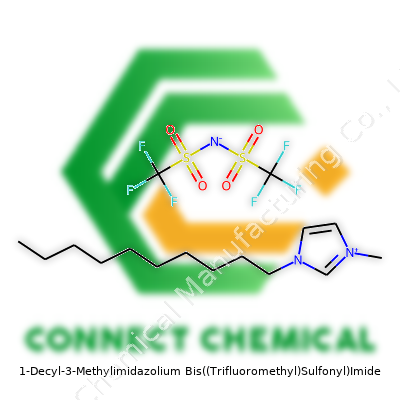

An Insightful Commentary on 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide

Historical Development

Long before chemists could isolate and bottle ionic liquids, researchers relied on more traditional solvents, struggling with issues like volatility and hazardous fumes. In the late 20th century, curiosity about imidazolium-based ionic liquids exploded, leading to a turning point for green chemistry. 1-Decyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide, known among scientists as [C10MIM][NTf2], grew out of this wave of innovation. Labs concentrated on tweaking these salts—swapping alkyl groups and anions—because fine-tuning the structure meant reworking the material’s temperature stability and solubility. The story of this compound reflects the broader shift toward seeking alternatives to volatile organic compounds, which were notorious for harming both health and the environment.

Product Overview

On the shelf, [C10MIM][NTf2] holds the form of a colorless to pale yellow liquid. It remains stable at room temperature, resisting noticeable change or breakdown, whether it stays open to the air or capped tightly. Manufacturers offer it with high purity—sometimes above 99%—to meet the requirements of sensitive lab procedures. Researchers and industry professionals recognize it for its low vapor pressure, which sets it apart from many classic solvents. The shift to ionic liquids like this one has boosted workflows in organic synthesis, separation science, and electrochemistry. Handling and labeling standards keep the product traceable, with clear identification using names, batch numbers, and detailed hazard information. Lab workers rely on up-to-date labels and Material Safety Data Sheets (MSDS), learning how to minimize unnecessary exposure risks.

Physical & Chemical Properties

At the molecular level, [C10MIM][NTf2] stands out with its long decyl tail, contributing to hydrophobicity and enhancing solubility for non-polar compounds. Its melting point hovers comfortably below room temperature, keeping the substance in a liquid state under most working conditions. With a density around 1.3 g/cm³ and remarkable thermal and chemical stability, the compound manages to stay intact even during extensive heating. Low volatility means its presence in the air counts as negligible, which slashes the risks tied to inhalation. Its electrical conductivity and viscosity support applications far beyond simple solvent use—enabling novel designs in energy storage and catalysis.

Technical Specifications & Labeling

Well-established suppliers articulate technical standards with clear-cut numbers: purity over 99%, water content under 500 ppm, and absence of significant impurities verified by techniques such as NMR and HPLC. Labels carry CAS numbers, structural diagrams, and warning signs if hazards exist. Operators check batch codes, shelf life, and container compatibility, steering clear of accidental degradation or reactions with incompatible materials. I have seen labs throw away expensive stocks—sometimes over ten liters—because careless adhesion to standards allowed contamination or unapproved use. Rigorous labeling prevents confusion and waste.

Preparation Method

Synthesis often kicks off with a quaternization reaction between 1-methylimidazole and 1-decylbromide, leading to the formation of 1-decyl-3-methylimidazolium bromide. This intermediate reacts with lithium bis((trifluoromethyl)sulfonyl)imide in an efficient metathesis process. Each step demands careful monitoring—temperatures, mixing times, and extraction solvents all play a crucial role. Crude products get purified via multiple washings, often with deionized water, until even trace halide content dips below detectable limits. Achieving a high-purity final product circles back to discipline in the lab and a solid grasp of practical synthetic chemistry.

Chemical Reactions & Modifications

Chemists keep pushing the frontiers by tweaking both the cation and anion of [C10MIM][NTf2]. Swapping the decyl group for a shorter alkyl chain tunes hydrophobicity, while replacing the NTf2 anion shifts properties such as viscosity and chemical reactivity. Sometimes these modifications serve to enhance solubility for pharmaceuticals or optimize extraction of rare earth elements. The imidazolium ring offers rich possibilities for further derivatization—either to introduce functional groups directly or create hybrid materials with tailor-made behavior. These chemical changes stand as a testament to the compound’s adaptability.

Synonyms & Product Names

In publications and catalogs, 1-decyl-3-methylimidazolium bis((trifluoromethyl)sulfonyl)imide appears under abbreviations like [C10MIM][NTf2], or more simply, DMIM-NTf2. Suppliers often market it under trade names or slightly altered formats, which can confuse even seasoned chemists searching for compatible protocols. I have fielded phone calls from frustrated colleagues unable to match supplier data, highlighting the everyday importance of consistent nomenclature across research and manufacturing environments.

