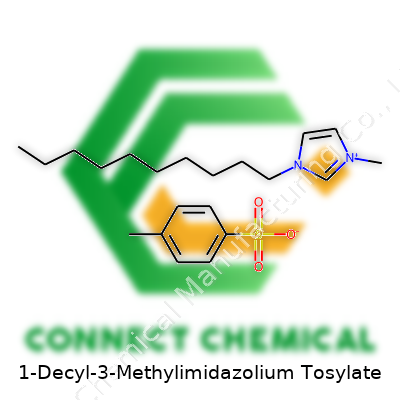

1-Decyl-3-Methylimidazolium Tosylate: Perspectives and Realities

Historical Development

Looking at the road that brought us 1-Decyl-3-Methylimidazolium Tosylate, things started from a broader fascination with ionic liquids in the late 20th century. Chemists started shaping new imidazolium-based salts that ditched volatility and flammability, swapping problems caused by traditional organic solvents for greener, less risky chemistry. I remember my first hands-on encounter with ionic liquids—puzzling over their thick, oily feel, nothing like the sharp sting of acetone or the slip of ether. The story of this compound carries echoes of that experience: balancing chemical ambition with practical demands. The focus on pairing decylmethylimidazolium cations with a tosylate anion drew on both innovation and a need for practical, non-volatile, and thermally stable materials in research labs.

Product Overview

There’s no shortage of special-purpose chemicals in the market, but 1-Decyl-3-Methylimidazolium Tosylate stands out. It comes off as a clear, slightly viscous liquid—oil-like and surprisingly stable. You can spot it in containers with clear labeling, reflecting its unique structure and properties. Chemical suppliers pitch it for situations demanding strong dissolving power and low vapor pressure. So many folks in catalysis and materials science choose it over traditional solvents, chasing safer handling and new performance levels. From direct synthesis experiments in university labs to prototype manufacturing, adoption steadily grows.

Physical & Chemical Properties

Anyone handling this ionic liquid right away notices the dense, slow-pouring quality. Its melting point usually lands below room temperature, and it holds a density near 1.0–1.2 g/mL. Thermal stability claims respect, with break-down not appearing until past 250°C. Solubility throws a twist—prefers organics, remains stubbornly unfavorable to pure water. Its ionic nature brings a high conductivity, attractive for electrochemical applications, and its hydrophobic alkyl chain (decyl group) shapes both miscibility and handling. Under a glass lens, the distinct imidazolium ring brings chemical versatility, while the tosylate anion steadies reactivity, setting this liquid apart from simpler salts.

Technical Specifications & Labeling

Suppliers sell 1-Decyl-3-Methylimidazolium Tosylate under strict standards. Purity typically tops 98%, with moisture content below 0.2%, meeting demanding research standards. Labeling highlights systematic names, CAS number (134298-36-5), and hazard symbols. Product sheets include spectroscopic fingerprints—NMR and FTIR peaks—which I always double-check before diving into trial runs in the lab. Chemical suppliers supply certificates of analysis confirming batch consistency and impurity profiles. This matters when experimental results hinge on solvent purity, not only for safety, but also for reproducibility.

Preparation Method

Making this ionic liquid calls for a well-planned process, starting with the alkylation of 1-methylimidazole using 1-bromodecane. After generating the 1-decyl-3-methylimidazolium bromide, the next step swaps the bromide for tosylate by reacting it with sodium tosylate or a similar salt. This ion exchange, often carried out in water or polar organics, ends with a separation, washing, and careful drying to remove trace water—lab staff can’t take shortcuts here, because moisture ruins both purity and performance. Purification sometimes takes chromatographic steps if byproducts cause trouble, and storage demands tightly-sealed vessels away from atmospheric moisture.

Chemical Reactions & Modifications

The imidazolium moiety holds up well against most bases and acids, unless you crank up the heat or add strong nucleophiles. The decyl tail resists oxidation in mild conditions but succumbs to aggressive reagents, especially under UV or ozone. Chemists exploring greener syntheses experiment with swapping anions, creating new tasks for this class of liquids—from chloride and hexafluorophosphate to oxoanions. The compound works as both a solvent and a reactant platform for organometallic catalysis, organic transformations, extractions, and phase-transfer reactions, thriving when nonpolar and mildly polar species must be managed together. The catalog of chemical tweaks extends as new researchers pursue custom alkylations or tune the anion for solubility and reactivity shifts.

