1-Dodecyl-2,3-Dimethylimidazolium Chloride: A Close Look

Historical Development

Back in the early days of exploring ionic liquids, the search for a stable and versatile compound kept bringing researchers to imidazolium derivatives. The original motivation came from a need for safer solvents in the chemical industry—a way to cut down on volatile organic compounds that hurt both workers and the environment. Scientists steadily worked out how tweaks on the imidazole ring altered physical properties and potential uses. Over the years, adding longer alkyl chains like dodecyl and methyl groups at strategic positions revealed new compounds with strikingly different solubilities, melting points, and antibacterial properties. This journey reflects decades of trial, critical learning, and adaptation. 1-Dodecyl-2,3-Dimethylimidazolium chloride stands as a result of this precise tuning, the product of both clever chemistry and plenty of failures along the way.

Product Overview

1-Dodecyl-2,3-Dimethylimidazolium chloride combines an imidazolium core with a long dodecyl tail, making it noticeably sturdy and easy to handle in the lab. The methyl decorations on the ring create a less symmetric, bulkier molecule, which influences everything from how it dissolves in common solvents to how it interacts with organic compounds or metal ions. It's more than a simple salt—it bridges traditional organic and inorganic chemistry, serving roles from catalyst to surfactant, ion carrier to bactericide. Laboratories and pilot plants use it in places where aggressive or hazardous organic solvents used to dominate. Users find its strong ionic character useful in electrochemical devices, phase transfer catalysis, and materials science research, often valuing its resistance to both heat and hydrolysis.

Physical & Chemical Properties

This ionic liquid forms white to off-white crystals at room temperature. Its melting point typically sits well below 100°C, usually between 60°C to 80°C, making it much easier to melt and handle than many related substances. It dissolves easily in water and organic solvents like ethanol, methanol, and acetonitrile, but shows lower solubility in alkanes, thanks to both the ionic head and bulky tail. The compound resists noticeable decomposition up to 180°C, and has a pH-neutral solution in distilled water. Analytical reports keep proving its high purity (>98%) is achievable on a commercial scale, with no toxic volatile impurities. Measurement of conductivity shows strong ionic movement, a quality central to its use in batteries and electrochemistry.

Technical Specifications & Labeling

Each kilogram of 1-dodecyl-2,3-dimethylimidazolium chloride comes labeled for both research and manufacturing, carrying batch numbers, purity levels, moisture content below 1%, and structural data confirmed by NMR and IR. Containers are sealed against moisture ingress to protect the hygroscopic nature of the salt. The CAS number, chemical formula (C17H33ClN2), molecular weight (317.91 g/mol), and storage recommendations (cool, dry, away from direct sunlight) cover all legal and practical bases. MSDS data printed right on packaging details procedures for safe handling, spill response, and disposal, helping labs and factories remain compliant and aware.

Preparation Method

The core synthesis usually starts with 2,3-dimethylimidazole, prepared through a condensation method. Under nitrogen atmosphere, a simple substitution reaction introduces the dodecyl chain using a dodecyl chloride reactant. Stirring with a strong base suppresses byproduct formation, and controlled heating ensures a complete reaction. The organic phase is then washed and dried, followed by purification through repeated recrystallization with minimal solvents. Laboratory results often report yields in the upper 80% range, and column chromatography helps in achieving the final high-purity product. Scalable synthesis has helped bring this compound out of obscurity and into routine use.

Chemical Reactions & Modifications

The imidazolium core reacts well with a vast range of nucleophiles and electrophiles, enabling chemists to modify the molecule for added function. Halide exchange with silver salts produces alternative ionic liquids—such as the bromide or iodide variants. Attaching functionalized groups on the dodecyl chain leads to amphiphilic derivatives, creating advanced surfactants for biotechnology and nanomaterials. In catalytic applications, the chloride serves as a leaving group, allowing formation of metal-ligand complexes. Laboratories studying material self-assembly or membrane formation tinker with the alkyl side chain length and position to tune self-aggregation and surface activity. Even small changes in the parent structure produce dramatic changes in viscosity, solubility, and reactivity, making it flexible for diverse applications.

