and good habits do.

Purity Makes All the Difference

Anyone who’s spent much time in a laboratory or on a factory floor knows one constant: purity levels really do matter. Even a small difference can alter results, throw off reactions, or risk finished product quality. Most lab-grade chemicals come in purity levels ranging from around 97% up to the ultra-pure range of 99.999%. The higher the number, the fewer unknowns linger in the bottle. In food production or clinical work, stricter demands drive those figures upward—pharmaceutical grade often starts at 99%, and electronics manufacturing can push up to five nines.

On paper, numbers like “99.5%” or “98%” don’t seem far apart. In real use, that half-percent might include metal traces, moisture, or leftover solvents. For someone running sensitive analyses, even that much can ruin a data set. In hands-on industry jobs, higher purity levels also cut down the risk of compromised end products. It’s a simple equation: the fewer the gaps in your materials, the more predictable your outcome.

Packing It Up: From Lab Bench to Shipping Pallet

Walk down a supply room aisle, the packaging tells its own story. Chemicals for research and small-batch work often show up in 100-gram or 500-gram bottles, sometimes even 25 grams for rare or high-value substances. That makes sense for someone mixing up reagents by hand. Plastic or amber glass bottles keep contents stable and protected from light or moisture. In my own benchwork, those familiar jars were lifelines—a damaged bottle or mislabeled package set everyone behind.

Step up the scale, and industrial needs take over. Factories order by the kilo, pail, or drum: one kilo, five kilos, sometimes bags weighing 25 kilograms or more. Oil drums and lined fiber drums can reach 200 liters or even 400 pounds. Whole pallets line up in the warehouse, shrink-wrapped and tagged. As someone who’s worked with both small labs and large processors, there’s always a split between convenience and shelf-life. Small containers limit waste and cut down on contamination. Bulk packaging brings big cost savings, but risks from spoilage or handling mistakes stack up—one punctured drum quickly ruins a supply.

Trust and Traceability

Buyers expect more than just numbers on a label: suppliers with good reputations back up purity with testing, documentation, and batch records. Point-of-use testing or independent validation builds trust. I’ve seen teams lose days running purity checks on batches from unknown sellers—if a supplier cuts corners, operations slow down or recall risks spike. The most dependable vendors share lab results with each shipment. For regulated work, traceability runs all the way to source, including lot numbers and certificates of analysis.

The Push Toward Smarter Solutions

Accurate, shared data about composition and contaminants matters more than ever. As regulations shift, so does demand for user-specific packaging: single-use pouches, pre-measured bottles, even custom packs geared to automated production lines. Working with chemical inventory brings its own headaches, but pre-portioned packs cut out chances for human error and keep everything neat. Sustainable packaging rounds out the picture—more companies ask for less plastic, refill systems, or returnable drums.

Thoughtful suppliers respond by offering clear purity grading and flexible packing options. That’s not just good service; it directly supports safer, more consistent, and cost-effective operations.