1-Decyl-3-Methylimidazolium Hydrogen Sulfate: A Commentary on Its Development, Properties, and Application

Historical Development

The journey of 1-Decyl-3-Methylimidazolium Hydrogen Sulfate roots back to the rising interest in ionic liquids through the late twentieth century. Researchers pushed away from volatile organic solvents, aiming for options that bring stability, low vapor pressure, and easy tunability. Looking back, the drive to forge greener chemical pathways prompted labs worldwide to experiment with various combinations of bulky organic cations and diverse anions. Building on predecessors like imidazolium-based salts, scientists started attaching longer alkyl chains—like decyl—onto the ring, figuring it would give better solubility in hydrophobic materials and shift melting points to suit commercially relevant tasks. It wasn’t just academic debate: as industry began demanding more robust, sustainable solvents, the teamwork between university research and corporate investment sped up the refinement of synthetic routes. Years of iterative trial, feedback from early adaptation in chemical synthesis, and increasing scrutiny of environmental footprint shaped the ionic liquid sector’s modern landscape, with 1-Decyl-3-Methylimidazolium Hydrogen Sulfate emerging as a key player.

Product Overview

This substance falls under the umbrella of ionic liquids—salts that become liquid even at room temperature or slightly above. Unlike old-school solvents such as toluene or hexane, 1-Decyl-3-Methylimidazolium Hydrogen Sulfate stays liquid under a wide temperature range, doesn’t evaporate into the air, and shows both polar and non-polar characteristics based on how you use it. The product appears as a pale to viscous, colorless liquid, not prone to rapid degradation under regular conditions. Many people in organic chemistry, catalysis, and material research see the potential right away, given how one liquid can blend physical robustness with chemical adaptability. In comparison to shorter-chain relatives, the long decyl sidechain gives it a margin of flexibility, enabling better dissolution of organic matter and non-polar compounds when traditional solvents fail.

Physical and Chemical Properties

What stands out to anyone handling 1-Decyl-3-Methylimidazolium Hydrogen Sulfate in the lab is its sturdy build. Melting points hover well below 100°C, typically around room temperature, leaving no need for complicated storage precautions like dry ice or refrigeration. Viscosity rises as alkyl chain length increases, so decyl-substituted salts pour a bit slower, but this trait brings stability in processes needing sustained contact or gentle phase transfer. It dissolves within both highly polar and moderately non-polar environments, showing a practically unmatched ability to act as a “designer solvent.” Electrical conductivity improves with temperature, though it won’t rival that of conventional aqueous electrolytes. Chemical resilience in the face of moderate acids, bases, and air oxidants means the risk of sudden breakdown remains low, assuming good lab discipline. On the downside, its thick nature sometimes complicates rapid mixing unless preheated slightly.

Technical Specifications & Labeling

A bottle of 1-Decyl-3-Methylimidazolium Hydrogen Sulfate typically arrives marked with its molecular formula (C14H29N2O4S), batch number, purity percentage (often >97% for lab use), and water content below 1%. Reputable suppliers include safety instructions, recommended storage temperatures, and immediate disposal guidelines in case of spills. Large shipments for research or pilot plant use may carry hazard pictograms reflecting its mild irritant potential and general chemical handling best practices. Transparency on trace impurity levels such as residual imidazole or sulfate byproducts has grown, helping users avoid surprises when reactions run close to the edge of tolerance. Clear labeling, batch tracking, and reference to analytical certificates give end users peace of mind when scaling up experiments or documentation for regulatory review.

Preparation Method

Synthesizing 1-Decyl-3-Methylimidazolium Hydrogen Sulfate starts with building the cation. A chemist typically combines 1-methylimidazole with decyl bromide under inert atmosphere, refluxing until the decyl group attaches firmly at the third position. After purifying the resulting 1-Decyl-3-Methylimidazolium bromide, the next step swaps out the bromide for a hydrogen sulfate anion, usually by mixing with sulfuric acid or sodium hydrogen sulfate under controlled pH and temperature. This metathesis step needs patience and close monitoring, as overheating or excess water can encourage unwanted hydrolysis or byproducts. Extensive washing with organic solvents and water ensures the final ionic liquid sits free of grime, residual acid, or halide impurities. Most producers finish off by vacuum drying the product until water content drops below set thresholds. This whole method supports batch-to-batch consistency, and knowledge gained during decades of small-batch work now aids chemical engineers when targeting industrial volumes.