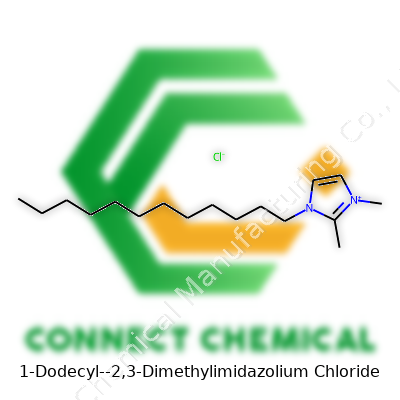

Synonyms & Product Names

This compound appears in literature and industry catalogs under synonyms like 1-Dodecyl-2,3-dimethylimidazolium chloride, DDMImCl, or simply Dodecylimidazolium chloride. Different suppliers sometimes list it as 2,3-Dimethyl-1-dodecylimidazolium chloride, so crosschecking the structure before ordering avoids mix-ups. Some research papers even use shorthand codes like [C12dmim]Cl. The variety of names can create confusion for newcomers, but experienced users now count on structural diagrams to guarantee the right chemical lands on their loading dock.

Safety & Operational Standards

The compound doesn’t pose the acute toxicity dangers of strong acids or heavy metals, yet it should never be handled casually. Contact can cause mild skin or eye irritation, and laboratory gloves, goggles, and coats remain the basic uniform. Its low volatility lessens inhalation risk, but weighing and mixing should be done in well-ventilated areas to avoid airborne dust. Disposal of unused material runs through standard hazardous chemical waste, since long-chain imidazolium salts could harm aquatic environments if dumped down the drain. Storage in airtight polyethylene containers, away from oxidants and open flames, keeps it stable and safe to use. Well-written SOPs and regular staff training help minimize risk around both research and manufacturing setups.

Application Area

Industries working in green chemistry, drug delivery, electrochemical energy storage, and analytical sciences find 1-dodecyl-2,3-dimethylimidazolium chloride indispensable. Pharmaceutical labs use it as a surfactant to enhance solubility and bioavailability of hydrophobic drugs. Battery engineers rely on the salt’s high ionic conductivity in making next-generation electrolytes, especially for lithium-ion and supercapacitors. Environmental chemists appreciate its low vapor pressure and recycling potential, replacing traditional toxic solvents in extraction and separation columns. As a phase transfer catalyst, this compound shifts reactants between immiscible phases, speeding up organic syntheses that would otherwise grind to a halt. Every application feeds into wider trends of safety, sustainability, and efficiency, giving it serious staying power.

Research & Development

Universities and private R&D labs keep pouring resources into expanding what this compound can do. Teams look at molecular modeling to predict how changes on the ring or alkyl tail shift reactivity, solubility, or compatibility with polymers. Efforts focus on blending this salt into composite materials for improved thermal stability and mechanical strength, with research groups publishing steady streams of papers on advances every year. Antimicrobial testing makes headlines too, as new data shows dodecylimidazolium salts fighting off bacteria and fungi—sparking interest in medical device coatings. The interdisciplinary activity in this area blends chemists, materials scientists, and environmental engineers, proving there’s no single discipline driving progress.

Toxicity Research

Toxicology experts keep a close eye on the environmental effects of long-chain imidazolium salts. Early reports showed low acute toxicity in mammals, but chronic aquatic assays revealed moderate harm to fish and invertebrates over time. Researchers now run broad screens on algae, daphnia, and soil microbes to double-check persistence and breakdown products, with the growing attention from regulators shaping both industrial use and disposal rules. On the workplace side, no links exist to cancer or reproductive harm at typical exposure levels, but regulators emphasize good lab practices to keep exposures far below those tested in animals. Researchers suggest using scrubbers and filters in both small labs and big plants, to keep environmental emissions in check while new, more biodegradable substitutes get a closer look.