Safety & Operational Standards

Strict routines in handling and waste disposal mark the backbone of safe operation. Protective gloves, splash goggles, and chemical fume hoods come out before a vial is unsealed. Accidental contact can irritate the skin or eyes, so safety showers and eyewash stations need to remain functional and accessible. The NTf2 anion, despite its stability, breaks down under sustained heat, producing corrosive fumes if mishandled. Disposal solutions cycle through dedicated solvent waste channels, supporting both environmental stewardship and regulatory compliance. Building a culture of respect for these routines saves both money and well-being in the long run.

Application Area

The range of applications reaches beyond laboratory beakers. In my own work, [C10MIM][NTf2] has delivered real value in designing selective extraction systems for metal ions, separating trace contaminants from industrial effluents. Colleagues in electrochemistry leverage its stability and conductivity in crafting safer, longer-lasting lithium batteries. Its low volatility reduces atmosphere contamination, which matters a great deal in pharmaceutical synthesis and purification where patient safety hinges on purity. Academics and industrial technologists alike cite its unique solvation properties, pushing forward fields from material science to catalysis.

Research & Development

Innovation doesn’t end at synthesis. Labs worldwide use high-throughput assays to test new derivatives, comparing performance in catalysis, separation, or electrochemical devices. Advanced simulation tools help predict interactions at the molecular level, guiding the design of next-generation ionic liquids with tailored reactivity, thermal stability, and biocompatibility. In recent years, the push to create biodegradable alternatives has driven collaboration between universities and industry, spurred by both environmental regulations and a sense of duty to future generations. Newer studies probe deep into solvent effects, revealing mechanisms behind remarkable selectivity in extraction and synthesis.

Toxicity Research

Toxicity stands as one of the main discussion points every time a new ionic liquid enters the market. Studies with [C10MIM][NTf2] point to moderate fish and algae toxicity, indicating real risks if spills hit natural waterways. Chronic exposure data in humans remains limited, which puts an extra layer of responsibility on those working with the compound. Regulatory agencies encourage comprehensive safety evaluations before large-scale adoption. My own experience underscores the need for early and thorough risk assessments—cutting corners here can lead to regulatory setbacks and negative press that wipe out years of good work.

Future Prospects

Advancement in this field almost always circles back to refining environmental compatibility, lowering toxicity, and slashing costs of production. Greater market acceptance relies on scaling up synthesis in cleaner, more energy-efficient ways. From my vantage point, the drive to adopt bio-based raw materials and closed-loop production models will define the next generation of ionic liquids. If research succeeds in dialing back toxicity while maintaining chemical resilience, the scope for industrial and pharmaceutical uses expands dramatically. Competition in the field keeps growing, drawing in interdisciplinary teams—chemists, engineers, toxicologists—racing to unlock more sustainable pathways.

Unpacking the Core Use

1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide—usually known as [C10mim][NTf2] in research circles—plays its big role in chemical labs as an ionic liquid. In short, that means it’s a liquid salt, stable at room temperature, and not the kind you sprinkle on fries. The main use actually shows up in the world of solvents, especially when other common ones don’t cut it. In my own lab work, I’ve seen it as the go-to for pushing difficult reactions forward, especially those stubborn ones that never seem to finish or leave unwanted leftovers behind.

Why Chemists Keep Coming Back

In traditional chemistry, solvents like acetone and methanol can dry out, catch fire, or react when you least expect it. Ionic liquids such as [C10mim][NTf2] don’t evaporate easily, and they don’t burn as readily, making them safer in a crowded, hot, and sometimes messy work environment. Besides, this compound doesn’t interfere with oxygen or water in the air. Chemists end up with more reliable reactions, cleaner results, and less need for a fume hood running all day long. For example, synthesizing advanced battery materials or pharmaceutical intermediates often means using this liquid to dissolve rare reactants that regular solvents can’t handle.

Green Chemistry Steps Forward

On top of performance, the environmental side can’t be ignored. Tight regulations on volatile organic solvents keep getting tougher in Europe and North America. Researchers and manufacturers take these regulations to heart, with the aim of cutting pollution and workplace hazards. [C10mim][NTf2] offers a serious alternative: it doesn’t escape into the air, so environmental impact narrows. The US Environmental Protection Agency points out the potential for ionic liquids to replace hazardous solvents in industrial processes, and this is no pipe dream. I’ve seen operations swap out traditional solvents for this compound, trimming their waste disposal bills and winning points with both regulators and workers.