Chemical Reactions & Modifications

In the lab, 1-Decyl-3-Methylimidazolium Hydrogen Sulfate steps in as a solvent, catalyst, or ionic medium for transformations that struggle under water or standard organics. Its unique structure means it can stabilize charged intermediates in acid-catalyzed reactions, help with alkylation or esterification, and improve yields in nucleophilic substitution experiments. Sometimes, researchers tweak the anion—replacing hydrogen sulfate with other “greener” acids—to match specific reactivity or environmental requirements. Addition of functionalized sidechains (longer or branched alkyl) on the imidazolium skeleton sometimes helps when one needs better solubility for polymers or nano-materials. This ionic liquid rarely stays unchanged in materials chemistry: it acts as a template in sol-gel reactions or a matrix for nanocomposites, setting the stage for innovative materials with new conductivity or mechanical strength profiles. The capacity for variation led me to see firsthand how shifting a single group or anion brings dramatic changes in viscosity, solubility, and compatibility.

Synonyms & Product Names

In catalogs or research papers, this compound appears under several names. Chemists label it as [C10mim][HSO4], or 1-Decyl-3-methylimidazolium hydrogensulfate, and variations on chemical company labels include decylmethylimidazolium bisulfate or DMIM HSO4. European suppliers sometimes abbreviate as DmimHSO4. Recognizing this variety saves time searching for literature or suppliers, and bridges the gap when teams collaborate across borders. Digital chemical registries, including CAS and Reaxys, track it under unique registration numbers, ensuring no confusion arises between the decyl, octyl, or dodecyl analogues.

Safety & Operational Standards

While 1-Decyl-3-Methylimidazolium Hydrogen Sulfate scores well on several green chemistry criteria, anyone using it should respect its ability to irritate skin, eyes, and mucous membranes. Standard gloves, eye shields, and bench hoods belong in routine handling, especially when working at elevated temperatures or mixing vigorous acid sources. Accidental ingestion or inhalation could provoke discomfort or, with heavy exposure, mild respiratory distress; therefore, spill control and materials safety data sheets should stay handy. Waste disposal ought to funnel through chemical waste streams, not sinks or general trash, even if ecological toxicity seems comparatively mild. My own training always highlighted the importance of keeping chemicals contained, cross-checking container seals for leaks due to the occasionally sticky, oily nature of these liquids. Companies investing in bulk storage need corrosion-resistant containers and spill trays sized for worst-case scenarios, especially during pumping or transfer.

Application Area

Across the board, 1-Decyl-3-Methylimidazolium Hydrogen Sulfate steps up in tasks where regular solvents break down or bring regulatory worries. In my experience, it carries particular clout in green extraction of bioactive compounds—its ability to dissolve a swath of organics from plant matter corners a growing market in pharmaceuticals and nutraceuticals. Academics lean on it for “one-pot” syntheses or as supporting electrolyte in new battery chemistries. Material scientists, including those I’ve worked with, use it to template nanoparticles, develop flexible conductors, and even assist in cellulose processing for newer films or fibers. Its low vapor pressure and strong solvating qualities make it suitable for CO2 capture, separation processes in petrochemicals, and targeted clean-up of heavy metals from environmental samples. Experimentation continues in solar cell assembly, lubricants, and beyond, indicating the appetite for such adaptable solvents in fields far removed from the original niche of organic synthesis.

Research & Development

Research teams worldwide keep pushing the boundaries on how and where ionic liquids like 1-Decyl-3-Methylimidazolium Hydrogen Sulfate can add value. Lately, universities have dived deep into “task-specific” modifications, tailoring side chains to direct chirality, enhance biodegradability, or control toxicity for safer industrial runs. Several consortia run real-world pilot trials for biomass conversion—turning agricultural leftovers into valuable chemicals—relying on this compound’s ability to process lignin and cellulose without drastic pre-treatment. Analytical chemists value the low-vapor, high-purity environment it creates for running mass spectrometry or chromatography separations. A strong focus continues on recycling and reusability, as process engineers build cradle-to-cradle loops, using filtration or back-extraction to recover and clean the solvent after each cycle. Deeper pockets and public grants accelerate the pace, opening more options beyond the bench-scale, and moving towards large reactors and continuous-run applications.