Synonyms & Product Names

Reading through supplier catalogs and academic literature, I’ve come across a variety of labels, sometimes causing confusion unless you keep sharp. You’ll see names such as [C10mim][Tos], Decylmethylimidazolium p-toluenesulfonate, or 1-decyl-3-methylimidazolium tosylate. Other variants include DMIM-Tos or shorthand like DMI-TS. Matching names with structural diagrams becomes second nature for anyone ordering or designing experiments, and mislabeling throws a wrench into procurement or regulatory compliance. Always double-check the structure and not just the product name.

Safety & Operational Standards

Working with this compound, gloves and goggles aren’t optional. Safety data calls attention to skin and eye irritation risks, with ingestion or high vapor exposure flagged as hazardous. Spill response guidelines focus on containment and solvent mop-up—ionic liquids don’t evaporate, so cleanup takes physical removal rather than simple airing out. Disposal regulations demand collection for hazardous waste, never the sink. Storage conditions need dry, room-temperature spots with clear hazard labeling. Experience tells me that training and up-to-date protocols beat careless handling, especially when working on large batches. Regulatory demands—CLP, GHS, REACH—push producers and users to tighten operations, document use, and prepare for audits.

Application Area

Research teams in organic synthesis laboratories have leaned on 1-Decyl-3-Methylimidazolium Tosylate for catalytic reactions that won’t tolerate volatile solvents. Industrial developers look to this ionic liquid for process intensification, resource recycling, and green manufacturing pilot lines. In extraction chemistry, the compound shakes up old routines by splitting phases that don’t respond to conventional solvents. Electrochemical researchers deploy it in supercapacitor development and energy storage layering, taking advantage of its conductivity and electrochemical window. As academic collaborations grow, new end-uses turn up in polymerizations, nanomaterial preparations, or as solvent media for biocatalysis. Colleagues report less vapor inhalation and improved product isolation thanks to the compound’s unique mix of solvent power and stability.

Research & Development

Development activity around 1-Decyl-3-Methylimidazolium Tosylate intensified over the past decade. Teams in Asia, Europe, and North America publish findings on new synthesis methods, aiming for better yields, cleaner reactions, and fewer waste streams. Studies highlight breakthroughs—for example, deploying the liquid as a reaction medium for C–C coupling, or as a cleaner phase in the extraction of valuable metals from ore leachates. Patent filings track into fields like battery tech and specialty polymer design. Joint ventures between academia and industry look for scalable, cost-cutting production routes. In my own bench experiments, ionic liquids like this one win out when standard solvents fail or regulations clamp down on VOC emissions. Technical hurdles stay, but R&D communities push boundaries with increasing creativity.

Toxicity Research

Toxicologists raise concerns about chronic exposure, aquatic toxicity, and eventual breakdown products. Peer-reviewed studies indicate that 1-Decyl-3-Methylimidazolium Tosylate, while less acutely toxic than legacy solvents, may disrupt aquatic systems if released untreated. Skin contact produces moderate irritation in animal models. Chronic dosing explores bioaccumulation, reproductive impacts, and enzymatic disturbance. Regulatory bodies require thorough documentation before industrial scaling. I’ve sat in on research seminars where ecotoxicity was debated, highlighting the need for wastewater controls, closed-loop systems, and continuous monitoring. Compared with chlorinated solvents, risks shrink, but blind trust never replaces thorough assessment.

Future Prospects

The future for 1-Decyl-3-Methylimidazolium Tosylate looks promising. More institutions shift to ionic liquids to slash emissions, boost safety, and squeeze efficiency from chemical processes. Market forecasts point toward growth in electronics, pharmaceuticals, smart materials, and specialty extractions. Ongoing research chases lower-cost production and less-toxic anion swaps. Sustainability pushes—driven by government incentive and grassroots effort—fuel adoption of high-performance, low-impact chemicals. From colleague discussions to published reviews, a consistent message comes through: innovation pays off only if safety and environmental standards keep pace with demand. Responsible use, closed loops, and better training hold the key to unlocking the compound’s full potential.

Breaking Down the Name

The long, tricky name—1-Decyl-3-Methylimidazolium Tosylate—carries weight in modern chemistry labs and the industries that follow. Lab workers and product designers look for new ways to replace old, often harmful solvents. Regular organic solvents usually bring headaches: flammability, volatility, environmental stress, tough disposal. Chemists start seeking something greener. Ionic liquids like this one step up, and what’s interesting is how versatile this salt in liquid form can be.

Better Solvents for Research and Synthesis

Typical solvents scatter into the air and make workspaces dangerous. 1-Decyl-3-Methylimidazolium Tosylate behaves as an ionic liquid, which means it hardly evaporates. That means workers breathe safer air, and chemists waste less time chasing down fumes. In organic synthesis, this liquid handles a wide range of reactions. Think of researchers seeking new medicines or running selective reactions that call for controlled environments. They can swap in this liquid and cut waste down sharply. Fewer toxins end up in the bin or swirling around work tables, and fewer headaches all around.