Beyond the Test Tube

The reach of [C10mim][NTf2] stretches past research. In real-world uses, companies turn to it to boost battery performance. Modern lithium-ion batteries often fail when pushed to higher voltages. This ionic liquid can help manage those problems by acting as a stable electrolyte, so batteries last longer and don’t overheat. Engineering teams at universities and private companies already run real-world experiments with it, pushing electric vehicle ranges and safety limits. The European Battery Alliance and the US Department of Energy both highlight ionic liquids as a critical path toward safer, high-density batteries, which matters when looking to cut reliance on fossil fuels.

What Still Needs Work

Cost and recycling show up as problems again and again. Full-scale adoption in factories asks for better ways to recycle and purify the liquid once it picks up chemical trash. Researchers keep working on new methods for cleaning and reusing these liquids, with promising results in pilot studies. Tech innovators look at ways to scale up from grams to tons, and regulations keep watch to make sure no new health surprises creep in with broader use.

A Practical Step Forward

The move toward 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide in science and industry traces back to one thing: solving real problems. Whether kicking stubborn reactions into gear or making the next EV battery safer, this compound brings practical benefits hard to ignore. Both on the bench and on the factory floor, people keep reaching for it when the usual tools fall short. It stands out as an example of science meeting day-to-day needs—a clear sign chemistry keeps finding new ways to matter.

Dealing With Chemical Complexity in the Real World

In the lab, chemicals like 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide pop up for all sorts of neat applications. Ionic liquids have earned a reputation for making solvents and industrial processes run smoother and greener. Sometimes the word “green” glows a little too brightly – safety gets sidelined in the rush to innovate.

I’ve run into this sort of compound in academic settings. Its chemical name stretches out like a tongue-twister, but in the bottle it looks tame enough. That can be misleading. Brands market ionic liquids as “non-volatile” or “low-toxicity” compared to classic solvents. Truth gets slippery once you start handling anything with sulfonyl groups and long alkyl chains, not to mention the imidazolium core riding on fluorinated tails.

Looking Past the Brochure

Sellers talk up stability and reduced vapor risk, which certainly makes spills less dramatic than spilling dichloromethane. I check the safety data sheet every time I see something unfamiliar. For this specific ionic liquid, things get murky. Standard reports often say “not enough data.” That means much of the risk profile relies on how similar chemicals behave or short-term animal tests that don’t cover every possible impact.

Scientific research points out a few issues. Skin and eye irritation come up in studies, especially if you skip gloves, splash goggles, or a good fume hood. Some early work suggests ionic liquids can kill off aquatic life at low doses, which hints at bioaccumulation risks. The trifluoromethyl groups ring alarms, since chemicals with similar fluoroalkyl parts cause problems in the environment and break down slowly. No one likes finding out ten years later that a “safe” product left a mess for the next generation.

Facts and My Experience Tell the Same Story

The best way I’ve learned to protect myself in a chemistry lab is old-fashioned: proper personal protective equipment every time and double-checking before pouring or mixing anything new. Researching beyond an MSDS, including peer-reviewed articles, helps get a truer picture. I’ve seen plenty of coworkers grow lax with so-called “green” solvents—until rash, headaches, or coughing fit send them out of the lab. Industries that want to deal in earnest with sustainability can’t just swap one hazard for a lesser-known one.

Waste is another pain point. Regulations often lag behind the commercial roll-out of modern chemicals. Our local waste facility refused unknown ionic liquids without detailed chemical analysis, pushing leftover product into “hazardous waste” just to err on the side of caution. I support this mindset, but it annoys plenty of people who still carry images of “environmentally friendly” in their heads from marketing trends.

What Safer Practice Looks Like Today

Before handling a new chemical, spend an hour hunting down scholarly articles, European Chemicals Agency reports, even anecdotal stories from veteran chemists. A healthy sense of skepticism pays off. Set up protocols that expect the worst possible splash, spill, or inhalation risk. Use gloves proven to resist organic solvents, even if nitrile seems good enough. Insist on fume hoods, not just open windows. When in doubt, label waste robustly and push for chemical collection that doesn’t dump things down the drain.

At the end of the day, the safety story behind 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide feels familiar: don’t believe the hype, don’t assume novelty equals harmlessness, and never let ease of use blind you to the responsibility that comes with putting new compounds to work.