Toxicity Research

Toxicological scrutiny matters more today than ever, as researchers and regulators watch for new risks with every chemical roll-out. For 1-Decyl-3-Methylimidazolium Hydrogen Sulfate, in-vitro tests suggest moderate toxicity toward aquatic organisms if large spills occur, but the relative safety in controlled applications still stands above many volatile organic alternatives. Lab animal tests indicate that acute exposure typically causes mild irritation rather than long-term damage; even so, regulatory bodies prefer abundant caution, flagging potential bioaccumulation or unexpected breakdown products. The long decyl chain sometimes hints at persistence in the environment, raising conversations about future wastewater treatments. Current studies target metabolic fate, seeking to pin down degradation pathways and ensure byproducts don’t outlast their usefulness in the wild. Based on both commercial and academic findings, best practice points toward tight containment, robust recycling, and step-by-step environmental impact reviews at scale-up.

Future Prospects

Looking ahead, 1-Decyl-3-Methylimidazolium Hydrogen Sulfate stands at the crossroads of innovation for green chemistry and material production. Academic and corporate laboratories both eye further reduction in cost through streamlined synthesis and renewable feedstocks—some groups already test routes from plant-derived imidazoles and biogenic sulfate. An increasing chorus calls for rapid assessment of biodegradability and full lifecycle analysis, pushing for versions that leave less of a mark on natural systems. Demand in energy storage, especially for safer, high-capacity batteries and supercapacitors, tends to pull research toward improving ionic conductivity and mixing behavior with metal salts. In the field of catalysis and pharma synthesis, ongoing tricks—including immobilizing this ionic liquid on solid supports—promise cleaner product separation and less downstream processing. For many sectors, the flexibility of this compound offers a toolkit, not a one-size-fits-all. Sustainable adoption feels within reach for those investing now in transparency, careful stewardship, and a commitment to working through the trickier questions of safety and environmental compatibility.

Green Chemistry in Action

After years of following chemical industry trends, I’ve watched the shift toward greener, smarter processes. 1-Decyl-3-Methylimidazolium Hydrogen Sulfate, an ionic liquid with a mouthful of a name, stands out for exactly this reason. Unlike many solvents relied on in the past, this molecule dodges issues with volatility and toxicity. Labs and factories face pressure to cut hazardous waste and emissions, so making the switch to ionic liquids often eases compliance headaches and future-proofs new setups.

Take catalytic reactions. Chemists look for media that boost reaction rates without requiring harsh conditions. Research published in the Journal of Molecular Catalysis A shows that this ionic liquid works especially well as a solvent and catalyst support in acid-catalyzed reactions. It speeds up esterification, alkylation, and even biomass processing—without breaking down or producing much waste. This kind of versatility matters for companies trying to handle multiple products or adapt quickly as markets shift.

Troubleshooting and Tuning

Anyone who’s ever worked with separation processes knows about the endless tradeoffs: purity, cost, safety. In extraction and separation, 1-Decyl-3-Methylimidazolium Hydrogen Sulfate’s unique molecular structure grabs certain organic and inorganic molecules efficiently. Industries from pharmaceuticals to environmental remediation use this advantage to pull out heavy metals or recover rare earth elements from complex mixtures. The result? Cleaner water, more useful reuse streams, and fewer headaches from regulatory audits.

Battery researchers also notice a serious benefit. Traditional battery electrolytes present flammability risks, and nobody wants a smartphone recall over fires. Ionic liquids like this one offer good conductivity and stability at higher temperatures. This makes them useful for lithium-ion battery projects aiming to hit the market with next-generation safety features.

A New Look at Cellulose Processing

Sustainable packaging has become more than a buzzword, and companies scramble for ways to handle cellulose. Typical solvents strip out natural molecules, but often leave behind hazardous byproducts. Some years ago, I read about work at a Finnish university where researchers turned to 1-Decyl-3-Methylimidazolium Hydrogen Sulfate as a cellulose solvent. It dissolves cellulose directly without extreme temperature or chemical additives.Both textile and bioplastics industries keep an eye on this route, since it cuts down on hazardous waste and opens up recycling loops barely imaginable with legacy methods.

A Safer and Smarter Laboratory

Many universities and labs, facing pressure to limit student and staff exposure to harmful chemicals, turn to ionic liquids for teaching advanced synthesis or extraction. Faster clean-up, safer handling, and better performance on exams: my old university switched a handful of graduate projects to ionic liquids, and both professors and students were happier with the results. This shift falls in line with growing evidence, like safety audits from the American Chemical Society, that favor switching to modern alternatives.