Cleaning Up in Catalysis

Catalysts often make or break reaction speed and quality. This ionic liquid offers a special spot for both reactants and catalysts to mingle. That happens because the ions in the liquid attract molecules in a unique way. It lets scientists boost reaction rates and make selective results easier to manage. The outcome isn’t just about higher yield—it means chemists can run the same catalyst for several rounds, saving money and trouble. This application shows up not only in labs, but in processes making fine chemicals and specialty coatings.

Extracting and Separating with Fewer Waste Streams

Labs and industry plants constantly look to extract useful compounds without hauling in buckets of hazardous solvents. 1-Decyl-3-Methylimidazolium Tosylate, with its strong ionic nature, can pull in particular organic molecules and leave the rest behind. Engineers use this property to refine rare earth elements, break down plant matter for biofuel, or snag valuable compounds from messy mixtures. Less mess means fewer barrels of hazardous waste waiting at the end of the line. People I know working in extraction swear by these new liquids for their flexibility and cleaner outcomes.

Electrochemistry, Sensors, and Storage

Storing and moving electric charge calls for a stable, safe medium. Chemists turn to ionic liquids in batteries, fuel cells, and supercapacitors. This particular salt pairs long-term stability with the right amount of electrical conductivity, so batteries can cycle again and again without breaking down fast. Supercapacitors using this liquid last longer and work safely even at high voltages, which benefits makers of electric vehicles and renewable energy systems. The liquid also pops up in sensors, where stable performance matters as much as sensitivity.

Environmental and Safety Benefits

Long hours working with solvents give plenty of reminders about what burns, what irritates, what lingers in lungs. With ionic liquids like 1-Decyl-3-Methylimidazolium Tosylate, there’s far less risk of fire, lower toxicity, and cleaner disposal routes. Efforts to clean up supply chains rely on safer chemicals that support circular economies—reusing, recycling. Businesses tackle regulations head-on if safer, greener alternatives run at scale.

Looking Forward: Challenges and Next Steps

Adopting ionic liquids still throws up hurdles: industrial costs, scale, and the need for more real-world data. Some ionic liquids remain pricey, especially ones fine-tuned for a single use. Research groups need to collect more performance results in live factories, not just in glass beakers. Collaboration between chemists, engineers, and regulators means everyone shares the load—testing new blends, tracking safety, and judging life-cycle footprints. Every bit of progress makes green chemistry look less like an experiment and more like tomorrow’s standard.

Understanding the Identity of a Compound

A chemical structure acts like the fingerprint of a compound. It shows how atoms join together and how those connections shape the properties we see in real life. For example, two compounds can have the same types and numbers of atoms, but if those atoms link up differently, you get two completely different molecules. I remember being surprised in college chemistry when I learned that glucose and fructose share the same formula, C6H12O6, but differ in shape, giving them unique tastes and reactivity. That twist in the structure can mean the difference between a medicine and a poison.

Chemists give the structure as a diagram where each atom sits at a junction, lines show bonds, and rings or chains snake across the page. Those drawings tell a story about reactivity and stability. Medicinal chemists rely on them to predict how a drug fits into an enzyme or how quickly it breaks down in the body.

Molecular Weight: More Than A Number

I once helped out in a pharmacy compounding lab, where getting the dosage exactly right meant calculating how much of each ingredient went into a pill. That’s where the molecular weight steps in. It’s the sum of the masses of all the atoms in a molecule, measured in grams per mole. Even a tiny error here ripples out, affecting drug potency, the way drugs pass through the body, and the safety of treatments.

Researchers use molecular weight to figure out how much of a chemical to add during an experiment. Biologists refer to it for calculating concentrations. Environmental regulators check it to judge how long a pollutant will stick around in soil or water. Even in food science, understanding why sugar dissolves quickly but cellulose doesn’t comes down to differences in molecular weight and structure.

Applying These Details

Say you’re running a quality control check in manufacturing. You need to make sure that the batch in front of you matches the compound in the paperwork. Looking at the structure and the molecular weight tells you if everything lines up as expected. If there’s any discrepancy, something went wrong along the line—maybe contamination, maybe the wrong ingredients, or maybe a mix-up at labeling. This real-world check saves time and money, and protects people who count on consistent, effective products.