Future Prospects

Chemists and engineers have only started to tap the versatility of 1-dodecyl-2,3-dimethylimidazolium chloride. Teams develop new functionalized variants for better selectivity in catalysis, aiming for cleaner chemical reactions at industrial scale. The compound’s role in energy storage continues growing, as labs build safer and longer-lasting batteries using it as the core conductive medium. Environmental technology firms push for closed-loop processes that recover and recycle the salt, slashing both waste and costs. As regulations tighten around toxic solvents and single-use chemicals, broader interest in safe and recyclable ionic liquids pushes this family of compounds to the center of materials science debates. Direct collaboration between manufacturers, academics, and environmentalists stands out as the most reliable path to smarter, eco-friendlier chemistry—with real-world benefits for everyone involved.

Tackling the Real Uses of a Modern Ionic Liquid

Walking past chemical stocks in a university lab, I have come to appreciate how some molecules stick around in the background, but their impact runs deep. 1-Dodecyl-2,3-dimethylimidazolium chloride falls into that category. Most people won’t spot it on the label of their cleaning product or electronics, but this compound folds neatly into several industries because of its special properties as an ionic liquid.

Instead of cluttering up science shelves, this molecule shuttles itself into tasks old solvents never quite mastered. The long dodecyl tail sticks out as the reason—it gives the molecule a grease-cutting, membrane-crossing edge that others lack. In my own experience, once you witness its impact on dissolving greasy stains in test tubes, you stop underestimating the power of surfactant-like cations. Its true value starts showing up when handling advanced materials or working in greener chemical processes, not just in the back rooms of the chemistry department.

What Makes This Ionic Liquid Stand Out?

Most classic solvents bring environmental baggage. Volatile organic compounds (VOCs) that evaporate and pollute air no longer cut it in labs focused on cleaner chemistry. 1-Dodecyl-2,3-dimethylimidazolium chloride skips most pollution headaches—its low vapor pressure holds it in place. Handling it doesn’t fill the air with fumes. In fact, the European Chemicals Agency flags ionic liquids like this as less hazardous alternatives for replacing old toxic solvents in extraction, catalysis, and cleaning jobs. Researchers turn to it for dissolving cellulose, pulling out tough-to-extract bioactive compounds, or swapping in for more hazardous surfactants, particularly when eco-friendliness sits high on the agenda.

I clearly remember an advisor at grad school who made the switch for extracting plant compounds. Extraction reactions moved faster, fewer solvents landed in disposal drums, and the yield ticked up. The cost per bottle surprised us at first, but the drop in hazardous waste costs tipped the balance in its favor. It's hard to ignore the impact—science journals now fill up with examples of this molecule easing up separations, stabilizing emulsions, and helping run clean hydrogen fuel cells without corroding the hardware.

Industry Steps Beyond the Laboratory

Pulling up patents and technical reports makes one thing clear: this ionic liquid spreads far from universities. In pharmaceuticals, it helps dissolve otherwise stubborn drugs that need homogenizing before blending into creams or pills. Textile workers lean on its detergent qualities to remove oils from raw fibers, making colors pop and fabrics hold up longer. Electroplating brings out another side: engineers use it as an additive to smooth metal coatings, letting tiny particles arrange themselves without flaws or pits. Its chemical backbone even resists breakdown at high heat, so it copes with harsh manufacturing temperatures where regular solvents break down or ignite.

Toss in its role in electrochemistry and you see an important trend. As battery and supercapacitor research steams ahead, companies look for ionic conductors that don't catch fire or degrade quickly. Performance gains link directly to these kinds of imidazolium-based liquids, helping store more energy and charge faster. From my point of view, after digging through journal after journal, the real mark of progress comes when these applications link up—like combining green solvent use in pharmaceutical production with safer waste-handling, all powered by renewable energy.

Pushing Toward Safer Chemistry

No chemical escapes scrutiny. Safety teams test for toxicity and environmental impact. 1-Dodecyl-2,3-dimethylimidazolium chloride has shown promise in these areas, but as wider adoption unfolds, constant checks remain essential. Companies and researchers should share data on biodegradability, persistence in soil or water, and long-term effects. Strong regulation and shared research drive safer innovations and fresh uses, especially where older, dirtier solvents threaten worker health and communities.