What Could Come Next?

Looking forward, water treatment and energy storage demand more robust solutions. As cost drops and research expands, anything that supports safer, more efficient, and flexible processes draws attention. 1-Decyl-3-Methylimidazolium Hydrogen Sulfate remains part of the toolkit for operations seeking practical change in chemical processing, resource recovery, and green manufacturing. As long as safety and sustainability hold value, creative chemists will keep pushing this class of materials into new corners of industry.

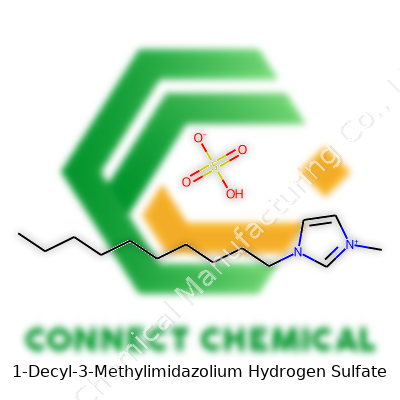

Chemical Structure and Formula

1-Decyl-3-Methylimidazolium Hydrogen Sulfate stands out for those who care about green chemistry and ionic liquids. Its structure says a lot about why scientists like to use it. The cation comes from an imidazolium ring, which chemists usually recognize as a stable, two-nitrogen, five-membered ring. In this molecule, the imidazole base holds two key groups—a methyl at the number three nitrogen and a long decyl (ten-carbon) chain attached to the number one nitrogen. The anion, hydrogen sulfate, balances the charge.

If you write that out, the molecular formula ends up C14H29N2O4S. The cation is C14H29N2+, and the anion is HSO4-. The decyl chain helps the molecule interact with both oils and water. This versatility makes these types of ionic liquids useful for all kinds of solvent applications and catalysis work.

Why Structure Matters in the Real World

People in my field talk a lot about “green solvents.” Many start with ionic liquids like this one because they usually have low vapor pressures so evaporation doesn’t add much pollution. 1-Decyl-3-Methylimidazolium hydrogen sulfate fits this category thanks to its stable ionic structure. Its long alkyl group comes with another benefit: it dissolves things traditional water-based solvents struggle with. This includes target molecules used in pharmaceuticals, chemical separations, or even clean-tech like biomass conversion.

I’ve seen researchers use it in lab extraction experiments because the hydrogen sulfate part helps with proton transfer. That means better control for acid-catalyzed reactions, which shows up in more efficient reactions and sometimes less unwanted by-product. Some teams in university labs love its ability to solubilize cellulose, which points toward biofuel potential. The chemistry department often stores a small vial close to the glovebox, ready for the next complex synthesis that needs less water and fewer toxic aromatics.

Sustainability and Safety Questions

It’s not all positive. Even though these ionic liquids seem like a cleaner option, some environmental groups have flagged concerns. Disposal methods and toxicology profiles need more research. The hydrogen sulfate anion, in high concentrations, can hurt aquatic life, and many ionic liquids do not break down quickly in soil or groundwater. The safety sheet for this compound won’t let anyone ignore splash hazards—corrosive to skin and eyes—reminding every chemist to treat it as a strong acid until it’s been fully neutralized after use.

Labs can reduce risks by running small reactions and using closed systems. Researchers keep good records and test water samples before and after using these liquids, looking for contamination or residue. Process engineers in the chemical industry are always searching for recycling or recovery strategies so ionic liquids don’t wind up in landfill or wastewater streams.

Looking Ahead: Improving Use and Reducing Risks

Research teams should keep pushing for better toxicity data. As a practical matter, finding streamlined recycling steps helps with costs and with regulations. Pilot programs testing membrane filtration and chemical recovery stand out as promising steps. Public databases that track the breakdown products—and effects on plants, animals, and people—help build trust.

With a strong understanding of structure, researchers can design improved versions that give the benefits of 1-Decyl-3-Methylimidazolium hydrogen sulfate but with fewer downsides. Every time someone adds a new alkyl group or swaps out the anion, they might discover a safer, cleaner solvent that still works as hard in the lab or factory. That’s the kind of result that drives innovation and keeps chemists on the hunt for greener chemistry options.