With so much depending on accuracy, institutions like the FDA, EPA, and international pharmacopoeias require these values before a chemical can see the light of day and be used commercially. Data-sharing platforms and chemical suppliers put both structure diagrams and molecular weights front and center for a reason. I’ve seen science educators put hours into teaching students to draw structures and calculate weights, since a single misstep can wreck a lab report or botch a clinical result.

Reliable Sources and Solutions

These days, databases such as PubChem, ChemSpider, and the Merck Index make it easy to check structures and molecular weights. Advanced tools like mass spectrometry let analysts double-check the details, even if new compounds show up in a sample. Open access to these resources helps the whole science community do better work. Of course, reviewing cross-checked sources and consulting experienced professionals still matters for the best outcomes.

Everyone from students to top-tier scientists trusts reliable chemical data. Fact-checking molecular structures and weights isn’t just busywork—it’s the bedrock for science, technology, and health. Getting these basics right means you’re building on solid ground.

Recognizing the Nature of the Chemical

1-Decyl-3-Methylimidazolium Tosylate stands out among ionic liquids because of its versatile role in organic synthesis and catalysis. I got a taste of its tricky nature early in my chemistry days. Its oily and hygroscopic character means it draws moisture from the air, changing its properties if left exposed. You learn quickly that proper storage does more than protect the material—it also protects your data and your team.

A Cool, Dry Shelter: Avoiding Decomposition and Clumping

Humidity messes with the accuracy of your experiments. So get into the habit of keeping this chemical in a tightly sealed glass bottle. If you’ve pulled a bottle off the shelf to discover crystals forming along the rim, you already know what poor sealing can do. Store it out of direct sunlight. Light and heat speed up unwanted reactions, and temperature swings invite water to sneak in. Temperatures between 2°C and 8°C help slow degradation. I keep mine on the lower shelves of a temperature-controlled chemical fridge, separate from any acids, oxidizers, or strong bases. Segregation keeps cross-contamination at bay and saves time sorting later.

Labeling and Tracking Make All the Difference

You won’t believe how fast a bench can get cluttered in a busy chemistry lab. That’s where proper labeling turns chaos into clarity. Always mark the container with the chemical’s full name, date received, and date opened. If you’re dealing with a custom or repacked sample, stick on the original safety data sheet (SDS) or keep a digital copy close. I've seen too many near-misses arise from mystery bottles with faded ink or shorthand.

Handling: Gloves, Eye Protection, and Respect

Some folks think ionic liquids are inherently safe because they don’t give off much vapor. That kind of thinking brings trouble. Skin contact transforms a routine day into a health scare—skin irritation, and even burns if you’re unlucky. So reach for proper nitrile gloves and goggles before touching the bottle. Spills, even small ones, should get immediate attention. Use absorbent pads, ventilate the area, and collect all waste as hazardous. Just tossing it down the drain invites environmental headaches. I always remind people that a few seconds of routine can prevent weeks of regret.

Community Knowledge and Documentation Protects Everyone

No one should work alone with unfamiliar chemicals. Walk your team through safe handling and storage routines. The chemical’s SDS offers more than regulatory fine print; it spells out first aid, fire hazards, and incompatibilities. Sharing your own experience can help newcomers recognize issues before they turn serious. I keep a logbook for every new compound I use, so odd smells, unexpected discoloration, or other surprises get tracked right away. Over years of handling a dozen different ionic liquids, this habit has caught more than one early warning of contamination or spoilage.

Conclusion is the Daily Routine

Daily habits around storage and handling set the foundation for safe and successful work. That means double-checking seals, handling with gloves, storing only in cool dry spots, and sharing insight with your crew. These steps help keep both the science and the scientists in top shape.

The Reality Behind Product Hazards

Shoppers don’t often stop to think about what really goes into the goods they haul home each week. Most people trust that if it’s on the shelf, it’s probably safe. That sense of security can be misleading. Not every product sitting in a box or bottle was designed with every user or every situation in mind. Some carry risks you won’t spot until you dig deeper or hear a story the hard way.

Growing up, I watched my uncle run a modest auto repair shop. Grease-stained hands, open motor oil containers, and the scent of solvents became normal for me. One night, an open can of solvent tipped over and the fumes filled the shop. My uncle brushed it off at first, but after a cough that wouldn’t quit and a pounding headache, he understood the label warnings weren’t just for show. That’s the moment a boring container turned into a hazard in our eyes.

Labels: Not Just Suggestions

Warnings on boxes and bottles come from hard-earned lessons and strict rules. The U.S. Poison Control reports that household products, including cleaners and automotive fluids, send thousands to the emergency room each year. Chemicals like bleach and ammonia create toxic fumes when mixed. Even something as simple as a lithium battery can turn dangerous if it’s punctured, overcharged, or swallowed by a child.