The Challenge of Water and Ionic Liquids

Science sometimes throws a curveball, even to folks who spend most of their days in labs. Ionic liquids—those salts that stay liquid near room temperature—look like miracle workers for solving tricky chemical problems. Their reputation for eco-friendliness and versatility draws interest from folks working on everything from green chemistry to renewable energy. But not every ionic liquid wants to play nice with water. Take, for example, 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide. Even the name is a mouthful, but the real issue is whether or not water dissolves this particular chemical.

What Happens at the Molecular Level

Anyone who’s spent time with ionic liquids understands that their structure decides a lot about where and how they dissolve. This particular compound carries a long decyl chain (ten carbon atoms) tacked onto the imidazolium head. That chunky hydrocarbon tail acts a lot like oil, nudging the whole molecule away from water. Fluorinated sulfonyl groups attached to the anion don’t rescue the situation. Most researchers who’ve tried to mix this stuff with water find that it just won’t blend—at least, not to any meaningful degree.

Lab work and academic papers back this up. Studies on imidazolium-based ionic liquids reveal that lengthening the alkyl chain cuts water solubility down by a large factor. Decyl chains prove especially stubborn, pretty much insisting that the ionic liquid form a separate layer when water enters the equation. You might coax a few milligrams per liter into solution, but expect the bulk to hang back in oily droplets. Even shaking and heating barely budge the balance.

The Practical Implications

Water solubility isn't just a textbook stat—it shapes how and where these chemicals fit into the real world. Lots of scientists want to recover metals, scrub industrial water, or boost battery performance with ionic liquids. Low water solubility limits those dreams, boxing this compound out of processes that demand wide compatibility. Extraction work becomes tougher, since the ionic liquid doesn’t want to mingle with water-borne materials or contaminants. Folks designing chemical separations must juggle phase behavior and settle for slower mixing.

Risks and Environmental Concerns

From an environmental point of view, this limited solubility offers mixed news. Biodegradation worries grow when chemicals dissolve easily and slip into drinking supplies, streams, or groundwater. The stubbornness of this ionic liquid to dissolve gives hope that accidental spills won’t spread fast. On the flip side, persistence outside of water presents its own headaches. The stuff could linger in soils or surfaces, hard to wash away or reclaim. Responsible handling and containment matter, like with many specialty chemicals.

Paths Forward and Innovation

People working in science and technology can’t always settle for “it doesn’t work.” If the natural form doesn’t dissolve, smart chemistry can sometimes help. Adding a solvent mixture, or tweaking the structure of the ionic liquid (perhaps swapping in a shorter chain) might open the door for better water compatibility. Those after real-world solutions get creative—using emulsifiers, specialized surfactants, or even encapsulation to “force” water and ionic liquids together. These tricks don’t always fix the challenges, but they might push applications a step closer to launch.

Takeaway for Researchers and Industry

Before committing a new material to an important job, testing and honest data sharing pay dividends. If you’re thinking about using 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide in a process involving water, expect headaches from poor solubility. Consider adjustments early—either to the chemistry or the design. Care and creativity make tough problems solvable, but the science doesn’t let you skip the homework.

Looking Beyond the Long Name: Why Storage Matters

Friends who work in lab environments know this chemical by its nickname, [C10MIM][NTf2]. If you ever visit a chemistry research facility or a specialty chemical plant, you might catch a glimpse of it on the shelf. Its liquid form, clear or slightly yellow, and oil-like feel set it apart from everyday reagents. What draws attention is not just the mouthful of a name, but the care it demands after the bottle gets cracked open.

Direct Hazards: Not Just a Lab Detail

An average researcher sees ionic liquids like [C10MIM][NTf2] as the golden child for solvent innovation, but from experience, they can turn messy without strong protocols. A splash on skin rarely burns like a strong acid, but long-term exposure raises concerns; the jury’s still out on what breathing in those tiny vapors or frequent skin contact might mean over the years. The smell, sometimes sweet and tangy, lingers well after a spill. Leaving it uncapped—especially in a humid and warm room—lets moisture creep in. Water contamination can shift its intended performance and can even trigger unwanted hydrolysis.

Simple Steps That Go a Long Way

I’ve learned from a few too many sticky drawers that a cool, dry place is not just a cliché. This compound doesn’t always scream for a cold vault, but somewhere between 15°C and 25°C keeps it from changing fate on you. If you store this next to a window or somewhere direct sun hits, the UV exposure starts to do strange things; color shifts and thickening occur after just a few weeks. Sunlight and heat together set the stage for chemical breakdown.