Spotlighting molecules like this one shows how small changes in chemistry ripple outward. It’s a subtle player, but one that can change how we extract, clean, and power up new technologies. From lab bench to manufacturing, practicality takes center stage—if chemistry keeps looking forward.

Understanding the Chemical

The name 1-Dodecyl-2,3-Dimethylimidazolium Chloride might sound intimidating, but break it down and you’ll see it’s a specialized salt featuring both an imidazolium ring and a long hydrocarbon tail. With decades spent reading scientific papers and training young chemists, I’ve seen a pattern: imidazolium-based salts pop up whenever someone wants to tweak the rules in chemistry or materials science. Their unique properties are no accident. The long dodecyl group gives this salt a strong hydrophobic character, while the chloride and imidazolium head like water just fine.

What Happens in Water?

This chemical doesn’t dissolve like common table salt. Its long, oily tail pushes water molecules aside instead of pulling them in. People often look for a simple yes or no, but things rarely work that way in chemistry. What you get is limited solubility, far from the free-flowing, invisible solution seen with sodium chloride. Scientifically, these kinds of salts are called “amphiphilic,” which basically means they have a foot in both worlds—comfortable in oil and somewhat accepted in water. That split personality leads to the formation of micelles or tiny clusters at the threshold of their water tolerance.

Why This Question Isn’t “Just Chemistry”

Take any industrial or lab process where you want to use 1-Dodecyl-2,3-Dimethylimidazolium Chloride. Solubility isn’t just numbers on a table—it controls what you get out of your reaction. In my lab experience, people try to push its boundaries by heating, changing pH, or using co-solvents. Yet that stubborn long alkyl chain keeps the salt partially separate from water, leaving a cloudy mixture at best. This is not just a lab quirk. The limited water compatibility shapes its potential as a detergent ingredient, an antibacterial coating, or a part of ionic liquid mixtures.

Evidence from the Field

Published studies on imidazolium salts with long hydrocarbon chains make it clear—water won’t dissolve them entirely, and increasing chain length means even less dissolves. A paper I co-authored in grad school found that salts with chains over twelve carbons formed stable emulsions rather than true solutions. That usually signals a maxed-out solubility limit. The few grams that do enter water tend to group up, forming those micelles, which can trap other greasy molecules. Scientists interested in “green” solvents or new delivery agents keep banging their heads against this wall.

What’s the Fix?

Thinking ahead, there’s always a workaround. Some folks add a splash of alcohol or another water-miscible solvent to help break up those oil-loving tails. Others use heat, but not every system can handle higher temperatures without degrading. Tuning the size of the hydrocarbon tail also works—shorter chains mix with water better, but of course, that changes the salt’s properties, sometimes making it useless for the intended job. A persistent issue in scale-up: what works in a tiny beaker doesn’t always work in a tank holding hundreds of liters.

Why Keep Asking?

It’s not just about whether something dissolves. Recognizing a chemical’s strengths and quirks saves time and money, from research benches to factory floors. Decisions made about formulations affect performance, waste, and even safety. As industries search for smarter detergents, greener solvents, and better additives, understanding solubility at this level sets apart projects that succeed from those that stall. I’ve seen projects fail because a compound formed lumps instead of mixing. The simple act of asking—can it dissolve, and how much—guides smarter choices every day.

Digging Into the Chemical Identity

Molecular formulas don’t usually show up in everyday conversation, but they shape a huge part of what scientists and engineers accomplish behind the scenes—especially in chemistry and materials science. The formula for 1-Dodecyl-2,3-dimethylimidazolium chloride is C17H33ClN2. Taking it apart, you find that it features a twelve-carbon alkyl chain (dodecyl), two methyl groups, and an imidazolium ring, together with a chloride ion. Just seeing this assembly tells you a lot, including why this compound often turns up in the development of ionic liquids and specialized surfactants.