Why Safe Storage Means More Than Just “Following Rules”

I’ve spent years working alongside chemists and lab techs from schools to large-scale plants. The one thing that always sticks out: the most dangerous moment isn’t when something goes boom. It’s the ordinary day, the “just moving this jug” day, when assumptions and routines replace thinking. When storing a chemical like 1-Decyl-3-Methylimidazolium Hydrogen Sulfate (let’s call it DMIMHS for short), the gap between “safe” and “unsafe” usually comes down to plain habits and honest attention, not just what’s written on an MSDS.

Don’t Hide It in Any Old Cabinet

DMIMHS belongs in a cool, dry spot, away from sunlight and away from damp basements or hot stockrooms. From experience, keeping any ionic liquid in a sunlit window or above a heater will lead to headaches and, sometimes, mystery leaks and ruined labels. Humidity sneaks into poorly sealed containers, and the next thing you know, you’re tossing out product or cleaning up a sticky mess. Sturdy, airtight plastic or glass containers work well, but glass should stay out of reach if your bench sees a lot of heavy lifting.

Shelves shouldn’t flex under weight, and containers need labels you can still read after six months. I’ve watched good scientists get embarrassed by faded tape or handwritten warning signs. Permanent marker, clear print, up-to-date hazard codes: these habits save more than just product. They save your morning from the panic of reaching for something unidentified mid-experiment.

Handling Isn’t Just a Checklist Item

I once saw a co-worker spill a few milliliters of something similar to DMIMHS on his gloves. A shrug, a wipe, and back to work — until his hand itched and we realized the glove was thinning. This was a wake-up call. Nitrile or neoprene gloves usually hold up better than latex with DMIMHS, and lab coats shouldn’t be optional, no matter how relaxed the project looks. Splash goggles, not just glasses, keep your eyes safe from splashes that can burn or cause eye irritation.

DMIMHS can cause irritation if it touches skin or eyes, and inhaling its fumes—especially during clean-up—feels a lot worse than breathing in your usual solvent whiff. Good chemical hygiene calls for closed transfer systems if you’ve got access, or at the very least, working in a fume hood every time you open or transfer it. I’ve taken shortcuts in my earlier days and paid with burning noses and coughs that last the rest of the day.

Small Steps, Big Impact

Most labs fail at disposal, not handling. Pouring DMIMHS down the drain contaminates water sources and can cause problems with pipes and water treatment. Instead, temporary waste containers with secure lids–clearly labeled as hazardous—keep things clear for your waste contractor and your conscience. Training every year, not just once during onboarding, keeps everyone’s memory sharp.

Reliable emergency showers and eyewash stations shouldn’t gather dust: regular checks and clear walkways make everyone safer. If something does go wrong—spills, accidental contact, or fire—knowing exactly where your safety equipment is and how to reach it beats any written plan. Talk through real-life scenarios, not just theory, during your lab’s next safety meeting. People remember stories, not bullet points.

Keeping It Simple Means Keeping It Safe

There’s no mystery to handling DMIMHS safely—just habits rooted in respect for the chemical and for the people sharing the workspace. Clear labels, fresh gloves, dry storage, and regular training form a real safety net. As someone who’s cleaned up too many hurried spills and stood over malfunctioning fume hoods, I know simple routines and honest reminders do far more than warning signs stuck to a fridge.

Straightforward Risks Hiding in Everyday Use

Using any product that promises convenience or a shortcut always brings risks on the side. Take my experience with everyday household cleaning sprays. What looks harmless on the shelf can sting eyes, cause sneezing, or burn skin. This lesson came quick after trying a new brand without gloves. In most cases, skin felt irritated, and breathing got tough if the ventilation wasn’t right.

Labels warn about chemicals, and they do it for a reason. Using the product without reading those instructions is asking for trouble. Many folks I know, grandparents included, have stories of rashes, sneezing fits, or stubborn stains on the counter and even on shirts from a careless squirt. Mixing brands only invites bigger problems.

Common Trouble Spots

There’s no sugar-coating it: careless use creates danger. Spills can trip someone in a hurry. Eyes can itch for hours if even a little mist gets blown around. Some products give off vapors you don’t want in your lungs. People forget to store them away from sunlight or extreme heat, and bottles can swell or leak, making an ordinary cabinet risky for kids and pets.