Sealing matters more than you might guess. Standard practice in my old lab meant using PTFE-lined caps and glass bottles, and always giving the rim a clean wipe before closing back up. Once moisture sneaks in, you can't fix it with a quick drying trip. You either toss it or find it’s useless the next time a project rolls around. I once watched a colleague ruin a whole batch of sensitive product because hydroscopic ionic liquid soaked up water overnight in a plastic squeeze bottle.

Why Labeling and Organization Count

Organization is not just to satisfy an obsessive streak; it keeps everyone in the workspace safe. You see a tidy shelf, you know right away which bottle is fresh, which is open, and what needs disposal soon. In one start-up lab, a clean labeling system with clear “Opened On” date stickers cut mix-ups down to zero.

Real Fixes—Not Just Precautions

It’s tempting to handle chemicals like this with a kind of casual routine. I’ve worked in settings where a single trip to the hardware store brought in flammable-proof storage cabinets, desiccant boxes, and new safety signage. That investment paid off in time saved and fewer safety incident reports. Storing this kind of material is less about fancy technology and more about basic responsibility.

The Bigger Picture

From university research benches to commercial labs, the way we store chemicals like [C10MIM][NTf2] speaks to industry habits. My own experiences taught me that shortcuts in storage usually come back to haunt you, sometimes in unexpected ways. A locked, organized cabinet with climate control, thorough labeling, and a habit of closing every cap tight—there’s no secret sauce, just a recipe for safe science.

Not Just Another Lab Chemical

Staring at the bottle of 1-Decyl-3-Methylimidazolium Bis((Trifluoromethyl)Sulfonyl)Imide, usually abbreviated as [C10mim][NTf2], a person untrained in chemistry might just see a collection of syllables. For those of us who have worked around solvents and industrial processing long enough, the letters spell “solution” – quite literally. This is an ionic liquid that finds a home where traditional solvents fail. Even early on, you can spot it replacing more aggressive and problematic chemicals on the bench.

Replacing Volatile Solvents

Behind every modern gadget, electronics plant workers wage a constant battle with heat and residue. Engineers look for liquids that stay stable, act as great ion conductors, and never catch fire or evaporate at a sneeze. Most familiar solvents bring environmental headaches and safety risks – nobody walks away from spilled acetone or toluene with a smile. I have seen research teams ditch dangerous organic solvents, picking [C10mim][NTf2] instead because it hardly evaporates and resists high temperatures. Circuit board manufacturing, battery assembly, and specialty coatings all benefit from this shift. If greasy hands and fumes once marked the job, now it’s more about gloves and a clear workspace.

Boosting Battery and Supercapacitor Performance

Portable electronics need batteries that live longer and charge faster than what came before. Everyone wants lighter phones with enough power to last all day. Inside modern batteries, ionic liquids like [C10mim][NTf2] play the role of conductor. They offer the blend of low flammability and chemical stability engineers dream up. Electrochemical performance improves, and so does safety. Old lithium-ion setups often failed due to moisture or short-circuits; batteries built with materials like [C10mim][NTf2] promise fewer thermal runaways and higher voltage capability. The power grid, electric vehicles, and wearables all lean on these incremental advances.

Separating Chemicals Without The Waste

If you have watched a plant churn out pharmaceuticals or fine chemicals, you know the pain of waste management. Traditional separation uses a ton of water and plenty of harmful solvents. Ionic liquids can dissolve dyes, metals, or even rare earth elements selectively and gently—no harsh acids flooding the plant. Instead, it’s a focused, clean extraction process with minimal leftovers to haul away. This goes beyond saving money or pleasing regulators; less waste means a lighter footprint and better neighborhoods around factory towns. In my time dealing with waste audits and endless spill drills, the push toward these greener processes never felt forced; the chemistry simply works better.

Opening the Door for Smarter Synthesis

Researchers always search for cleaner, faster reactions. Many new catalyst developments hinge on finding media that let molecules zip around but don’t gum up the system with extra byproducts. [C10mim][NTf2] came up again and again in my conversations with colleagues running organic syntheses or enzyme-based procedures. Its stability under heat lets specialists coax out yields that would otherwise lag. Including this ionic liquid has meant smoother operations, fewer surprises, and far less rework—saving countless hours huddled in the lab.

Solving Industry Challenges step by step

No single material fixes every problem, but the ongoing shift towards safe, stable ionic liquids keeps supply chains running cleaner and leaner. As more companies reconsider legacy materials, the practical benefits stand taller than any marketing pitch. Swapping out old solvents with [C10mim][NTf2] spells fewer injuries, lower emissions, and stronger product reliability. Engineering still requires care, oversight, and scrutiny, yet working with ionic liquids moves everyone one step closer to industries that respect workers and the environment.