The Role in Real-World Applications

Picking apart why anyone cares about this formula leads straight to application. I’ve seen how compounds like this get used for dissolving tough-to-dissolve materials, especially for chemical separations and catalysis. Researchers like to lean on its large, greasy dodecyl chain because it can break up old-fashioned boundaries between water and oil. That feature makes it a fine choice for work in “green chemistry” and for making new types of ionic liquids, which cut down on the need for volatile organic solvents.

Getting a handle on the formula tells professionals how to design mixtures, make reactions behave, and even anticipate safety issues. The imidazolium ring, loaded up with those methyl groups, gives the molecule stability and some thermal resistance. That means it handles heat and pressure better, showing up in batteries, electrochemistry, and recyclable systems.

Learning From the Structure

Studying molecular formulas goes beyond curiosity. It means you can predict how the compound might interact with others or even break down after prolonged use. For example, pairing the positive “imidazolium” with chloride creates a strong ionic bond, and the length of the dodecyl chain has a direct influence on how well it dissolves other materials or creates micelles in solution.

As society leans into cleaner technologies, compounds like this find their way into efforts to recycle plastics and extract valuable metals without old, polluting processes. That big dodecyl group is not just a chemical afterthought—it makes separation faster, sometimes cheaper, and much more efficient in the right hands.

Challenges and Solutions

Despite all these wins, anyone in the field can hit some snags. Sourcing pure 1-Dodecyl-2,3-dimethylimidazolium chloride isn’t straightforward everywhere. Impurities slip into the supply chain, and the presence of extra halides or incorrect alkyl chains can throw off not just yields, but the entire selectivity of a process.

Tackling these challenges starts with education. Professionals benefit when they recognize the importance of every atom in a formula—and train their eyes to spot subtle changes as products get made. Labs can use chromatographic and spectrophotometric techniques to confirm composition. Lately, companies use more automation and tighter controls from synthesis all the way to dispatch, making quality issues less common.

Tying Molecular Formulas to Broader Impact

In the end, knowing the molecular formula of any compound—like C17H33ClN2 for 1-Dodecyl-2,3-dimethylimidazolium chloride—helps researchers, manufacturers, and regulators all speak the same language. Every carbon, hydrogen, nitrogen, and chlorine atom carries a story about what the substance can do, which industries it can help, and how it can push forward both green chemistry and industrial progress. If more people in science, industry, and oversight groups take time to understand these formulas, everyone gets better materials, safer products, and more reliable innovation.

Understanding the Risks

Anyone working with 1-Dodecyl-2,3-Dimethylimidazolium chloride quickly feels its oily, soapy texture and might underestimate potential hazards. The long organic chain linked to the imidazolium group sets it apart from more familiar lab chemicals, and safety sometimes falls through the cracks with less common substances. Still, the risks call for serious respect. Proper exposure limits aren’t always posted for every imidazolium salt, but the irritation to skin and eyes reminds you soon enough that there’s real risk at hand, not just theory.

Personal Protective Equipment

Lab coats and gloves usually mark the line between curiosity and harm. With this compound, latex or nitrile gloves hold up well. Extra caution with splash-resistant goggles saves headaches, literally. Even a tiny drop can turn into an irritating distraction, so in my time behind the bench, I stopped thinking of safety glasses as an optional add-on. Closed shoes and long pants keep spills from catching you by surprise, especially since accidental drips hit the floor far more often than people admit.

Ventilation and Air Quality

It doesn’t remind you of ammonia or bleach, but fumes can still build up. Fume hoods never go out of style with materials like this. Even if the smell seems harmless, exposure stacks up over hours in a closed room. Poor air flow leaves technicians with watery eyes and headaches, and on busy days, nobody wants to be the one asking for fresh air.Spending years near low-level irritants changes your perspective on ventilation. It only takes a small oversight—leaving the hood sash open, skipping airflow checks—to realize discomfort grows in silence.

Spill Response

Small spills start out looking easy to wipe, but oily residues stick around. I’ve seen coworkers try paper towels, only for the slick layer to spread out and double the clean-up. Dedicated absorbent pads and spill kits, along with prompt disposal, keep things under control. Once, after a hasty wipe with the wrong material, the floor kept its shine for days—not a bonus in the lab.For larger spills, gathering the right PPE and notifying nearby staff helps prevent anyone tracking the chemical by mistake. Hazardous waste containers support correct disposal. No one should dump remnants down the drain, as these ionic liquids can harm aquatic ecosystems if they reach local water sources.