Food surfaces are another danger zone. Lots of people wipe down kitchen counters with a multi-use spray, then forget to rinse before prepping a sandwich. Those invisible residues can cause stomach pain, especially for small children. Anyone who touches treated surfaces and rubs their eyes can face a burning reminder.

Respect the Label, Respect Yourself

Years of seeing problems after ignoring directions taught many families a lesson. With most household or industrial products, every label counts. Symbols on the packaging might look generic, but they speak loud: “Wear gloves.” Simple advice, huge payoff. Clear instructions about airing out a room matter, too. Stories about folks fainting or dealing with days-long coughs often start with closing a window during use.

Wearing gloves, goggles, or even a mask may seem like overkill until a single mistake costs a trip to urgent care. Personal experience and reports by groups such as the Centers for Disease Control and Prevention back this up. In some cases, chemicals burn or cause swelling right away. In others, the effects build over days. Both deserve respect.

Practical Solutions for Everyday Users

A kitchen timer solves more than cooking woes. Set it to remind you to ventilate the room or rinse surfaces after spraying. Keep the product out of reach from kids and pets. Think twice before using it near food or around people with allergies or asthma. If your hands sting or your eyes water, stop right away and wash up. Don’t mix the product with others, even if Google suggests a “quick fix.”

Disposal matters just as much as use. Closing the cap tightly keeps fumes in and accidents out. Follow the recycling or hazardous waste instructions. Neighbors and garbage collectors shouldn’t face surprise burns or fumes.

Common sense and a little patience go a long way. Respect for the product and the rules keep everyone healthier. Personal stories from friends and family show that the biggest hazard comes from ignoring basics. With a little care, risk goes down — and so does the stress that nobody needs in the middle of real life.

Not All Chemicals Share the Same Quality

Walk into a chemistry lab, and purity makes all the difference. 1-Decyl-3-methylimidazolium hydrogen sulfate isn’t any different. Over the years in research, I’ve seen firsthand the difference between a high-purity batch meant for analytical chemistry and a technical grade that gets used for industrial reactions or cleaning tasks. Impurities can show up as noise in data or trigger side-reactions that make you question your whole experiment. Purity directly impacts how well a reaction works or how reliable the numbers look in quality control tests.

The Core of the Issue: Why Purity Matters

Some companies supply 1-decyl-3-methylimidazolium hydrogen sulfate in a form suited for synthesis work, listing purity above 99%. Here, the focus lands on minimizing traces of water, halides, or metal ions. In a catalytic process where imidazolium salts play a role, stray ions may slow reactions down or lead to unpredictable results. In a research group studying green chemistry, we tried different grades side by side. The reagent-grade sample gave dramatically more reproducible outputs. Any chemist trusting their data to questionable purity faces heavy troubleshooting down the line.

Lower grades exist too. These may go by names like “technical grade” and end up in industrial applications, like ionic liquid solvents for cellulose processing or desulfurization, where some contamination barely registers. If a process isn’t sensitive, the trade-off can bring real cost savings. The downside: imagine scaling up a promising lab process, only to see yields drop off because the purity dropped with the price.

Purity Impacts People, Not Just Products

Safety concerns shape the demand for certain grades. In labs where new applications get tested, the team should know what’s in each bottle. Every impurity means a potential for health exposure, waste, or environmental concerns. Detailed certificates of analysis let users spot unwanted elements before any harm gets done.

The regulatory side adds another layer. For chemical manufacturers selling across borders, providing documentation and samples with strict purity guarantees is often the only way to satisfy safety agencies. Companies in the EU or US frequently ask for REACH or TSCA compliance papers, and these depend on production quality.

What Users Can Do

It pays to check what’s behind the label. Suppliers often provide more than one grade, but the real difference comes through technical sheets and in-house validation. A university lab carefully testing new catalysts might even re-purify a product through additional evaporation or chromatography. In my experience, reaching out to chemical suppliers for clarification about trace impurities or batch records has avoided major setbacks.

For larger-scale users, building a relationship with a reliable supplier saves time and money. Audits, reference materials, and external testing by independent labs create accountability. Open discussions help anticipate shortages or batch variations that impact workflows. It all traces back to knowledge and vigilance—key habits for anyone handling specialty chemicals.

The Takeaway

Every bottle of 1-decyl-3-methylimidazolium hydrogen sulfate serves a different purpose, and the value of knowing the details goes beyond chemistry. Producers and buyers make choices that affect not just the bottom line, but also the safety and trust invested in science and industry.