Stories of recalls fill the news every year—batteries that burst into flames, children’s toys containing toxic paint, and garden supplies with hidden risks. These aren’t flukes. That’s why it makes sense to check the label, even if you feel suspicious that danger is being exaggerated.

Why It Matters—At Home and At Work

Safety goes beyond following a rulebook. Nobody forgets the kid who swallowed a coin battery because it looked like candy. The damage from just one mistake can last a lifetime. On building sites, cutting corners with protective gear has left workers with burns, breathing problems, or worse. At home, failing to store cleaning products out of reach lands too many kids in the hospital.

Fires have started in kitchens and garages because folks ignored simple warnings—cleaning rags soaked in oil can self-ignite, and aerosol cans near heat sources have exploded. It happens more than anyone would like to admit. All these incidents simmer down to skipped instructions or a rushed job without proper gear.

Solutions We Can Put Into Practice

Education makes the biggest difference. Community classes or honest talks at home give kids and adults the tools to spot danger. Clearer product instructions with diagrams go a long way, especially for folks who speak English as a second language. I’ve seen neighbors trade stories during block parties about product mishaps—sharing personal stories sticks with people more than cold warnings.

Storing supplies on high shelves or behind locks, adding childproof caps, and putting up bold, easy-to-read warning signs work better than rules buried in a manual. Businesses can invest in basic safety training sessions. Manufacturers don’t need to make labels so technical that people tune out, but add a simple checklist with “do’s and don’ts”—even busy parents and workers read a short, punchy list.

A hazard isn’t real until you experience it, or you trust the lessons of others. For me, taking an extra minute to check the label now feels like second nature. One simple action can stop a story from ending the tragic way someone else’s did. Safety isn’t just about rules—it’s about looking out for the people around you and insisting every product, no matter how ordinary, gets the respect that experience has taught us it deserves.

Why Purity Matters More Than You Think

Years of working closely with researchers and manufacturers taught me something: purity isn’t just a number on a datasheet. The difference between 98% and 99.9% purity can mean the difference between success and failure. Imagine running a pharmaceutical study—one unexpected impurity can wreck the results and waste months of work. Even in industries like electronics, a pinch of contamination disrupts delicate reactions and chips end up unusable. Simply put, purity controls trust in the process and the outcome.

The market takes this seriously. For example, pharmaceutical-grade chemicals demand purity ratings as high as 99.9%, and testing labs spend resources confirming each batch meets that mark. Food companies hold suppliers to equally tough standards, given the health risks at stake. It’s not only about passing regulatory requirements—it’s about safety and reliability for the end user. Chemical suppliers publish certificates of analysis with every shipment for this reason, keeping transparency alive throughout the supply chain. Numbers aren’t just for show; they’re a cornerstone for the next stage in research or manufacturing.

Packaging Sizes: Convenience or Complication?

Anyone who’s ever opened a shipment in a tight lab or noisy plant knows that the way a compound arrives shapes the workflow. Academics favor small glass vials—10 grams, 50 grams—because budgets are small and storage gets crowded. A chemical engineering outfit might ask for a 25-kilogram drum or even bags by the metric ton, aiming to support continuous processes. Some compounds ship in 1 kg bottles, others in 5-liter containers, and the type of packaging matters just as much as size. I’ve seen well-sealed HDPE drums chosen for moisture-sensitive powders, and dark amber bottles used for compounds that lose strength under light.

The wrong choice leads to waste or product degradation. If 100 grams arrive in one giant container, but a lab needs only 5 grams at a time, each opening lets in contaminants. Break it down and quality stays consistent. Wholesalers and manufacturers often work with chemical suppliers to pick sizes that reduce this risk and match real needs, not just for cost savings but for safety and quality.

The Push for Smarter Solutions

Still, problems creep in with availability and logistics. Many times I’ve watched researchers stuck waiting because the required quantity wasn’t in stock, or a supplier limited sales to industrial-scale barrels only. Chemical distribution requires flexibility—stocking enough sizes, keeping shelves labeled, ensuring traceability. The best suppliers ask for feedback and adjust their product lines, moving away from a one-size-fits-all mindset. The industry can do more here. Offering sample packs, splitting shipments, and recycling packaging are small steps that keep waste low and productivity high.

Transparency, flexibility, and responsiveness mark the trusted suppliers in this space. They know that with purity and packaging, the details carry weight. Paying attention here means safer chemicals end up in safer hands, and everyone along the line benefits.