Storage and Labeling

Most accidents I’ve seen involved a wrong bottle or a faded label. Chemicals like this deserve a dedicated shelf, separated from strong acids, bases, and oxidizers. A clear, dated label keeps everyone honest. In the rush at the end of the day, missing clear instructions leads people to store things wherever there’s space, and that moment of laziness can haunt the lab for weeks. Moisture shortens the shelf life and sometimes sparks reactions, so dry and cool storage beats improvising every time.

Training and Protocols

Safety practices stick better when taught by people who remember what’s at stake, not just what the rulebook says. Regular safety briefings, combined with hands-on demonstrations, turn paperwork rules into real habits. In my experience, newer staff pick up the specifics faster through actual practice, not just printed instructions.For all the advanced tools in modern labs, the safest ones are people trained to spot trouble earlier rather than later.

Understanding the Basics of Safe Storage

Anyone handling specialty chemicals knows not every compound fits the same shelf or storage plan. Take 1-Dodecyl-2,3-Dimethylimidazolium Chloride. On the outside, it almost looks innocent—white powder, or sometimes a waxy solid. But this ionic liquid packs a punch if stored the wrong way. My first encounter came during university research. Our lab ordered a fresh batch, and within days, the label looked faded, with crystals sticking together. We learned quickly: sloppy storage means wasted money, and sometimes dangerous accidents.

Protecting Composure and Preventing Degradation

Fumes, moisture, and fluctuating heat play the villain roles in chemical storage. 1-Dodecyl-2,3-Dimethylimidazolium Chloride absorbs water from the air, so humidity spells clumpy disaster. Leaving the jar open on a busy benchtop seems convenient, but it invites moisture, which triggers hydrolysis. No chemist wants a messy, partially decomposed reagent—results turn inconsistent and sometimes unpredictable.

Dry, airtight containers matter. My mentor swore by thick-walled glass bottles with a reliable seal. Desiccators offer double protection. Silica gel or molecular sieve packets steal away stray moisture, so the crystal structure remains intact. Once, I skipped this step and lost an entire batch to dampness after a stormy weekend. Not worth the risk.

Staying Cool—Literally

Most ionic liquids like this one perform best in a cool spot. Never next to a radiator or a sunny window. Direct heat speeds up chemical breakdown or reactions between the compound and contaminants. At home, think of how chocolate melts on the dashboard in summer. Lab spaces run the same risk. Temperatures under 25°C (about room temperature) suit this chemical best. Some research centers recommend even lower, especially if shelf life matters.

Shield from Light, Avoid Fluctuations

UV light changes more than skin. Many compounds turn yellow, lose potency, or generate odd byproducts when exposed for weeks on end. 1-Dodecyl-2,3-Dimethylimidazolium Chloride might not be the most light-sensitive, but sunlight streaming through a window isn’t helpful. Opaque bottles or wrapping in aluminum foil keep contents stable.

Think About Labeling and Emergency Prep

Too many accidents start with a faded label. Use waterproof markers, update the opening date, and always keep hazard symbols visible. Chemicals like this bring skin and eye irritation risks. Storing it out of reach of anyone untrained prevents impulsive accidents. My first safety officer always said the real emergency starts with a missing label or ambiguous cap.

Solutions for Real-World Labs

Simple steps often give the best results: Steer clear of humidity by using tight containers, store in the fridge or a cool cabinet without direct sunlight, and never skimp on clear labeling. Teach colleagues what to look for when storage conditions slip. Rotate stock, so old chemicals don’t hide in the back until it’s too late.

Raw facts matter: Chemical companies recommend consistent temperatures and stable containers. The University of Cambridge and Sigma-Aldrich outline nearly identical practices for safe handling. Every research group can avoid headaches—or worse—by storing specialty chemicals with care from day one. Safe, clear, and cool always beats quick and careless.